Assignment 4 - Computer-controlled cutting

In this fourth assignment as a group we need to characterize the lasercutter, making test parts that vary cutting settings and dimensions and for individual assignment we have to cut something on the vinylcutter and design, lasercut, document a parametric press-fit construction kit, accounting for the laser cutter kerf, which can be assembled in multiple ways

Group assignment

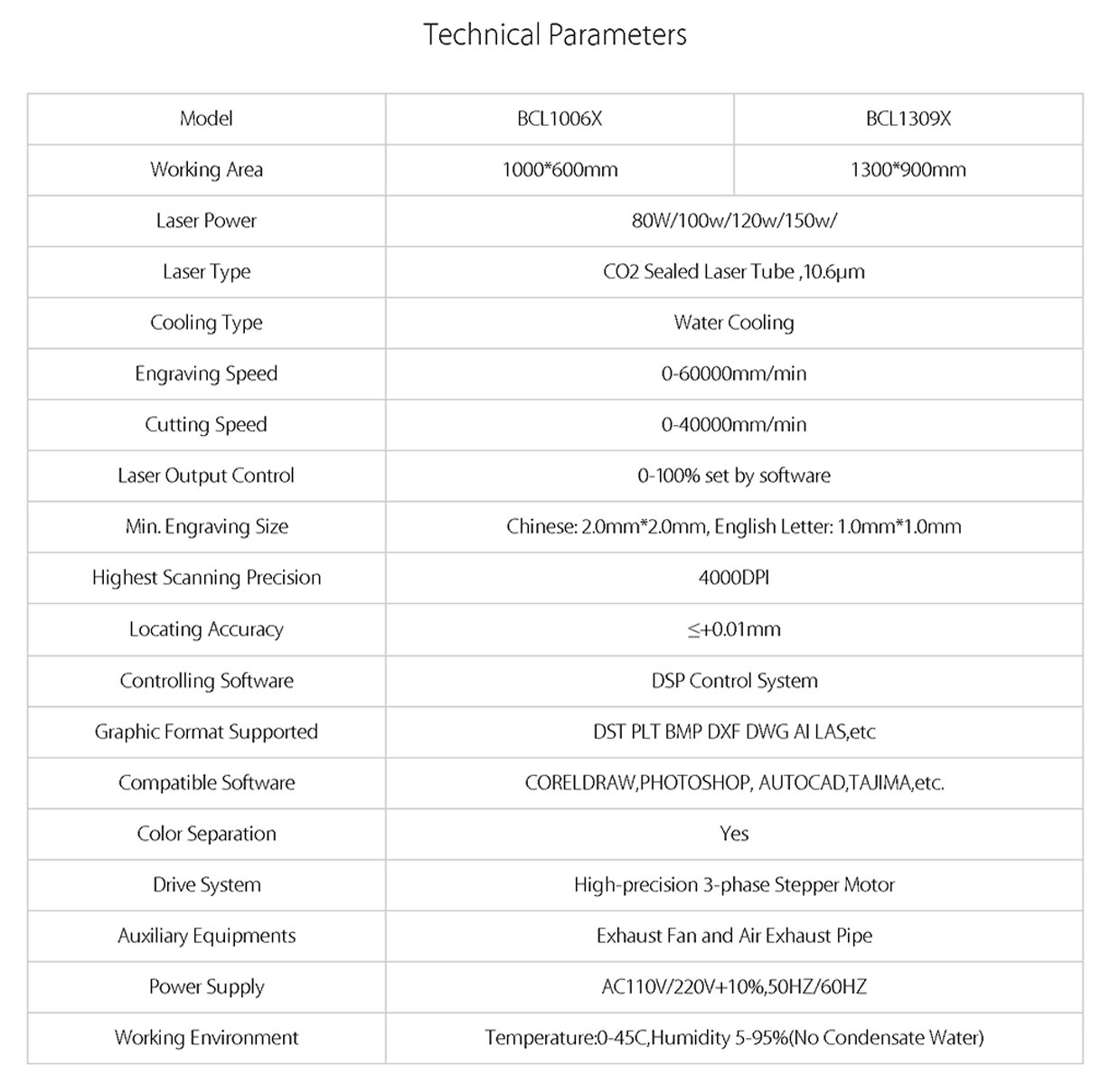

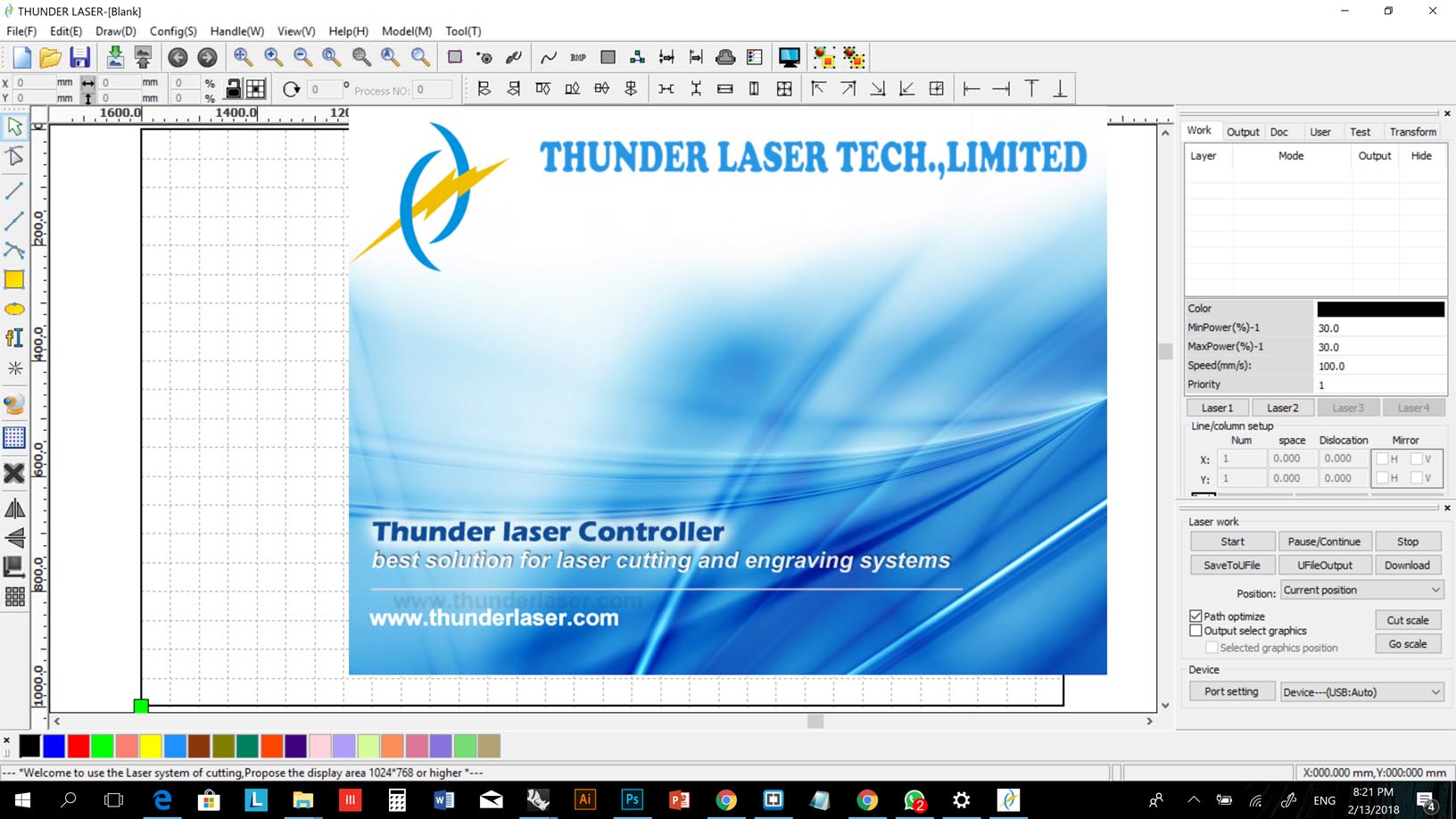

Laser cutter machine

Laser engraving and cutting machine BCL-1610X

1. Drive system with high precision linear guide and slide block, high precision, wear resistance, small resistance, high speed; arc-gear synchronous belt 3m, stable transmission, strong shock absorption ability and small noise.

