14. Networking and communications¶

This week I worked on fafricating and networking multiple boards simultaneously

Having never worked with networking board before, I decided to start from the begining and manufacture the Hello Bus outlined in the Fab Academy Tutorial as a way to introduce myself to the concept, before moving on to more difficult concepts.

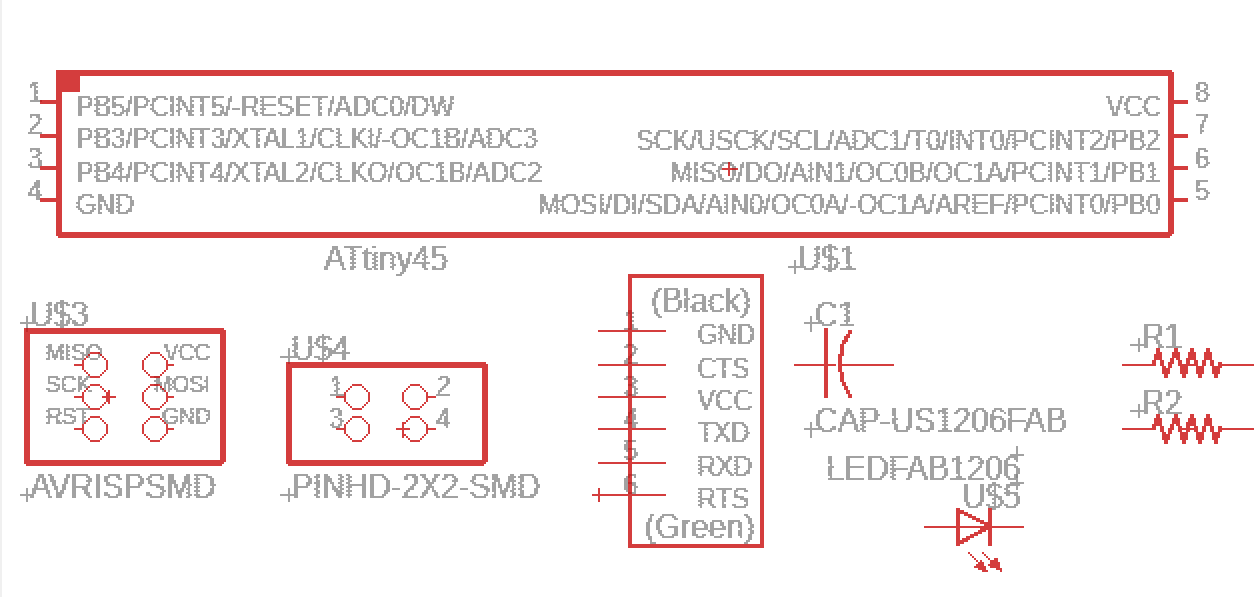

I started by Designing the Hello Train in Eagle. I have been working with Eagle quite a bit recently and I find its not as hard any more. Althought somewhat unintuitive to begin with, I found that once you get the hang of it, its actually relatively straighforward.

