WEEK-17

Wildcard Week

Assignment

Group Assignment

• produce test coupons for your composite fabrication process(es)

Individual Assignment

• read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it, with resin infusion and compaction

Group Assignment

As a group assignment this week we did mill a curved surface more like bowl. As it was for testing and earning know-how about composites, it really helped us undertand how different it is to cast here compared to molding and casting week. So we simply machined it

After cutting it did look like

and as we casted it, it ended up being not the perfect but reasonablly good result, as it was our first experiance with composites.

Individual Assignment

In the individual assignment, we had to read the safety data sheet (SDS) and technical data sheet (TDS) of the epoxy resin that i will be using. I was using the resin, which is a Transparent two-component epoxy impregnation agent.

Part A

here are some safety measures and warnings before using this material:

•Causes serious eye irritation •Causes skin irritation •Toxic to aquatic life with long lasting effects •Wear protective gloves •Wear eye/face protection •Wash thorougly after handling •if ON SKIN: wash with plenty of soap and water. If skin irritation or rush occurs: Get medical attention. •if IN EYES: RInse cautiously with water for several minutes. If eye irritatipon persist. Get medical advice and attention •Take off contaminated clothing and wash before reuse

Part B

here are some safety measures and warnings before using this material:

•Causes serious eye damage •Causes severe burns and eye damages •May cause an allergic skin reaction •Harmful to aquatic life with long lasting effects •Wear protective gloves/protective clothing •Wear eye/face protection •Wash thorougly after handling •If SWALLOWED rinse mouth •If IMNHALED Remove victim to fresh air and call a POISON Center or doctor/physician •if ON SKIN: wash with plenty of soap and water. If skin irritation or rush occurs: Get medical attention. •if IN EYES: Rinse cautiously with water for several minutes. If eye irritatipon persist. Get medical advice and attention •Take off contaminated clothing and wash before reuse

Important Points from Technical Datasheets

•The solution is mixed with 5:4 Ratio •Mix components thorougly till 10 minutes when it starts heating it is good for nexgt process •it takes 24 hours to dry