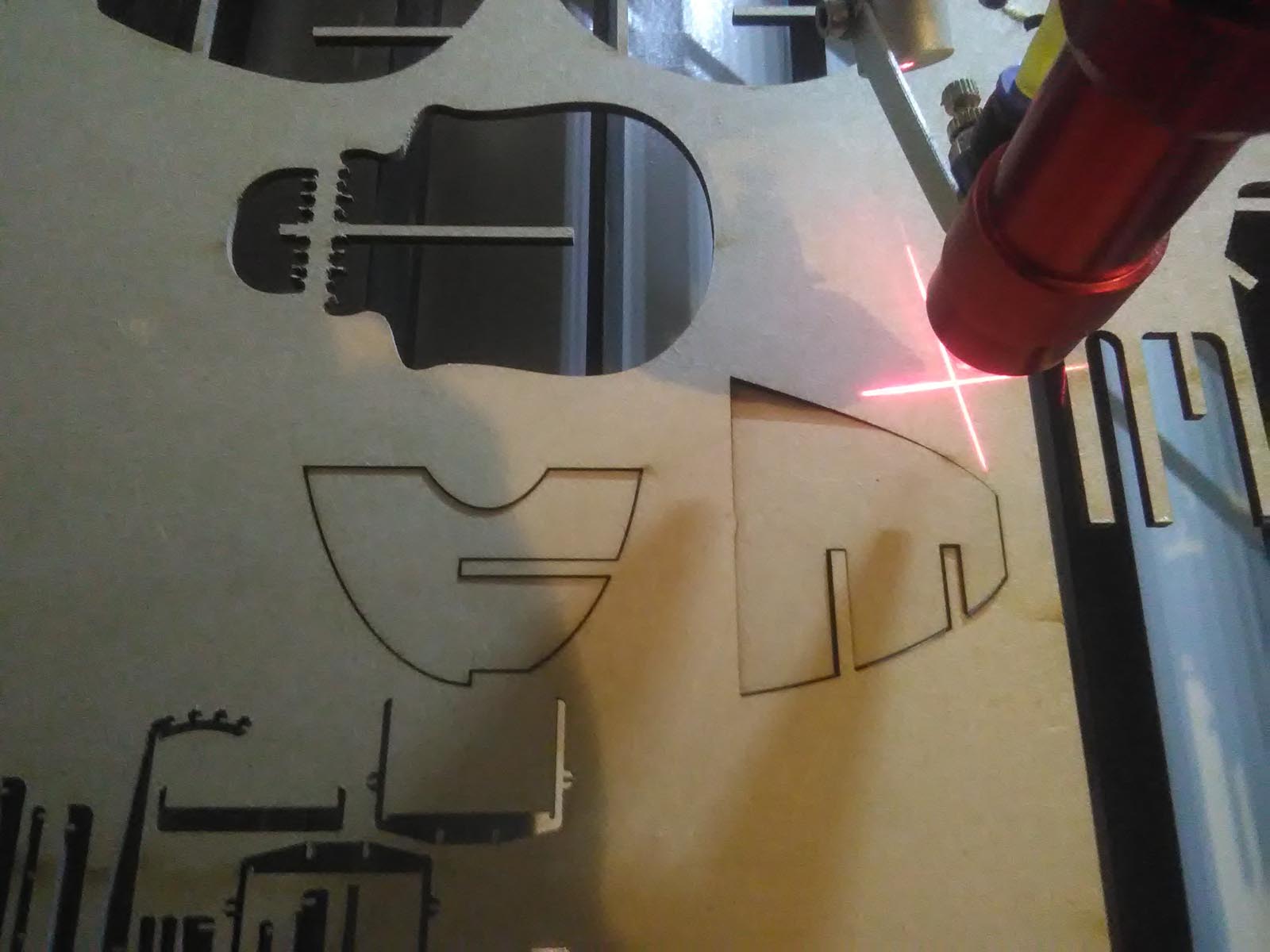

2. Red Cross accurate positioning, convenient and quick in finding engraving and cutting position.

3. Three-mirrors and one focal lens path system to deliver outstanding engraving and cutting effect.

4. Equipped with manual modulation focused laser head, responsive and accurate, the machine can adjust the focus position according to engraving and cutting alternation and the material characteristics and thickness of the plank, to ensure sculpture quality.p>