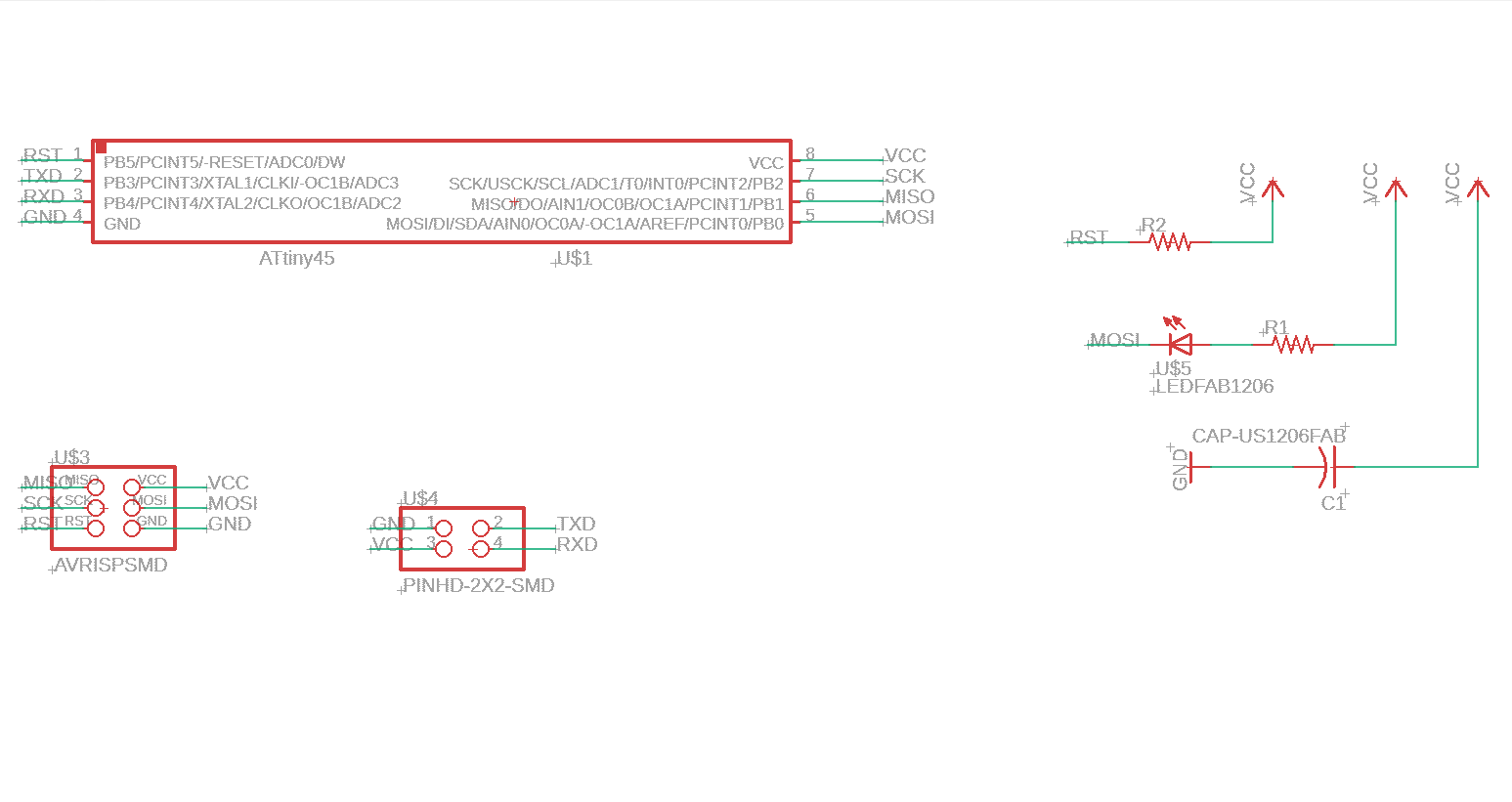

The Hello Train Consists of two designs, The Nodes and the bridge.

First I made the bridge, as the node is esentially the same desing minus the main connector.

Then I removed the main connector and re did the desing.

