6. 3D Scanning and printing¶

Collected 3D data is useful for a wide variety of applications. These devices are used extensively by the entertainment industry in the production of movies and video games, including virtual reality. Other common applications of this technology include industrial design, orthotics and prosthetics, reverse engineering and prototyping, quality control/inspection and the digitization of cultural artifacts.

I still remember the test made last year with DAVID 3D scanner nowadays from HP. Its resolution look very professional.

Group assignment¶

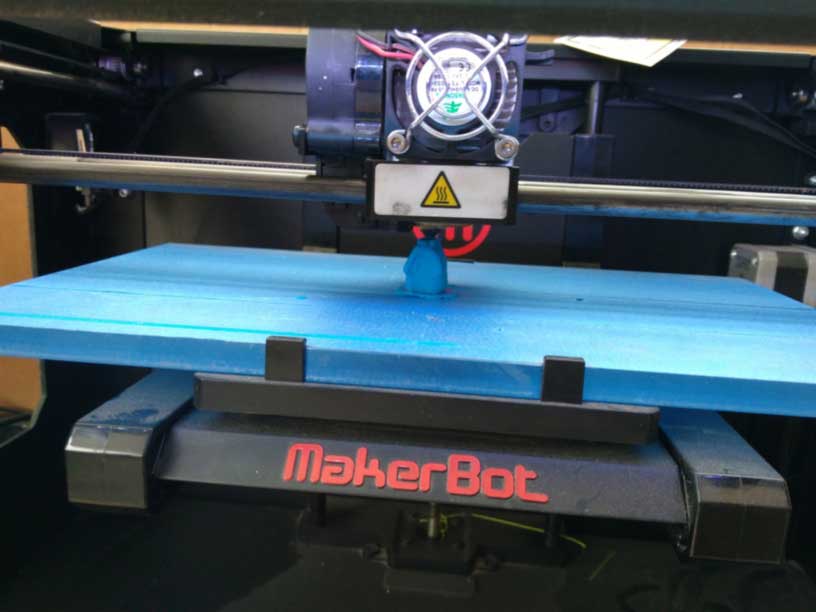

For some of us it was the first time we print an object on a 3D printer. Our lab has these filaments such as: PLA and ABS. For these time we only use PLA.