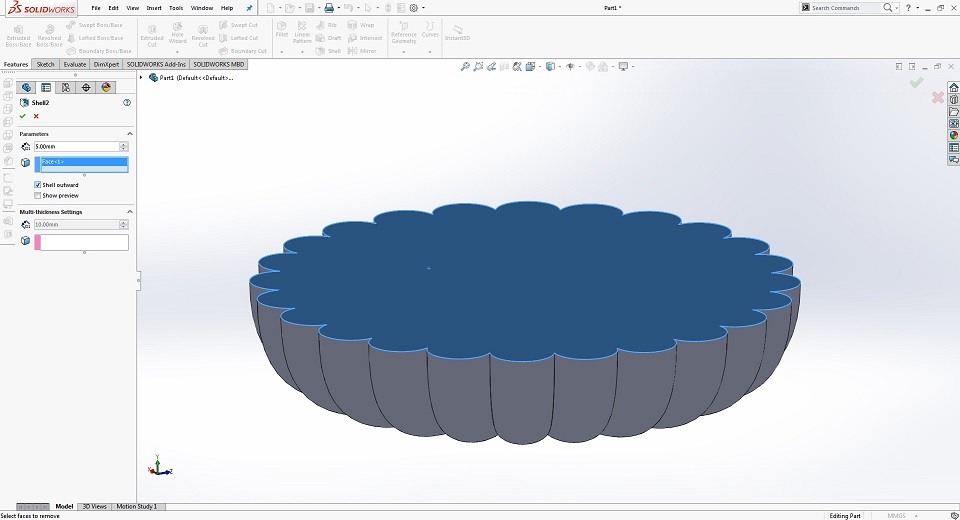

Designing 3D Model

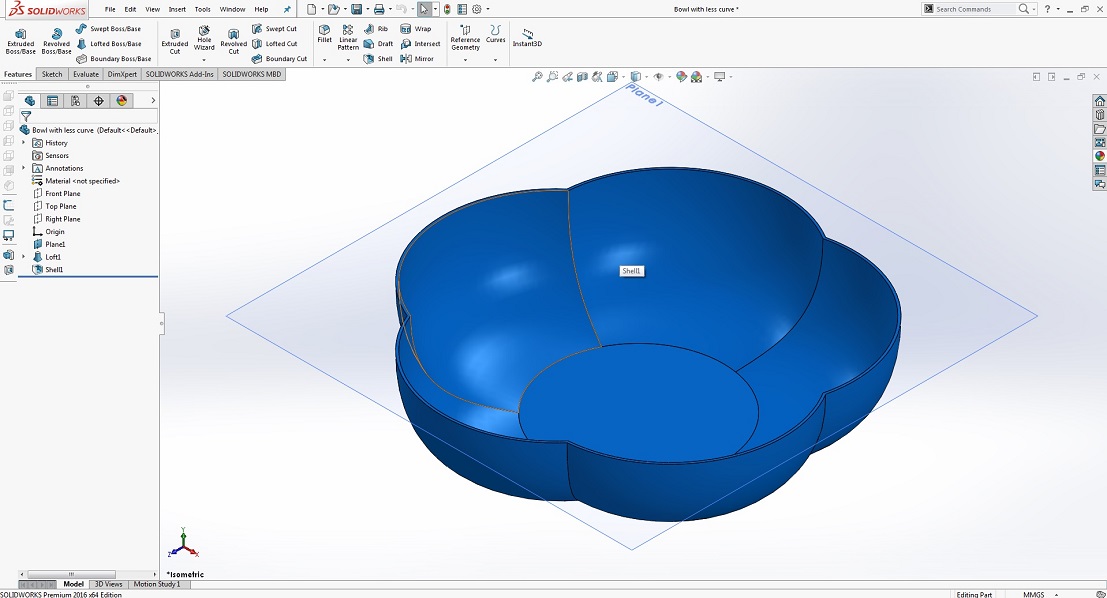

I design a Bowl in this week. I used SolidWorks to design my model and below I mentioned steps:

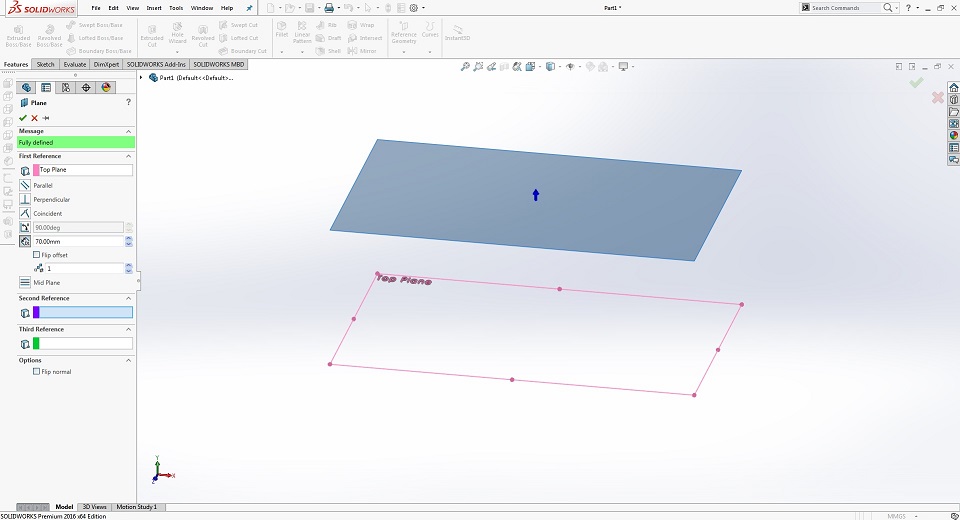

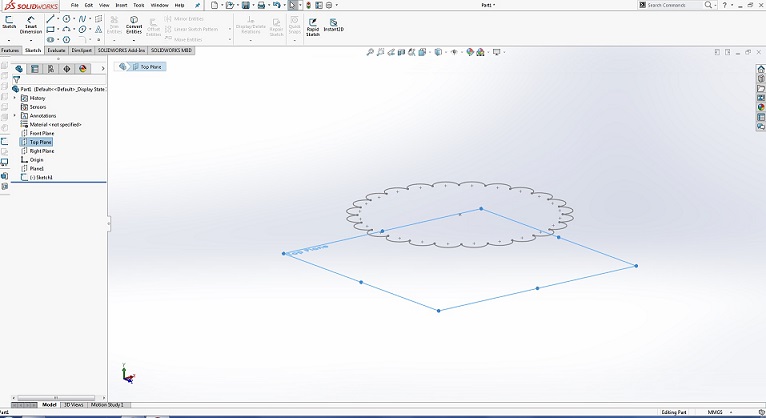

First step is to select top plane than go to reference geometry select plane and 70mm above the top plane.