|

|

|

|

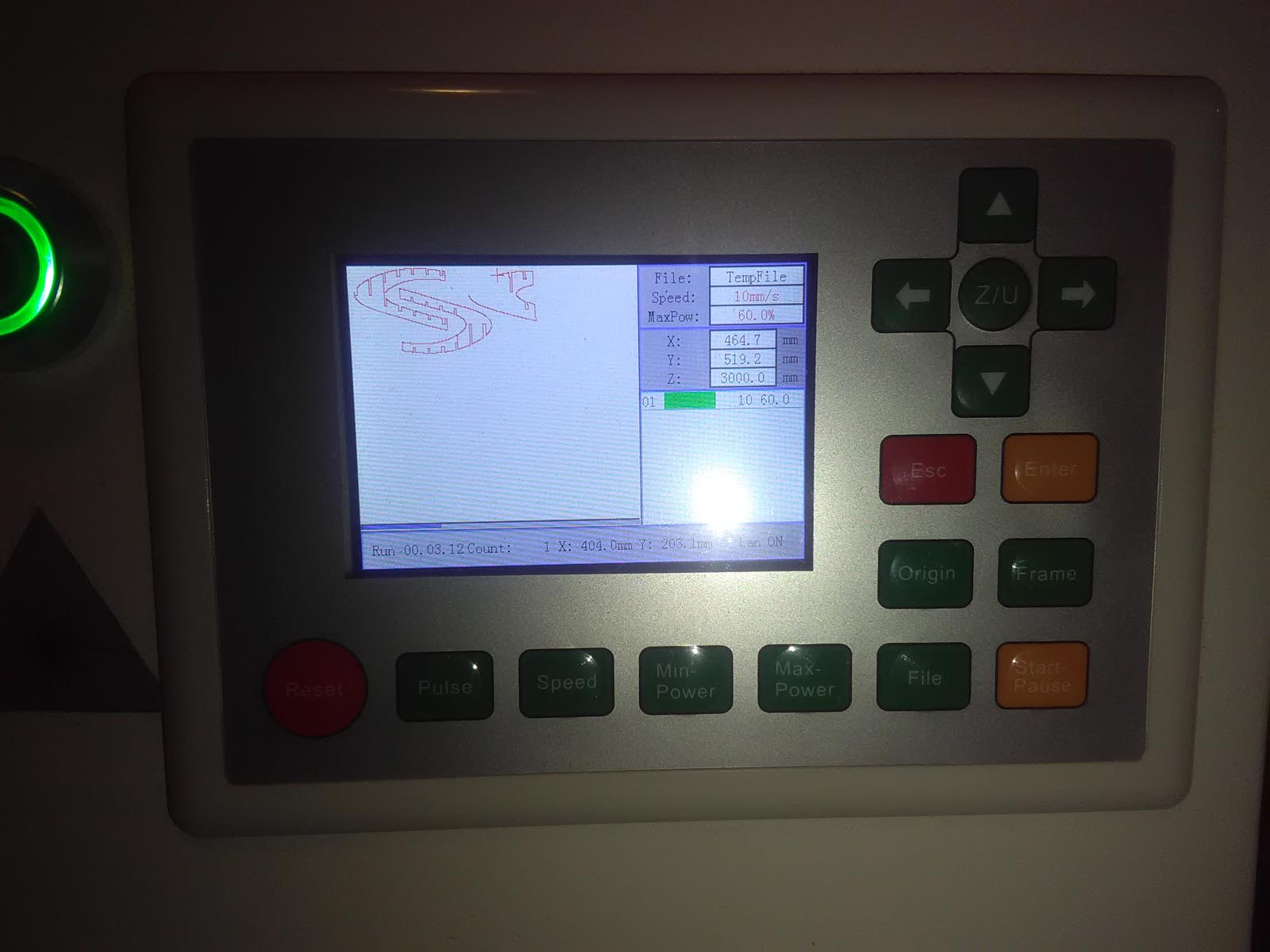

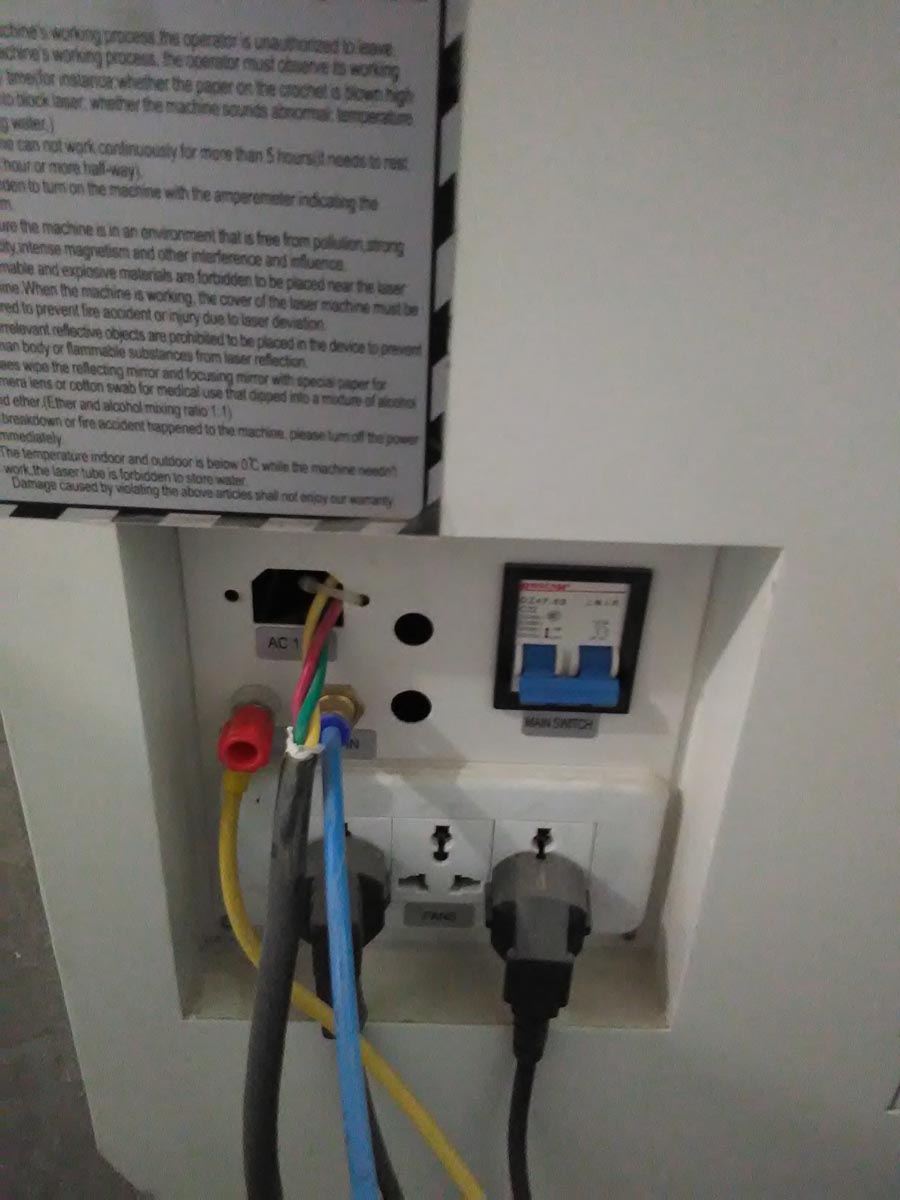

This laser cutter is a robust machine with 150 watts power. It has a working are of 1600mm x 1000mm. It has a transparent cover that allows to visualize the process and for security reasons. The emergency stop botton has a illuminated green light which is a very clear and big red button. The laser has a screen that allows a to visualize the file on the USB and on real time the exact process. On the right of the screen control panel it has 4 on/off buttons that allow to control the laser power, the light, the fans and the air pump.

