Computer-Controlled Cutting

- Salem AlMarri

- Super FabLab UAE

- Last Reviewed on 10/2/2019

- Last Modified by Salem AlMarri

Group Project Introduction

In this week, we worked on making a user guide manual for our laser cutting machine as a group. Each member had to design an A5 sized drawing that would show varying speed/power settings used on a material such as MDF, Acrylic, Plywood etc.

Design - Front Page

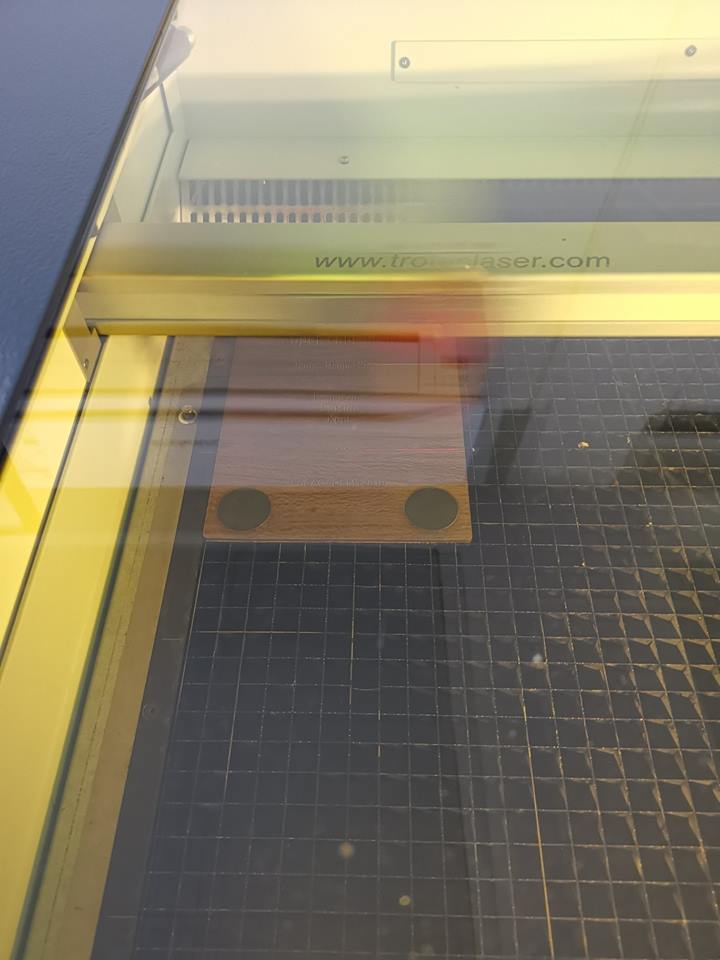

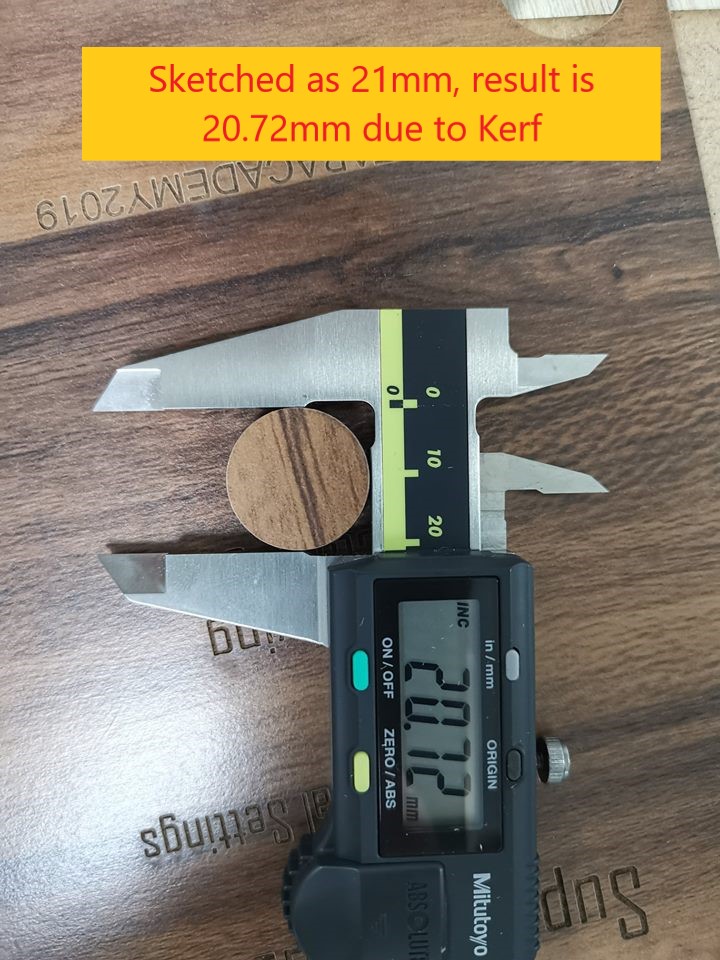

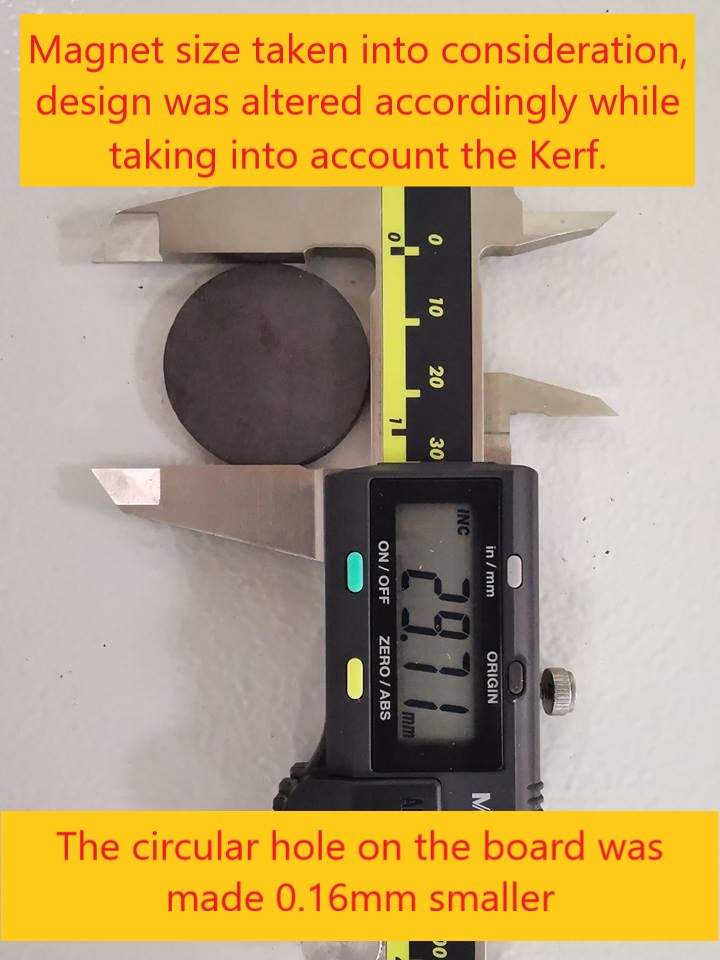

I decided to take the front page of laser guide manual. The front page included name of manual, lab's name, sections covered like engraving, cutting, and kerf. Now we decided that a binded book might end up somewhere away from the laser cutter, so then we came up with an idea of using magnets to hold the page on the laser cutting machine. This idea would also help us experiment machine's kerf and find best value to fit magnets on the sheet page.

