17. Machine design¶

This week we continued the machine building group work that started in the mechanical design week. Our target was to automate our machine.

Group work is described on the Group work page.

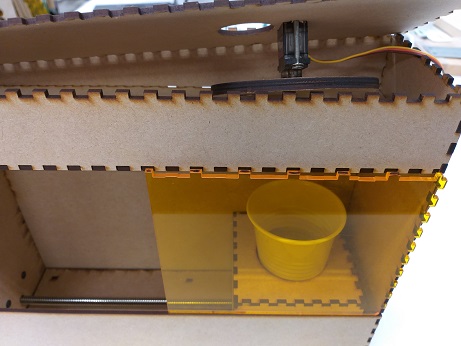

“VitaFab is an automated vitamin drink dispenser/maker. Every time you put a cup with water inside and press the button - it will make you a vitamin drink.”

Individual part of the group work¶

This week we did a lot together. The work had two major parts: attaching the motors and programming the control boards for the motors. For this week we needed following new parts:

Arduino UNO - heart and brain of our device Servo motor - in order to dispose tablet 4-phase stepper motor - cup moving mechanism Motor driver - as this part cannot be powered from Arduino board

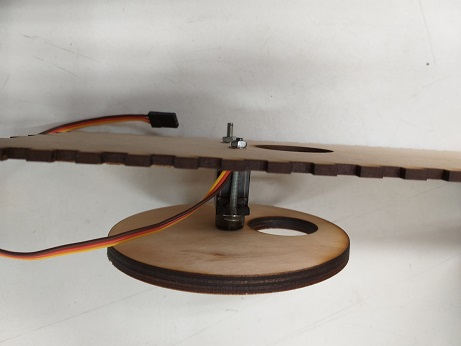

First we have the servo motor for the dispencer, that is located in the top part of the machine. Attaching the servo motor required some thinking and testing. We noticed that we had to do some modifications (attachment holes for screws) to the machine box parts.

I did the laser cutting of the new parts (files are in the end of this page).

Also we wanted to encrave a logo and name of the machine to the front panel. It was Gleb’s idea to name the machine as VitaFab (we are using multi-vitamin tables for the testing). In addition to that I drew a picture of a cup with tablets and I did the encraving.

Reflection¶

This was a fun week (actually two weeks). After having the idea of the machine it was pretty streight forward to start working. It required quite lot of planning and sketching, and re-planning and re-sketching to get everything working. Small details are also very important, e.g. how the motors are attached and where to drill screw holes. Several parts were also re-cut after some design modifications. But finally the machine was working and Perttu edited a very nice video!

Files¶

Box top

Arduino mounting holes

Box back

Wire holes

Logo file