13. Applications and implications¶

Applications and implications is a week to define in more depth the final project. I had to answer the following questions :

What does it do? Who’s done what beforehand? What did you design? What materials and components were used? Where did they come from? How much did they cost? What parts and systems were made? What processes were used? What questions were answered? How was it evaluated? What are the implications?

The project should incorporate 2D and 3D design, additive and subtractive fabrication processes, electronics design and production, microcontroller interfacing and programming, system integration and packaging.

I’ve already answers a series of those questions but not all, so I will merged the answers here.

What does it do?¶

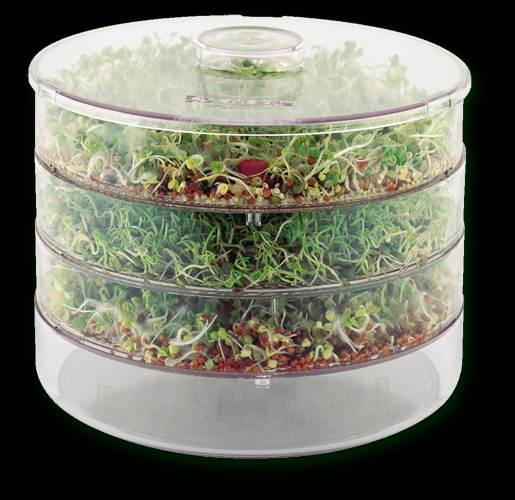

It is an automatic sprouter. Seed sprouted have many qualities for nutrition, a lot of vitamins and some seed like the Alflafla are nutritious. The seed sprouting is an ancestral food in many culture.

Who’s done what beforehand?¶

Basically, you just need water and sun. And you want to avoid moisture.

With the manual sprouter, you pour water twice a day and flip the seed. The enclosure let the water flow to avoid stagnant water. Some systems have several level to have differents sort of seeds or seeds at different growing stades (2 days old).

An automatic sprouter¶

Automatic sprouter exists, I’ve found 2 family of them.

One run water with a pump in a close circuit (the same water is used and reused). It’s problematic because the quality of the water geets poorer each time.

One use some kind of fogger system. It cost about 250$ . It’s a big device that has 5 trays. The 5 trays are in the same enclosure. So you have to control many things if you want to grow differents sort of seeds.

My system¶

I’d like to build a compact system for one person. I’ll integrate a luminosity sensor. After the FabAcademy, I’d like to integrate a more powerfull microcontroller (like an esp32) have a way to select the kind of seed and that it’ll select the specific program for that seed family, a humidity and temperature sensor could optimise the process.

