Week 7

Electronics Design

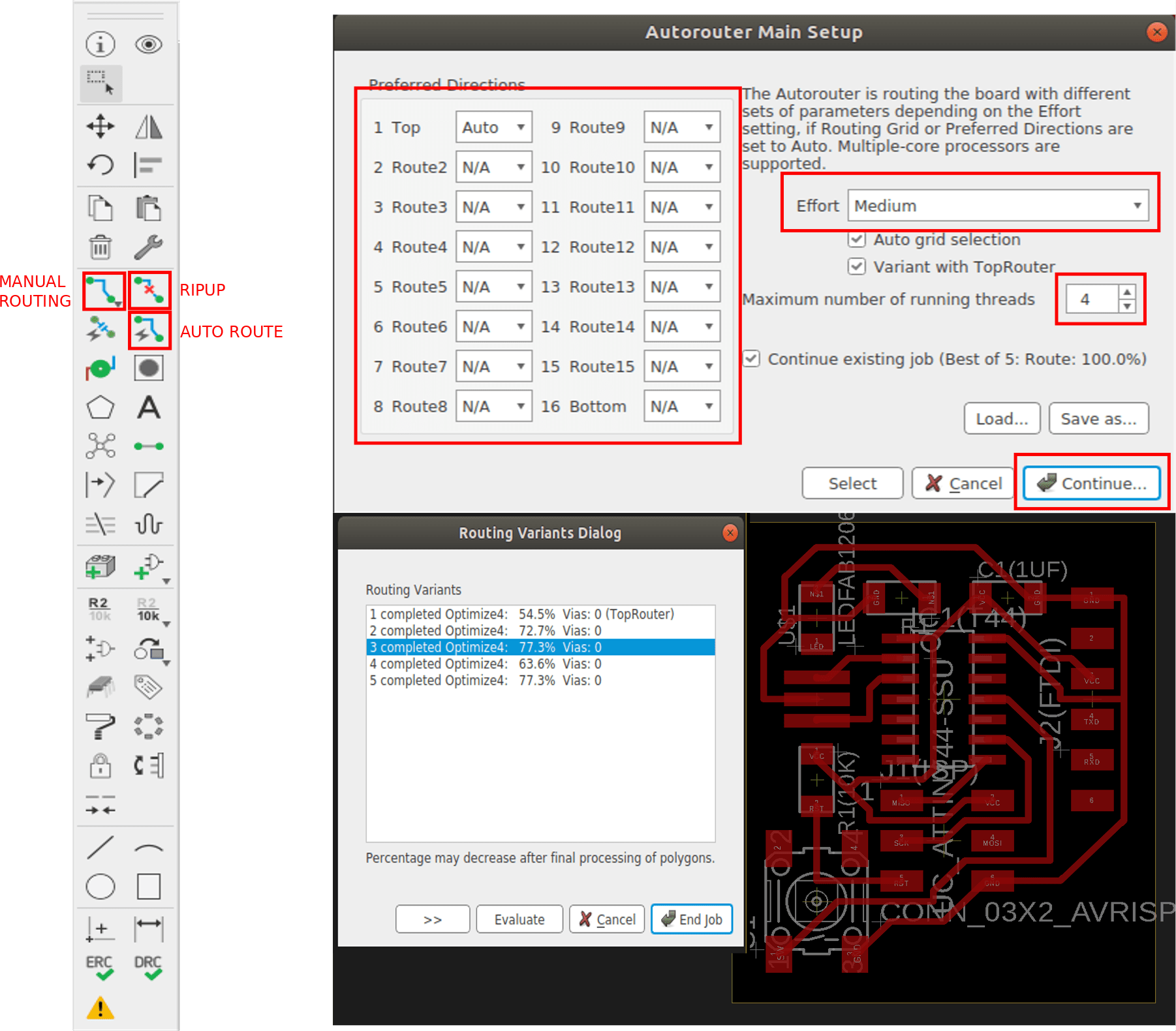

Objectives

Individual Assignment

Group Assignment

Learning Outcomes

Individual Assignment