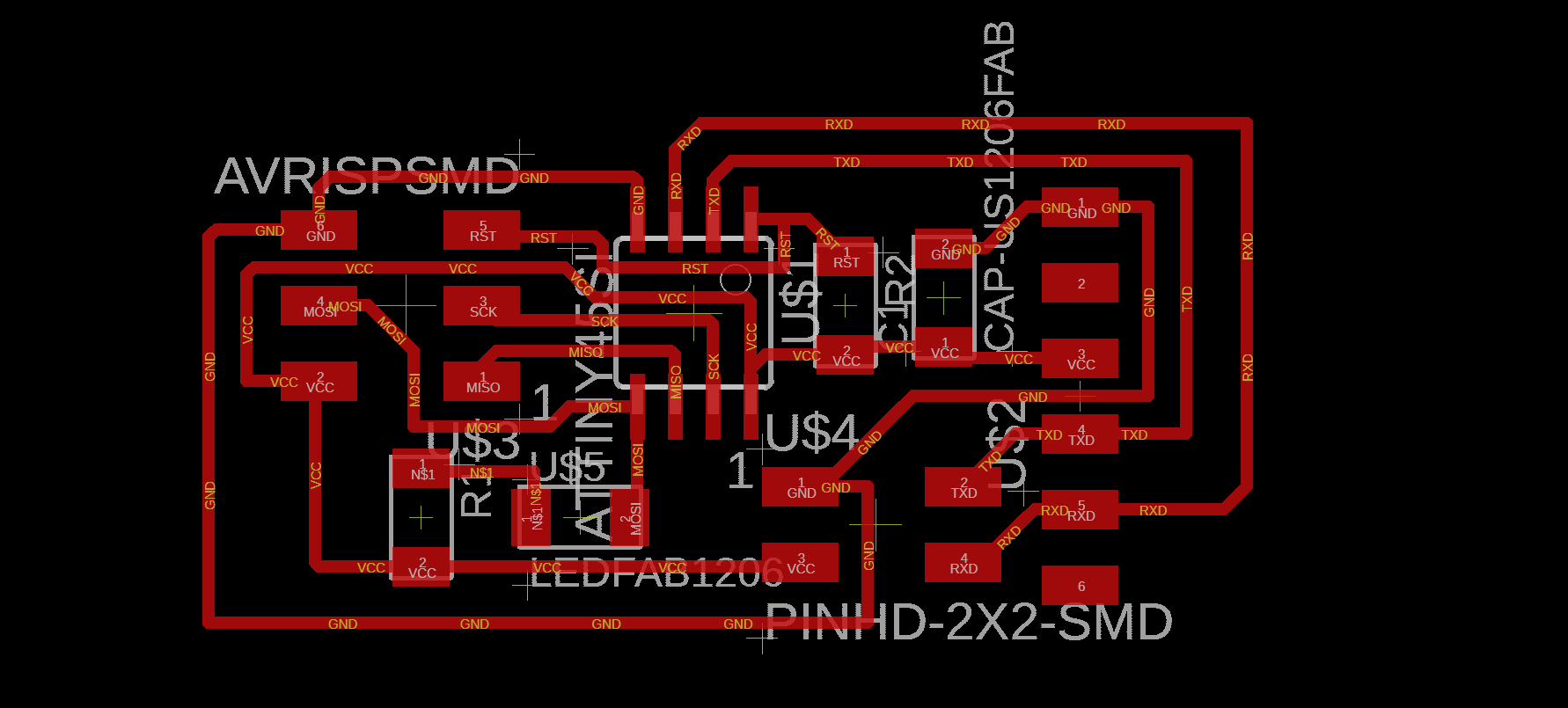

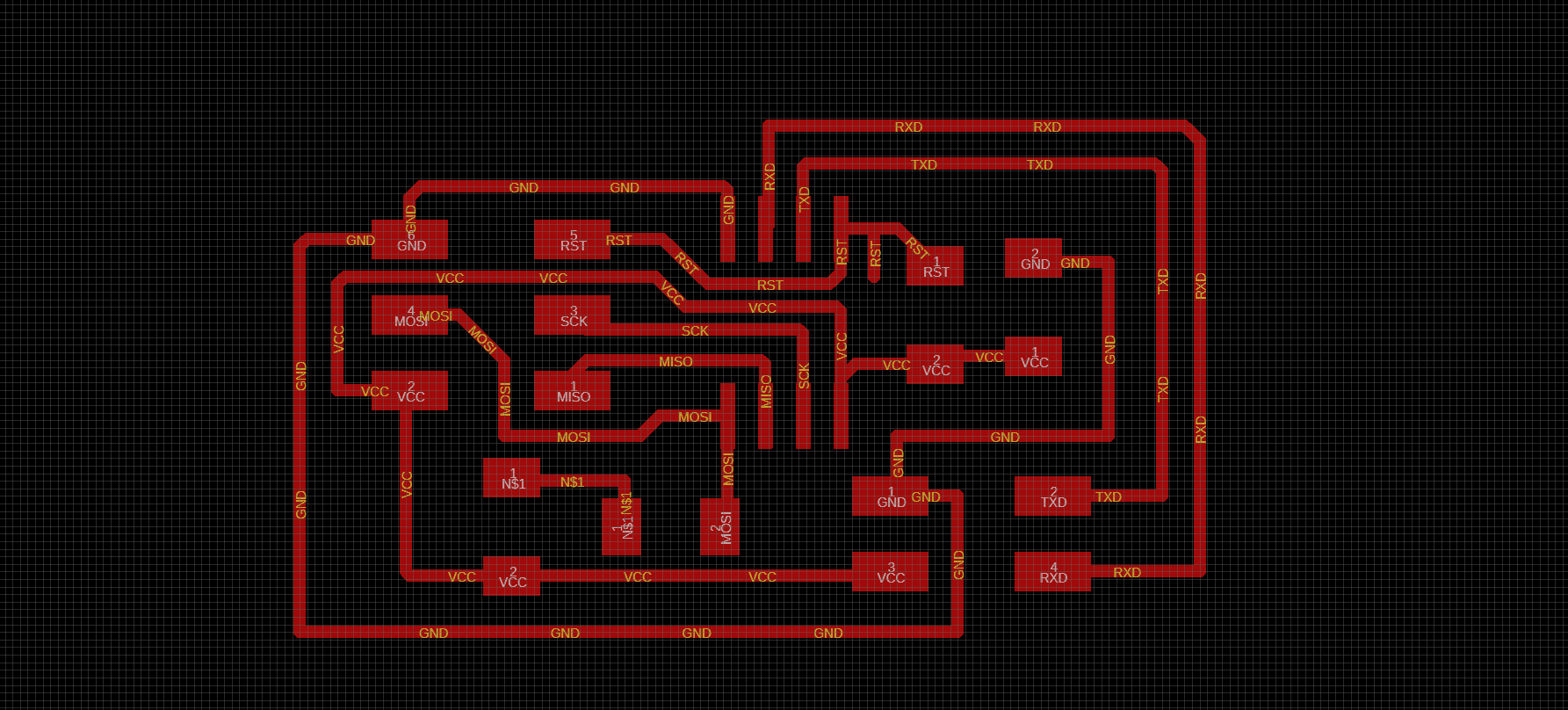

Once both designs where done, I then proceeded to create the traces for boards. This process took a little while as a fiddled with the software, however eventually I managed to find a way where everything made sense. Thus, these are my results.