Assignment:¶

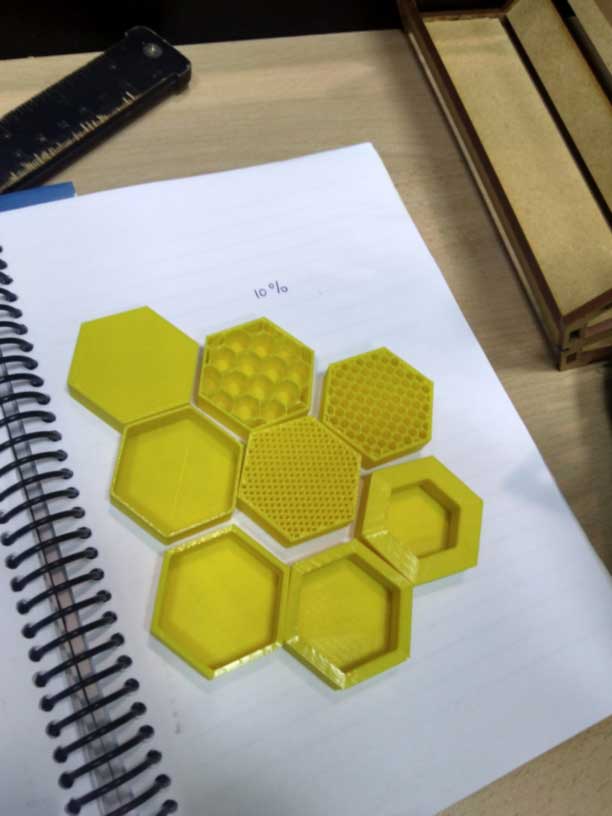

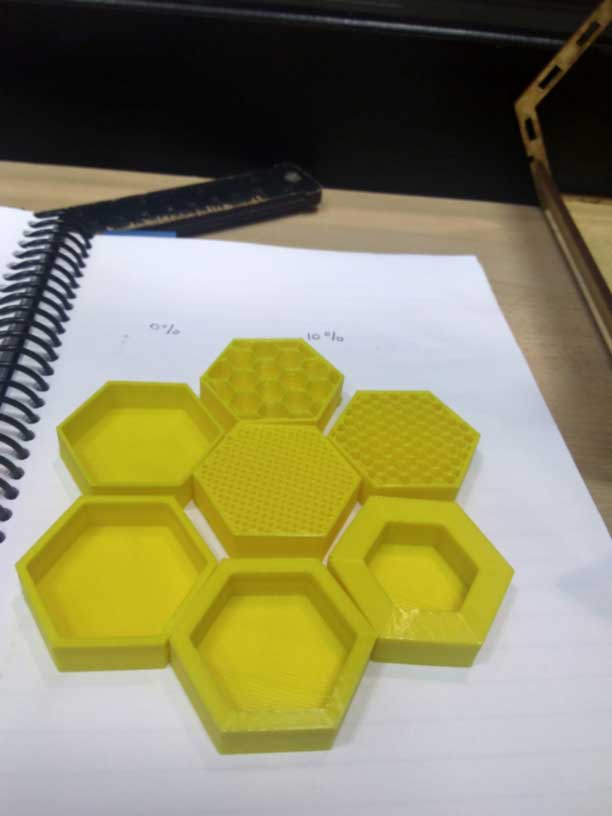

The assignment consist of: * Test the design rules for your 3D printer

Test the design rules for your 3D printer¶

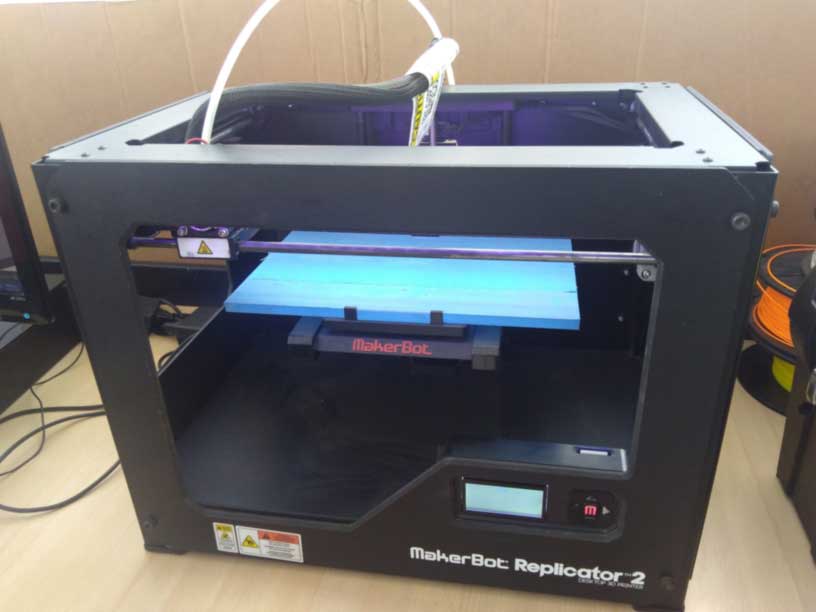

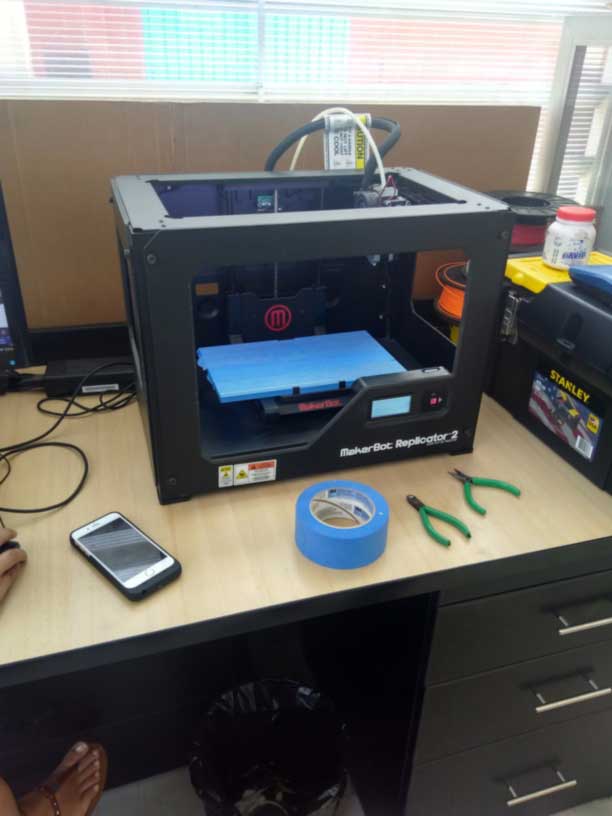

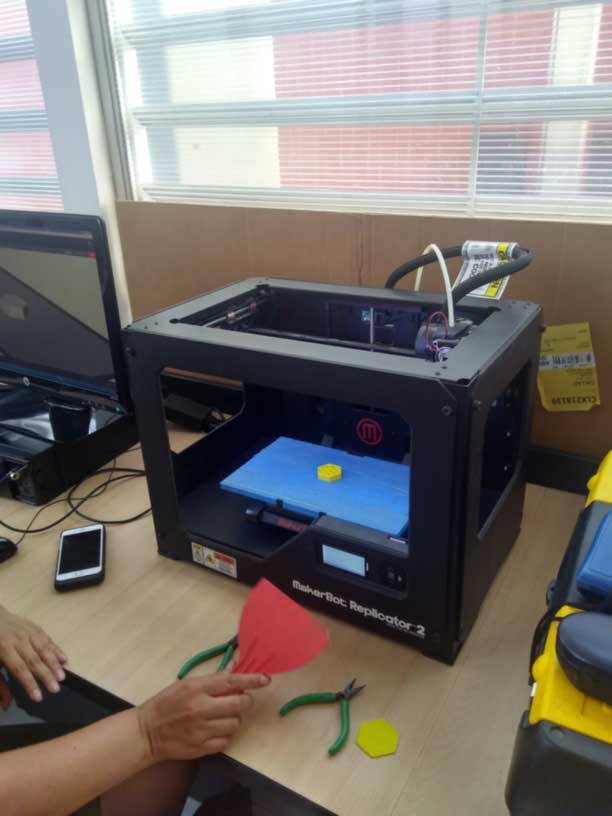

TECSUP Lab has these 3D printer machine: * Makerbot. * Sindoh

Some important things to consider prior the put it on operation.

Please see the following link for learning purposes.

Infill is the support structure inside your object. Changing Infill affects your print’s density. A higher percentage will result in a more solid object, while 0% infill will make your object hollow. Shells are the outer layers that make up the surface of your prints. Adding more shells does not affect its external dimensions, but can make your object stronger.

You may see some printing examples made by us.

3D scan an object and print it¶

Our Lab is implemented with a Kinect and 3D Sense scanner, for these activity we used the Kinect Scanner, since last year I used the Kinect.

In order to scan the object the support of three persons is required. (holding the table, the computer and moving the arm with the scanner.