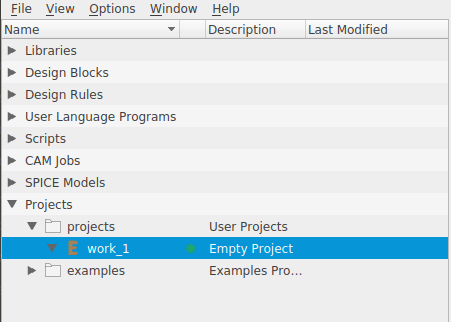

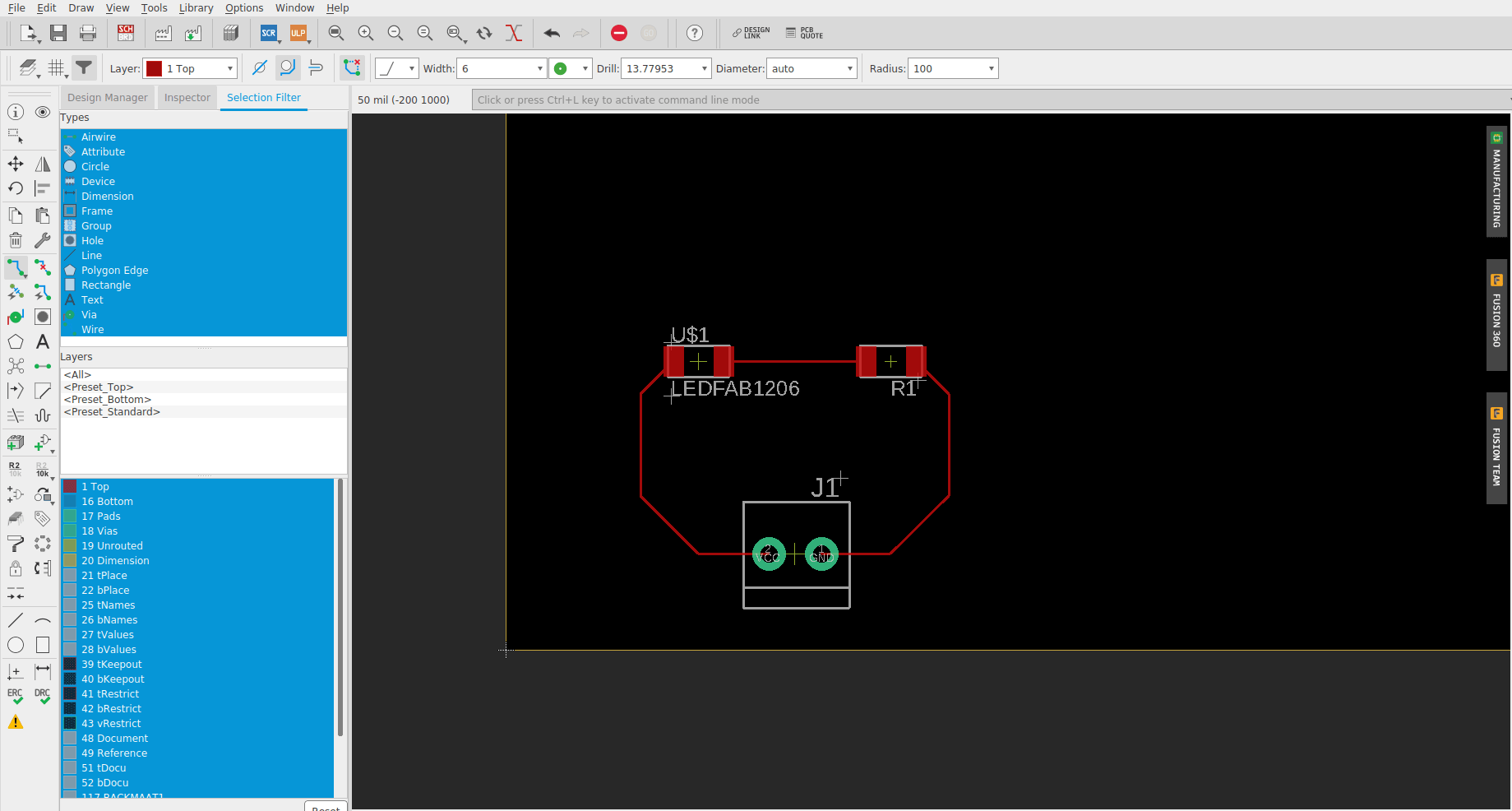

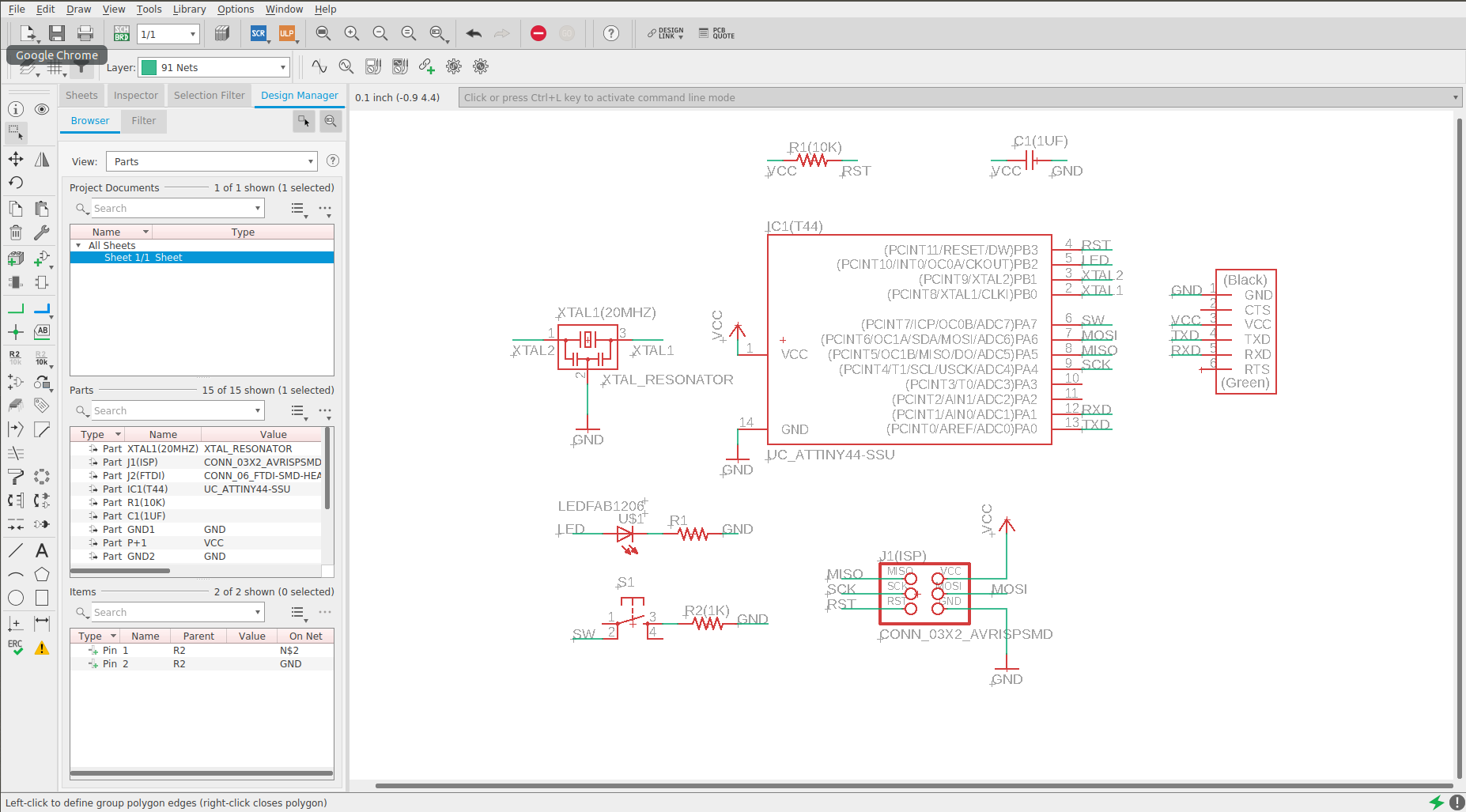

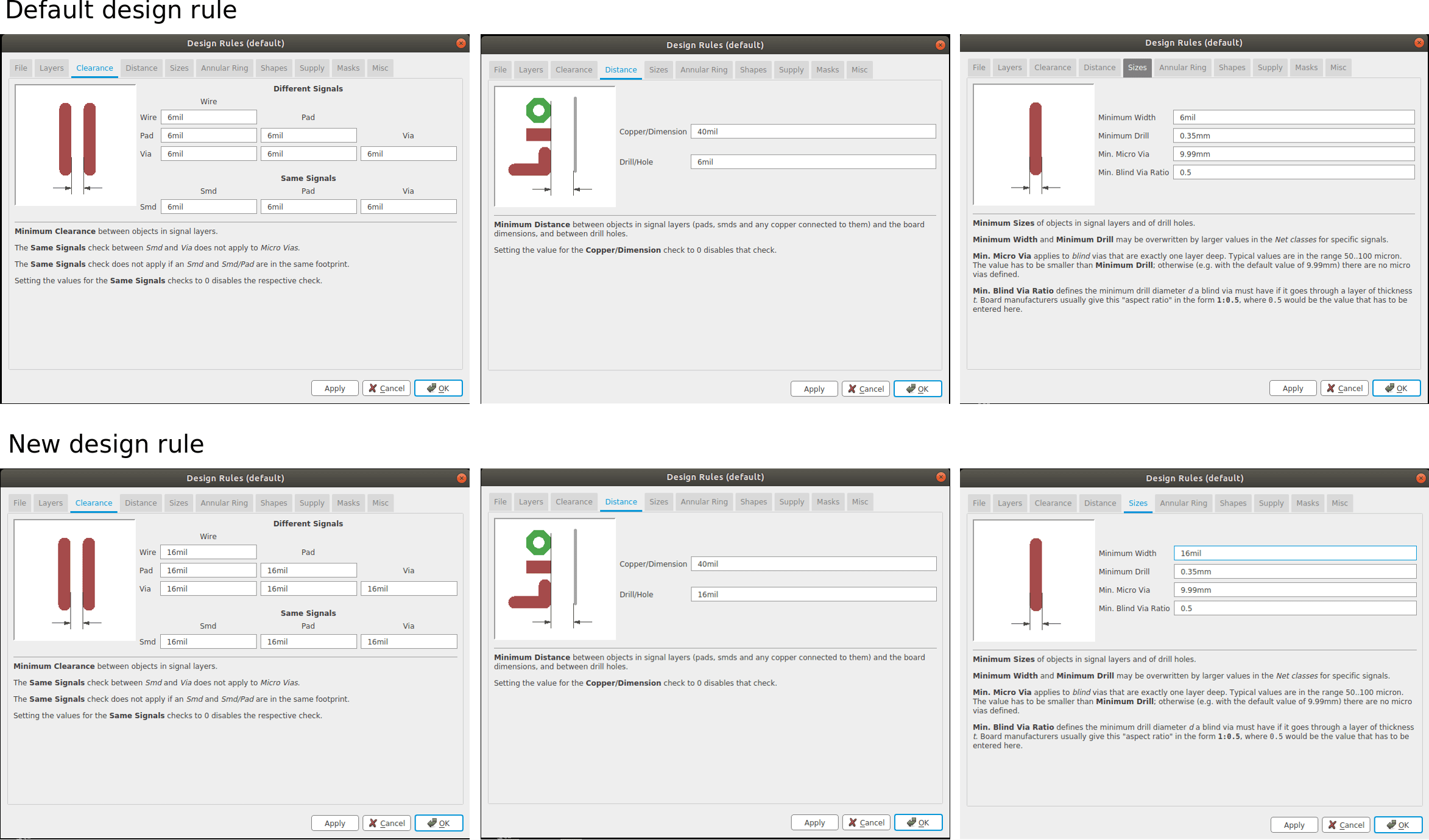

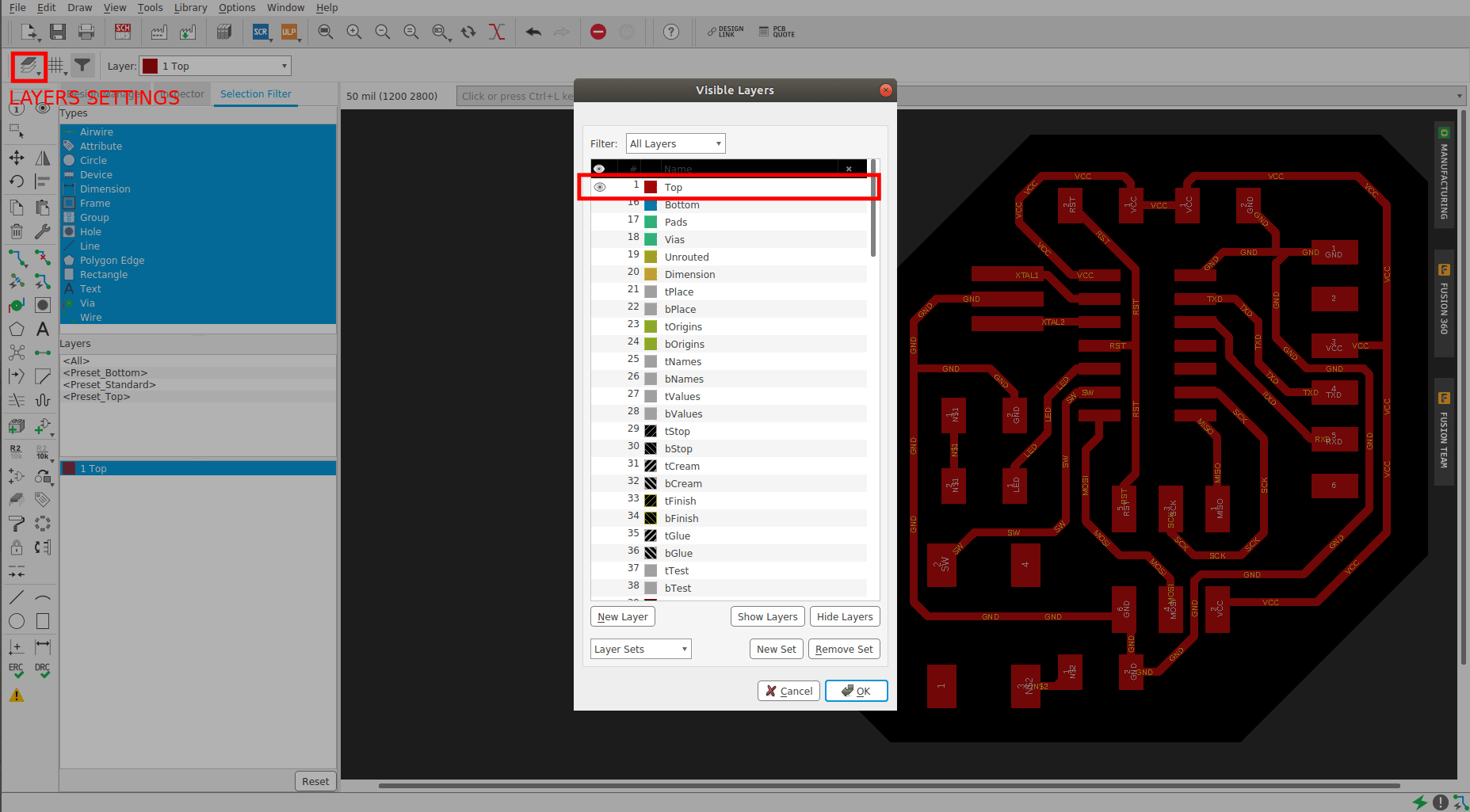

