Week - 10

Molding and Casting

Assignment

Group Assignment

- review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Individual Assignment

- design a 3D mold around the stock and tooling that you'll be using, machine it, and use it to cast parts

Molding

It is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix.

Casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify.

Group Assignment

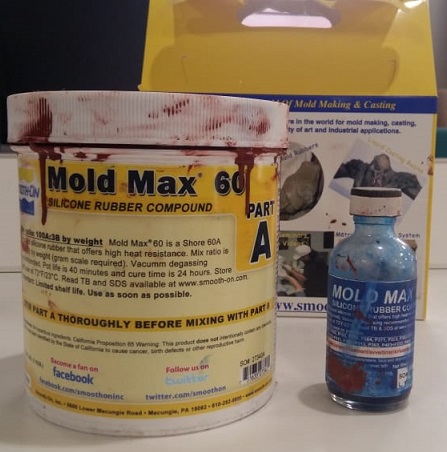

This week group assignment is to review the datasheets of the materials we are using in making mold and cast. Below we are sharing some important points after reviewing safety datasheets of Mold Max 60 for molding and Smooth-Cast 305 for casting materials

Mold Max 60 Safety DataSheet Review:

Mold Max 60

Product/Chemical Name: Mold Max 60 Part A:

- Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 300 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Product/Chemical Name: Mold Max 60 Part B:

- Hazards Identification

- Harmful if swallowed.

- Irritating to eyes, respiratory system and skin.

- Harmful to aquatic organisms may cause long term adverse effects in the aquatic environment.

- Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 150 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves and aprons to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Eye Effects: Irritation

- Skin Effects: Irritation

- Carcinogenicity: None Determined

- Mutagenicity: None Determined

- Teratogenicity: None Determined

Smooth-Cast 300 Series Safety DataSheet Review:

Smooth-Cast 305

Product/Chemical Name: Smooth-Cast 305 Part A:

- Hazards Identification

- Harmful by inhalation.

- Irritating to eyes, respiratory system and skin.

- Limited evidence of a carcinogenic effect

- Harmful; danger of serious damage to health by prolonged exposure through inhalation environment.

- Inhalation - Remove source(s) of contamination and move victim to fresh air. If breathing has stopped, give artificial respiration, then oxygen if needed. Contact physician immediately.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse; seek medical attention if rash develops.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 262 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Reseal partial containers. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eyeand face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Hazardous Component: 4,4’ Methylene, bis(phenylisocyanate)

Product/Chemical Name: Smooth-Cast 305 Part B:

- Hazards Identification - Not hazardous according to United States Occupational Safety and Health Administration (OSHA).

- Inhalation - Remove source(s) of contamination and move victim to fresh air.

- Eye Contact - Flush eyes with plenty of water. If irritation persists, seek medical attention.

- Skin Contact - In case of skin contact, wash thoroughly with soap and water; remove contaminated clothing and launder before reuse.

- Ingestion - Do not induce vomiting unless instructed by a physician. Contact physician immediately

- After first aid, get appropriate in-plant, paramedic, or community medical support.

- Flash Point - 262 °F

- Handling Precautions - Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. Use good general housekeeping procedures.

- Storage Requirements - Store in cool dry, well-ventilated area

- Protective Clothing/Equipment - Wear chemically protective gloves to prevent prolonged or repeated skin contact. Wear protective eyeglasses or chemical safety goggles, per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166. Contact lenses are not eye protective devices. Appropriate eye protection must be worn instead of, or in conjunction with contact lenses.

- Toxicological Information:

- Acute Inhalation Effects: None Established

- Acute Oral Effects: None Established

- Reproductive Toxicity: None Established

- Mutagenicity: None Established

- Teratogenicity: None Established

- Sensitization: None Established

Individual Assignment

I decided to make a shape of starfish which will be casted in wax. The first mold made out of the wax will be the positive shape of the job.

