10. Molding and casting#

group assignment review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Material Datasheets#

Smooth Cast 300#

- TB / SDS

- Color: White

- Pot Life: 3 minutes

- Cure Time: 10 minutes

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 100A:90B

- liquid plastics. ultra-low viscosity casting resins

- Not a hazardous substance or mixture

- safety glasses and gloves recommended

- some heat of reactions

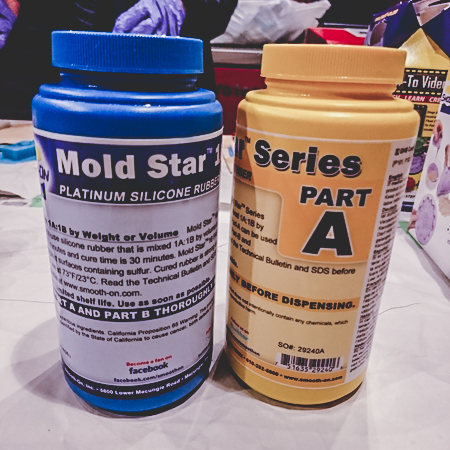

Mold Star 16 Fast#

- TB / SDS

- Color: Blue-Green

- Pot Life: 6 minutes

- Cure Time: 30 minutes

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 1A:1B

- platinum silicones

- Not a hazardous substance or mixture

- safety glasses and gloves recommended

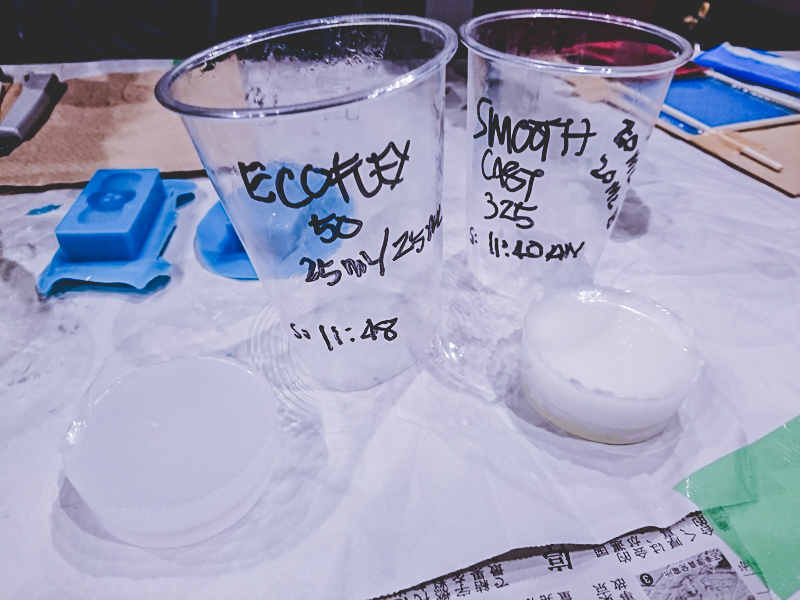

Smooth Cast 325#

- TB / SDS

- Color: Clear Amber

- Pot Life: 2.5 minutes

- Cure Time: 10 minutes

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 115A:100B

Safety datasheet part A

- Polyeurethane Elastomer…flexible

- Safety Requirement: wear eye, mouth/nose, gloves, sleeve protection

- Don’t eat or breathe, touchng will cause irritation

- Part B…no hazzard

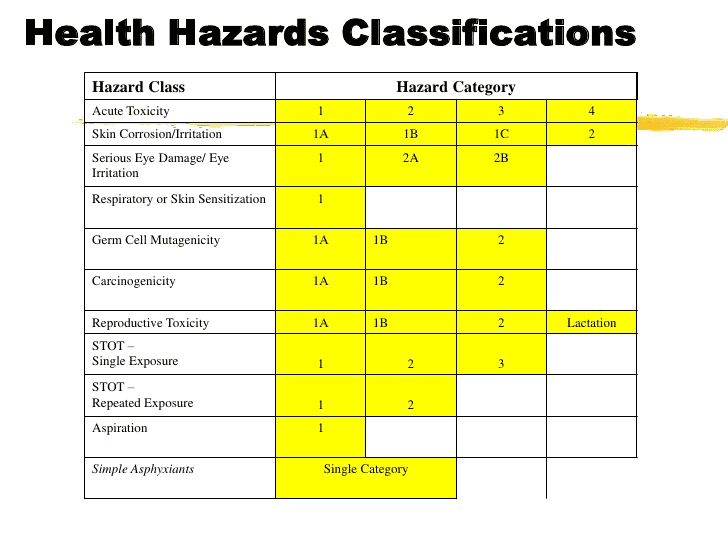

This material, among the 5 we tested in the lab, is the one with the greatest hazzards. Many of them Class 1 and 2 (the highest risk) Eye, nose, mouth, skin protection needed to work with this material.