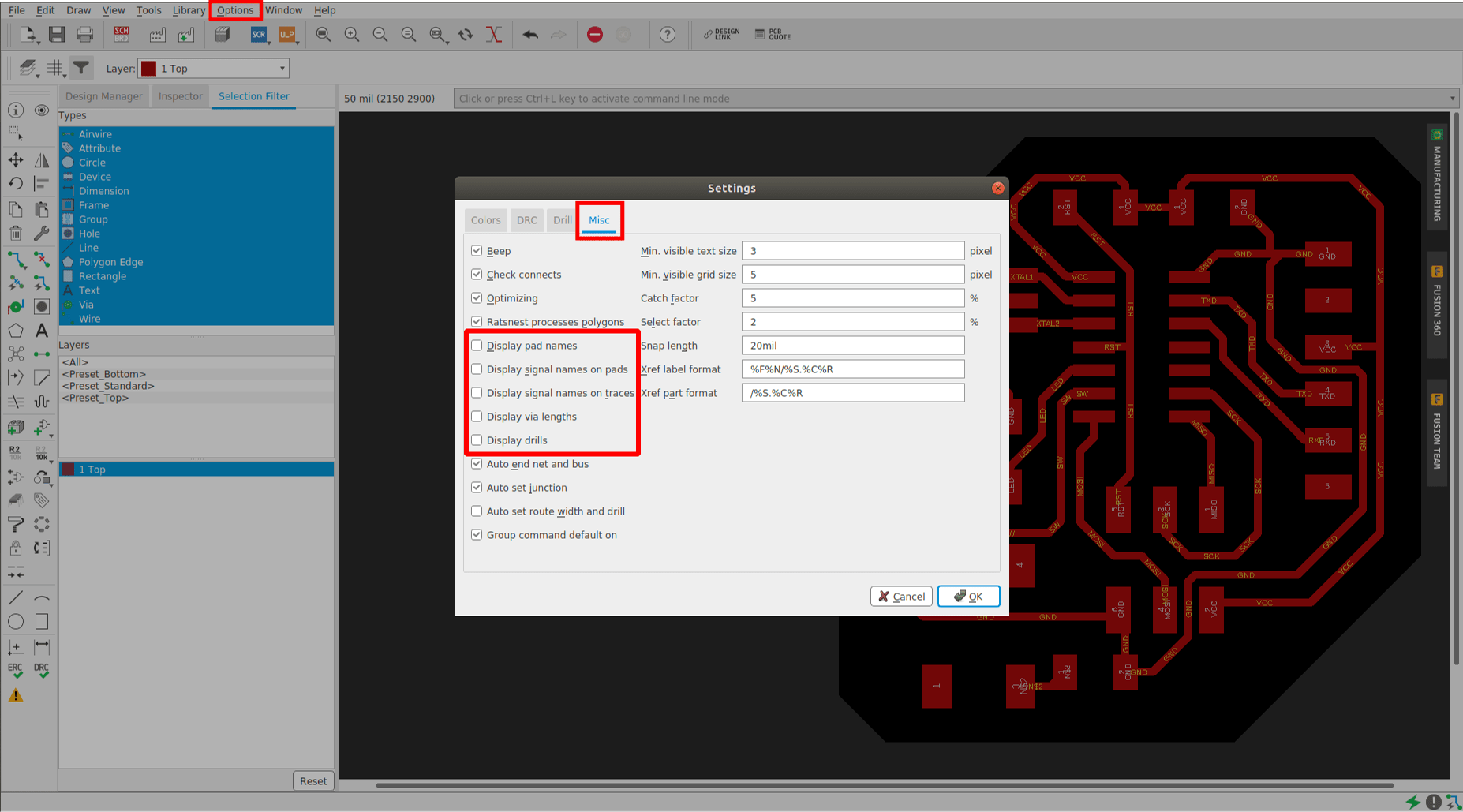

Autodesk Eagle

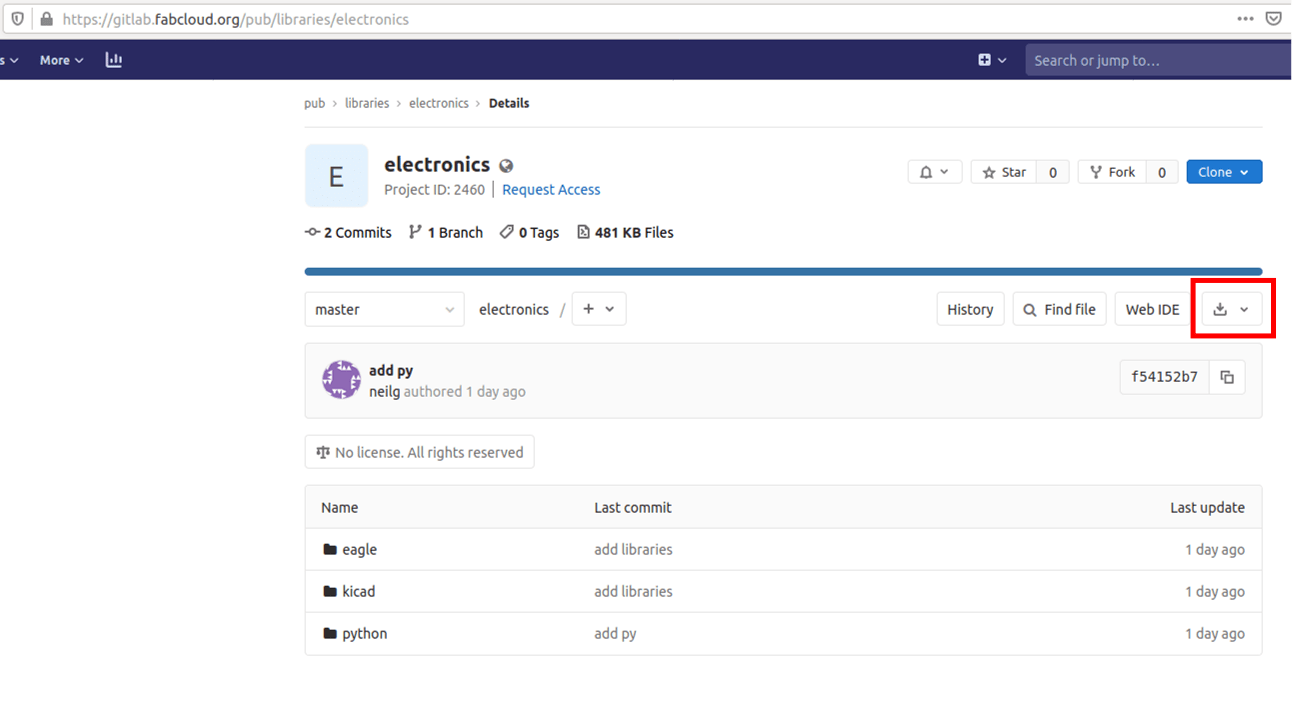

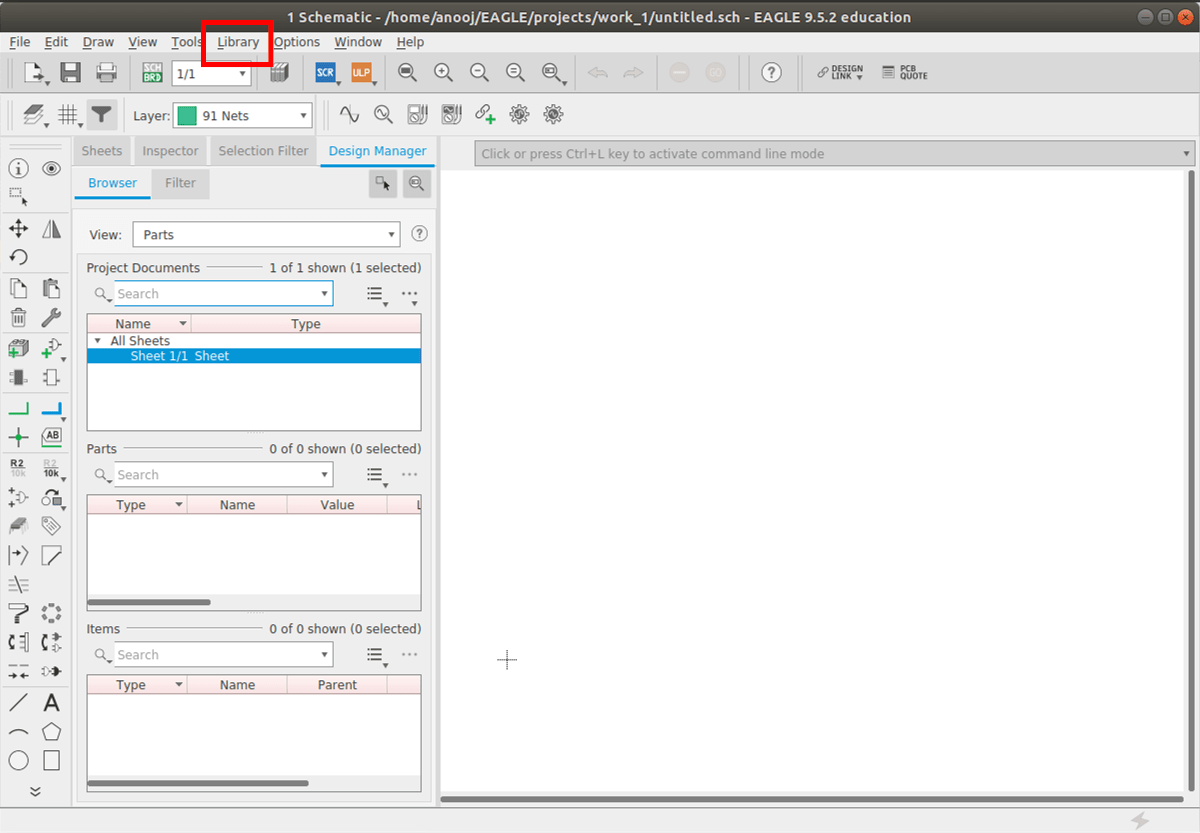

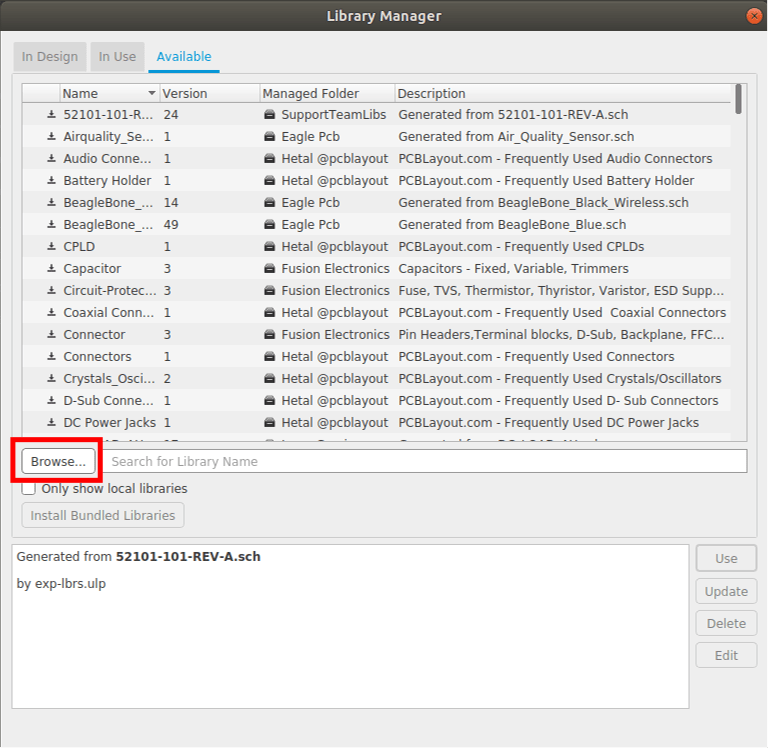