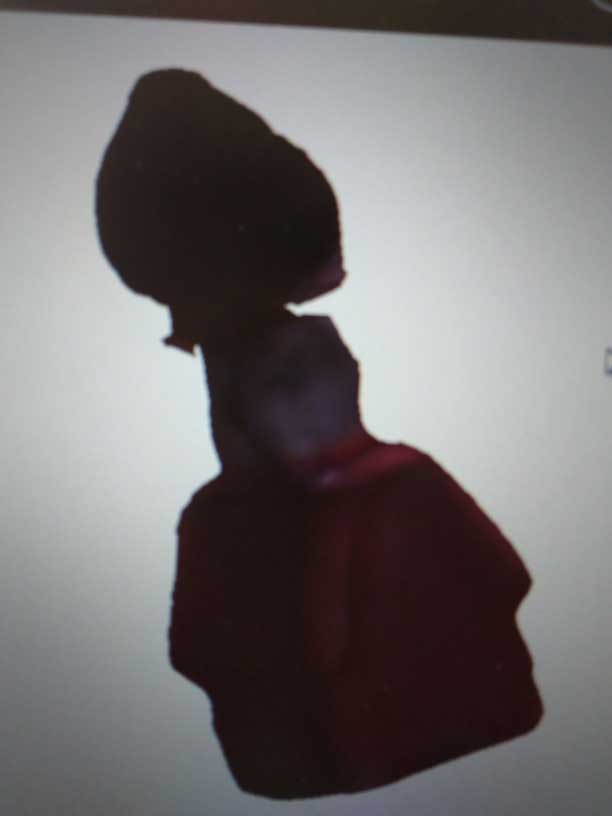

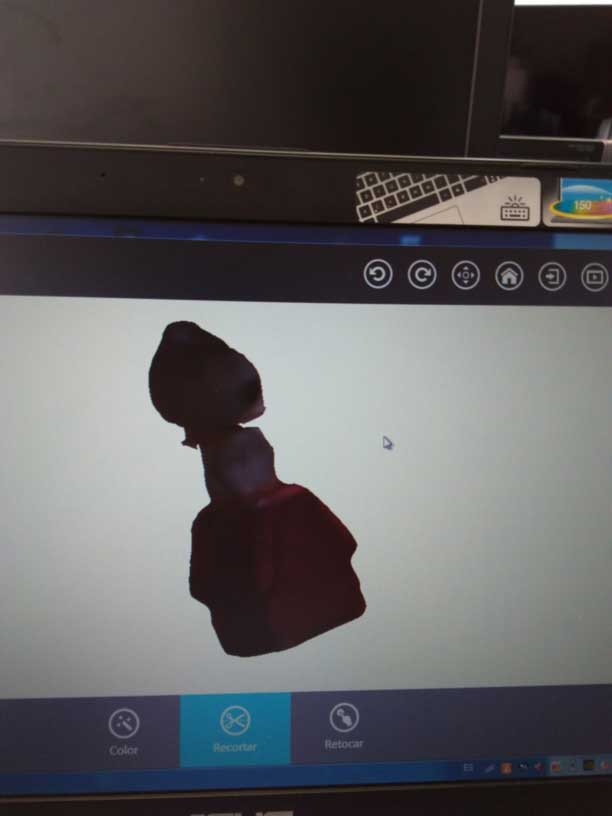

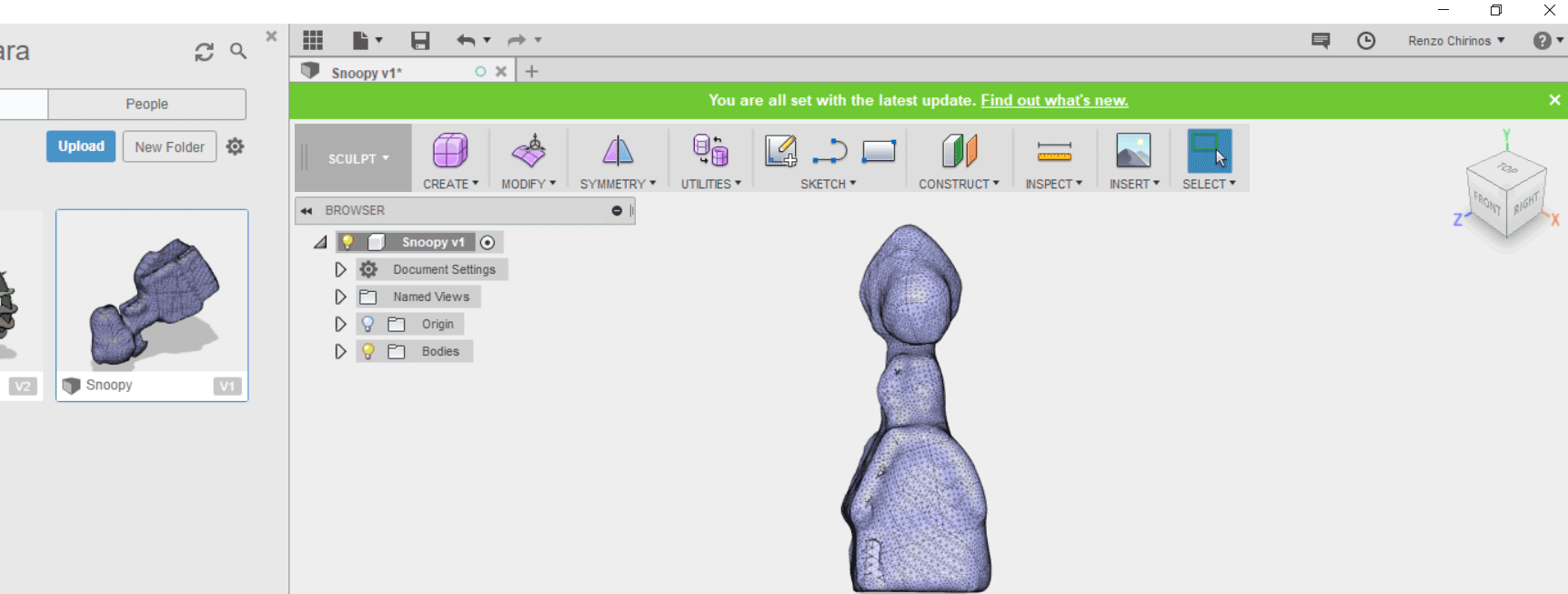

Once the scanning is done, some parts of the scanning should be delete, because they are not part of the object. The object should be close, and later on the STL file should be edited at Fusion

Here you may see the pictures of the process:

Object printing¶

Please see the pictures of the edition of the STL object and printing.

Additonal information¶

Please take a look at the Group assignment of Silvia Lugo web page.