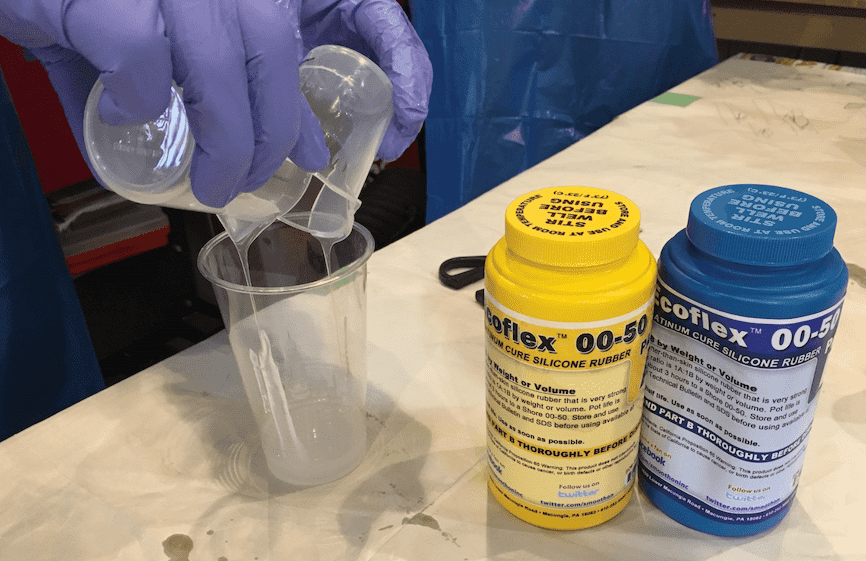

Ecoflex 50#

- TB/SDS

- Color: Translucent

- Pot Life: 18 minutes

- Cure Time: 3 hours

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 1A:1B

- Platinum Cure Silicone Rubber Compound

- non-hazzardous

- safety glasses and gloves recommended

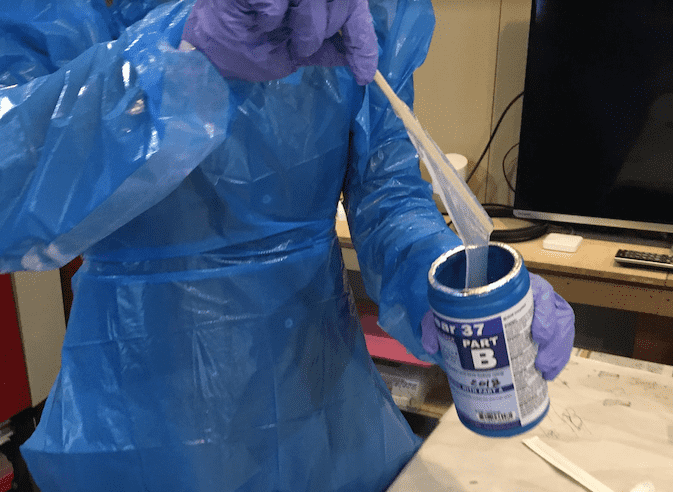

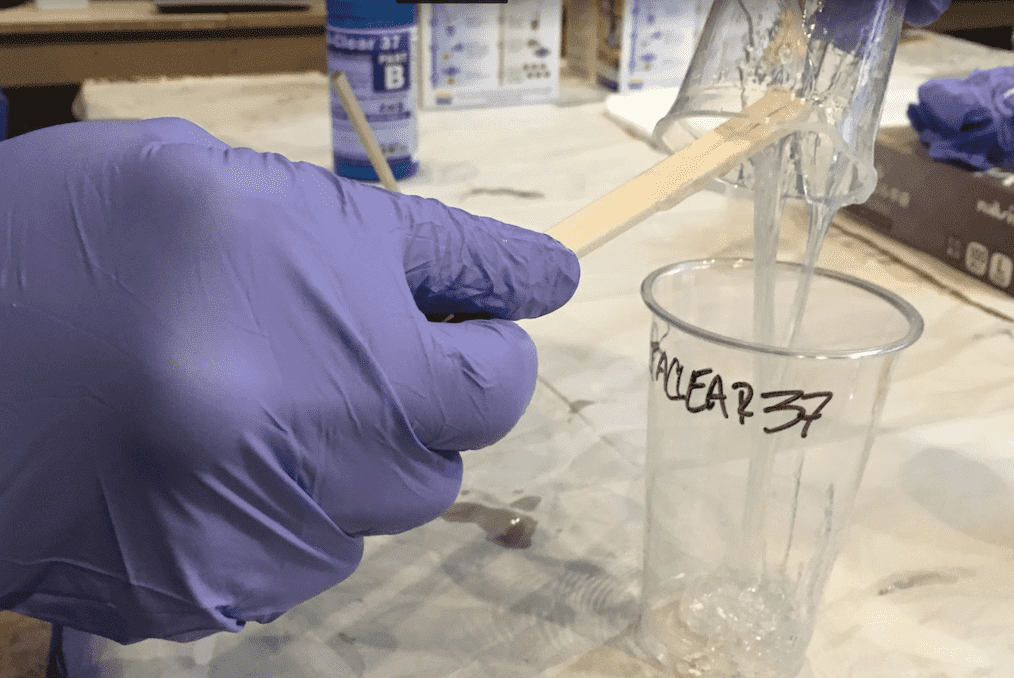

Sorta Clear 37#

- TB / SDS / Food Safe Technical Bulletin

- Color: Water Clear Translucent

- Pot Life: 25 minutes