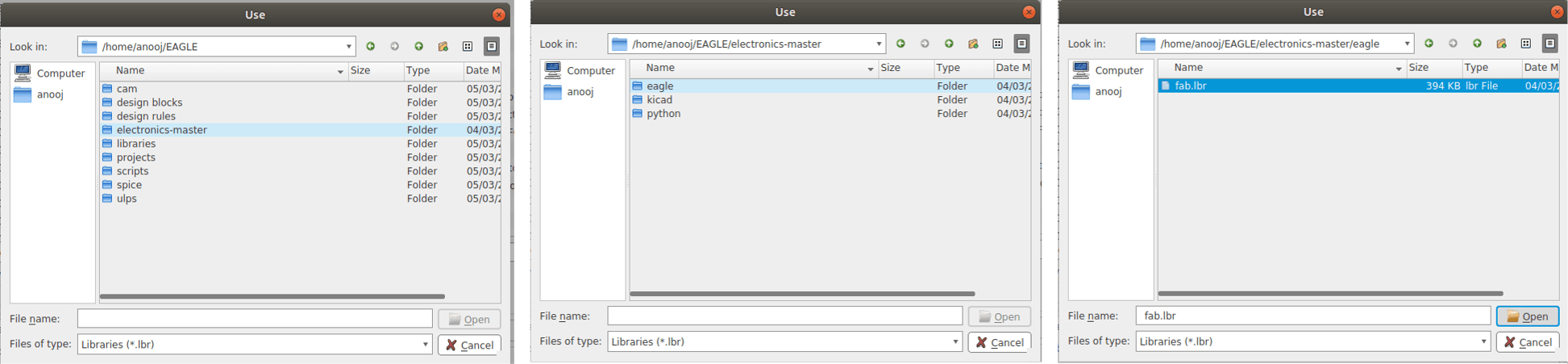

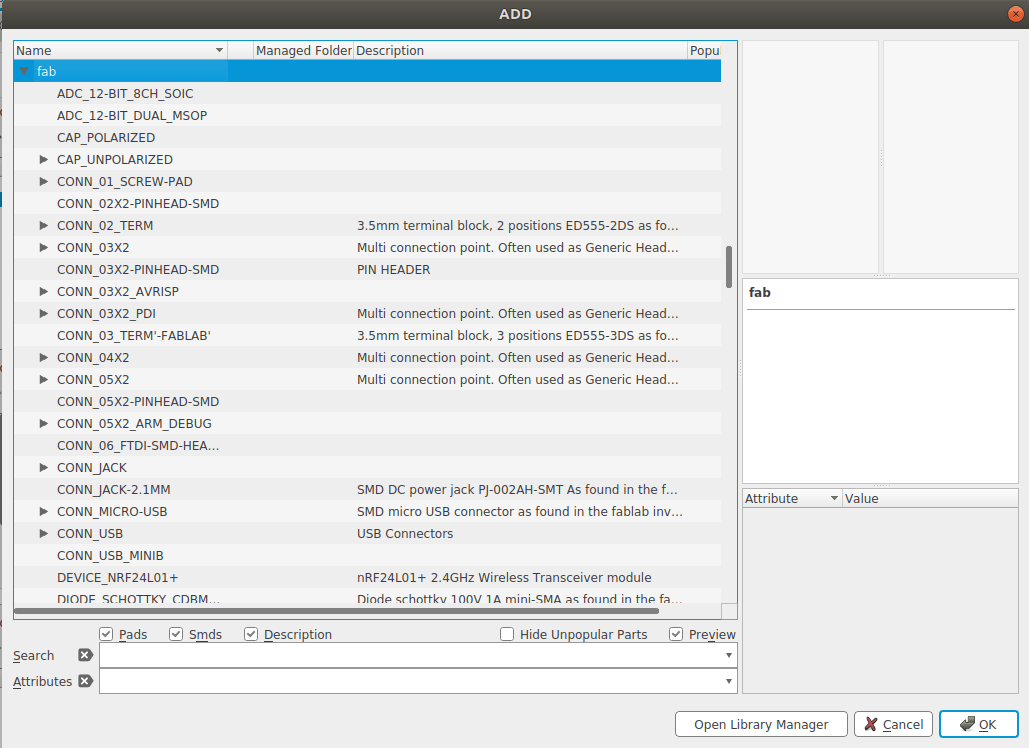

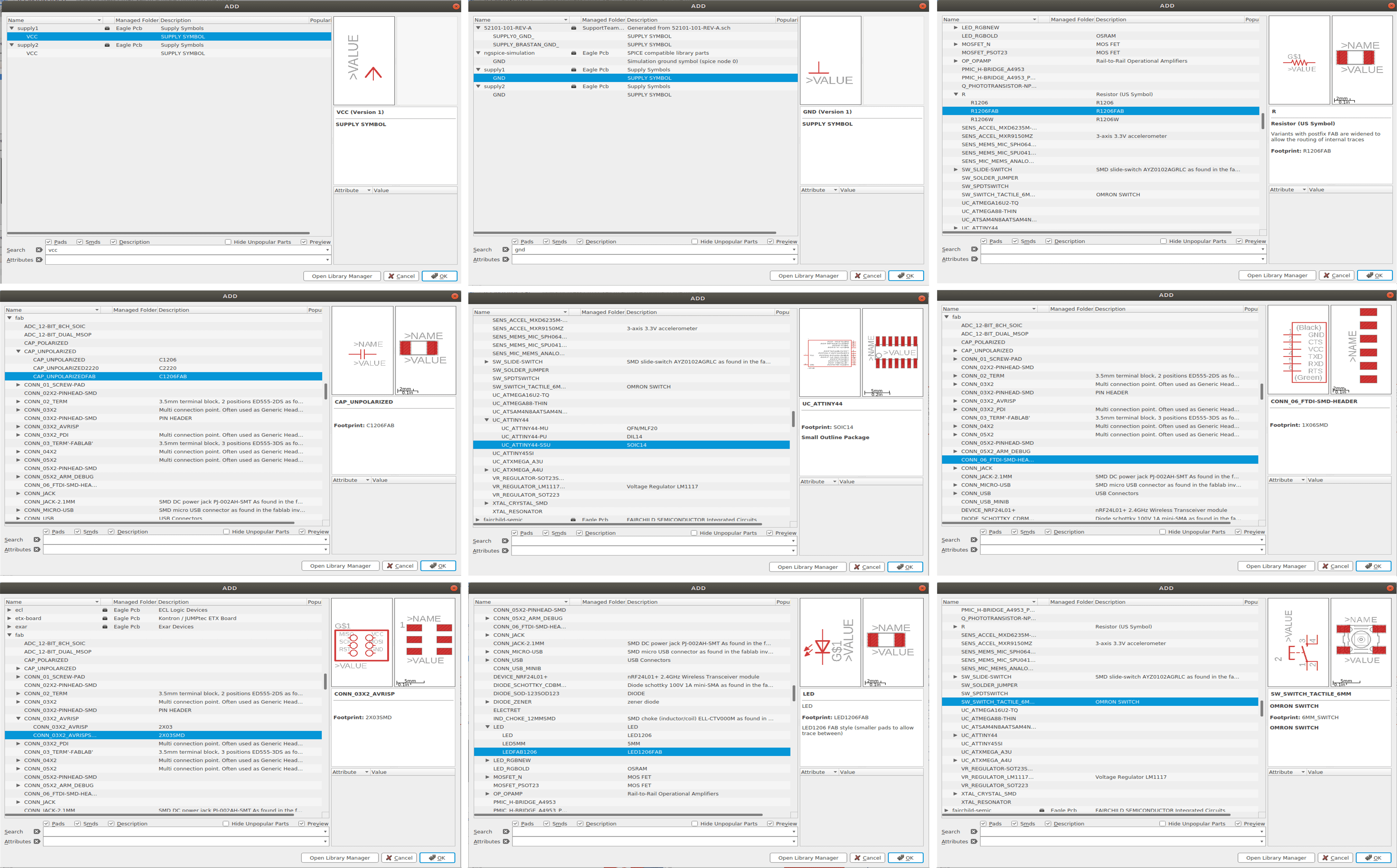

FAB Library

Learning Eagle