This machine has an air pump that helps the air extractor to remove the smoke produced during the process, it also has a chiller thats cools the tube that uses to generate the laser. This chiller should not exceed 28 degrees centigrade avoiding the overheated warning.

|

|

|

|

...

...

...

...

...

...

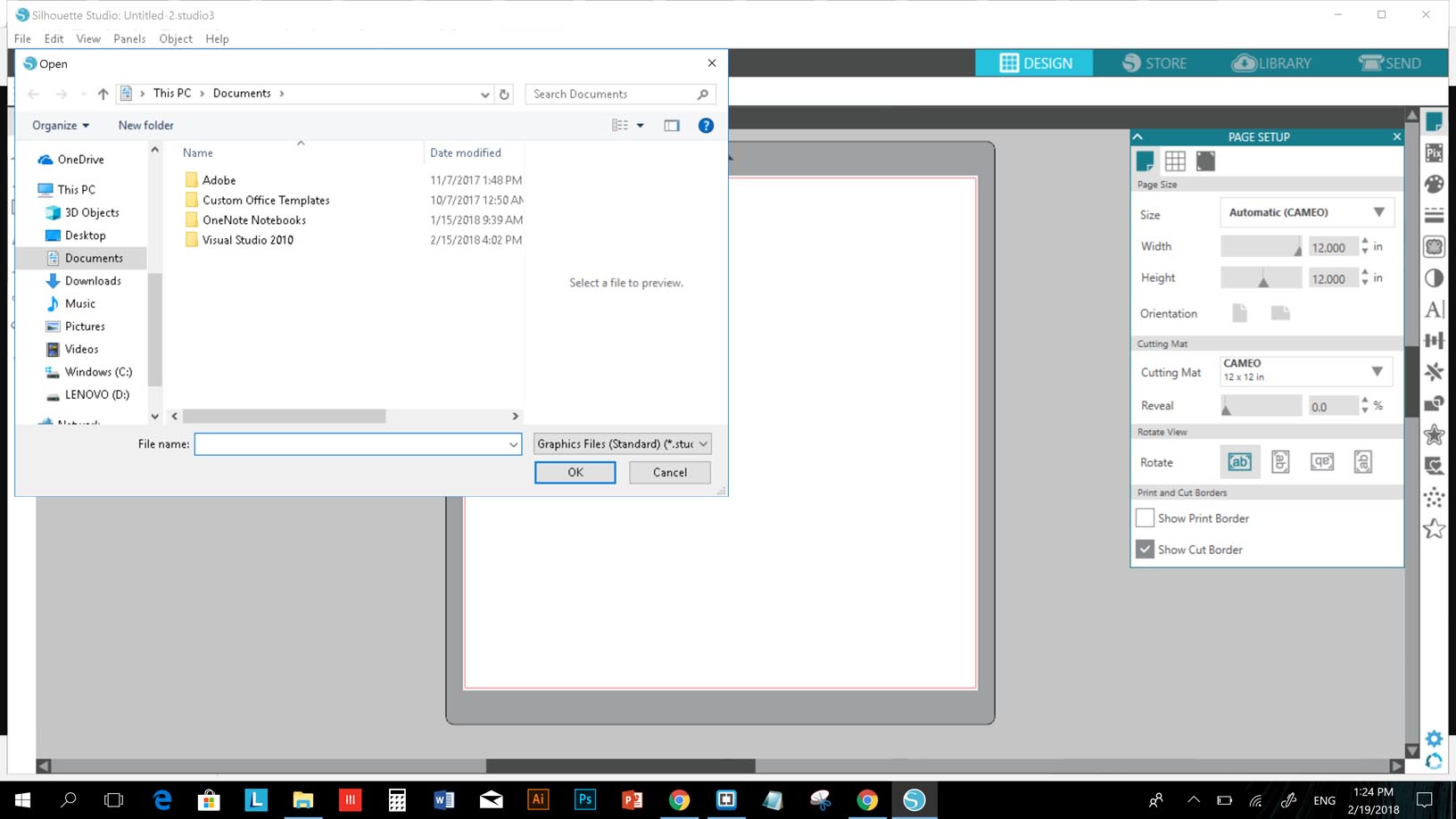

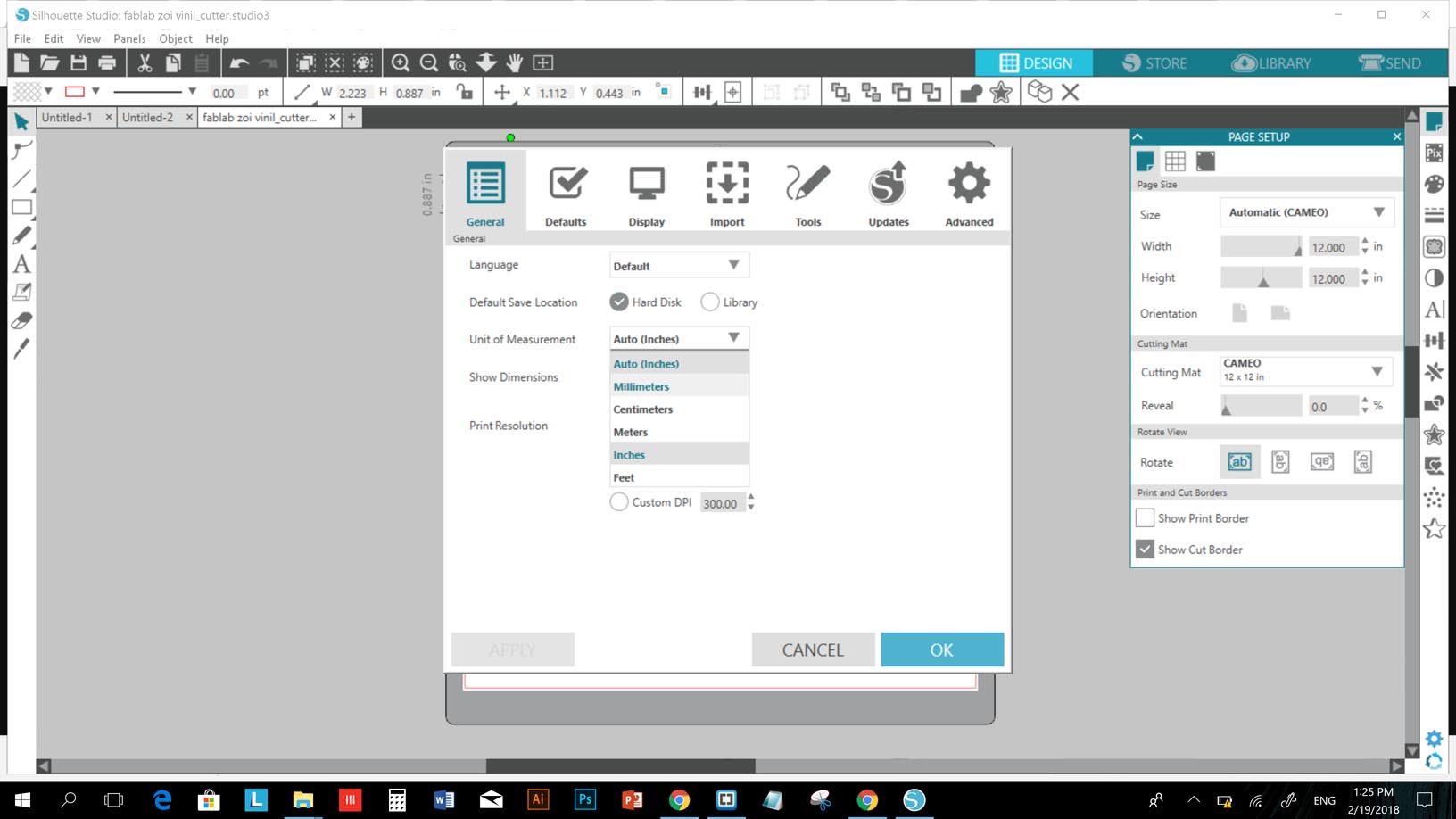

Vinil cutter machine

...

...

...

...

...

...

...

...

...

...

...

...

...