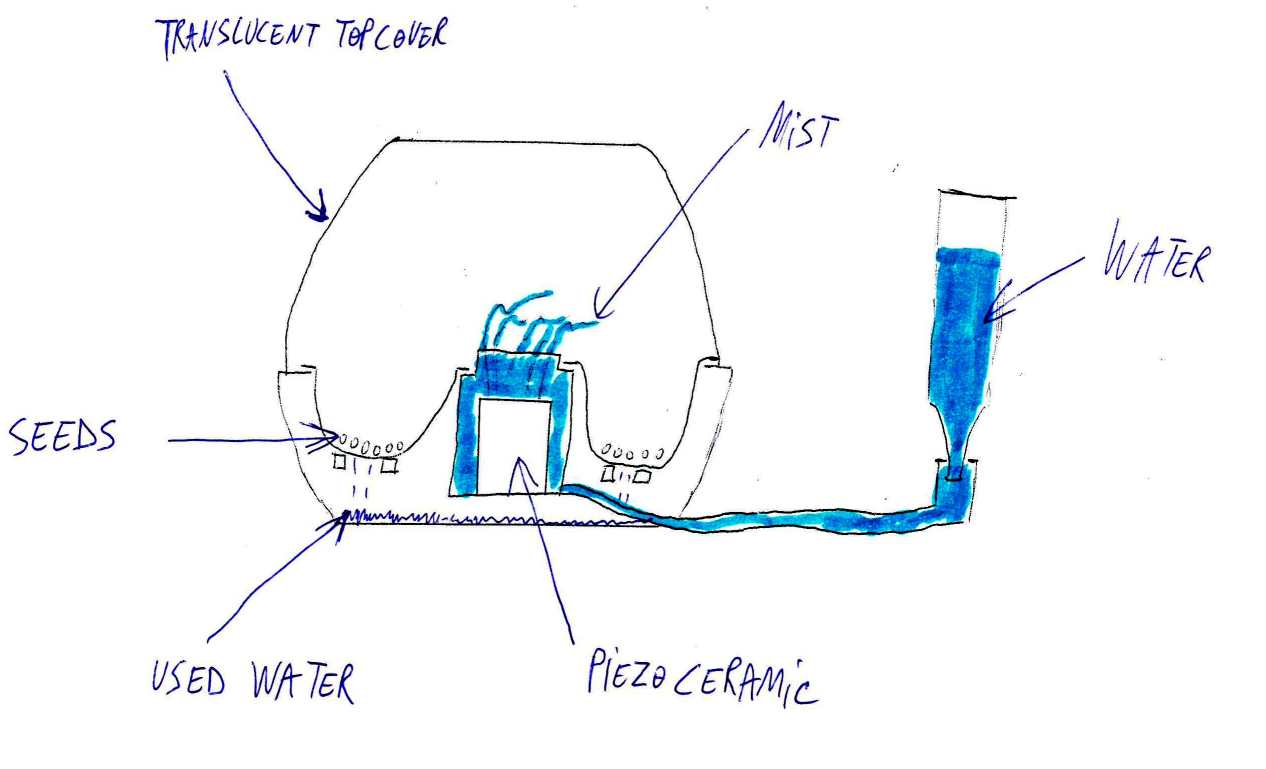

I’ve found small and compact system that make a small amount of mist. They are based on a piezzo electric element exited by electricity at 1.7MHz.

They are cheap, mostly sold for decoration for fountain or for effects during halloween.

Advantages¶

It’s automated and can work several days without oversight, it produce small quantities, it will not reused poor quality water and could be made cheaper.

What did you design?¶

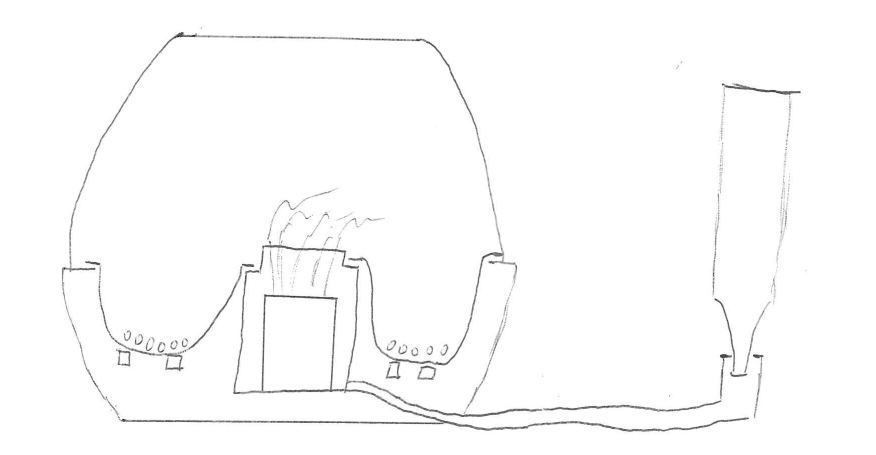

I design a skecth on week 1 , to determine the differents parts and functions.

I’ll build an enclosure to keep the mist and the warm generated by the seed. It has to be translucent, the seed needs a small amount of light. I’ll have a system to add the water for at least 3 days and a way to get the water back.

The sketch with the path of water.

