Assignments

- Design a mold around the stock

- Mill it

- Cast parts

Subject¶

A long time ago I realized a wooden pendant called southern cross (traditional jewel of the sahara peoples). At the time I did it with the shapeoko 1 in walnut wood. I decided to resume this work as part of this week’s molding exercise.

Design¶

To create the mold, I used the SVG file I made from a photo of the pendant. I imported the SVG file into Fusion 360 to create an STL. I added some fillets and chamfers to the the model. I also generated a dxf file with the decorative traces (stars, dots…).

Process¶

Find in this video how i create the STL file of the pendant from an SVG file.

Milling the wax¶

Process¶

Find in this video the step by step method I used to mill the mold with Vcarve and the Shopbot PRSalpha 96-48.

Result¶

I used a ball nose end mill to make the finishing path. As you can see in the photo below, this kind of tool creates furrows in the material. If I had used a flat nose end mill with a small stepover I would have obtained a better result. But the work would have been much longer.

Molding and Casting¶

Products¶

- Wax

- Silicon Mold Star 16 from Smooth On

- Urethane Task 18 from Smooth On

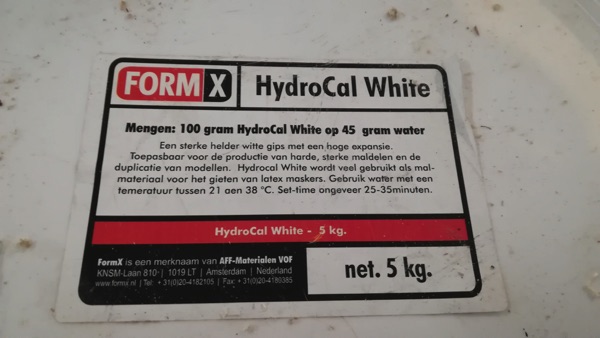

- Hydrocal white from Form X (i can’t find a link…)

Process¶

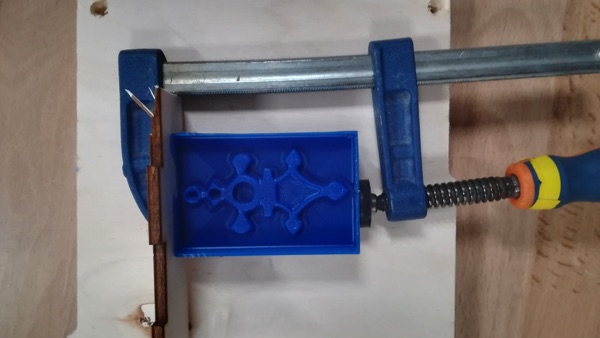

| Fixing the milled part |  |

| Work area |  |

| Silicon preparation |  |

| Molding |  |

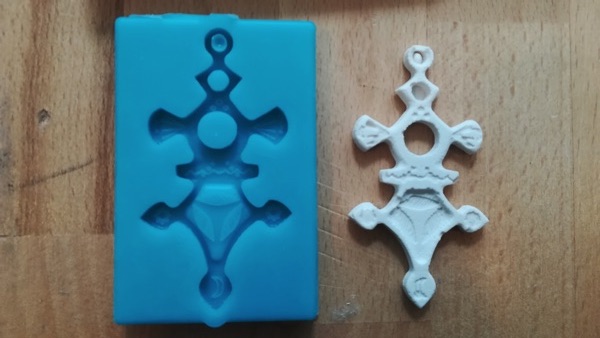

| The silicon mold |  |

| Casting with Hydrocall white |  |

| Hydrocall white part |  |

| Casting with TASK 18 FAIL |  |

Result¶

Molding with the Hydrocall white did not give a good result. Air bubbles were present and make small cavities on the surface of the part. I prepared the mixture with the recommended amounts (100g of Hydrocall white for 45g of water) but I did not mix slowly enough and air came in. It should also try by vibrating a little more the mold at the time of casting to raise the bubbles.