13. Applications and implications¶

Propose a final project masterpiece that integrates the range of units covered, answering

- What will it do?

- Who’s done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will they come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

Your project should incorporate

- 2D and 3D design,

- additive and subtractive fabrication processes,

- electronics design and production,

- microcontroller interfacing and programming,

- system integration and packaging

Where possible, you should make rather than buy the parts of your project

Projects can be separate or joint, but need to show individual mastery of the skills, and be independently operable

Brainstorming on a final project, “the alcove office”…¶

As stated in week01, the idea is to build an deployable booth for open spaces office, like a “alcove office”…

Thoughts…

In open spaces office, it would be nice to have some more closed personal spaces when needed…

with comfortable seating and working space…

but still connected to the world…

using new technologies, new materials…

What will it do?¶

So, it would be an partially closed space, surrounded by panels having good acoustic properties

There would be an “intelligent” system, based on microcontroller, providing data on the office environment (temperature, humidity, time,…) and controlling some actuators: motors, light switches,

Access to loudspeakers, power plugs and internet connection could be a plus

Who’s done what beforehand?¶

On the net, you could find several type of personal spaces, from simple seats in a semi-closed space to volumes that can be mounted in a short time thanks to their deployable structure. Closed glass phone cabins and booths are available in open space offices… See week01 for some references and links.

What will you design?¶

- The idea is to think first about a planar working surface on which the deployable structure will be fixed that could be made by means of the Kinetic CNC*

- deployable separation panels, to be covered or even made in special textile with acoustic properties, e.g. felt.

- The brain, made of a microcontroller on a main board with extensions for input and output devices (PCB milling, assy and programmming)

- Encapsulation of PCB to protect them from a environmental hazards, to be made out of a laser cut wood.

What materials and components will be used?¶

For the mechanical structure, there is no clear idea yet, working with my colleagues, we are developing the design of the seat, the working surface and its incorporated panels. There will be wood for the seat and working surface, and fabrics for the panels

For the electronic part, design is already on-going (see weeks 11, 12)

Where will they come from?¶

All materials needed for the fabrication are available at the fablab or commercial stores

How much will they cost?¶

UPDATE SEPTEMBER 2019.

Detailed bills of materials are found in Project development, week20,

A summary is given here:

| materials | price |

|---|---|

| wood support - plywood panel | 33.99€ |

| deployable structure - felt structure | 134.388€ |

| 3D filaments (PLA, PETG) | 58.90€ |

| electronic material (specific to this project) | 88.75€ |

What parts and systems will be made?¶

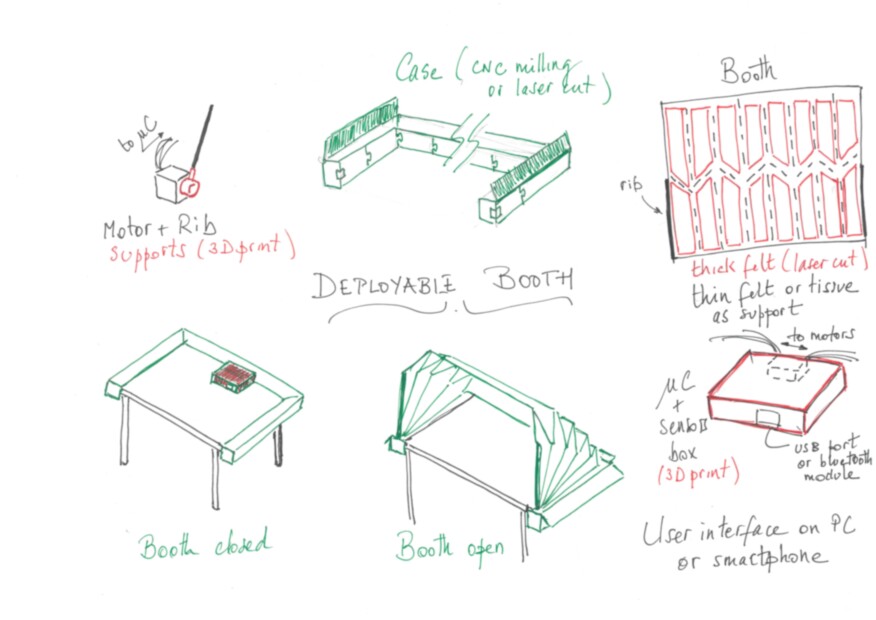

Everything will be ‘homemade’: * Electronics parts will include microcontroller, sensors (temperature, humidity, …), actuators (motor control) and user interface through serial or bluetooth communication * 3D printing will be used to make the different supports and electronic packaging * Laser cutting will be used to make the felt origami booth * CNC milling will be used to make the case of the booth

And as it is usual said that a small picture is worth a thousand words, here is the sketch of the project with process used:

What processes will be used?¶

See above: this has been defined while developing the design of the structure

What questions need to be answered?¶

Not clear yet, but beside technical points, there will surely be questions of safety and reliability, commercialization, for which I do not have answers yet…

How will it be evaluated?¶

The correct functioning of the system will be done on-site, on a 1:1 scale

Models¶

Plan of the origami , half model, in paper:

To do:

- Double the model to create an arch

- Contact felt manufacturer to get felt samples to play with cutting and doubling to create an origami sample felt origami

- Think on the manufacture process : laser cutting of felt? 3D printing on felt?

- Rigid parts (stick?) to put the structure in motion

Motion control¶

Stepper motor controlling the opening of the origami, driven by microcontroller

User interface¶

Bluetooth communication between microcontroller and user’s smartphone. I’ll use the Kodular platform to develop my app.

Temperature and humidity measurements in the environment are displayed, position of the booth may be given (as double check in case of mal functioning)