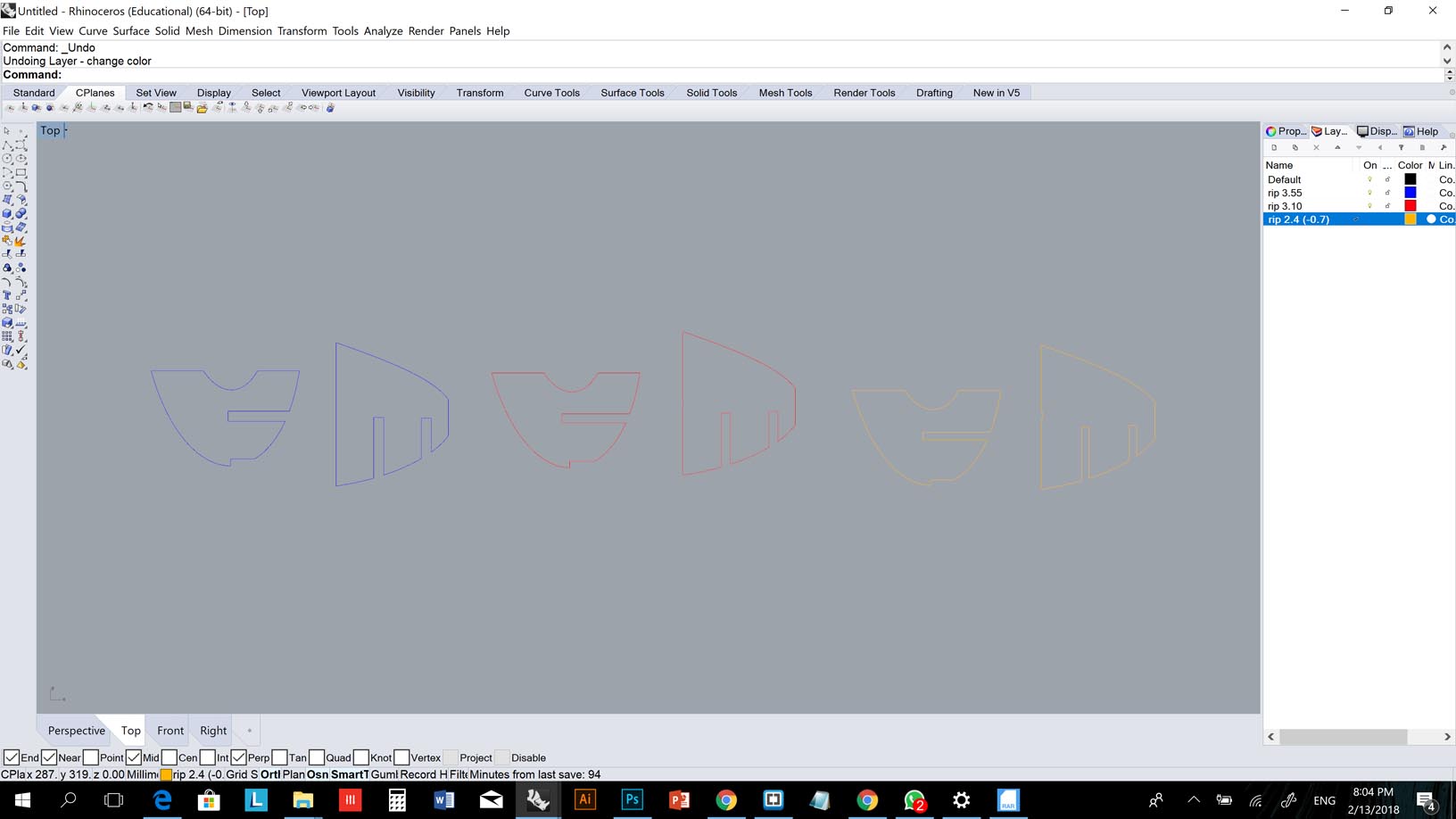

First 3D modelling test waffle laser cut

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

...

.jpg)

.jpg) |

.jpg) |

...

.jpg)

...

.jpg)

contact me if you wish further information

EMAIL: fabiolopezmora@gmail.com - CEL: +573017679430