Assignment

This week assignment is to design a 3D mould around a stock and tooling that will be used milling it.

I had a logo of a friends company that I built a mould around it.

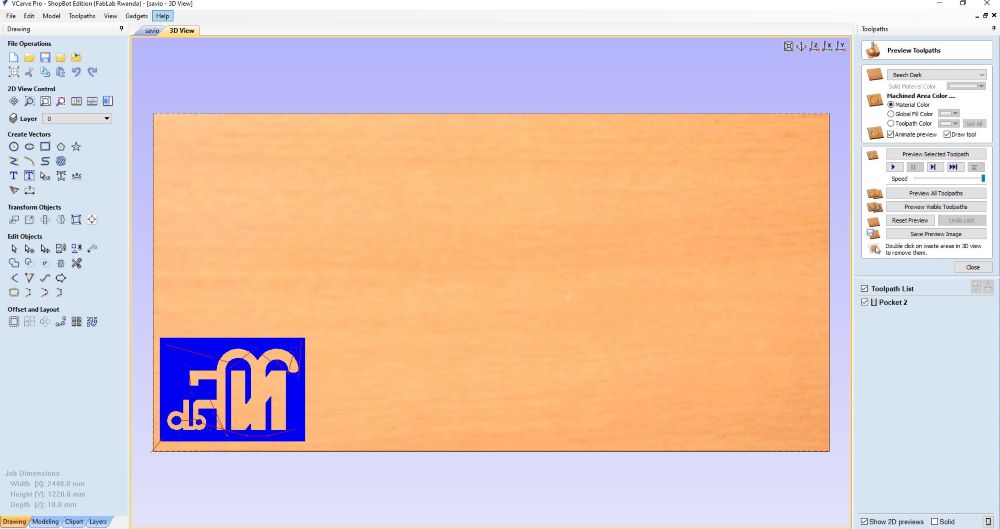

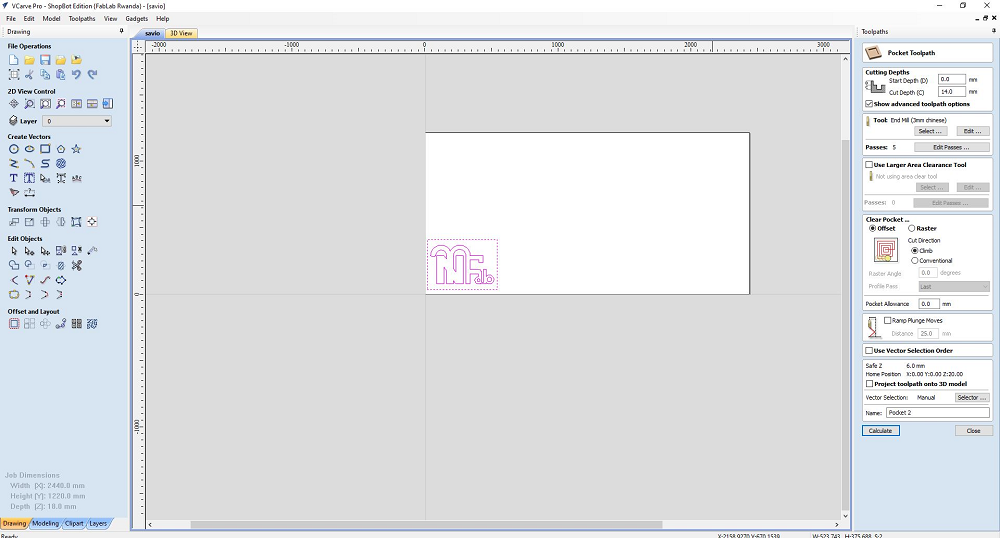

First I imported it in Vcarve software since I will be using the big CNC to mill the mould.

I generated toolpath for the milling this part of the mould.