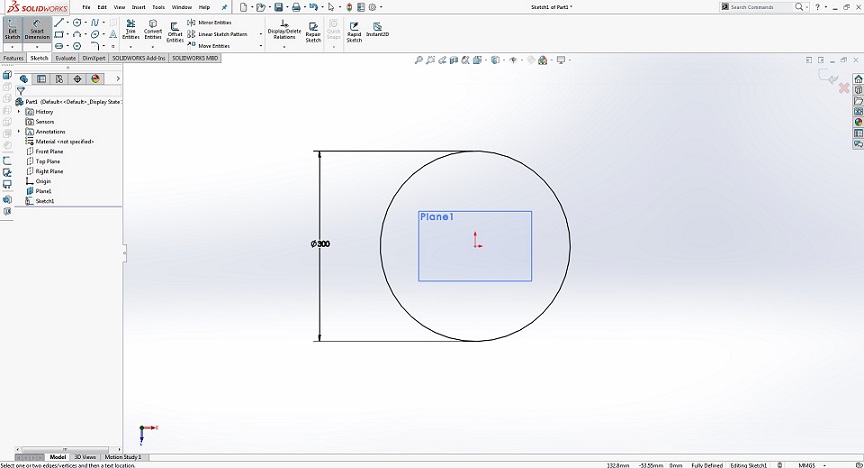

Than draw a circle with diameter of 300mm

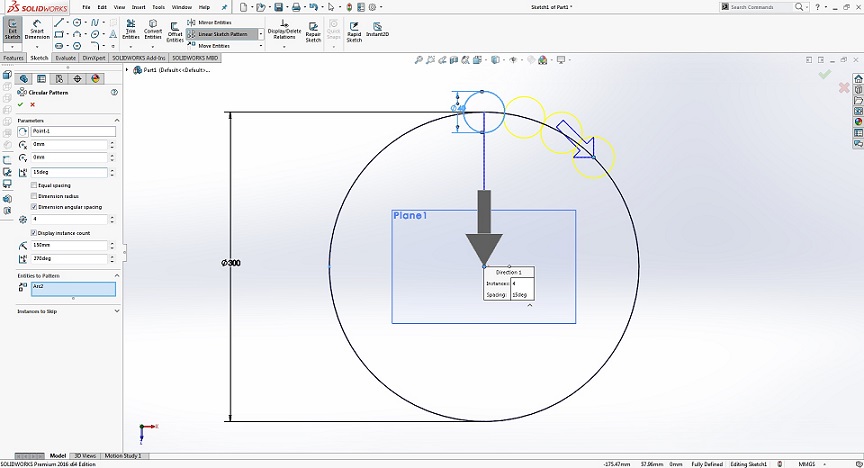

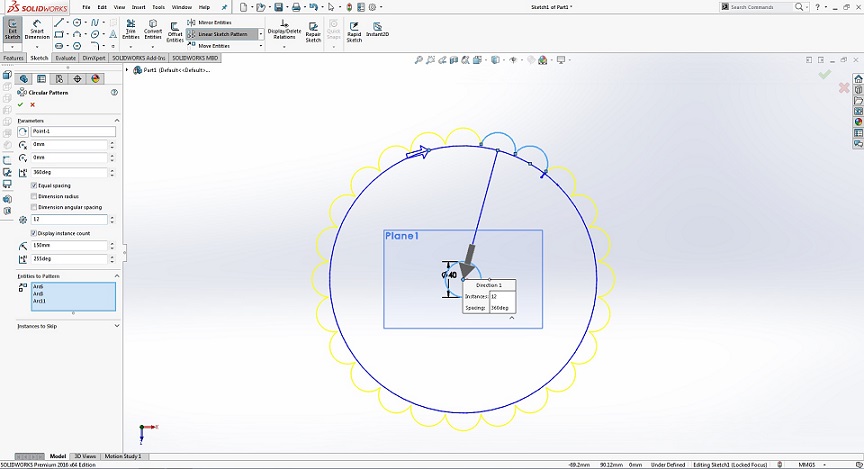

Draw a small circle on outer line of dia 300mm circle and making circular pattern with four numbers.

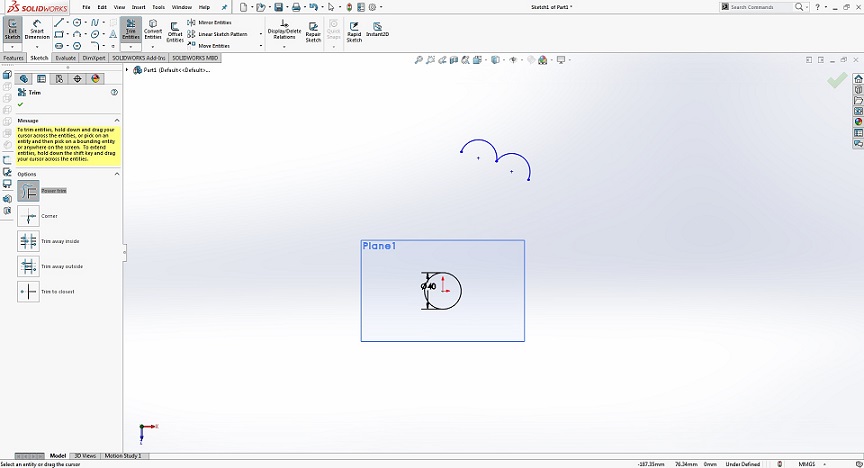

After that use trim command to trim all circle except two center circles and draw a circle at center of the plane.

Now click circle which is on center of the plane than select both halves circle to make circular pattern with twelve numbers

use trim command to delete the center circle and go to top plane.

