My objective of my final project is to create a system that can demonstrate to little kids how electricity could be generated used natural sources like flowing water.

I work on an initiative named Naqsh, we aim to increase the interest of young kids in science and scientific research throw a seriels of interactive science shows and experiments.

Naqsh is an Arabic word that means Engrave. We have an old saying; "Seeking knowledge at a young age is like engraving on a stone".

My final project comes in the electricity and power part of our topics. The idea is to show the kids system, where a water stream rotating a mill, could cause an apartment to light. My plan and expectation is that, this act will trigger their minds, and they would want (with the right direction and coaching) to seach and understand more about power generation.

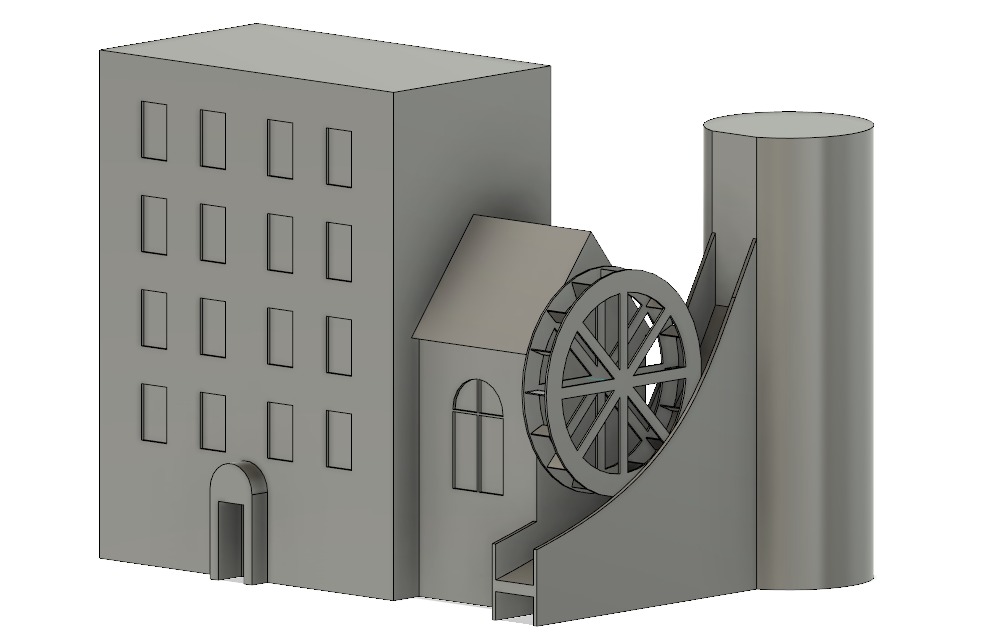

I have created a model to show my idea or final result of the product using Fusion 360.