Electronics design and production, microcontroller interfacing and programming, system integration¶

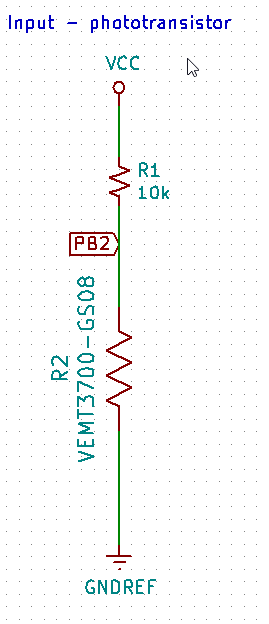

The light sensor will monitor the ambiant light, normally daylight, it’s one of the few clock in nature. I’m also curious about the influence of artificial indoor light. The seeds normally does not have the same activity under nigtlight/daylight and will not consume the same amount of water.

If combine properly those input and output can be optimise to make the seeds grow faster or to make them more vigourous.

2D and 3D design, additive and subtractive fabrication processes¶

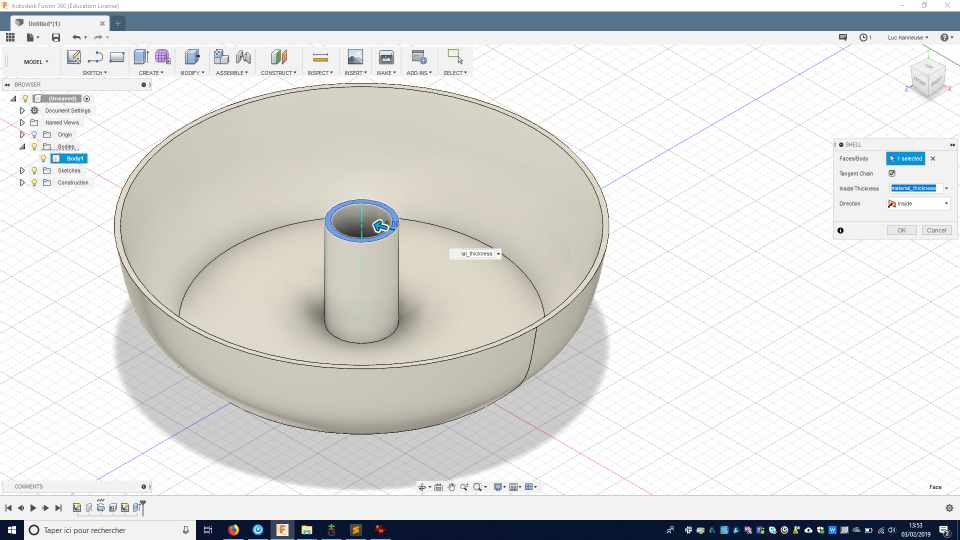

On Week 03, I design a first version with CAD tools.

I will certainly build a mold then vacuum formed with alimentary plastics.