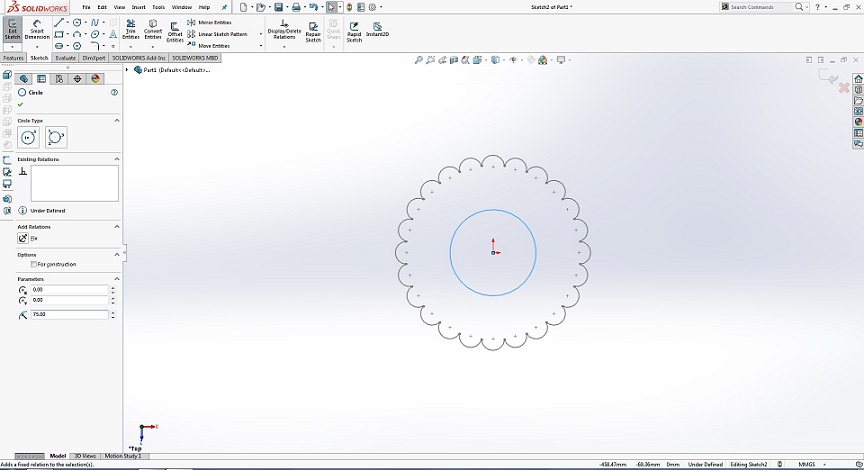

Now draw a circl with the radius of 75mm

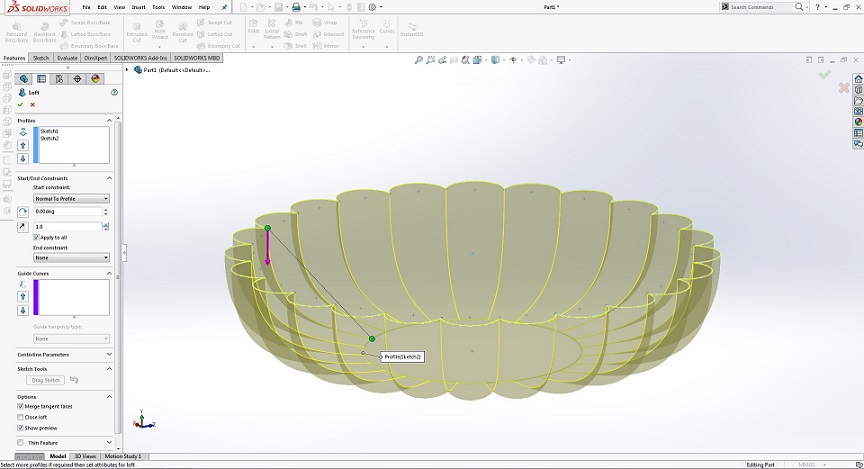

Than go to loft boss features and select both sketches to extrude.

after that go to shell features and make a bowl hollow.

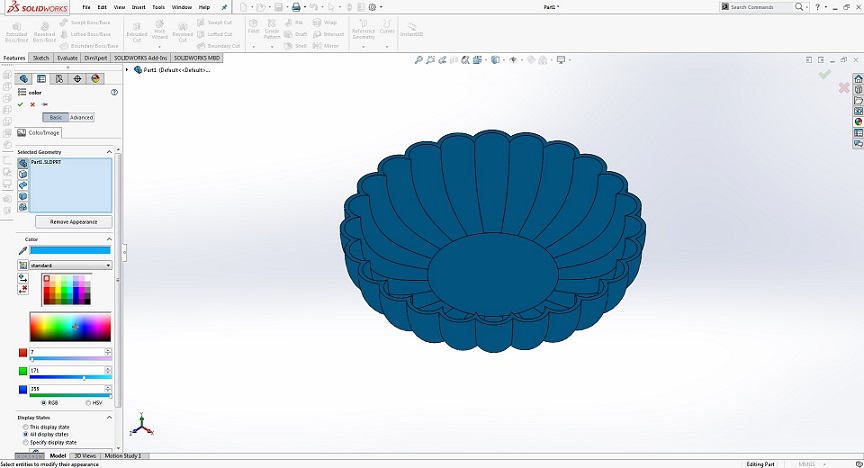

For rendering go to appearance and choose different colours

Now go to renders tools and select final render.

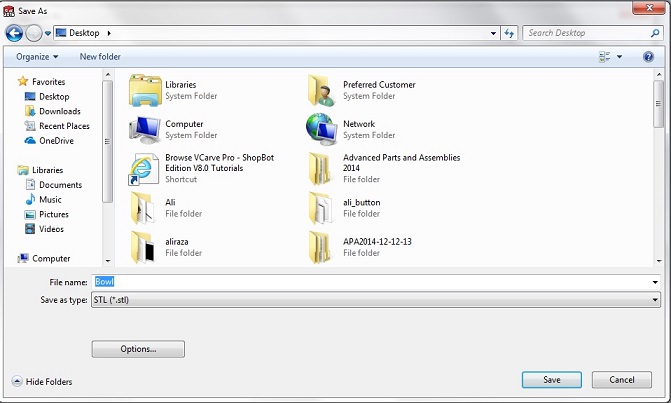

Save as file, STL file

i followed this tutorial to make bowl Link

Milling

For this week assignments we are using High Density Foam which has thickness of 76mm. For milling high density foam we are using Shopbot (to understand how to work with Shopbot please visit Week-8). VCarve Pro is used to generate G-Code for Shopbot