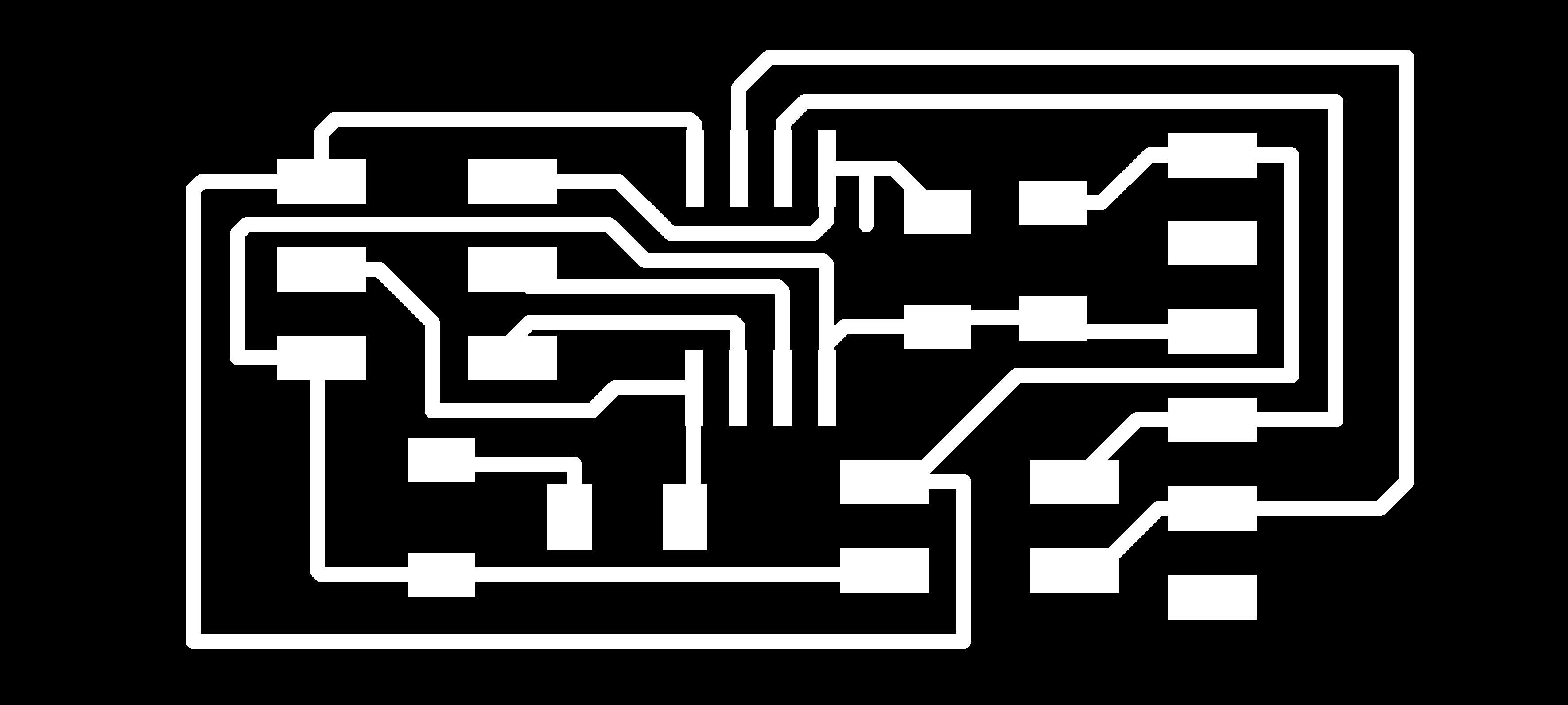

- The Bridge:

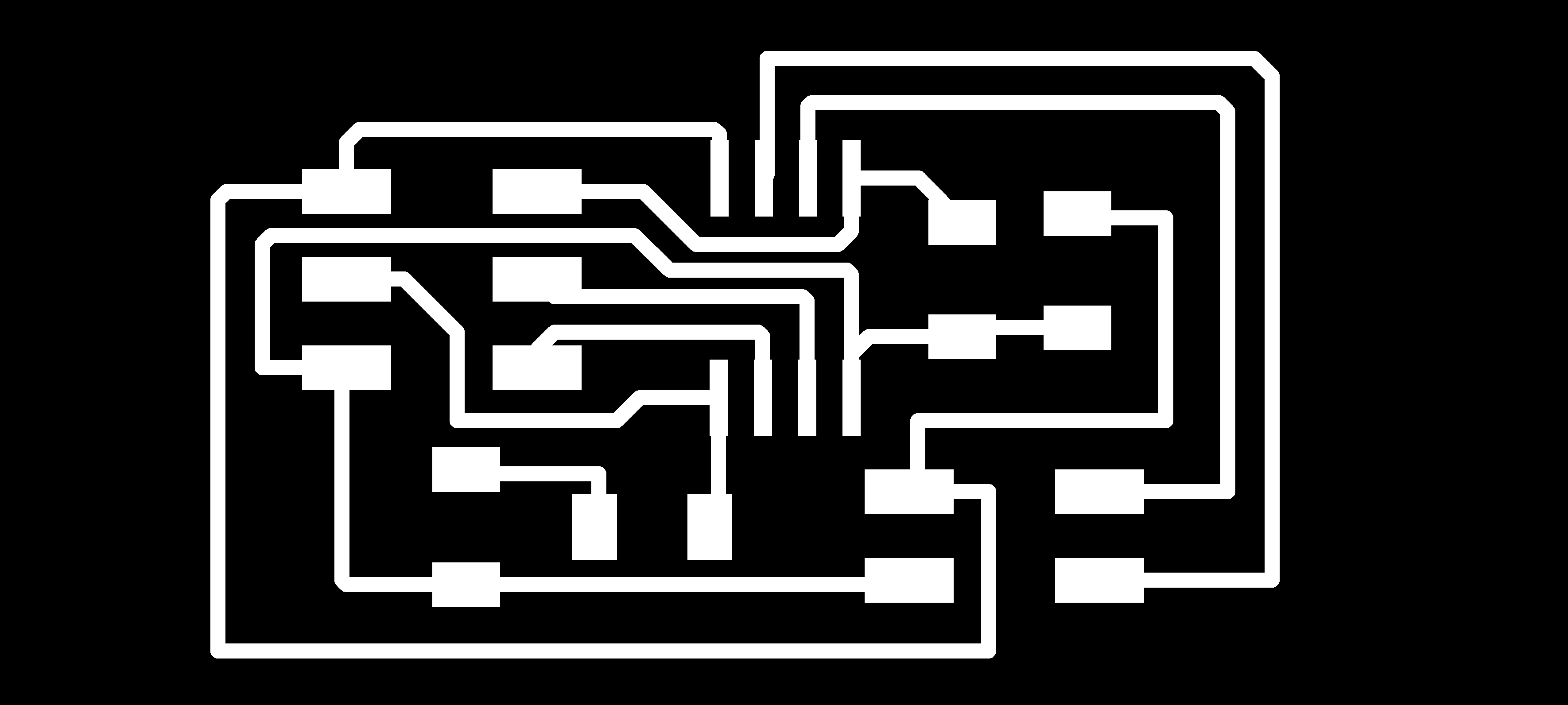

- The Node:

Once the desings where done I then proceeded to export both of them into a monochrome image at 1000dpi which I can then load into Fab Modules in order to cut with the Rolland Mill

- The Bridge:

- The Node:

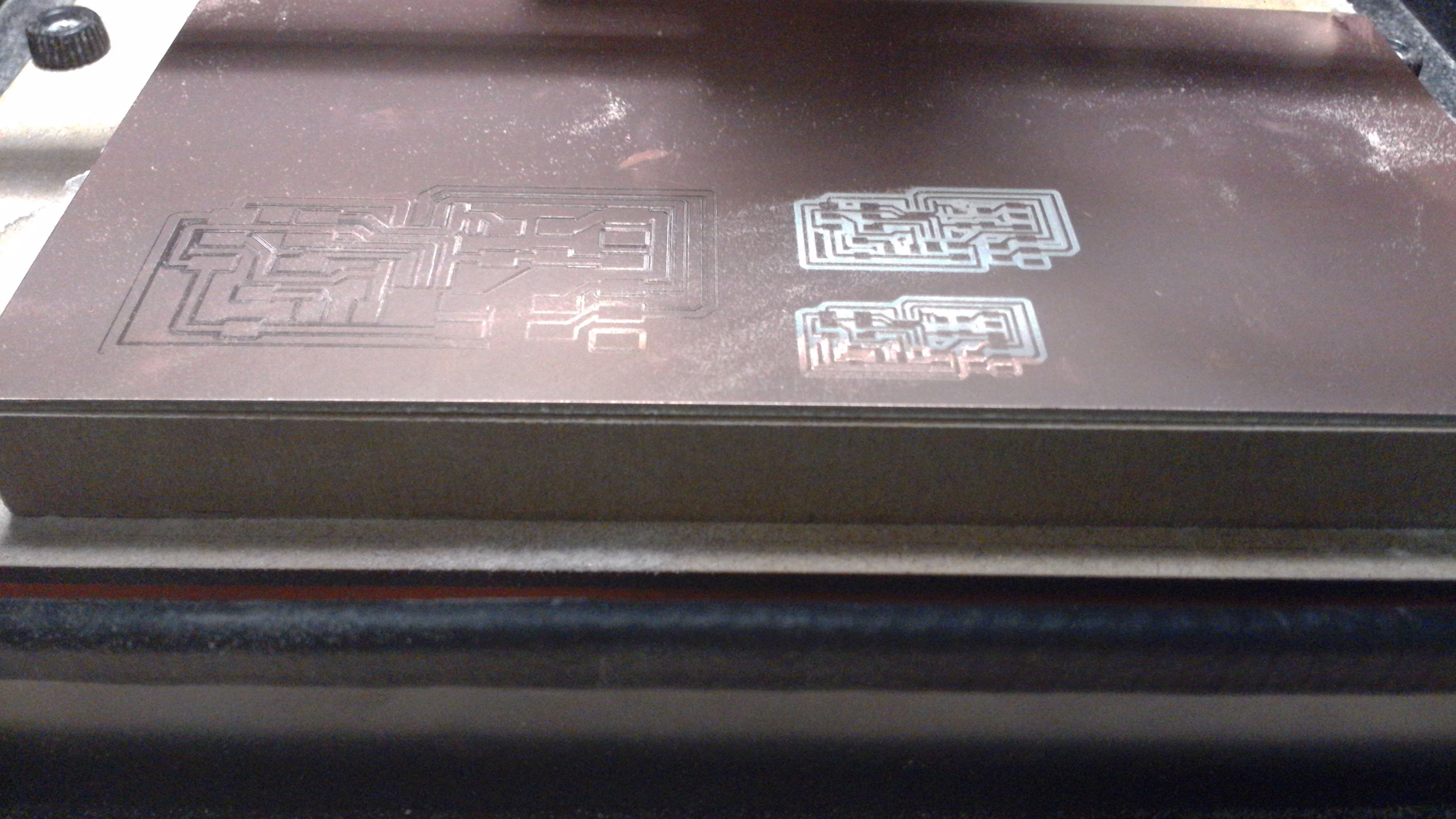

Armed with my designs, I then proceeded to cut them on the rolland mill. I followed the same procedure as I have before, using Fab modules to generate the Gcode needed to mill the boards out of the copper.