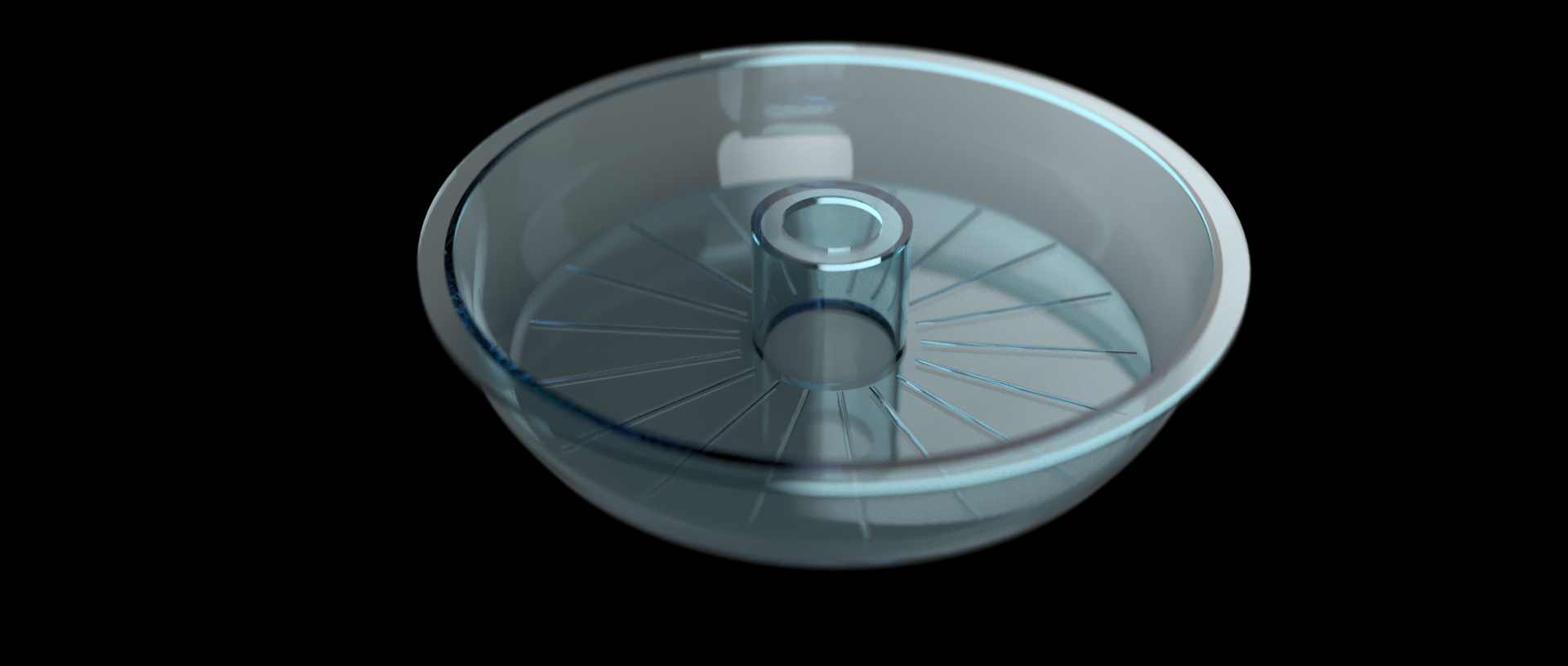

The render version :

The bottompart :