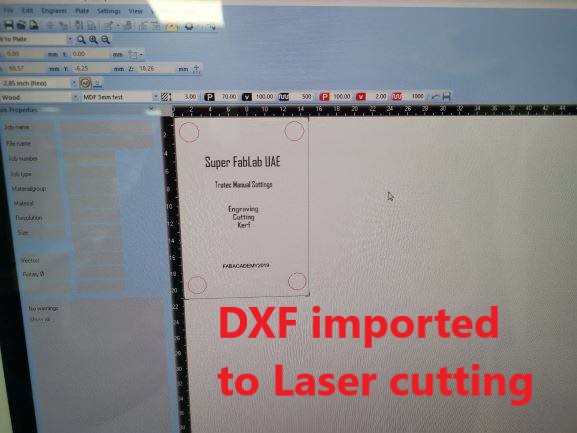

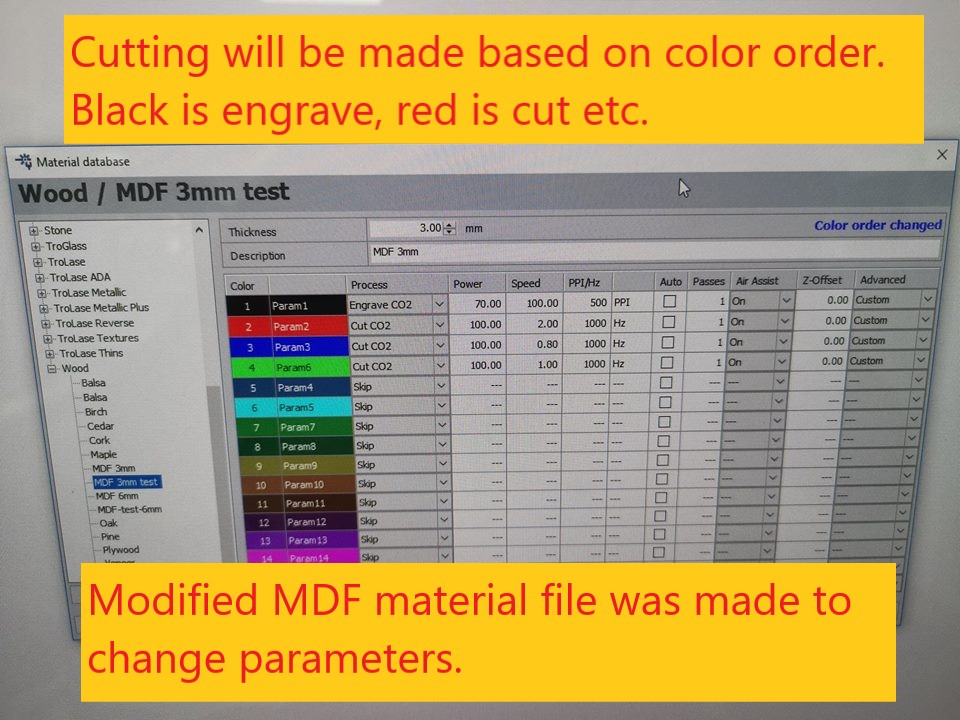

Laser Cutting Machine - Settings

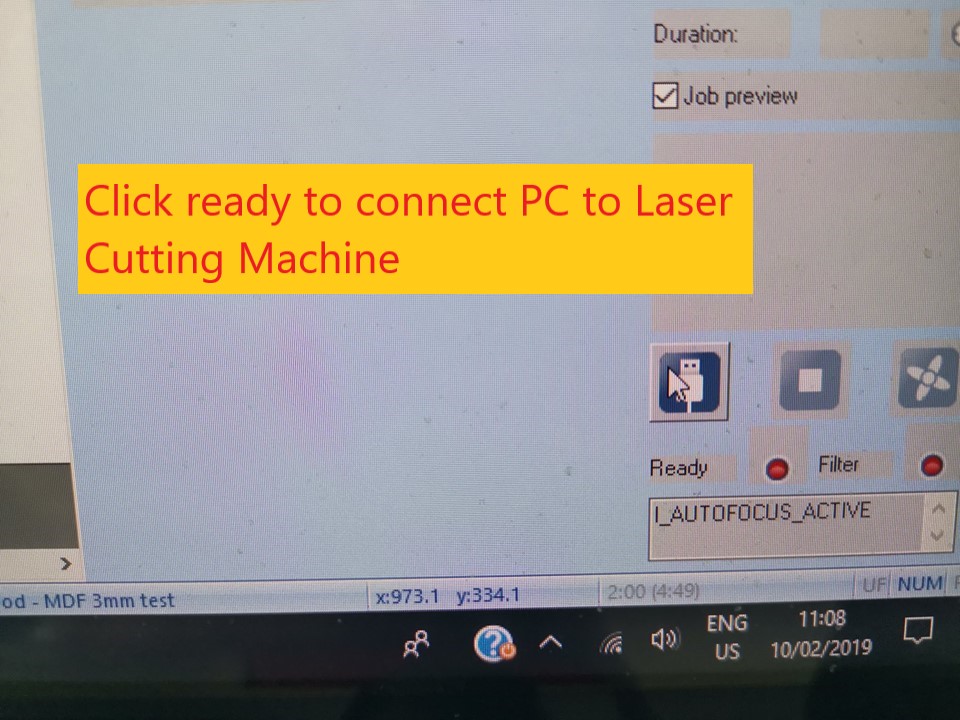

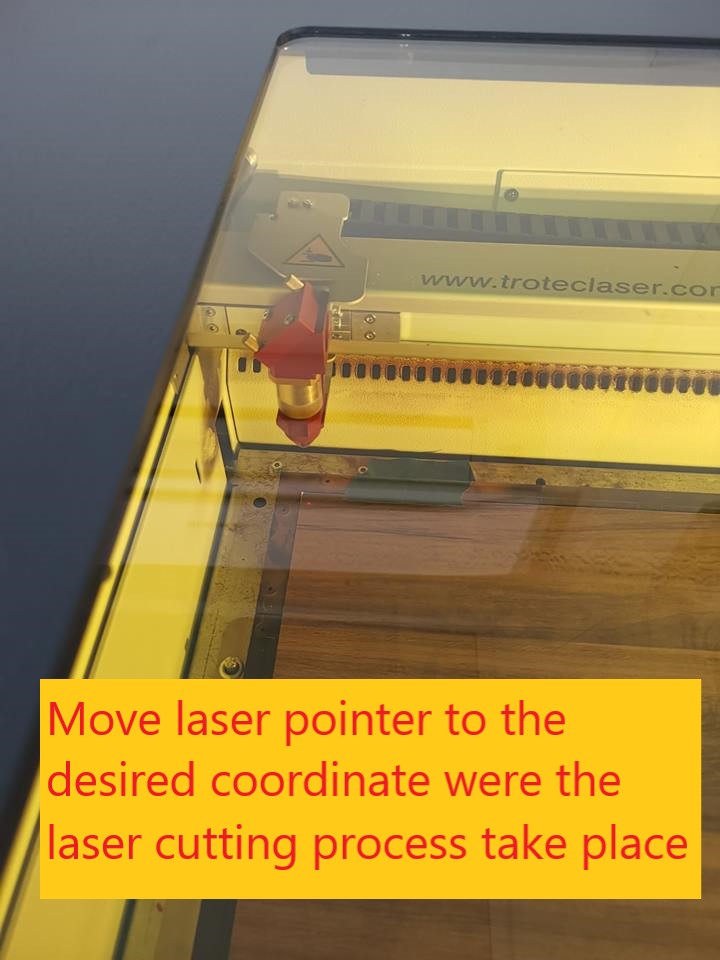

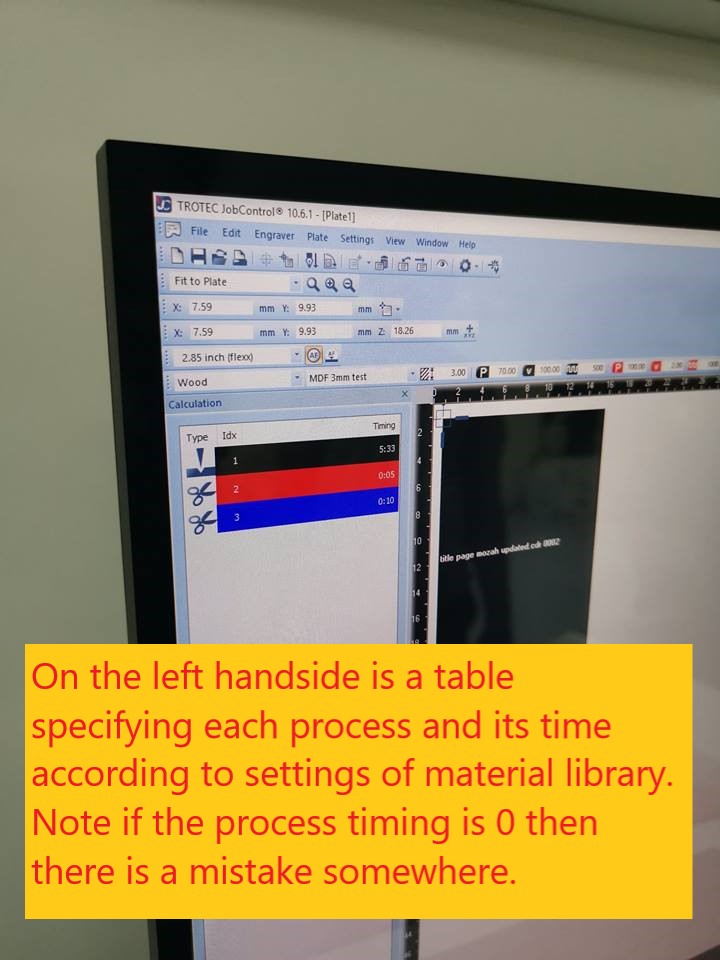

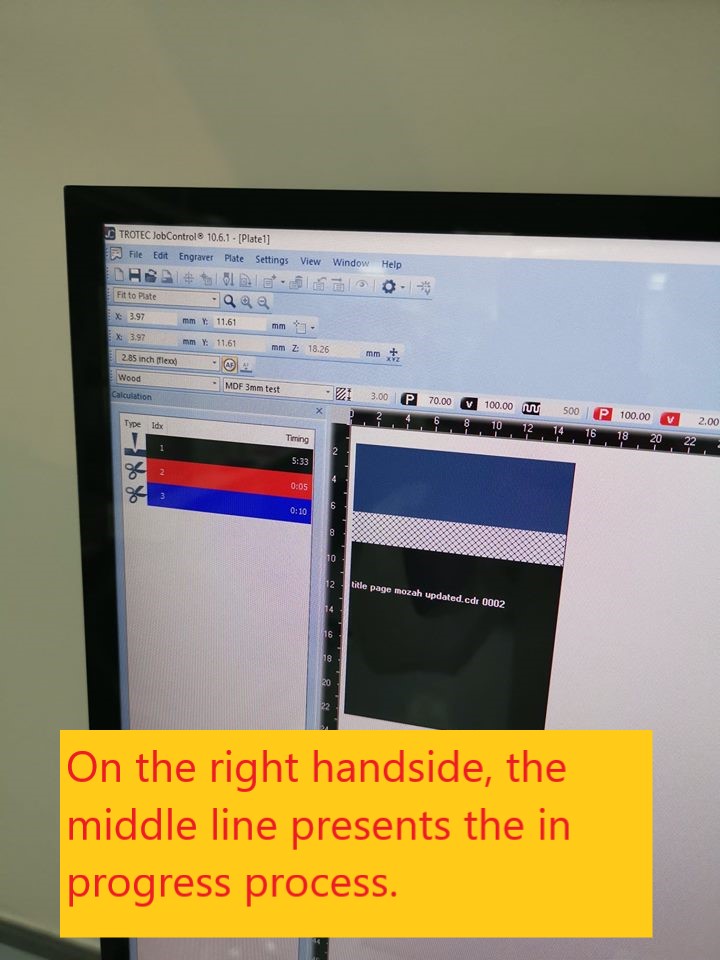

Taking things slowly is not my bread and butter, but as part of having consistant results in FAB Academy I must learn to take things slowly. The first major presetting that must be done before using the machine is to make sure all lines on the drawing are hairline, else a line will be engraved (0.5 pt). Also after that the file must be ctrl+P to the laser cutting machine. From there, we must double click on software's dashboard after choosing our file, then in settings we choose the desired material. We can then go to back to the main dashboard and look at the colors on the left hand side, the inner most material must be first cut after engraving, and then the outter layer. Some settings may have to be changed to control burn effect.

Focus - Kerf

Our manual covers settings for cutting and engraving. The manual also includes machine's default kerf value, and different kerf values by joing different materials cut with different dimensions. My focus was on Kerf, I was able to determine machine's kerf value (0.28), and from there I have made some test were I cut two materials with different dimensions, joined them together with kerfs of (0.12) and (0.16). This information is all included in the manual for the user to experience joint strength with different kerf values.