- Cure Time: 4 hours

- Mix Ratio By Volume: 1A:1B

- Mix Ratio By Weight: 1A:1B

- Food safe

- Non-hazzordous

- safety glasses and gloves recommended

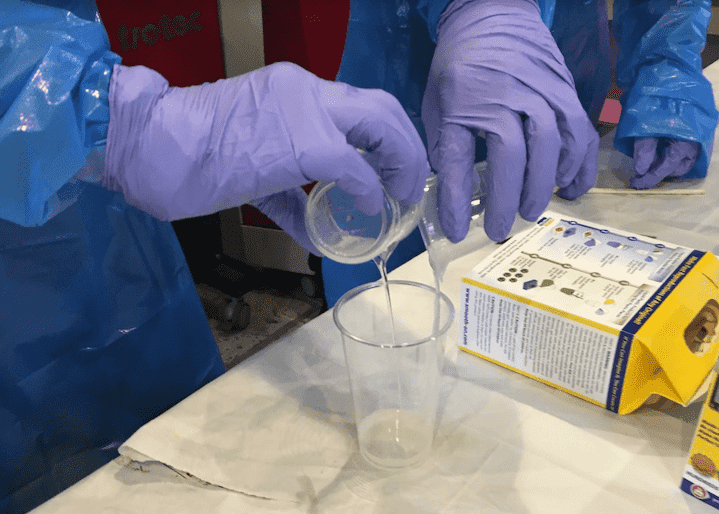

Safety Prepartations#

Taking safety seriously.

- Goggles

- Masks

- Apron with sleeves (avoid particles attaching to our clothing)

- Gloves

Material Observations#

These are our impressions of working with the various materials. All the materials were 2-part mixes of two chemical compounds in liquid form.