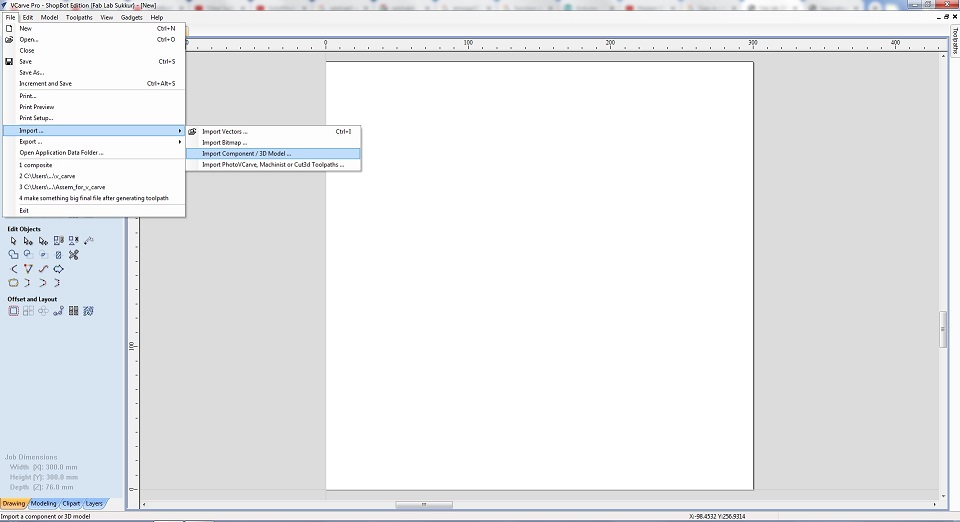

The steps to generate G-Code shown below:

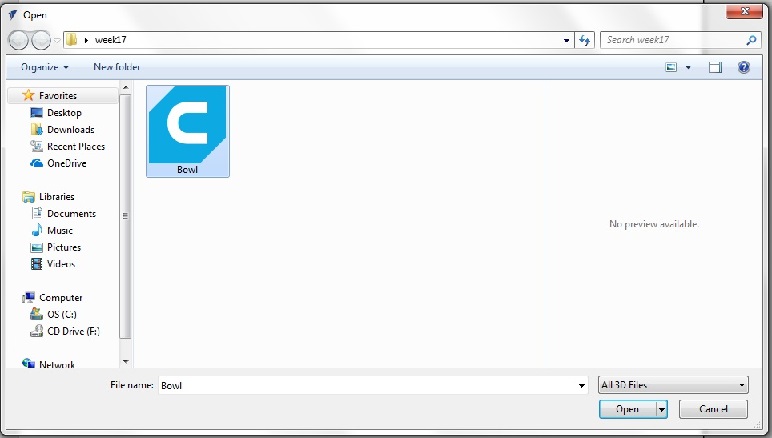

First open VCarve and click on File > Import... and select Import COmponent/ 3D Model ... in a window select .STL file which we made in designing part

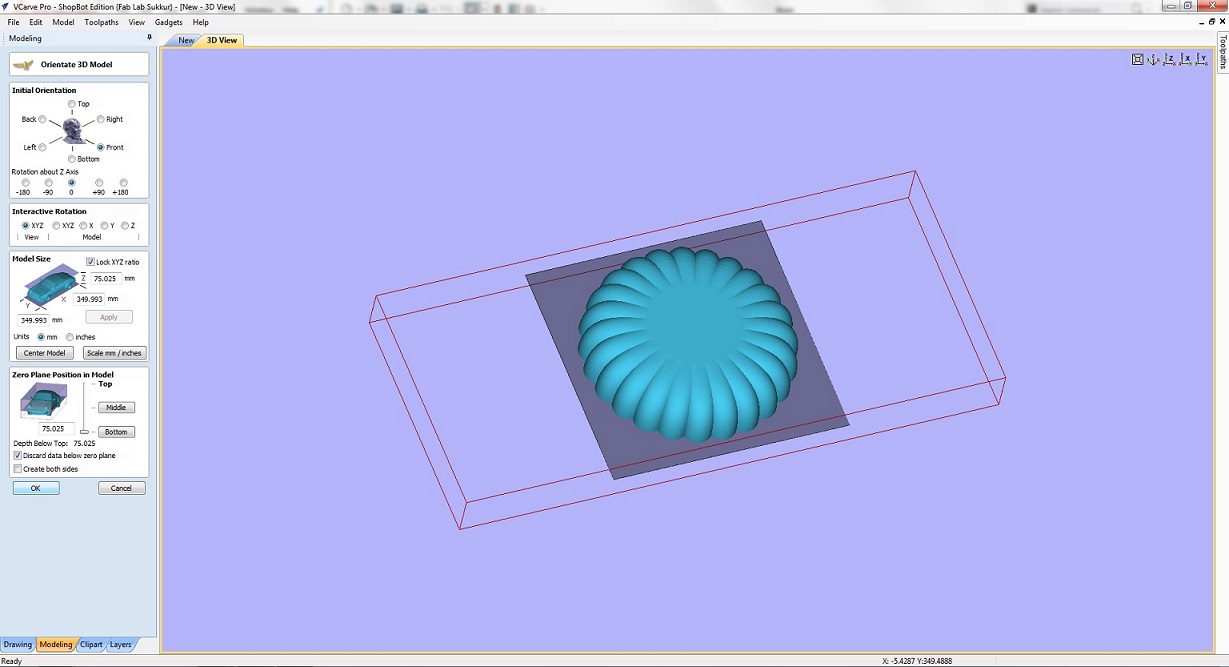

The model is set with in boundaries by using settings in a picture, then click OK for further process