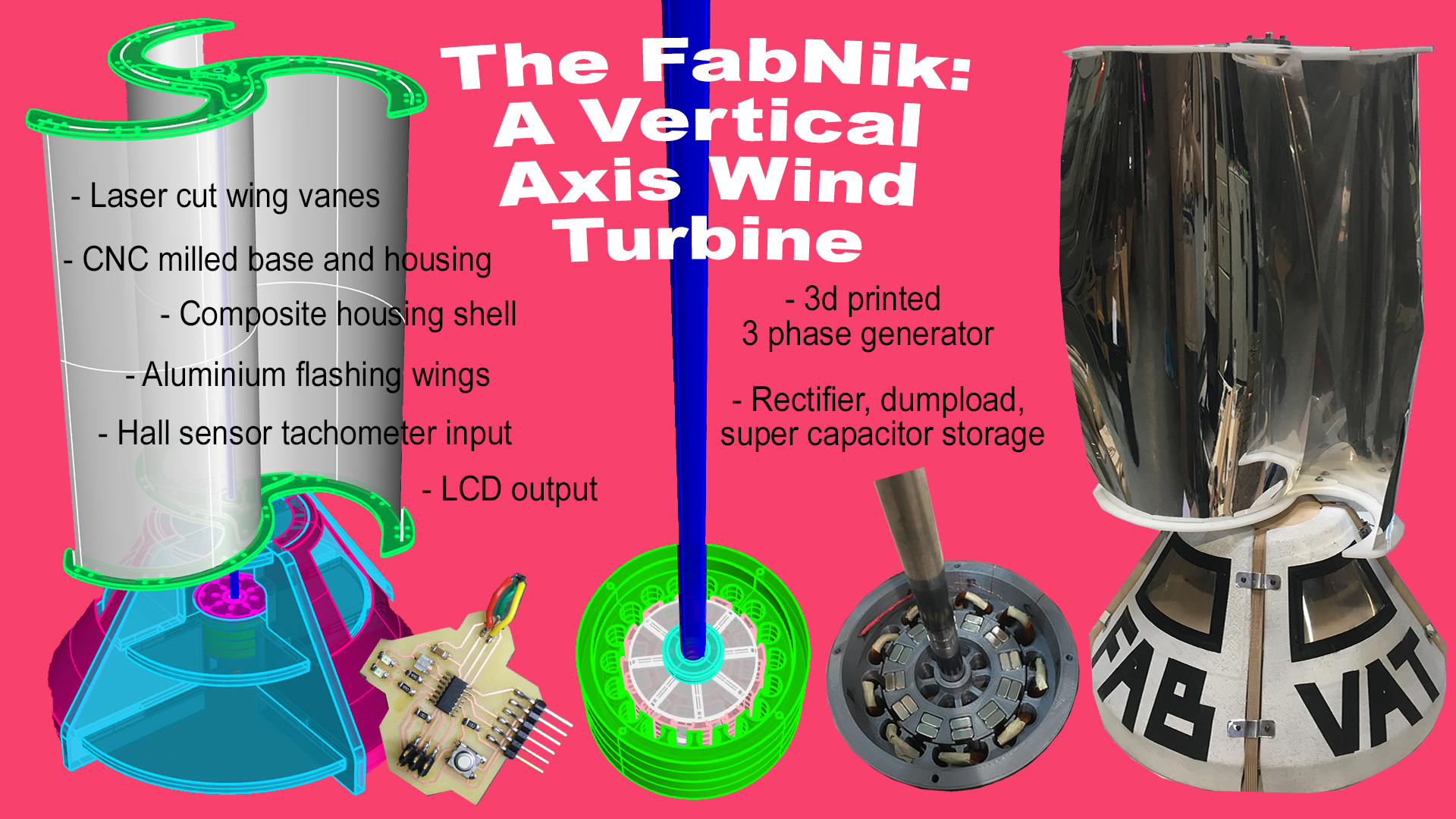

1. The FabNik

One of FabAcademy final projects created by Nicolo Gnecchi in 2018. He made a vertical windmill designing the coil and generator himself, which is pretty epic!

He used 3D printing and coiled it with copper wires. So his system is actually a power generating one, while mine won't actually generate power but demonstrate its generation.

2. Windmill in a Box

One of FabAcademy final projects plotted by Carl Pantosconquilla in 2018. Although it seems he did not continue with the idea for his final project, but he started with it, made a study and manufactured some gears!

His idea was to create a mini windmill, a portable box with a rotating device coupled with a lithium battery, so you can racharge the battery manually from anywhere.

3. Jordan Museum Exhibit

I remember I have seen once in a local science museum an exhibit that has mini windmills with a small prototype of a Jordanian city, that when someone blows on the fan of the windmill and rotate it, the city's lights will turn on.

***

I will design my project mainly using Fusion 360, and other 2D softwares like CorelDraw. So far, I have created the embedded electronics system, which is going to read a signal using a

I will design my project mainly using Fusion 360, and other 2D softwares like CorelDraw. So far, I have created the embedded electronics system, which is going to read a signal using a DC motor with its shaft attached to the watermill. This signal will be sent to an Atmega board, and depening on its value, LED stripes will be lit. The electrical system covered the input and output weeks as much as electronics design and production.

I will build the apartment building using acryllic cut by the laser cutter. The watermill it self will be 3D printed and desgined to be perfectly assembled with the system. The sliding slope of the water would be either 3D printed, or molded and casted because it is a relatively big structure with curvatures that can not be made using a laser cutter. The water tower should be a steady structure to reserve the water, so I will use the CNC machine to make it with a 18mm thick wood (either plywood or latte).

Some of the components would not be easily manufactured, so I will buy them. The following table is a cost report showing these components with their cost and a link to get them.

| Component | Image | Price | Resource |

|---|---|---|---|

| DC Motor |  |

6.89$ | Link |

| Atmega 328p | 3.96$/Piece | Link | |

| Lithium Battery 12 volts | 24.16$ | Link | |

| LED Stripes | 7.99$/20pcs | Link |