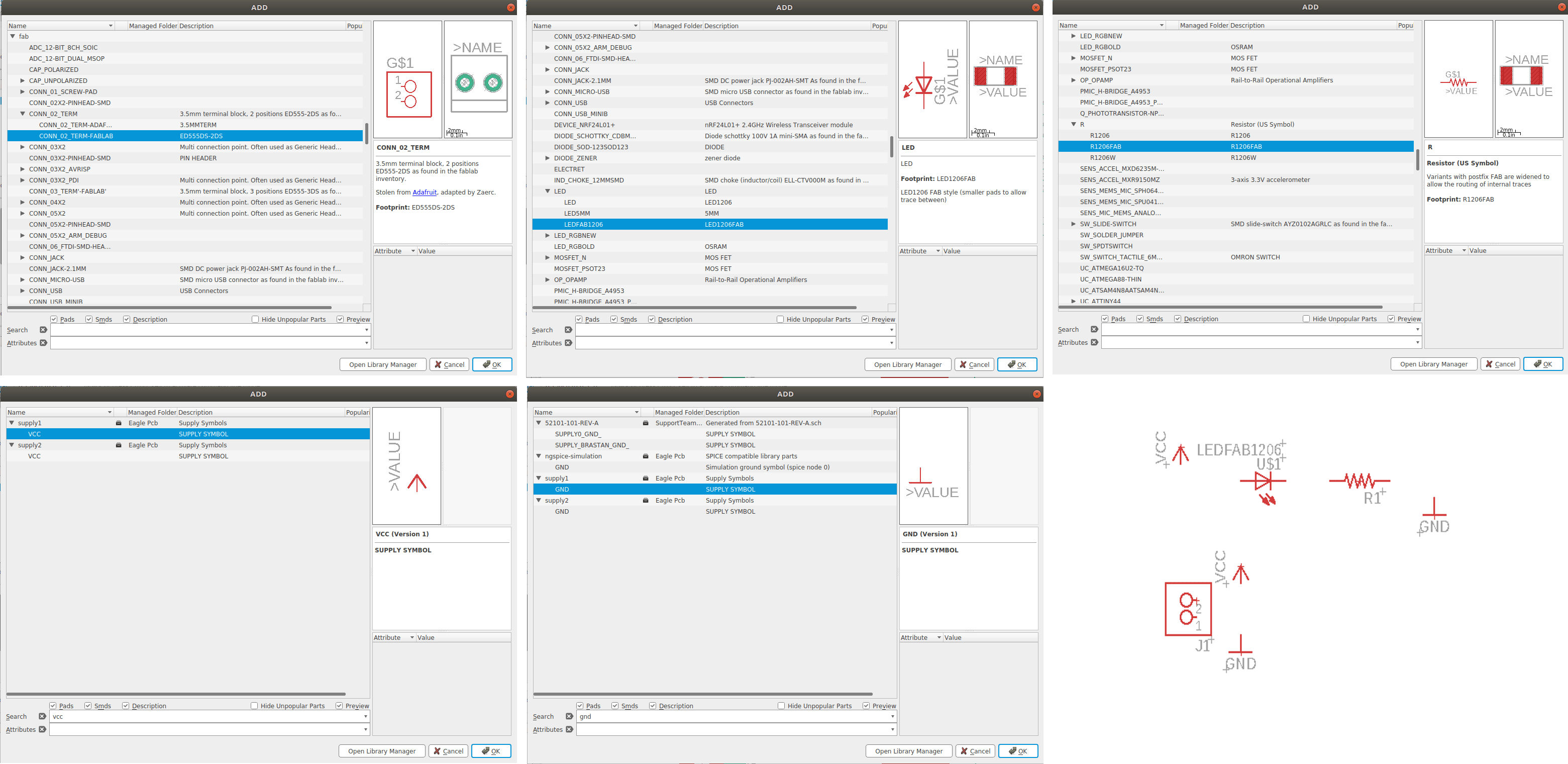

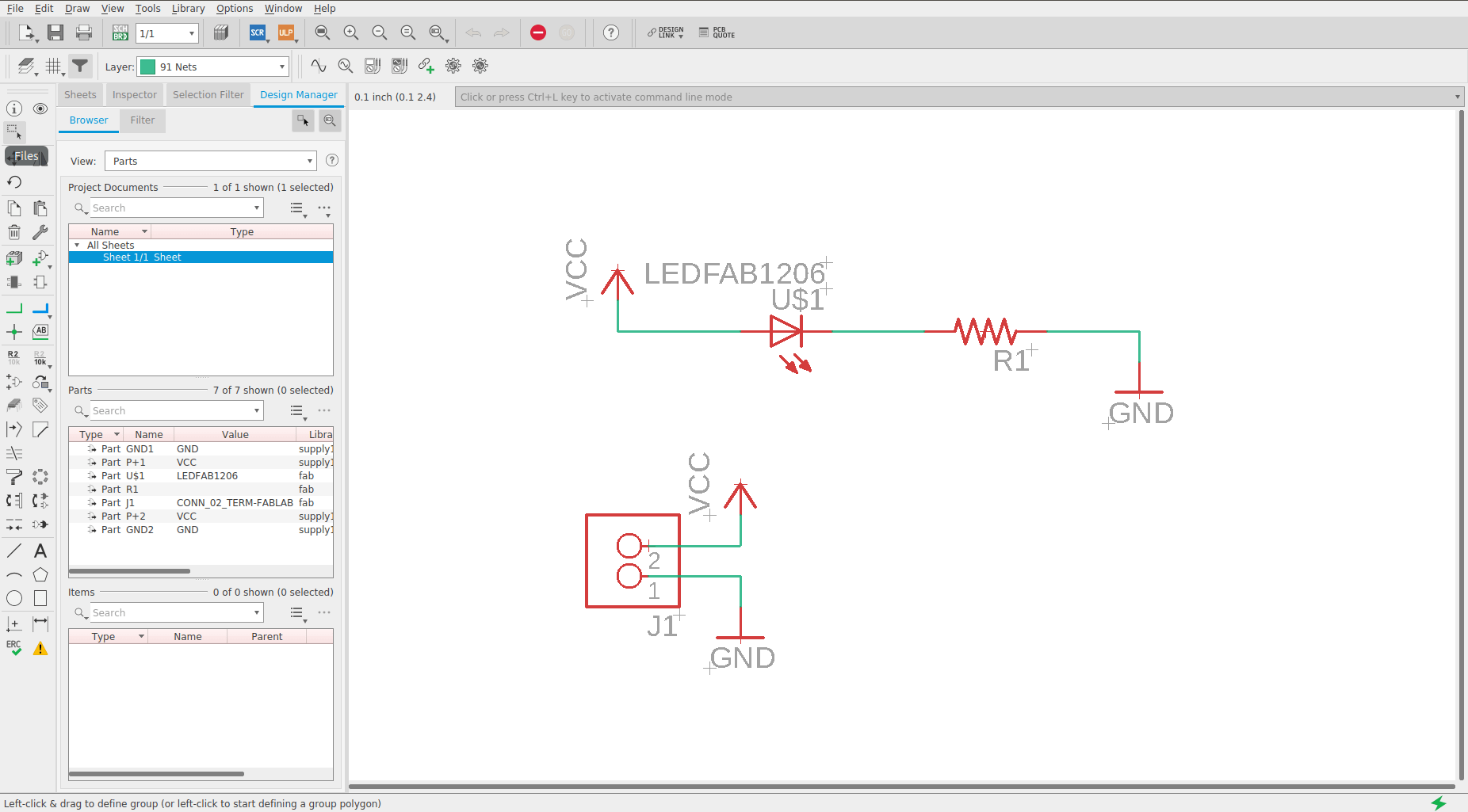

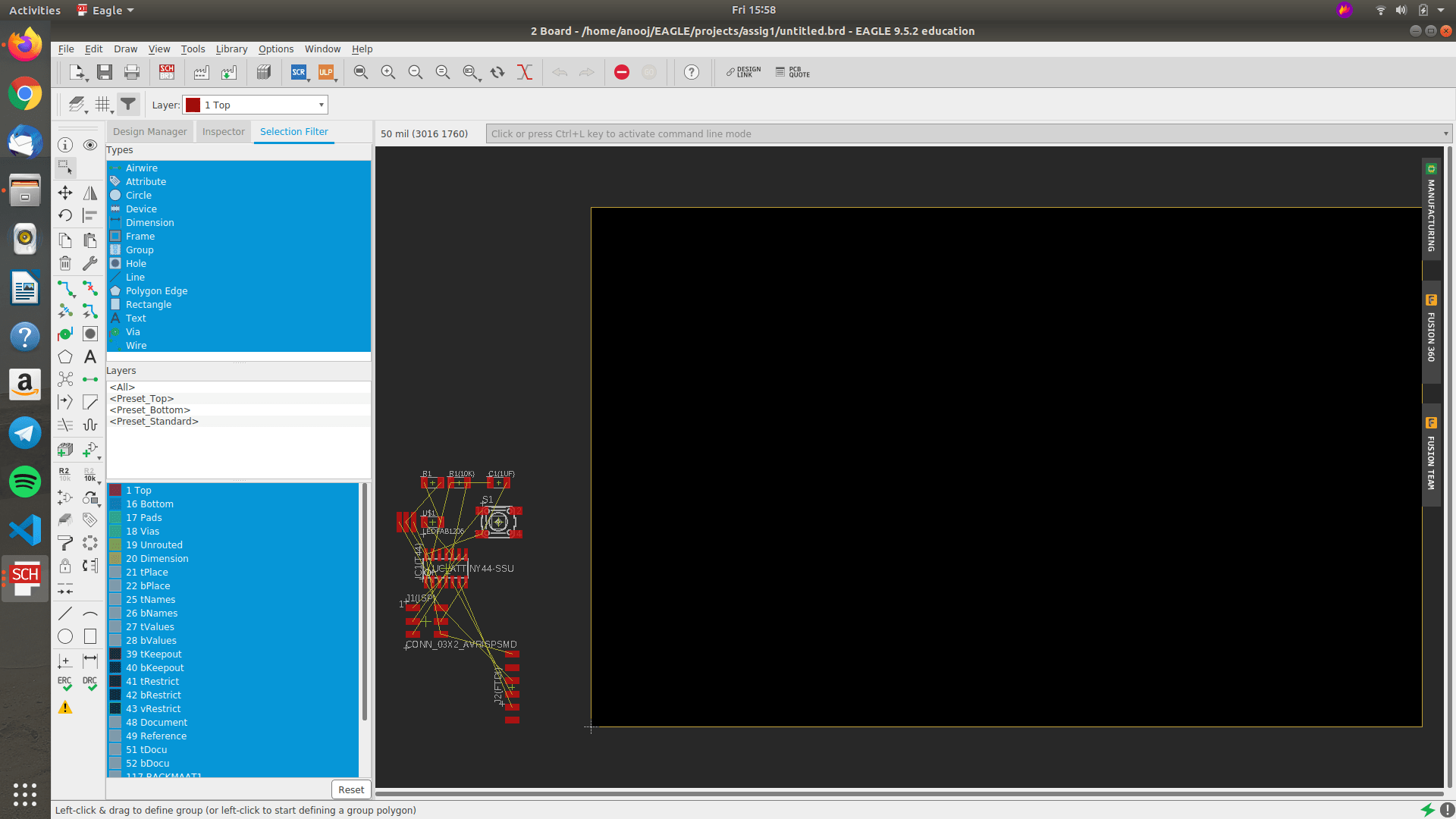

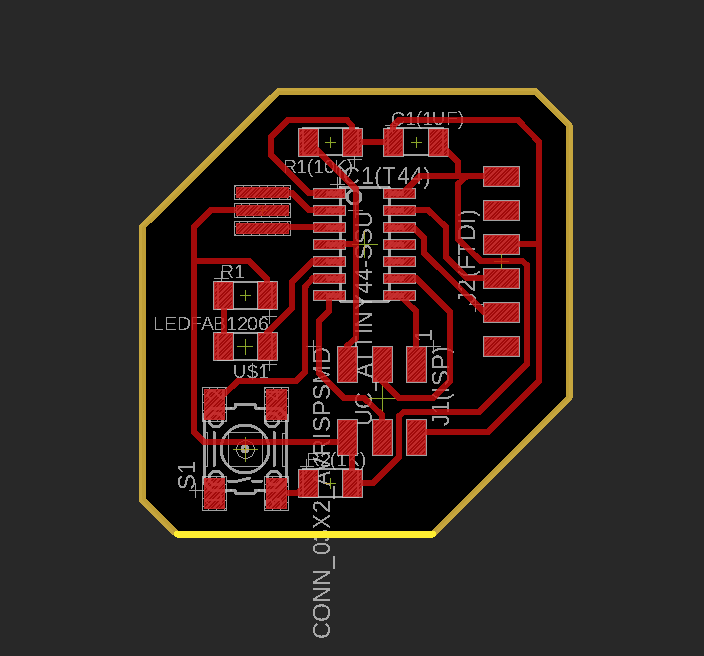