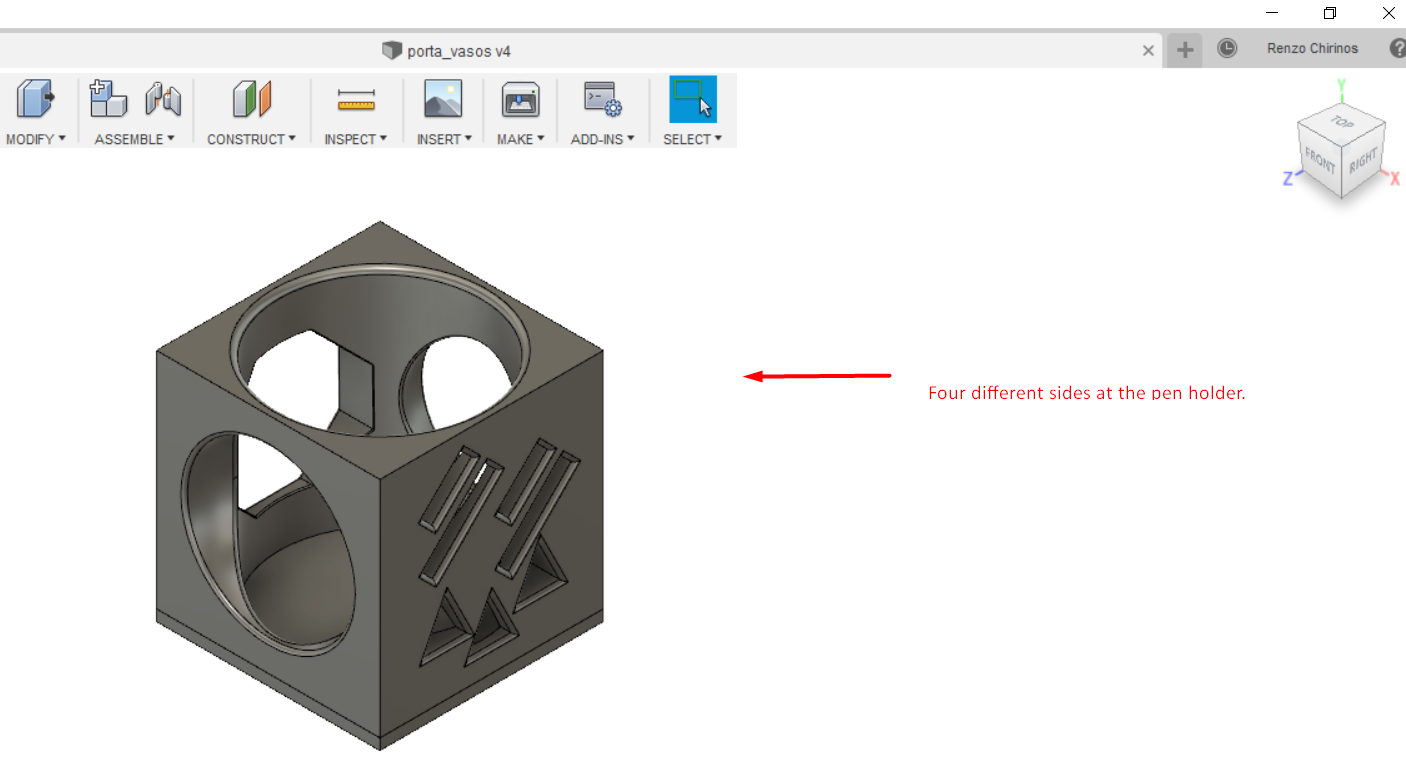

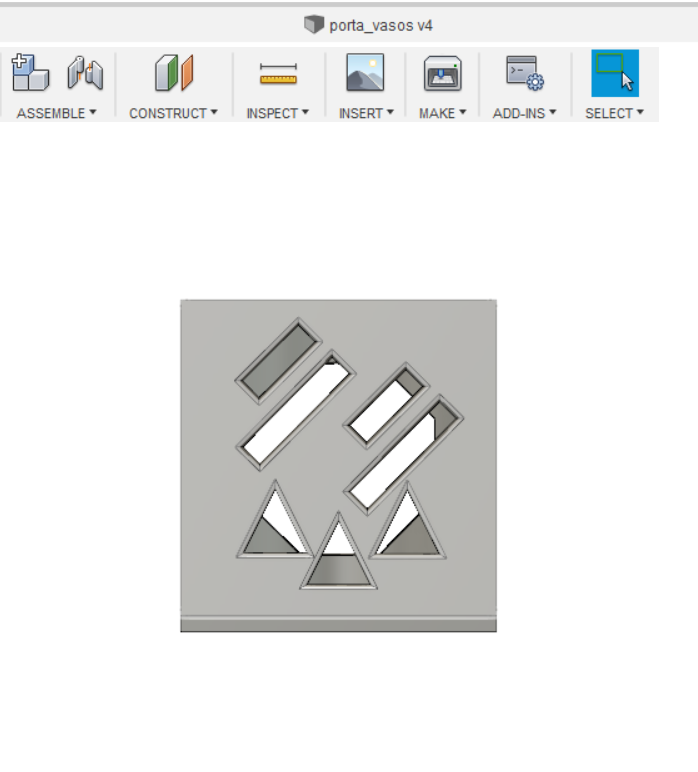

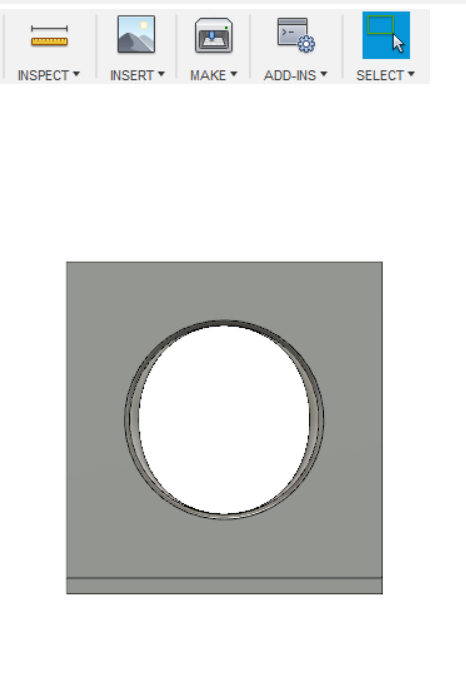

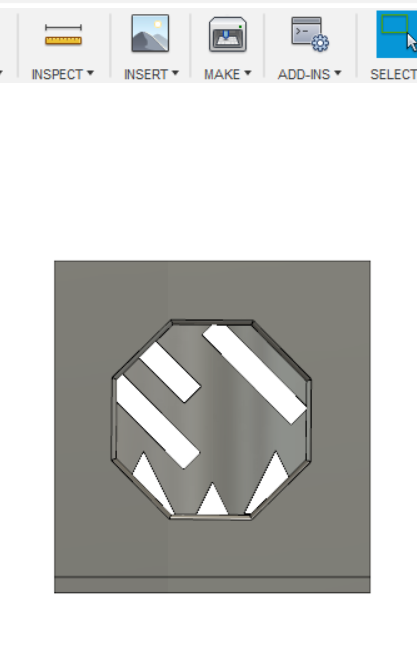

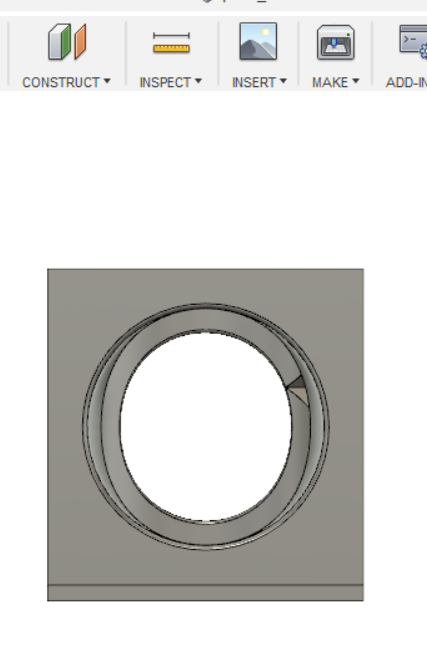