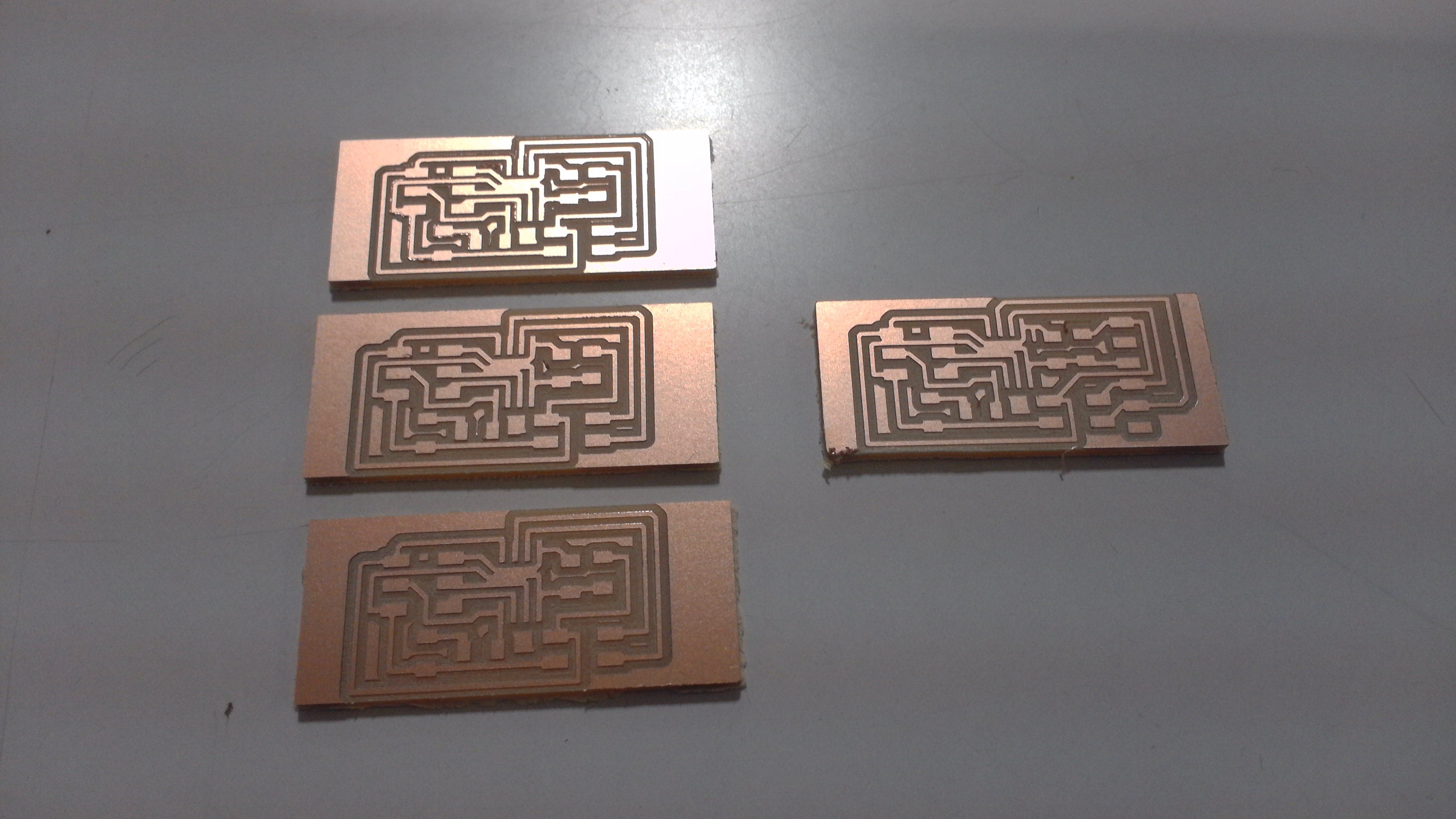

It took me a couple tries to get the design right (I made a mistake when inputting the dpi into fab modules, and so I ended up with both a design that was way too big, and a bit small, however I quickly realised the problem and rectified the issue)