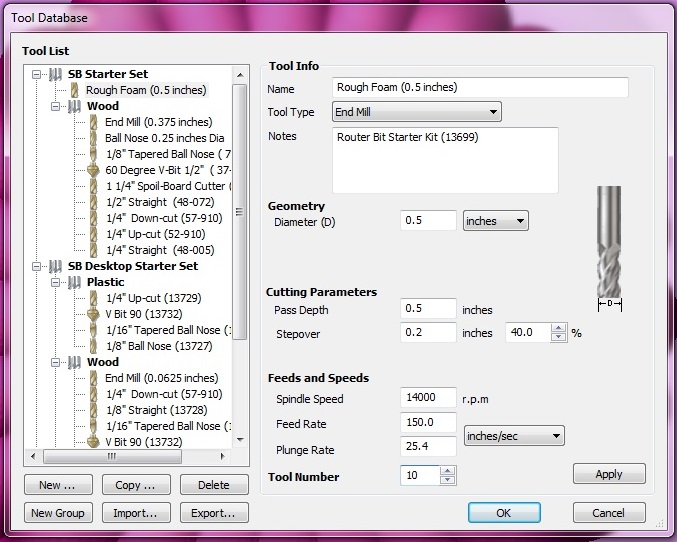

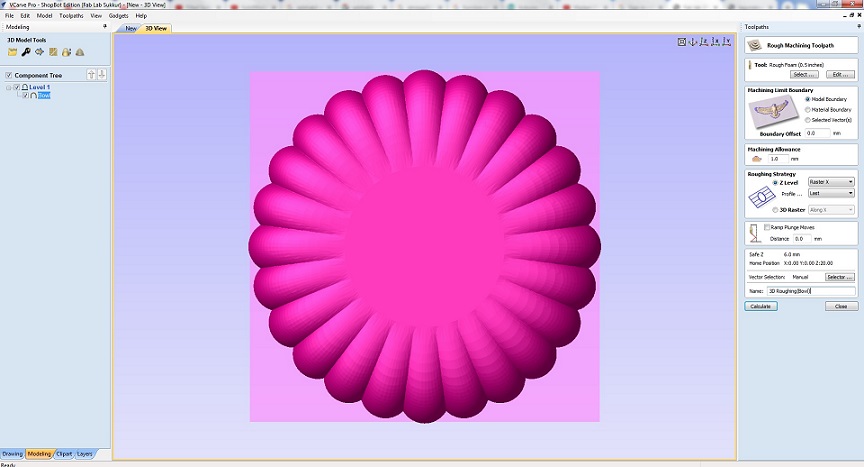

Now click on toolpath and select Rough Machining Toolpath we are using 0.5 inch End Mill drill bit, but it was not present in Tool database so we create New database, settings are shown in picture

