4. Computer controlled cutting¶

Assignment : characterize your lasercutter, making lasercutter test part, making test part that vary cutting settings and dimensions(group project)

cut something on the vinylcutter

design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Vinyl cutter¶

A vinyl cutter is a type of computer-controlled machine. Small vinyl cutters look like computer printers. The computer controls the movement of a sharp blade like a knife. This blade is used to cut out shapes and letters from sheets of thin self-adhesive plastic (vinyl). A vinyl cutter can be used for cutting stickers,Creating mask for screen printing ,making flexible circuit etc.

buckle up¶

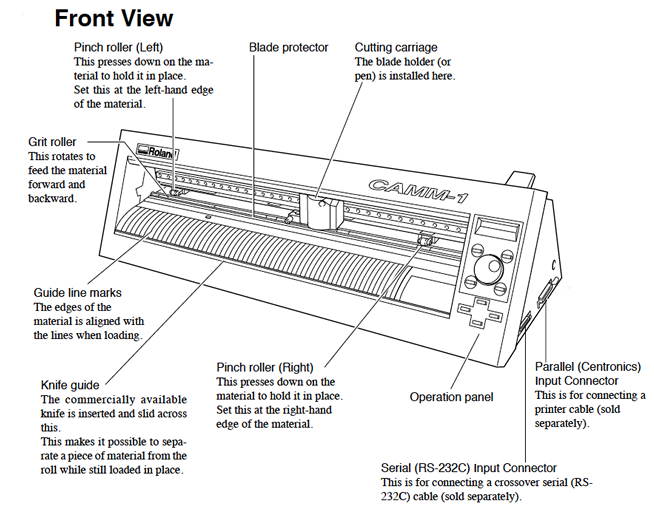

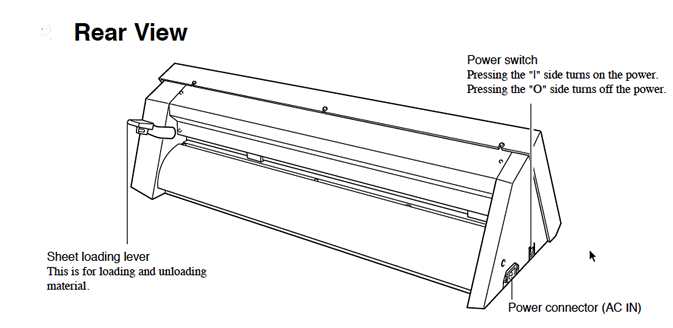

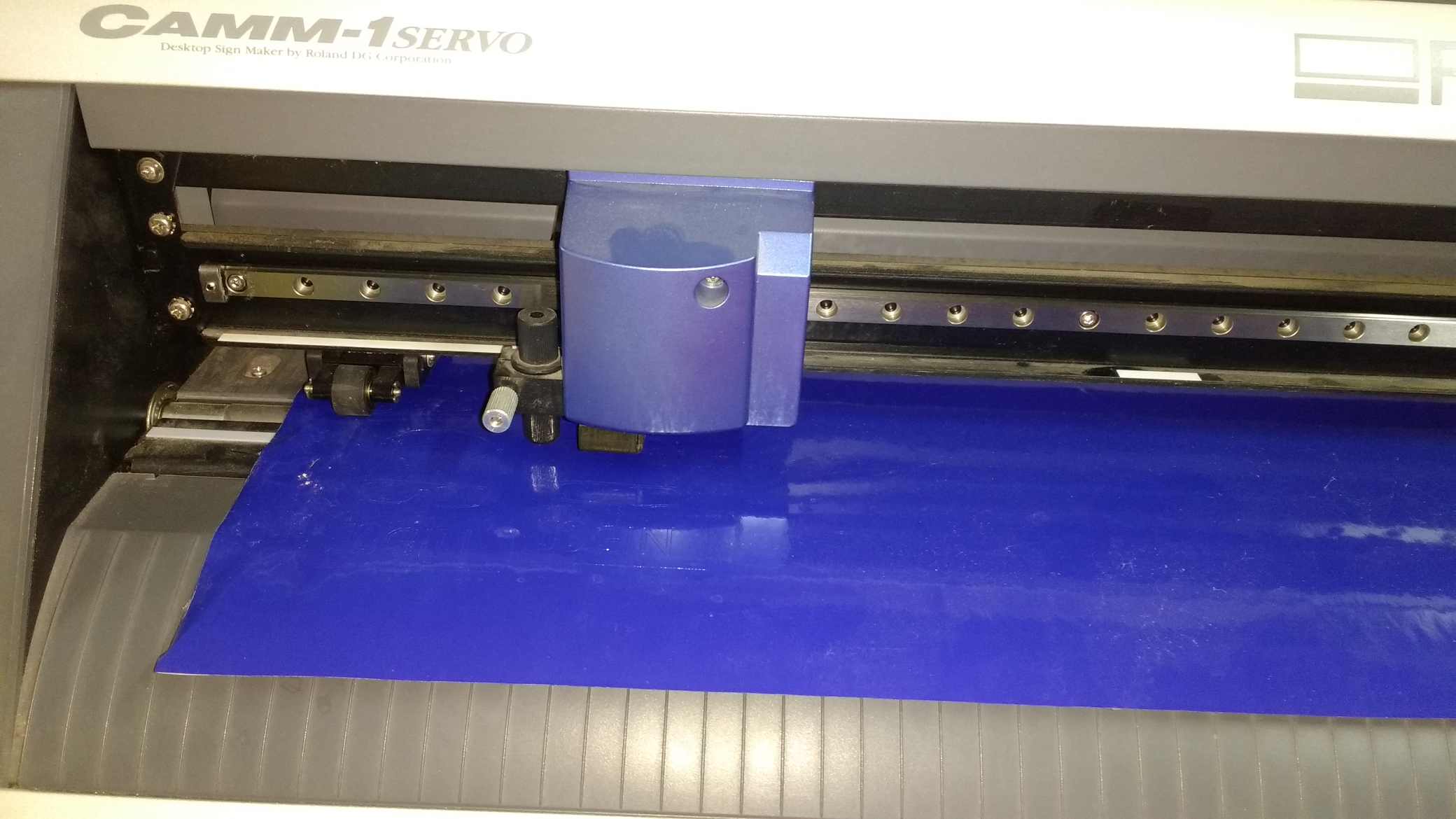

These are the functional parts of the roland vinyl cutting machine

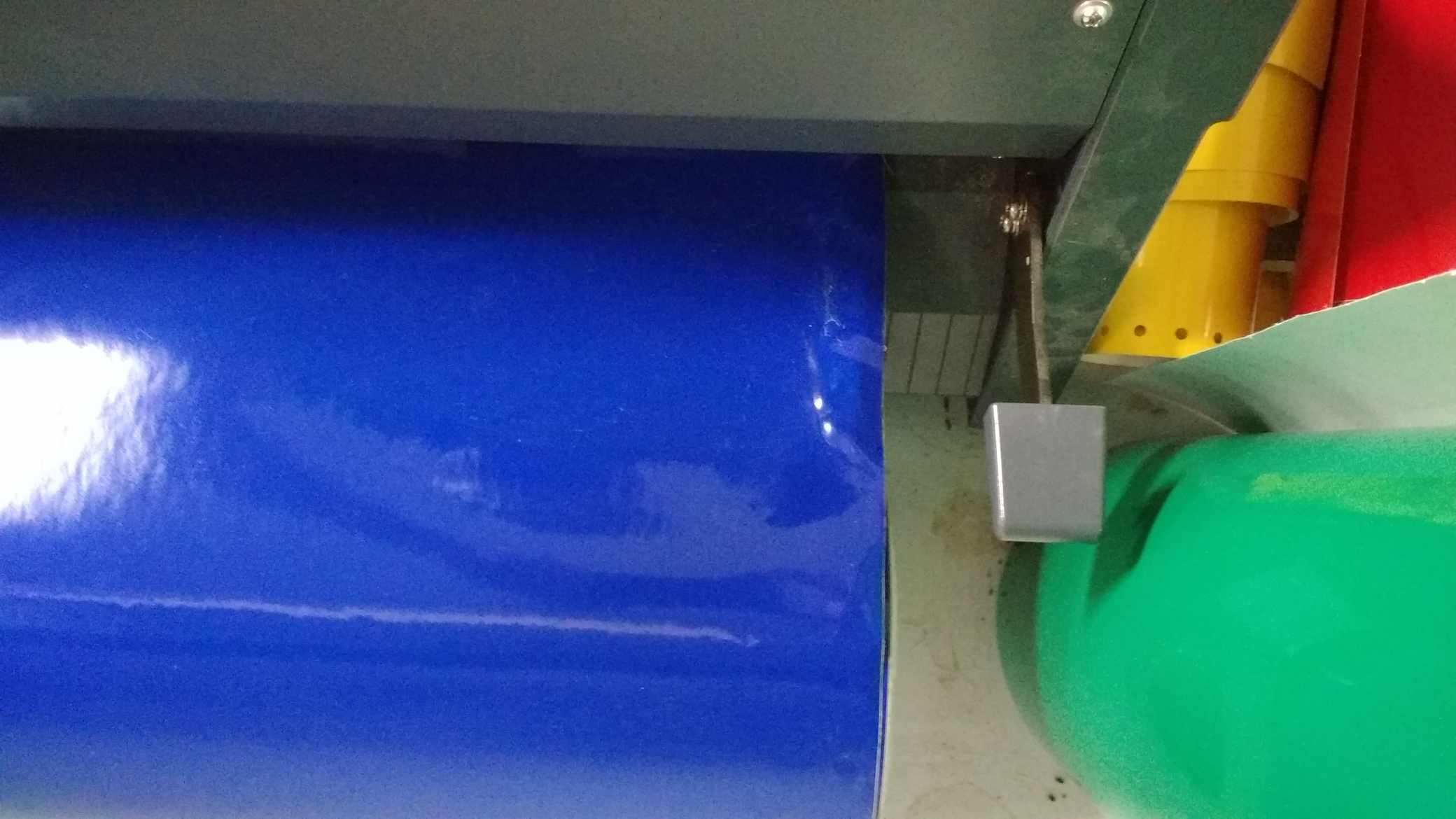

To place the vinyl sheet in the machine push down the sheet loading liver.

Place the sheet in between the rollers and pull up the loading liver.

Always make sure that the pinch rollers are placed under the white lines and it is placed over the sheets also.

Make a test cut to ensure that adjucent parts could be peeled without any interference . if it is not working proerly adjuest the force on the machine or adjuest the screw which control the blade height.