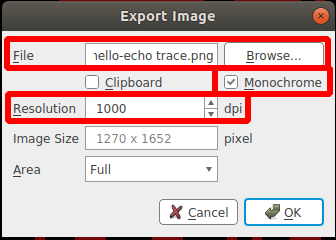

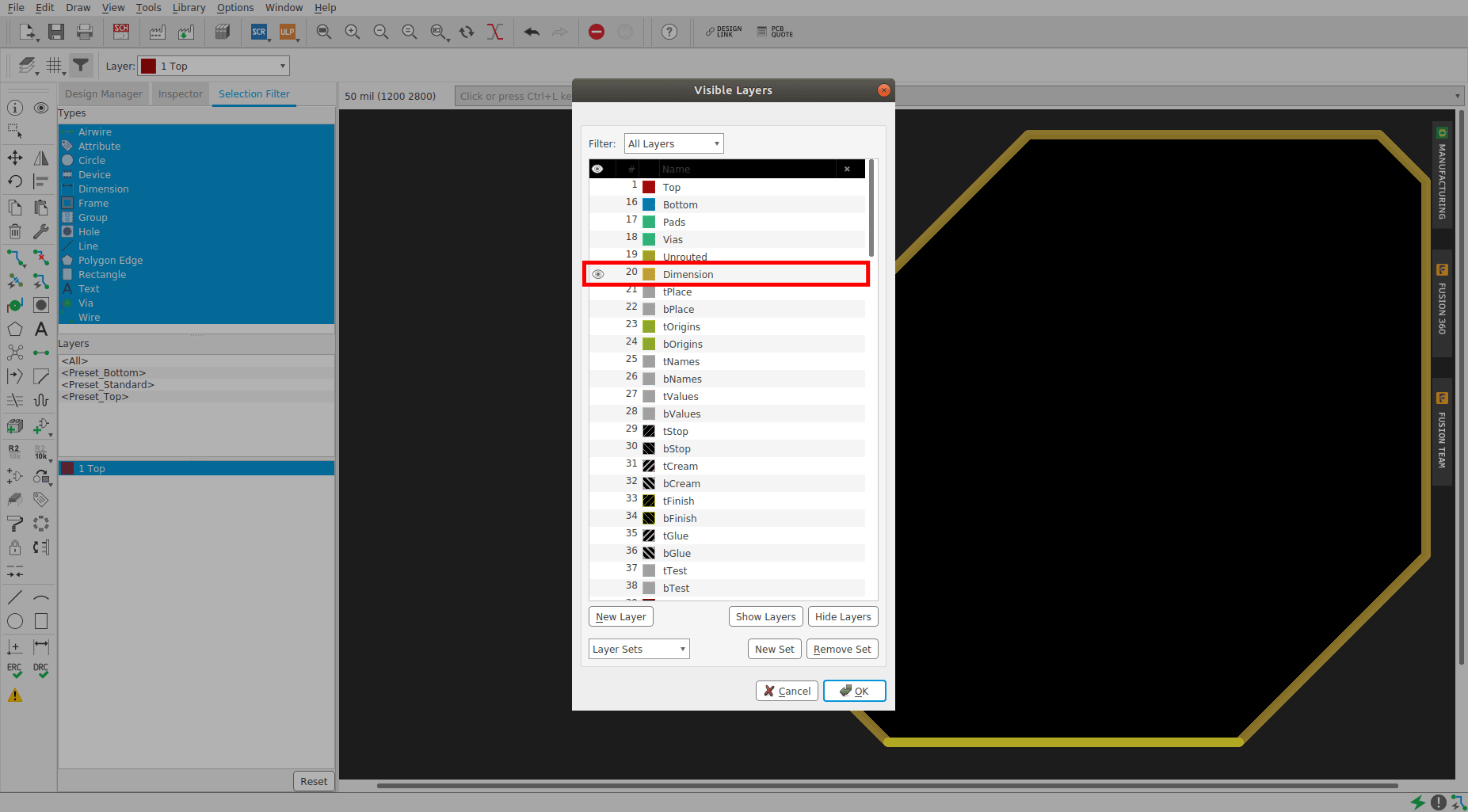

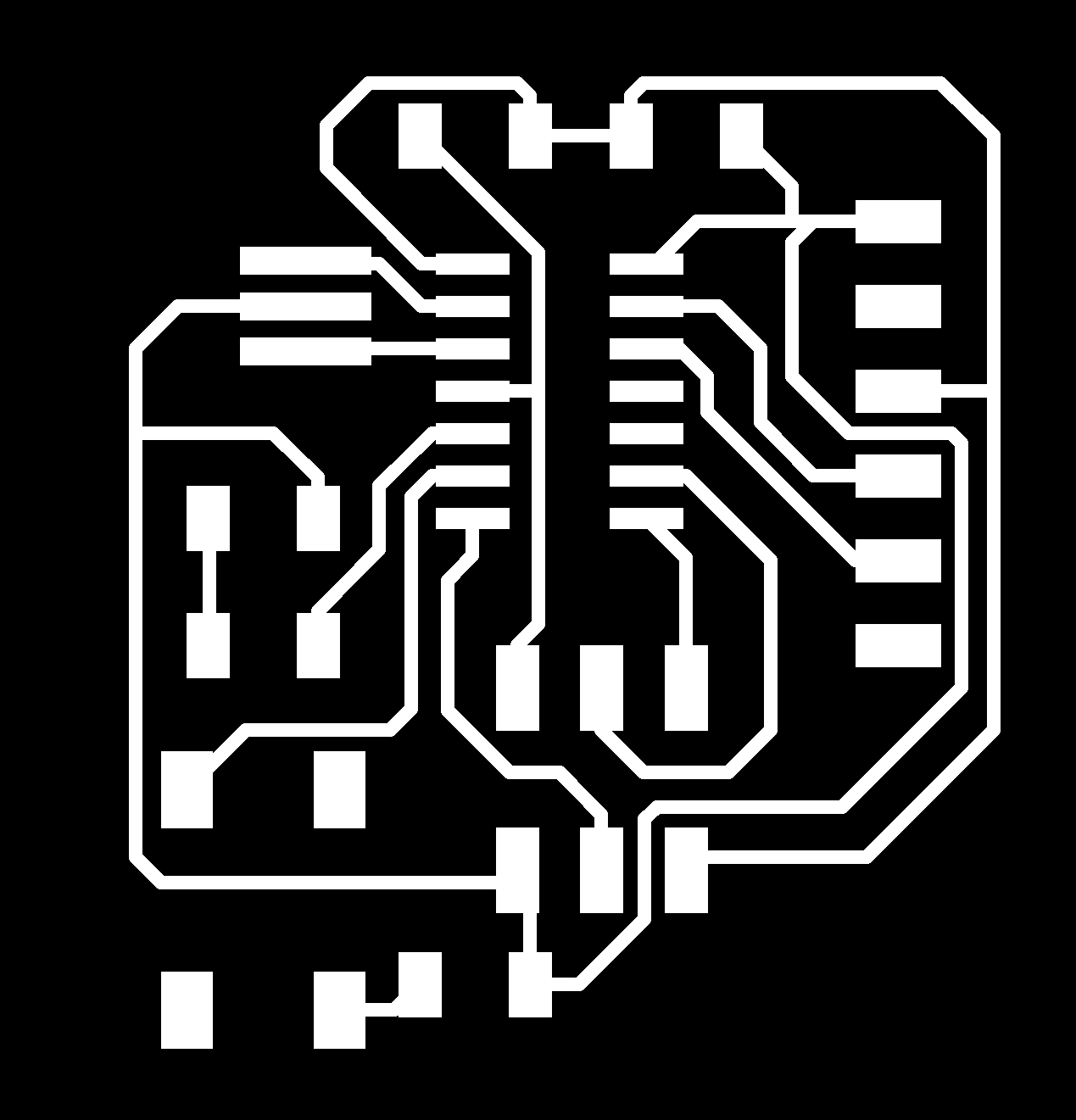

1) Redraw one of the echo hello-world boards, add (at least) a button