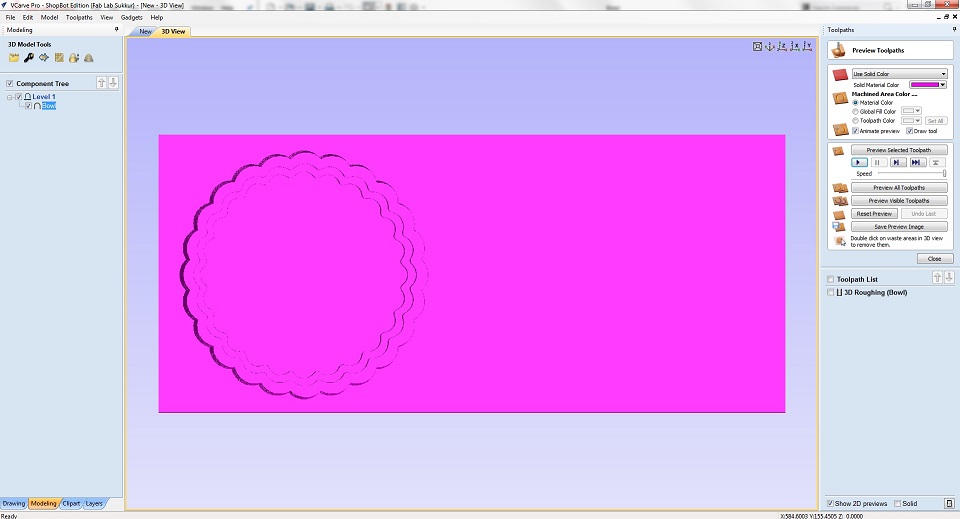

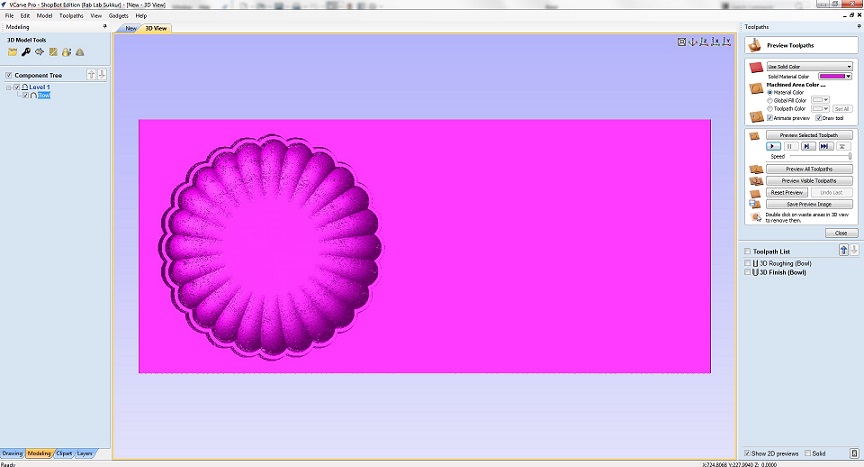

Preview of roughing toolpath

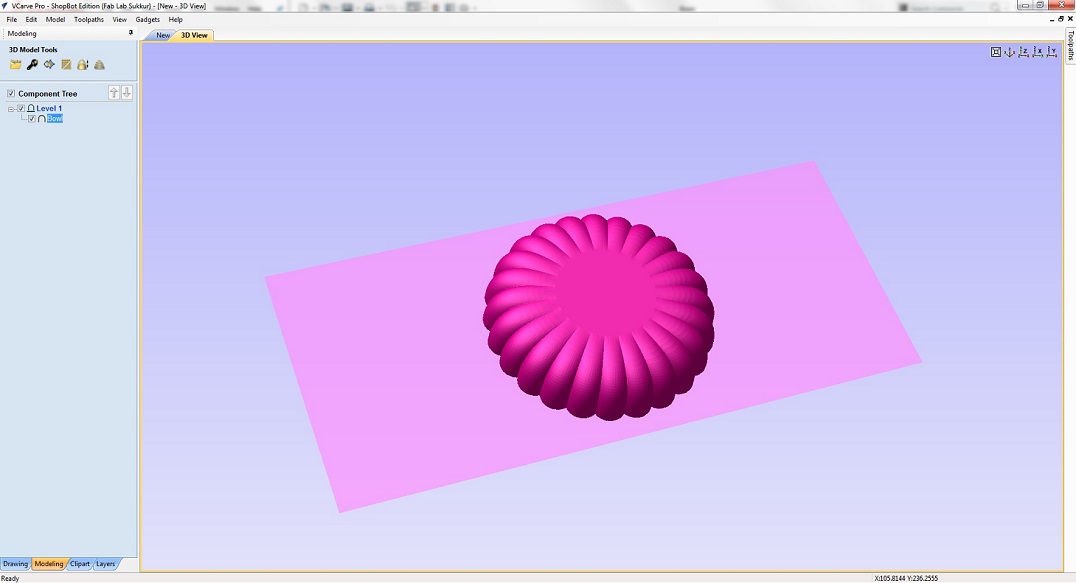

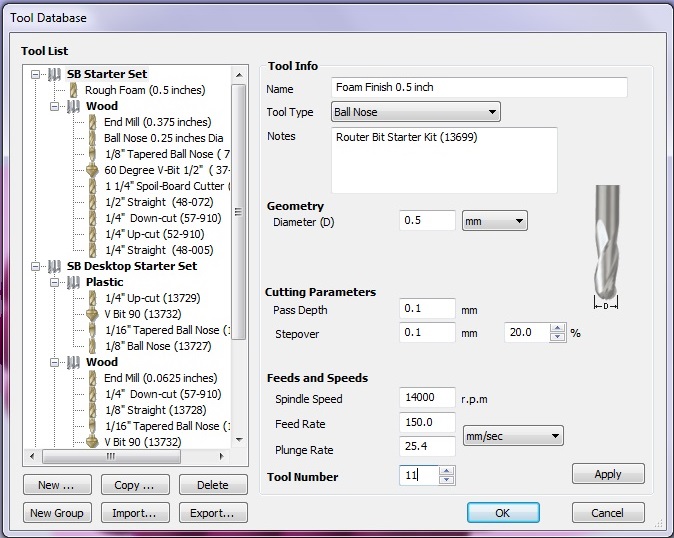

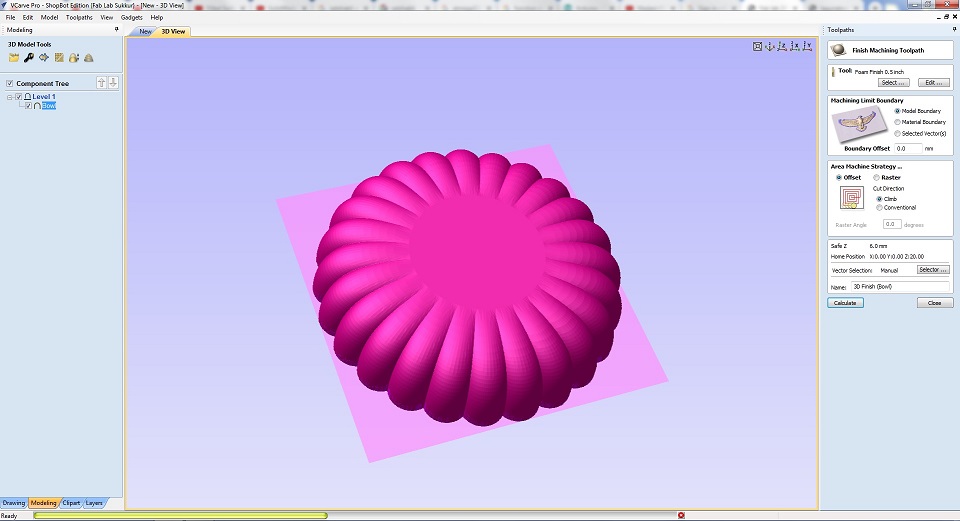

Finishing process is same the bit database is not present so we make with Ball Nose inch diameter other settings are shown in picture

Preciew of Finishing:

Then i went on to shaopbot to cut my job, but unfortunately electricity tripped-off during job with only 23% job being finished hence i had to cut the job again.