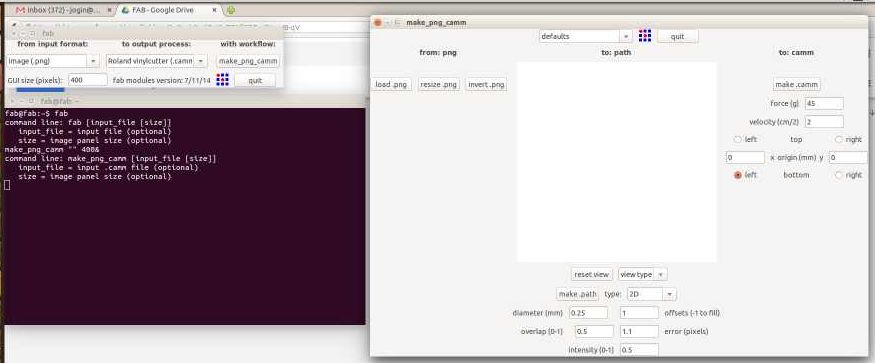

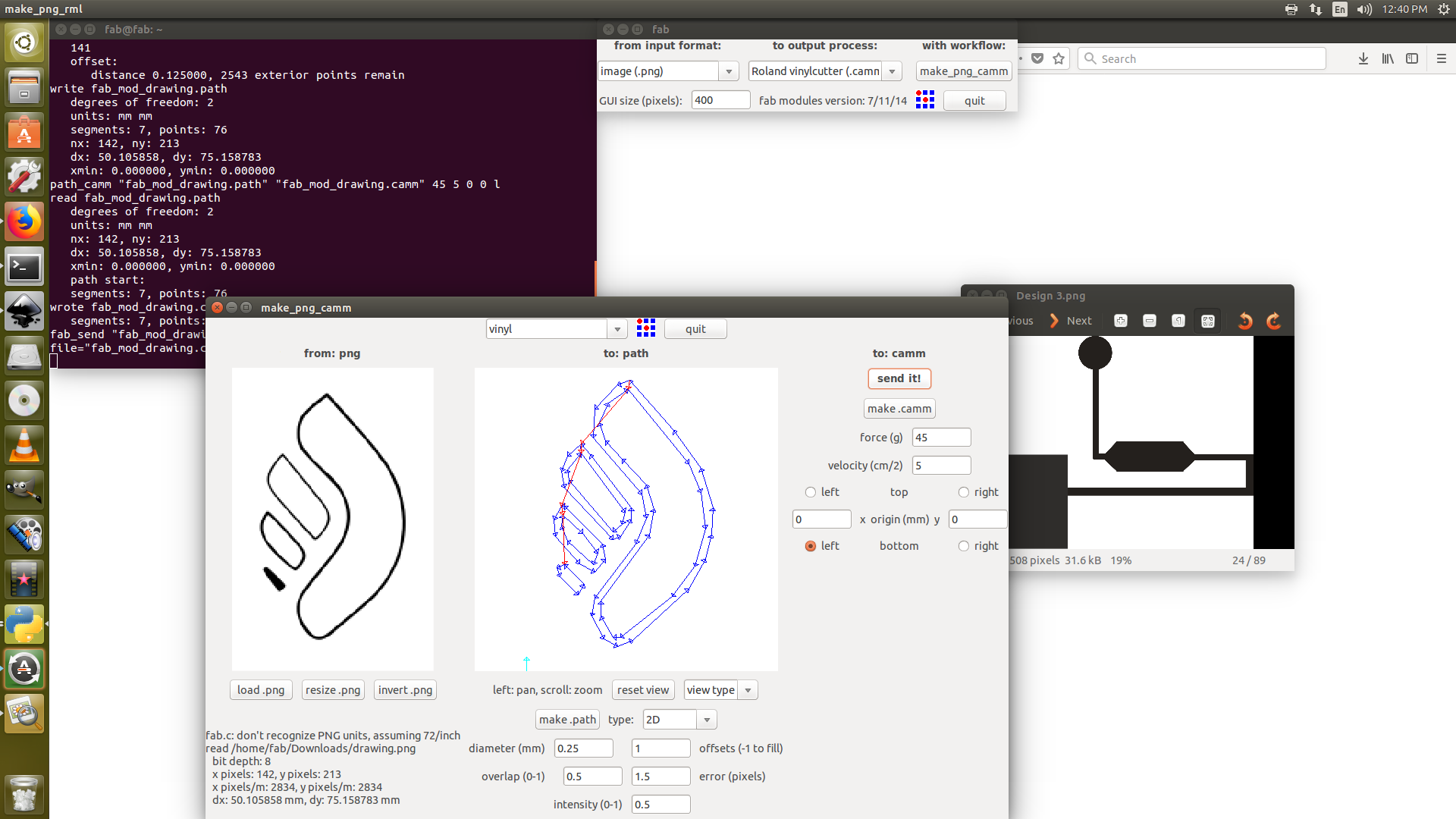

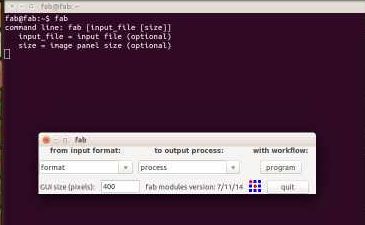

To start a cutting open a terminal and type “fab” .From the window opend select Image(.png) as format and Roland vinyl cutter as process.select “make_png_cam”

Select load png and open the required png file.

select the setted vinyl as tool and go for make path. verify the path and make sure everything is fine .

Set the force and velocity properly according to your test cuts . I have choosen force as 45 and velocity as 4 cm/second.there after move the head to the proper position to set origin double press on the origin button to set the position

.

Set the force and velocity properly according to your test cuts . I have choosen force as 45 and velocity as 4 cm/second.there after move the head to the proper position to set origin double press on the origin button to set the position

.

at last !!! :-)