and LED (with current-limiting resistor)

1) VCC

2) GND

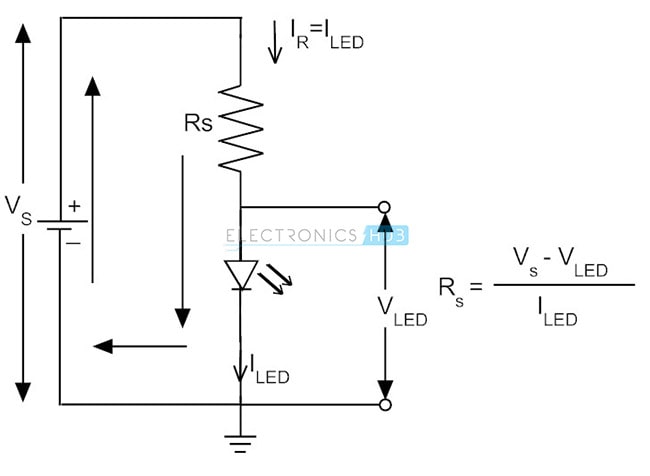

3) Resistor

4) Capacitor

5) ATtint44

6) FTDI

7) ISP

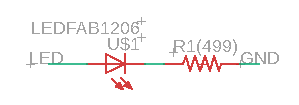