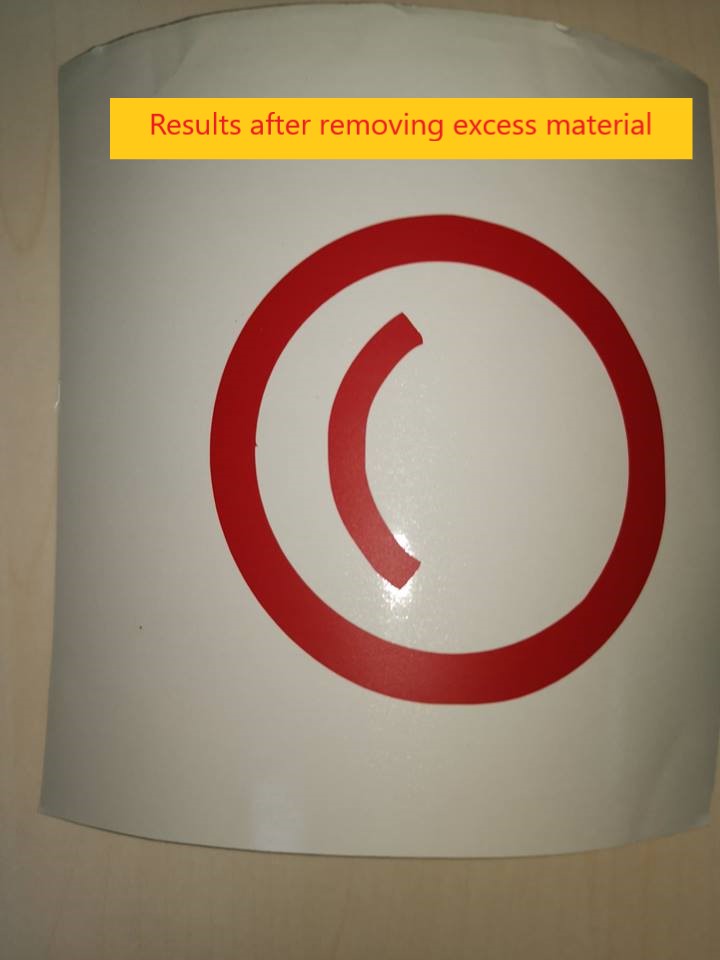

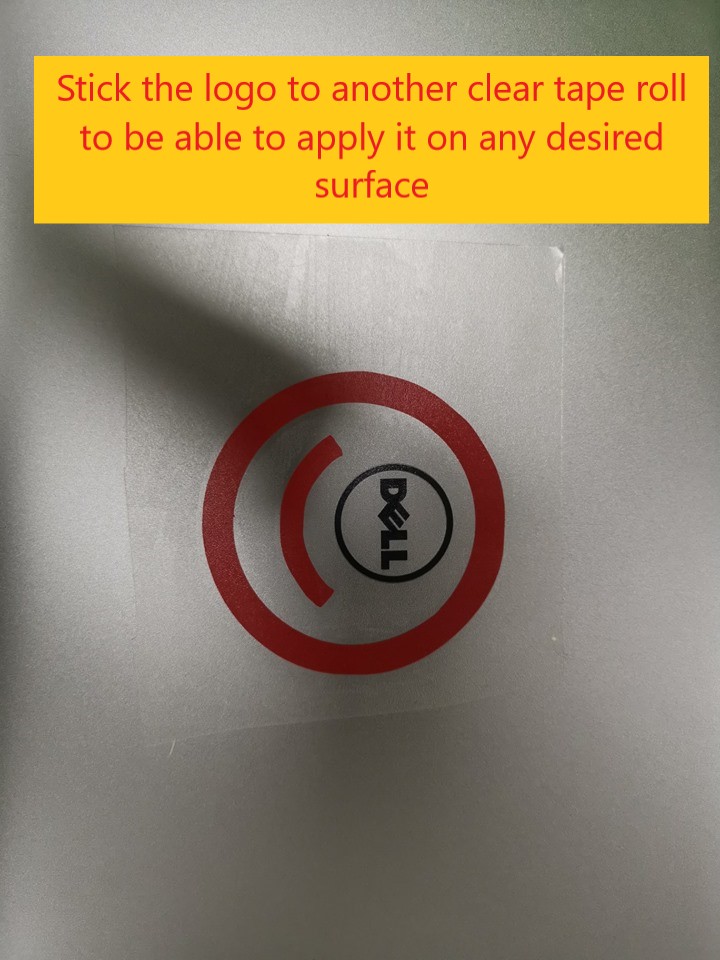

Logo - Vinyl

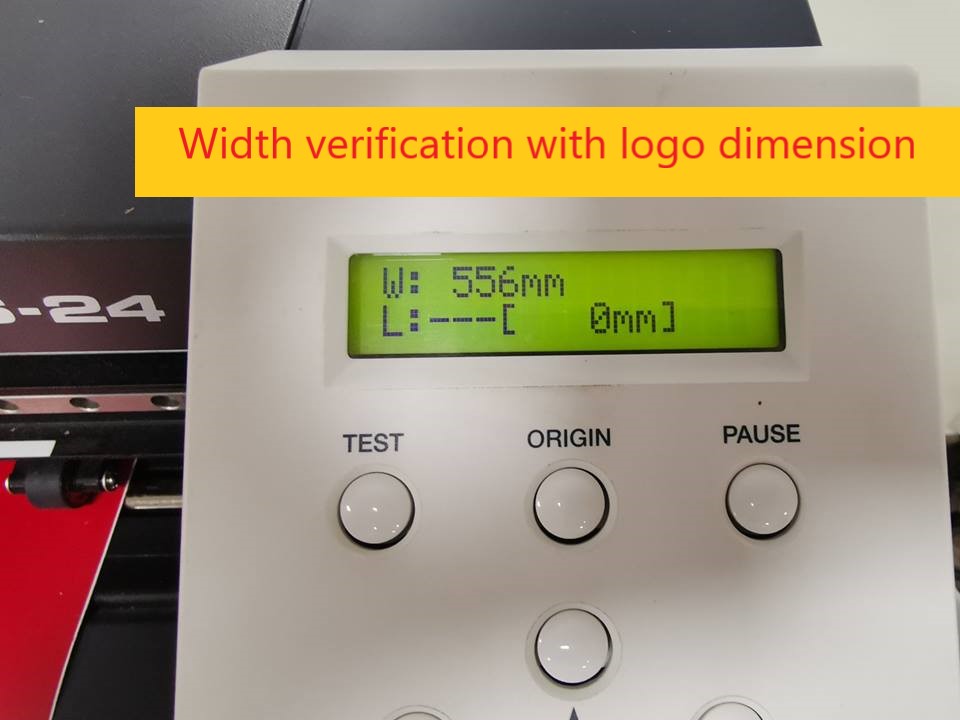

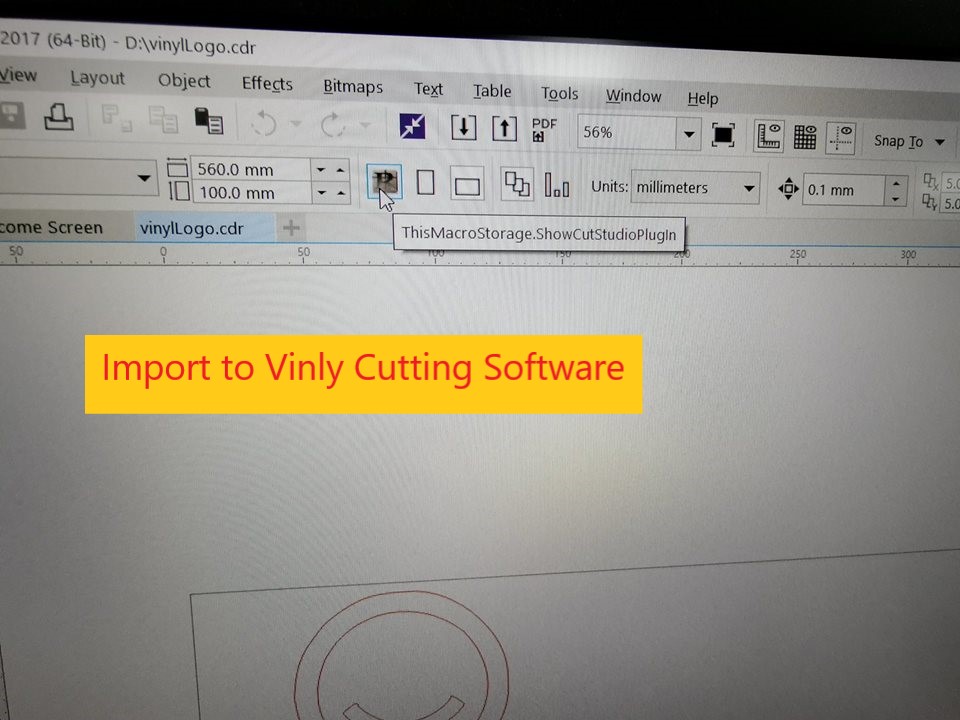