This time i made a small bowl with less curves and followed same steps as mentioned above.

Small bowl with less curves

After Milling

Fabric and Composites

I am using double layer of fabric in my assignment, it makes the surface more hard. The fabric are in arrangement that one layer is set to another with 45 degree of angle.

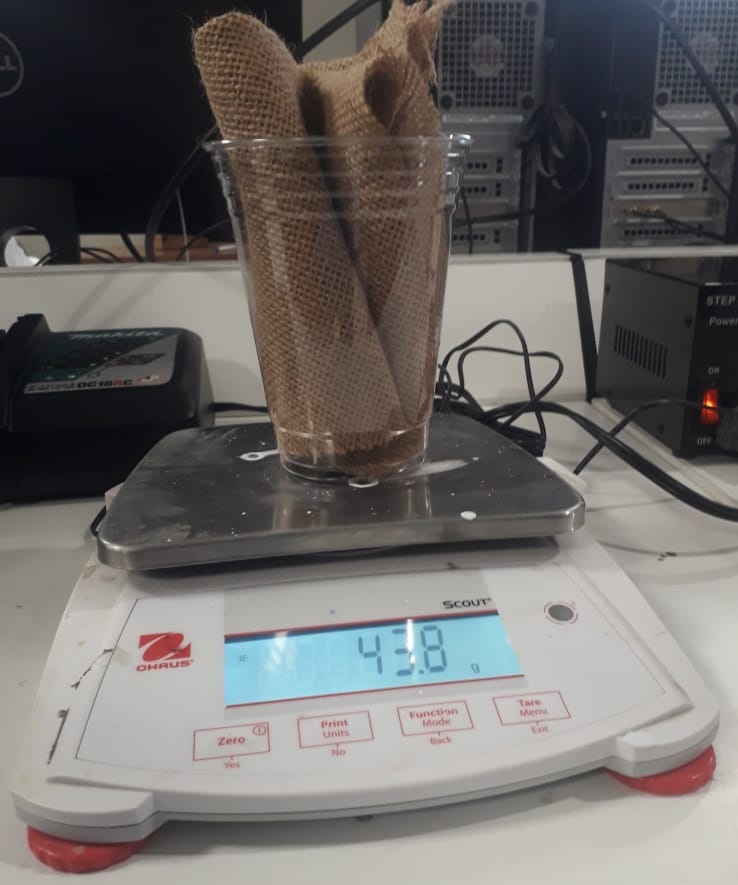

Cutting Fabric of mold size

A fabric weighted for finding the quantity of ratio of Resin and Hardner

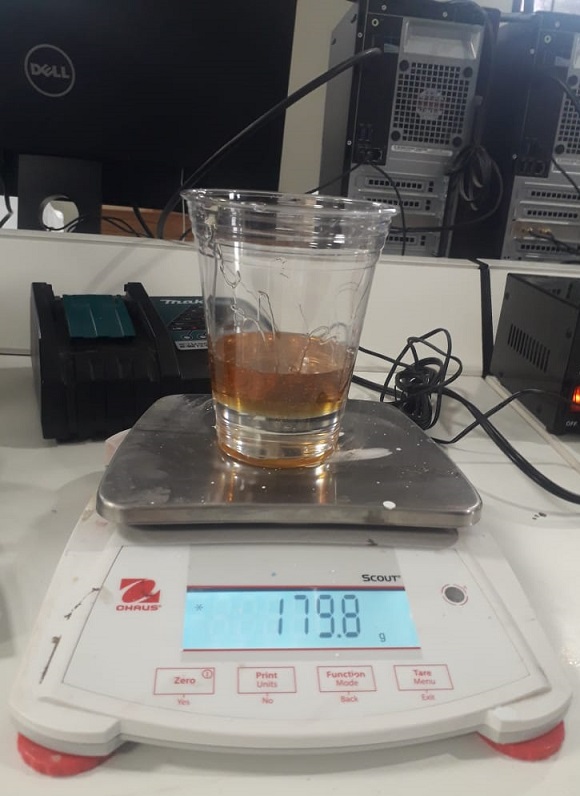

The ratio of Resin and Hardener is mixed in 5:4 and the total quantity is 3xweight of a material which is 180gm approximate.

After that mix the the mixer and dip fabric into it.

The plastic layer is covered on mold so it safe from Resin and can be use again

Paste the resin dipped fabric on Mold then again make a layer of plastic on it and squeeze it over surface so it can attain a shape

Place a breather and put the whole experiment into air bag which is used to suck the air and build pressure on composite to attain the shape.

Wait a day to dry the material and the result was hard like rock

"Click here"to download all files of this week

« Week16 Week18 »

Automatic Hot Water Dispenser by Tariq Ahmed Shaikh is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Based on a work at http://fabacademy.org/2019/labs/khairpur/students/tariq-ahmed/