3-D Model

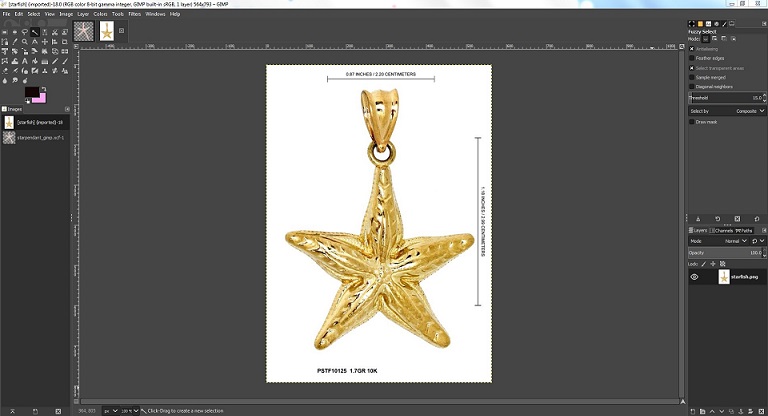

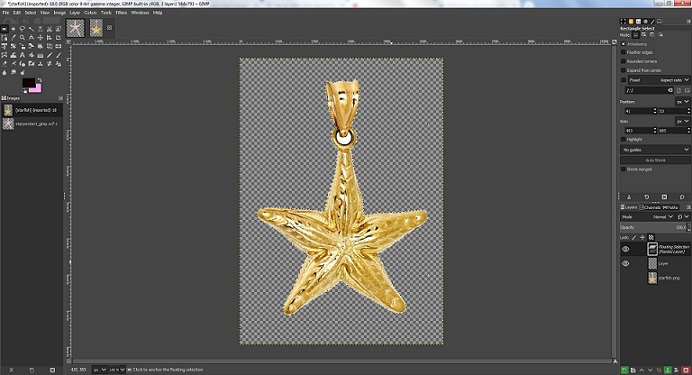

To make starfish, first i download a starfish and simplified image of starfish from Pinterest ,then i opened in GIMP software to remove its background and save it as .png format.

Starfish image

Removing background

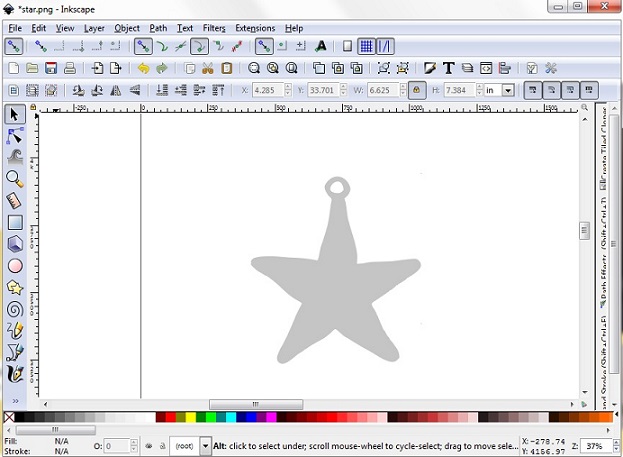

Then I import gimp image in InkScape for making scalable vector file by using trace bitmap and save that as .svg format.

Making SVG file uisng Inkscape

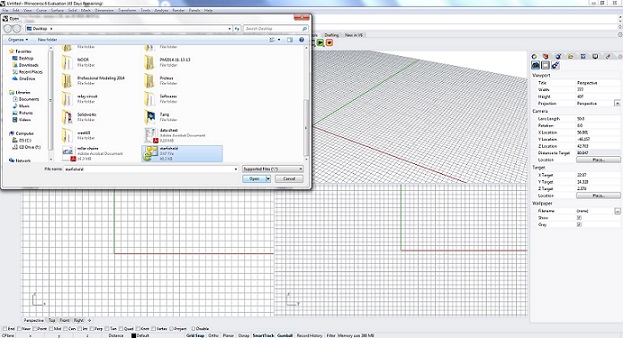

To open an DXF file in Rhino, for that I export a file from .svg to .dxf format and followed below steps

Import image in Rhino

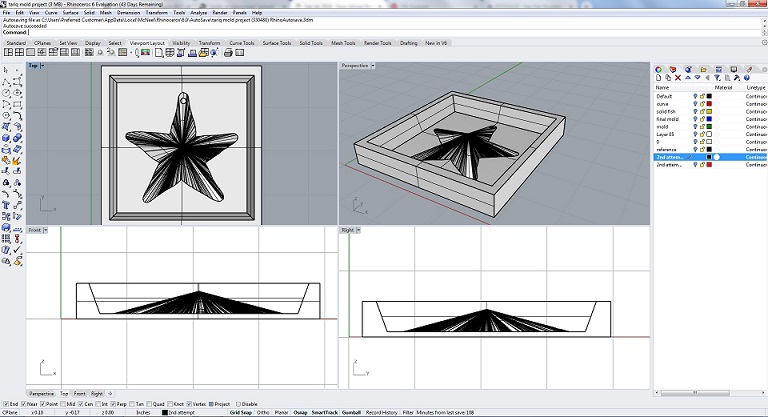

- "point extrude" Extruded starfish curve to point extrude.