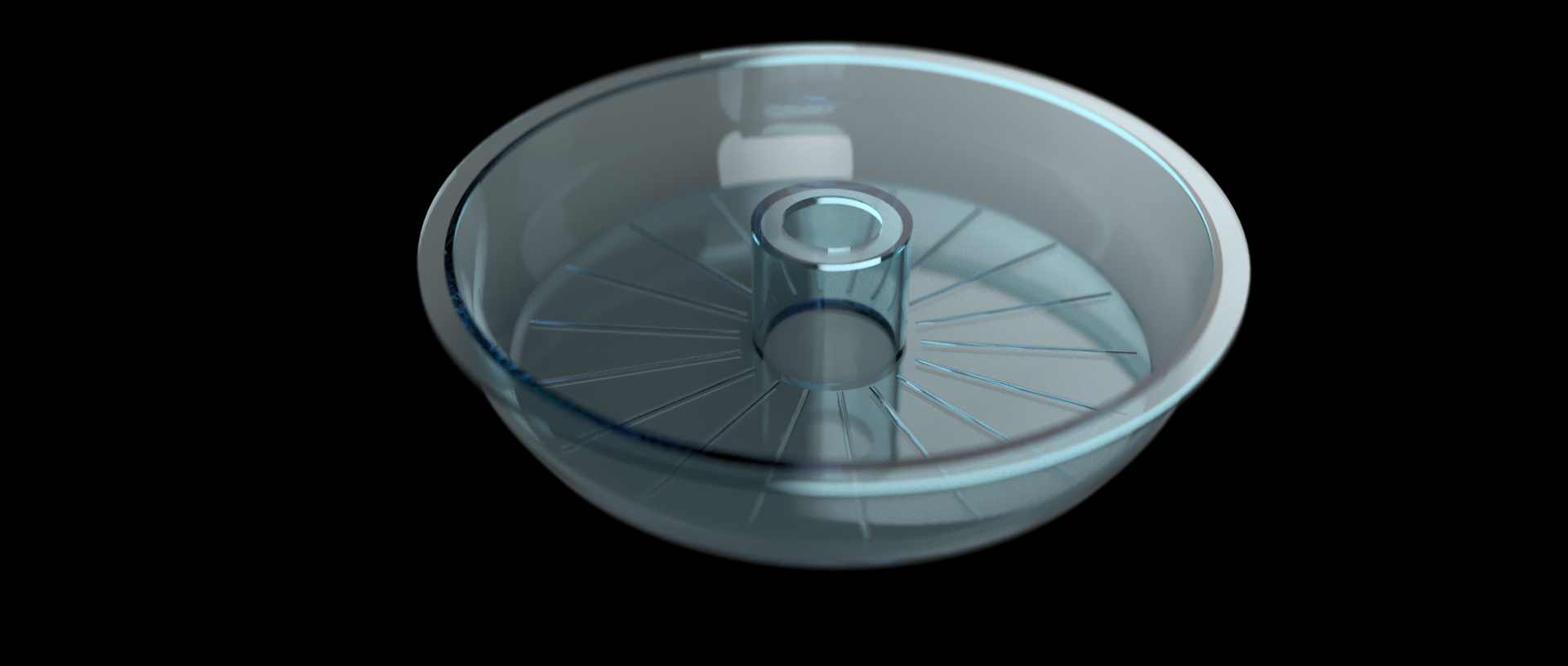

The tray

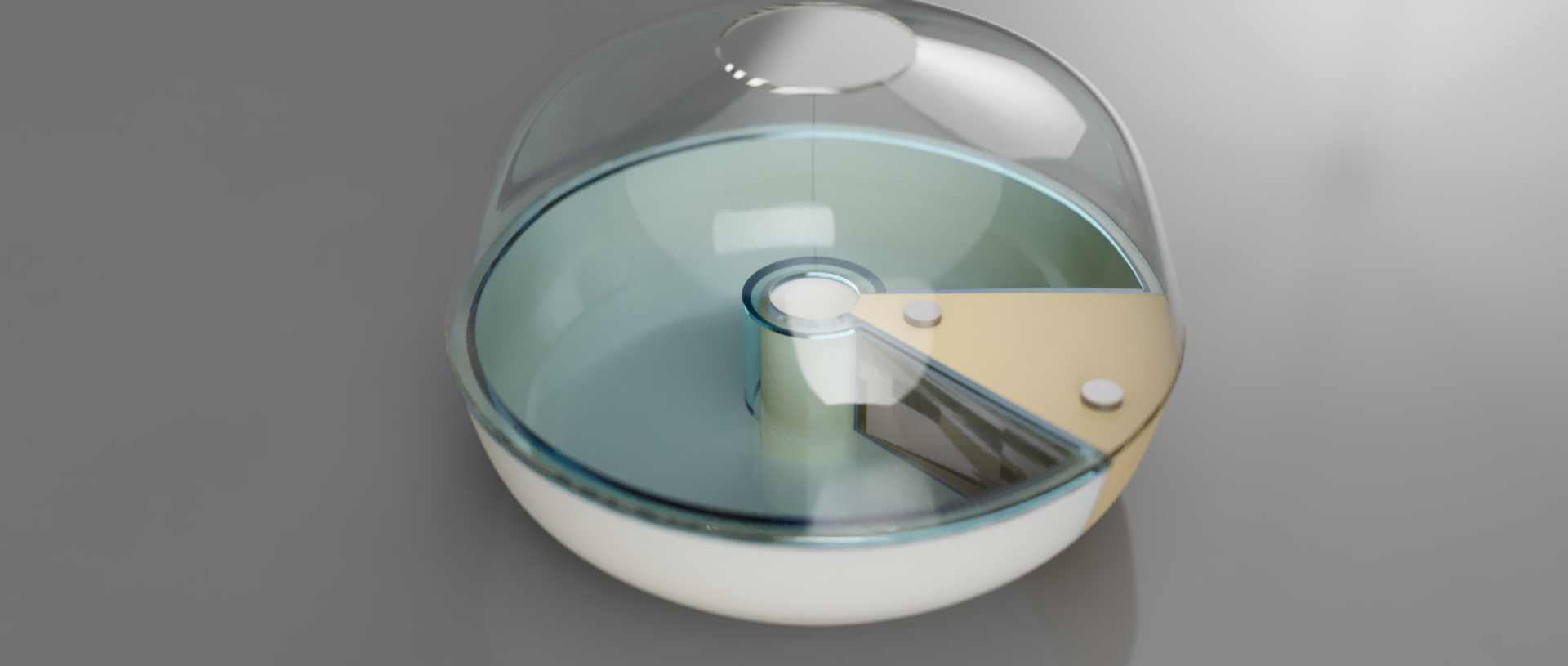

The top cover :