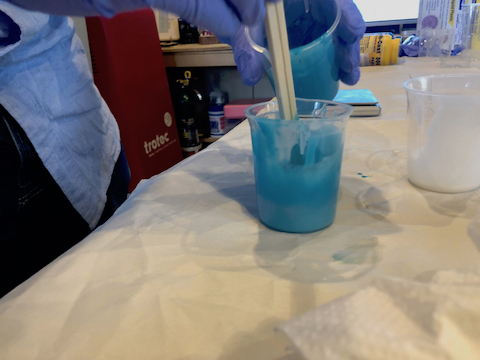

Mold Star 16#

- Use: As the name suggests, the primary use of this material is for making casting molds

- Pour: Medium viscosity…pours like thick honey

- Mixing: Mixes with a bit of effort…the 2 parts are different color…must mix until it becomes a single color

- Curing: Fast cure time…non-malleable after only about 5mins

- Post Processing: Can post-process away flashing and burrs with a sharp knife…no other post-processing needed

- Finish: Cures into a flexible but seemingly strong, solid blue color finish. Peels easily away from wax molds.

- Flexibitlity: Second most flexible among the materials we tested, bends and distorts with little force

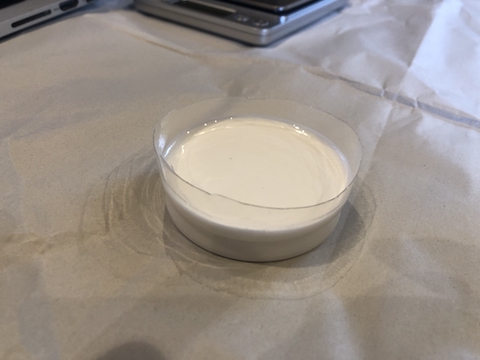

Smooth Cast 300#

- Use: Used primarily for final object Casting

- Pour: VERY low viscosity…pours like thin honey

Pro tip: use chopsticks under the lip of the container when pouring) to control the direction of the pour stream…prevent dribbling back to the side of the canister

- Mixing: VERY easy to mix…but be mindful of making bubbles

- Curing: Cures in minutes…starts to harden within a couple of minutes, full hardness at 10 minutes; tangible warmth when curing

- Post Processing: Can post-process away flashing and burrs with a sharp knife…not certain if it can be sanded

- Finish: Hardens as a beautiful, opaque white plastic finish

- Flexibitlity: Zero flexibiltiy

Smooth Cast 325#

- Use: Not certain why this material would be used when other better, low-hazzard options exists…

- Pour: Medium viscosity…pours like thick honey

- Mixing: Mixes with a bit of effort…but be mindful of making bubbles (it is possible that we either did not get the mix ratio between part A and B correct or did not mix well…which led to poor results)

- Curing: Long cure time…hours; tangible warmth when curing

- Post Processing: Can post-process away flashing and burrs with a sharp knife…not certain if it can be sanded

- Finish: Hardens as a semi-opaque white plastic finish…not so beautiful

- Flexibitlity: Zero flexibiltiy

Ecoflex 50#

- Use: Used for making soft molds (?)

- Pour: Medium-high viscosity…pours like thick honey in cold weather

- Mixing: Mixes with a bit of effort…tendency to generate big bubbles that stay trapped in the material if mixing is too rough

- Curing: Long cure time…hours

- Post Processing: Can post-process away flashing and burrs with a sharp knife

- Finish: Cures as a semi-translucent finish of reasonable eveness

- Flexibitlity: Most flexible among the materials we tested, bends and distorts easily with little force…may be easily broken if too much force applied (?)

Sorta Clear 37#

- Use: Not certain why this material would be used when other better, low-hazzard options exists…

- Pour: Very high viscosity…pours like thick honey on a cold day

- Mixing: Mixes with a lot of effort, feels like mixing chopsticks would break…big bubbles generated and hard to remove

- Curing: Long cure time…hours

- Post Processing: Can post-process away flashing and burrs with a sharp knife

- Finish: Hardens as a semi-translucent finish…lots of air bubbles trapped (maybe needed to mix in higher temperature??)

- Flexibitlity: Some flexibility, distorts when a reasonable amount of force applied

Hardness/Flexibility Ranking#