- "Tapered extrude" Make square tapered solid .

- "Subract" Starfish curve from tapered sqaure solid and it became negative mold but i need positive mold

- "Square solid" For making positive mold i made another sqaure and subract negative mold.

Using "Extrude" and "Subract" commond

Milling

For milling I am using Rolnad SRM-20 machine and the material to mill is Machinable wax which is used as Rigid Mold here. SRM-20 is workdone .rml format and to generate that

Steps for RML File

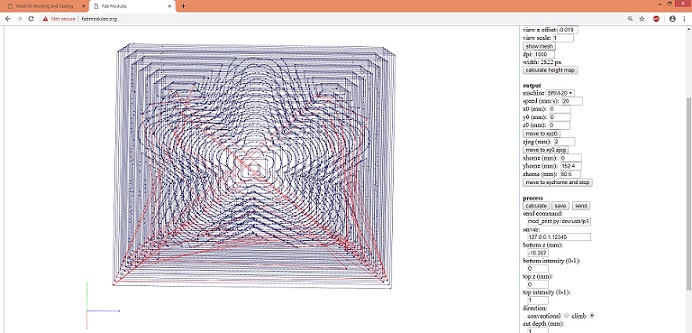

- First open the www.fabmodules.org for online generating rml file

- Click on mesh(.stl) as your input formate file.

- Browse and open your desired .stl fil.

- After that, go to output format and select Roland mill(.rml).

- Then go to process and select wax rough cut 1/8.

- At right coner shows output and select SRM-20 machine.

- Now set the origions x0=0, y0=0 and z0=0.

- Finally click the calculate and save the file.

RML rough cut

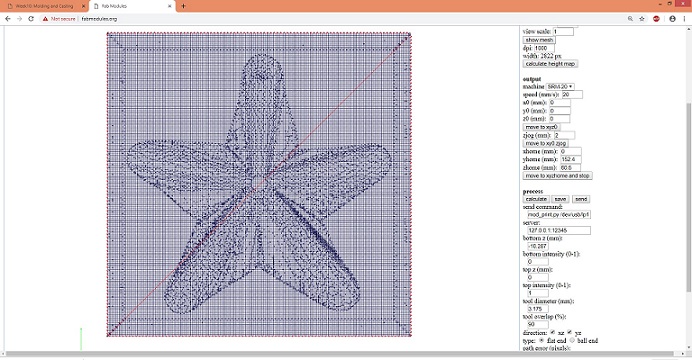

Same steps follows for finish cut, click on wax finish cut 1/8 and click calculate to save the file.

RML finish cut

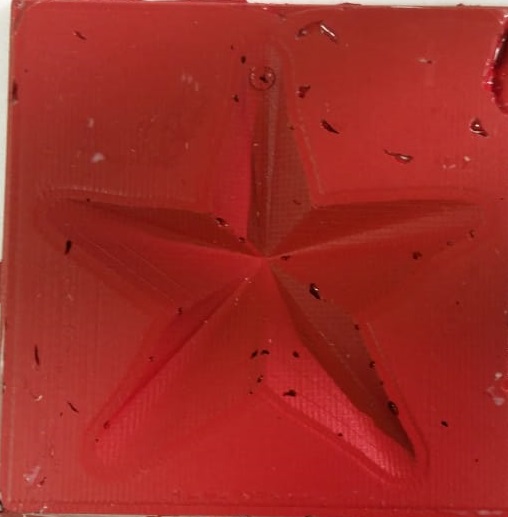

The milling Result:

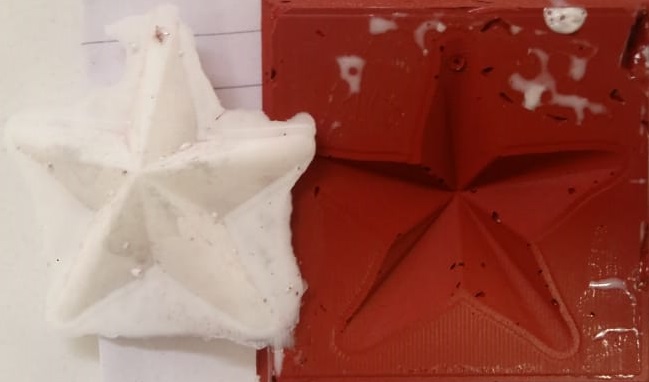

Rigid Mold

Making Flexible Mold

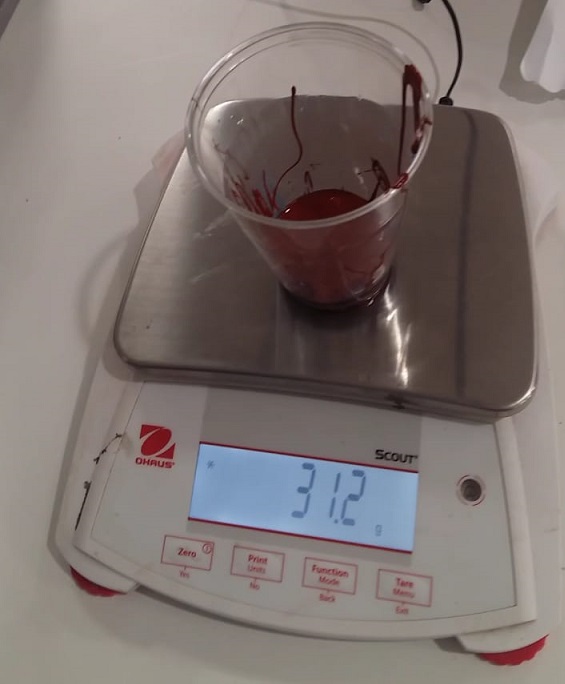

After making Rigid Mold its time to make flexible mold from it. I am using Mold Max 60 which is used to cast both metal and plastic. The procedure to make mold is define below: First I need to measure the quantity that how much material is needed. For this I poured water in my mold, and weight an empty glass. Then I put water into glass from mold and measured it.

Measuring required weight

Both part A and B are mixed in a ratio of 100:3 respectively, which is described in datasheet to get the same gram value measured in water.

Mold Max 60

Mold Max 60 part B

Mixing Mold Max 60 part A & B

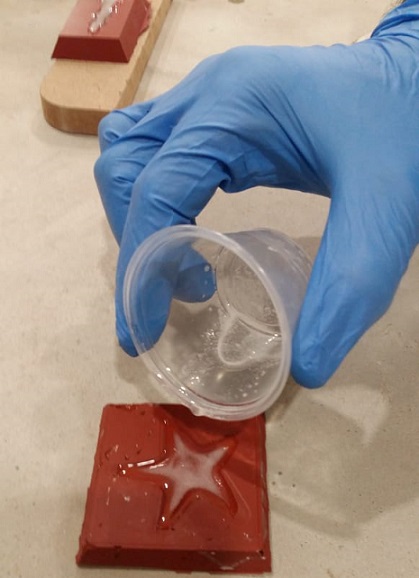

Now mixing part A and B, when i poured mixture into rigid mold the mixture was became less because of specific gravity difference between "water" and "mold max 60".The specific gravity of "water" is 1 and specific gravity of "mold max 60" is 1.45.

After that i left mold for drying at room temperature about 2days because of holiday.

Final result

Mold Max 60 is able to cast both metal and plastic. So we try both casting in our Lab.

Metal Casting

The material we are using in metal casting is Bismuth. It has low melting point which is 271.4 C so it is less harmful to work on.

- First we heat the material till it reaches 300C

Heating Bismuth

- Then pour melted bismuth in mold.

Pouring bismuth into mold

- After demolding metal part the resut was not good because of less depth in mold, for getting perfect result it should be keep more depth than exact object.

Cast made with Bismuth

Plastic Casting

For plastic casting we used Smooth-Cast 305,with the ratio of part A and B is 1:1, after mixing the mixture poured into flexible mold.

Pouring Smooth cast 305 mixture into mold

after drying the plastic mold.

After demolding Model

Now remove unwanted material from starfish model with the help of blade and final result is here.

After removing unwanted material

After removing unwanted material i fixed key-chain in plastic model.

Final result with key-chain

All process Rigit Mold > Flexible Mold > Cast in Plastic & Metal

"Click here"to download all files of this week

« Week9 Week11 »

Automatic Hot Water Dispenser by Tariq Ahmed Shaikh is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Based on a work at http://fabacademy.org/2019/labs/khairpur/students/tariq-ahmed/