A render of the evolved version :

An inside part will contain the electronics. It will be 3D printed, the shape would be too complex for vacuum forming.

What materials and components were used? Where did they come from? How much did they cost?¶

For the differents plastic parts, I think PET could be a good material, it’s food safe. Some others part will be directly 3d printed.

| Object | Material | Process | Price | Visual | link |

|---|---|---|---|---|---|

| top cover | PET material | ? 4€ |  |

custom CAD files | |

| bottompart | PET material | ? 4€ |  |

custom CAD files | |

| tray | PET material | ? 4€ |  |

custom CAD files | |

| Mist Foger (piezzo electric element and 24V DC) | bought from China | 10€ |  |

https://www.aliexpress.com/item/2Pcs-With-Plug-Or-No-Plup-Industrial-Incubator-humidifier-Ultrasonic-Mist-Maker-24V-Nebulizer-Atomizer-Head/32821355140.html?spm=a2g0s.9042311.0.0.7ac54c4d1Jyhep | |

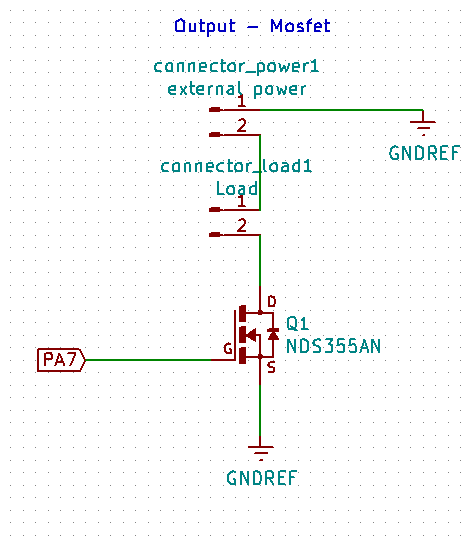

| NDS355AN | n-Mosfet SMD | 0.60€ |  |

https://www.digikey.com/product-detail/en/on-semiconductor/NDS355AN/NDS355ANCT-ND/459000 | |

| VEMT3700 | PhotoTransistor | 1€ |  |

https://www.digikey.com/product-detail/en/vishay-semiconductor-opto-division/VEMT3700-GS08/VEMT3700-GS08CT-ND/1681484 | |

| Attiny84 | microcontroler | <5€ | |||

| Resistor | SMD component | 1€ |

What processes were used?¶

3D printing, CNC 3D milling, vacuum forming, 2D PCB milling, electronic design, electronic production, input/output, automation.

How was it evaluated?¶

It produce sprouted seeds. It should be more easy and more quick than the traditional manual way of sprouting.

What are the implications?¶

A cheap way to grow vegetables with high values in vitamins.

Later Optimisation¶

My Optimistic option is to use an ESP32. And to build a small web interface to enter parameters like the kind of Seed , the amount of water and water cycles, the expected duration of sprounting.

But the ESP32 could be really complex.

My project is to make a sprouter : the different pieces and an electronic system that launch the misting.

The use of an humidity/temperature sensor :

The humidity sensor will confirm that their is mist when the fogger is in action (in case the system run out of water). Then monitor the decrease of humidity to feed back more fog following the growing cylce of the seeds. Temperature is one of the parameter. Some seeds need a certain temperature, if it’s hotter, the growing time is faster. If it’s too hot the seed will die. If it’s too cold the seed is in dormancy. The seeds release a small amount of temperature during certain phases of the growing.