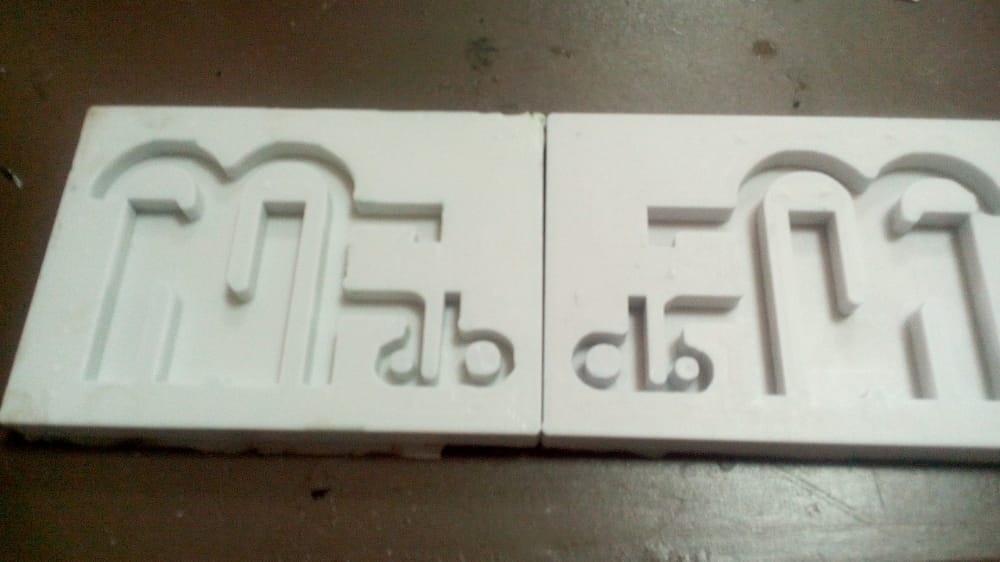

Here I made milled the material I was working with, and below is how the results looks like.

The milling time for making that part was around 2 hours.

I assembled all the material I used in creating the moulding.

These material were bought in Japan and there instruction we used we found them on the sticker attached on it, but they were also in Japanese to understand them we used Google translate.

These are the first I used to create the negative of the mould.

The mix ratio for this was 100:1 in weight.

I used digital scale to get the right weight for my mould.

After preparing the solution I poured it in the mould stock.

I filled it fully and made the second one.

Here is the two when are done.

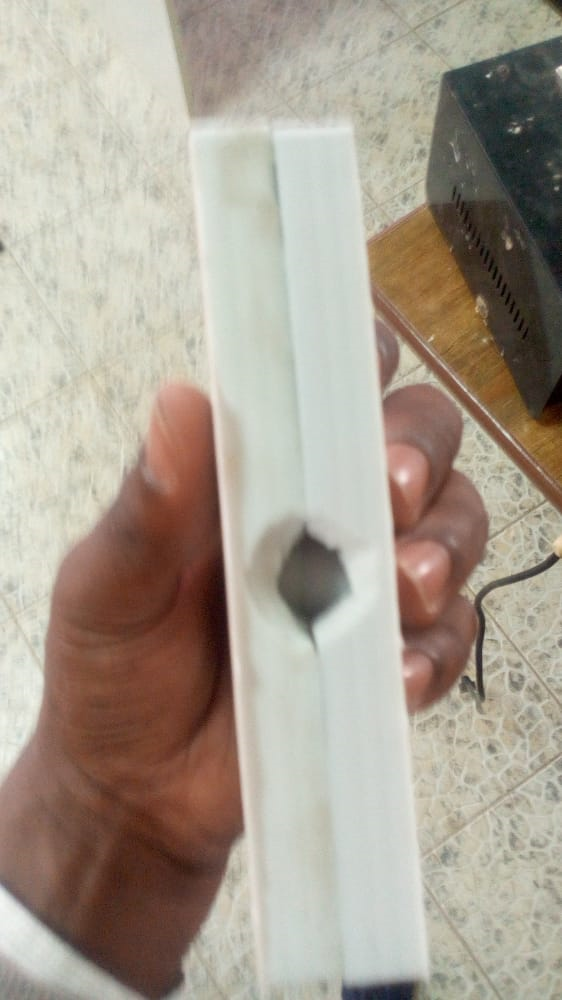

I made a hole on both to leave a space where I will use to pour the other solution.

I mixed the two solution with a 1:1 ratio.

I poured the mixed solution in here.

I left it to dry for hours after I came back to this final part.

Conclusion

Making this assignment I faced many challenge, moulding solution I had to use were in language I don't understand and my final product was broken into pieces when I was removing it in but this was due to not apply any oil before in the mould, if I had done it, it would haven't happened.