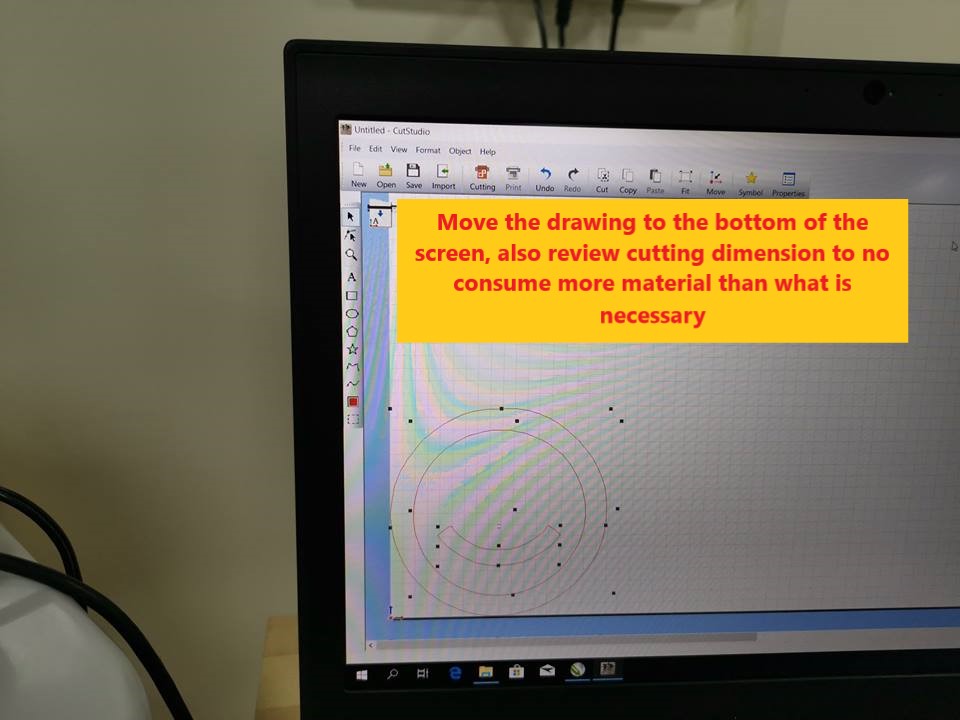

This task is about designing a logo and using a vinly cutting machine to make a sticker of designed logo. The logo was obtained from Smart Dubai.