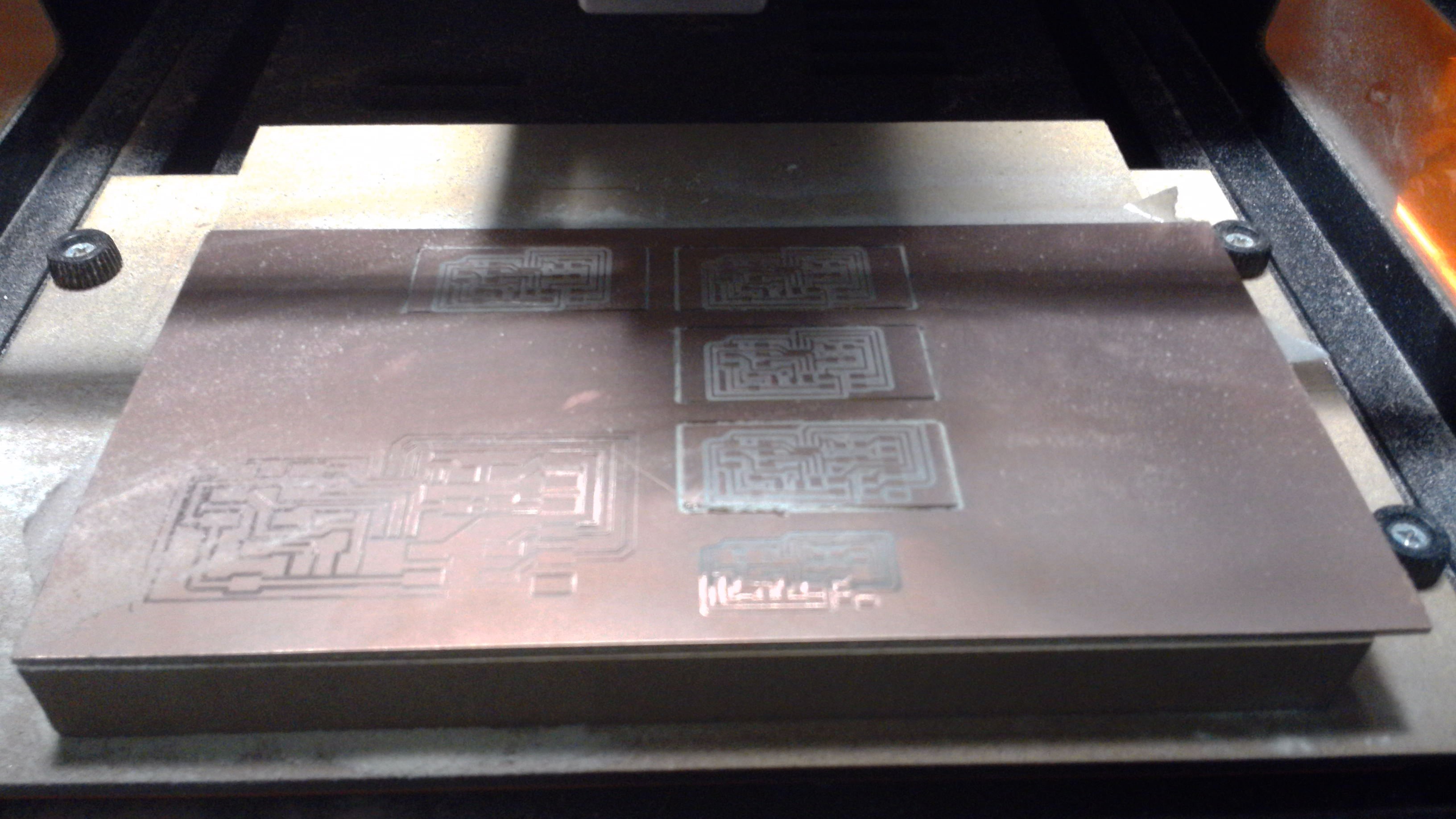

Once I was confident in my design, I proceeded to cut out the rest of the parts. I find that its quicker to make the traces for all the boards in one go, followed by cutting out the outlines also in one go. So I did the traces for all the designs and then cut out the outlines simultaneously.

Once the designs where done I pried them off with a stanley knife. I was quite happy with how well they came out and the ammount of time they took to produce. I seem to be getting better at making nice looking boards in a shorter ammount of time than before.

Once I checked everything anf was happy witth the results, I proceeded to begin soldering.