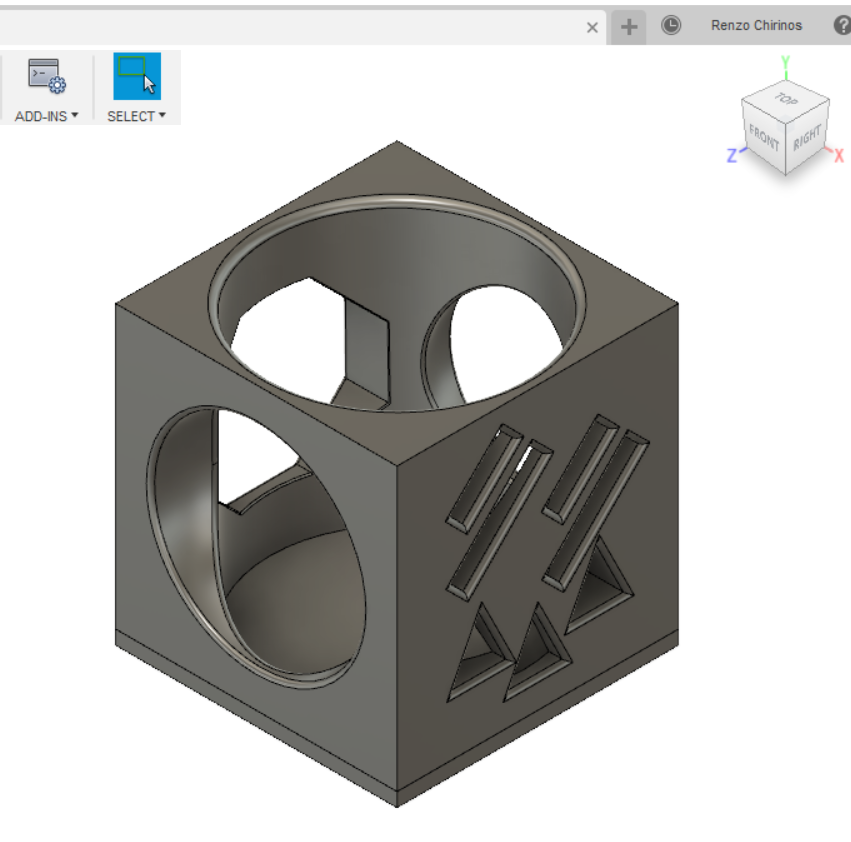

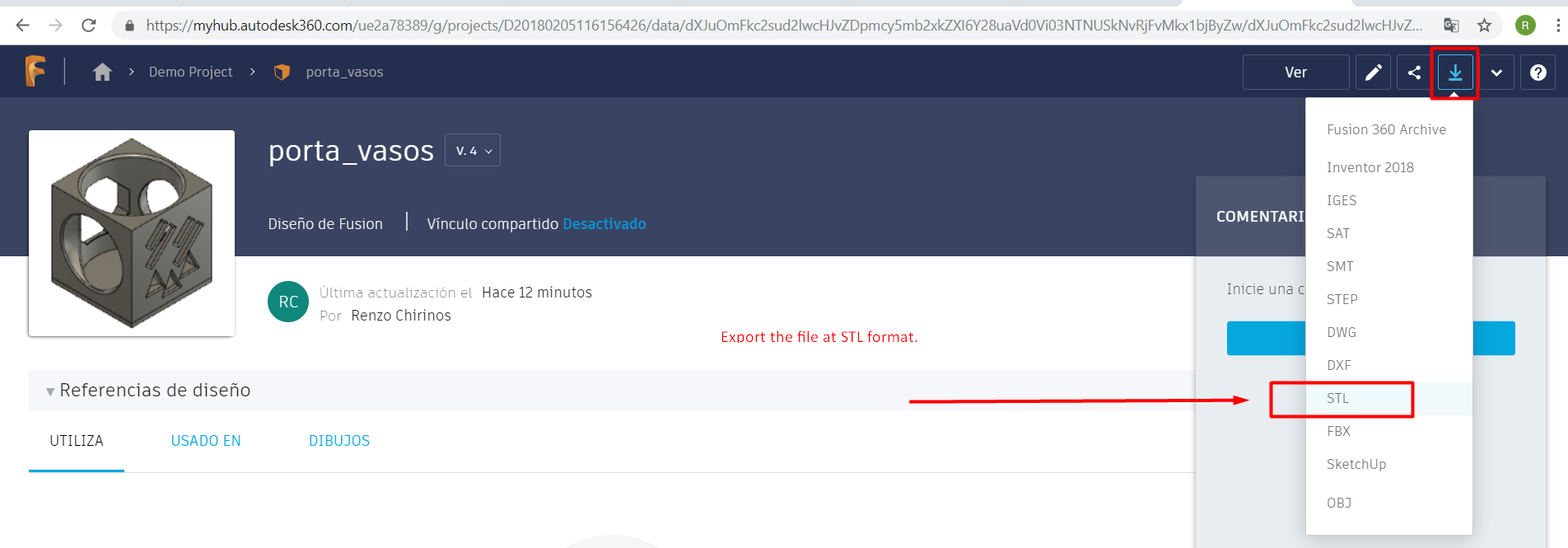

Individual assignment¶

I had made a portable glass for pen, pencil and colors, this design should be able to make only at the 3D printer. It cannot be do it by a CNC tool, using extractive tools. This penholder has four different sides with an internal cylindrical hole. The intersections can not be done by a extracting tool.

You may get the files here. I did a scaling of it at 50% also.