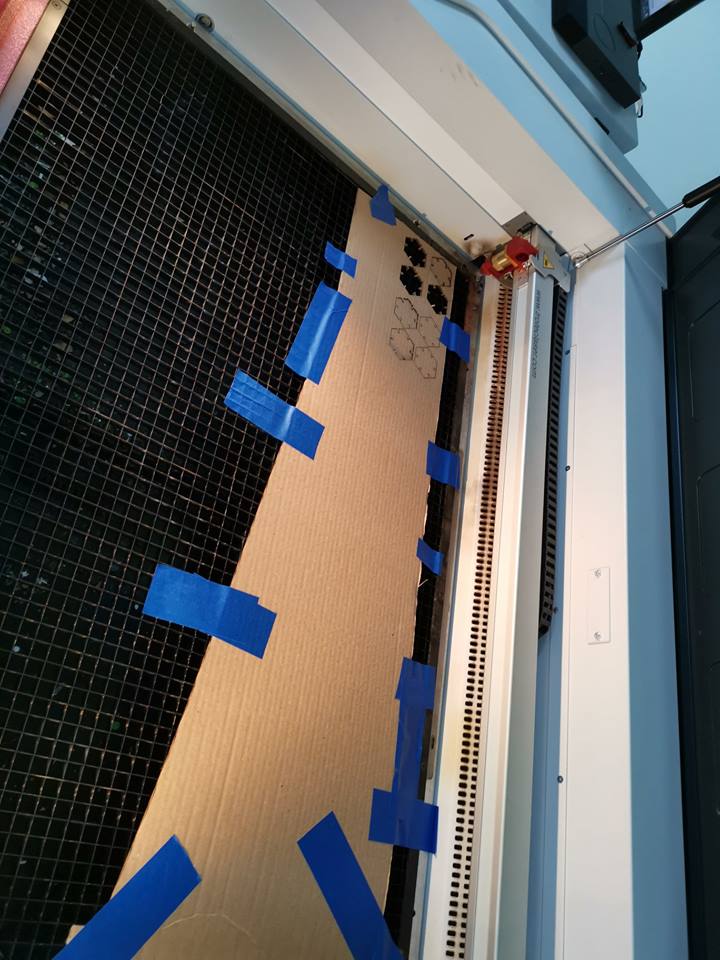

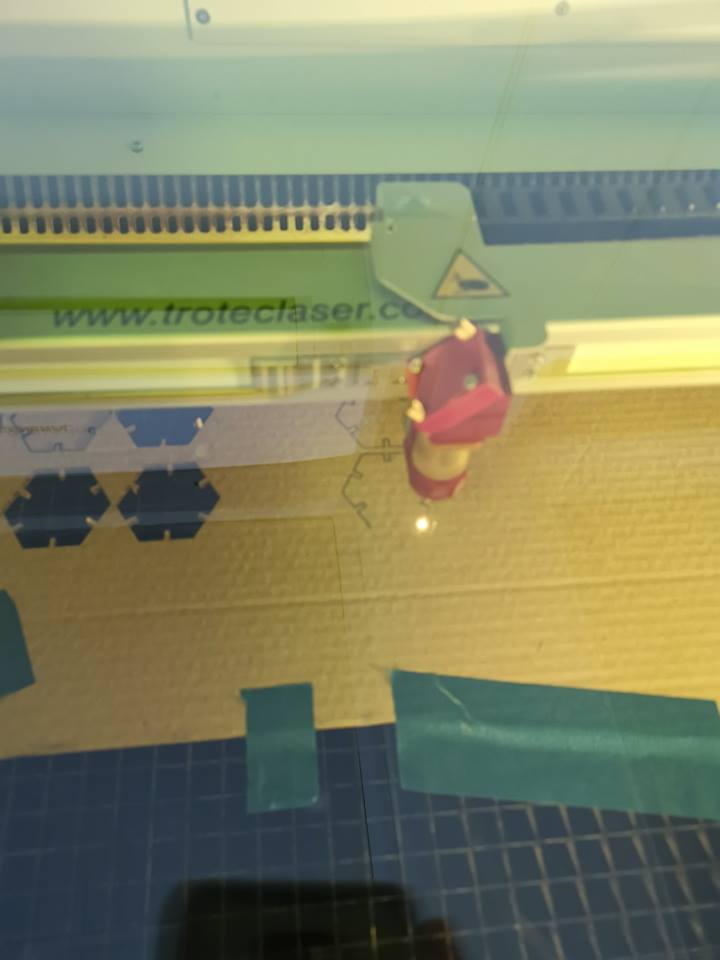

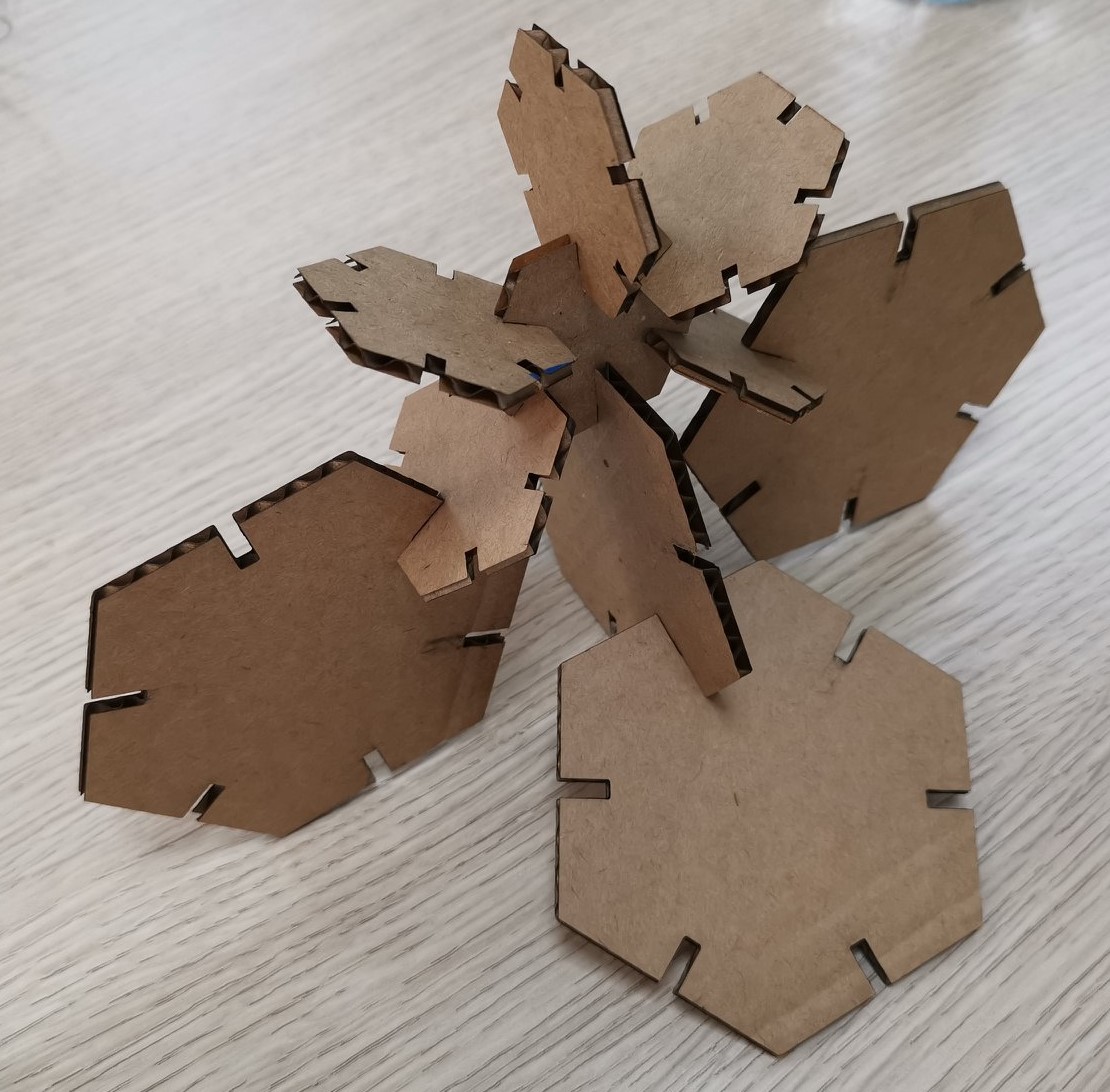

Parametric Kit - CNC

In this task a press fit kit is designed and cut using laser cutting machine. I wanted to note that parametric design is an interesting aspect for me as it brings flexibility and robustness to the design, I have used parametric design since last week when it was optional. Doing it again using constraints and construction lines helped me to design parametrically in an effecient manner. Though not a fully press fit kit, this video would bring lots of insight to involving Fusion360's features like mirror, joint extrusion, projection etc. This would be helpful to get you started for this task.

Tape must be applied around the cardboard as it was not completely flat. Else, the laser may not be able to fully cut through the cardboard, nor correctly engrave on its surface. Auto-focus feature takes care of leveling laser pointer with the material given that its completely flat.

Assignment Files:

Front Page - Group ProjectVinyl Logo