8) LED

9) Tactile switch

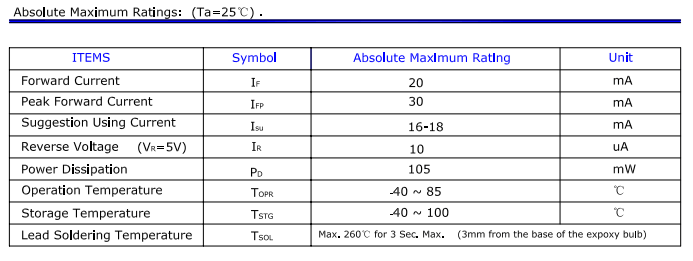

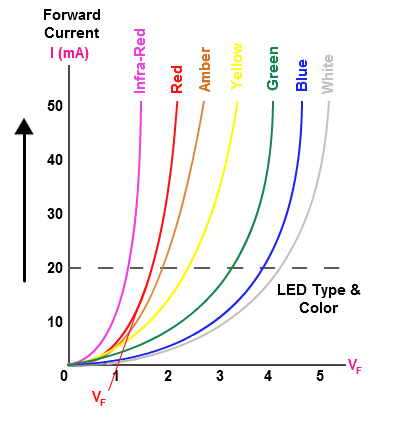

Vf = 2V

If = 20mA

Rs = (5-2)/0.02 = 150 ohms

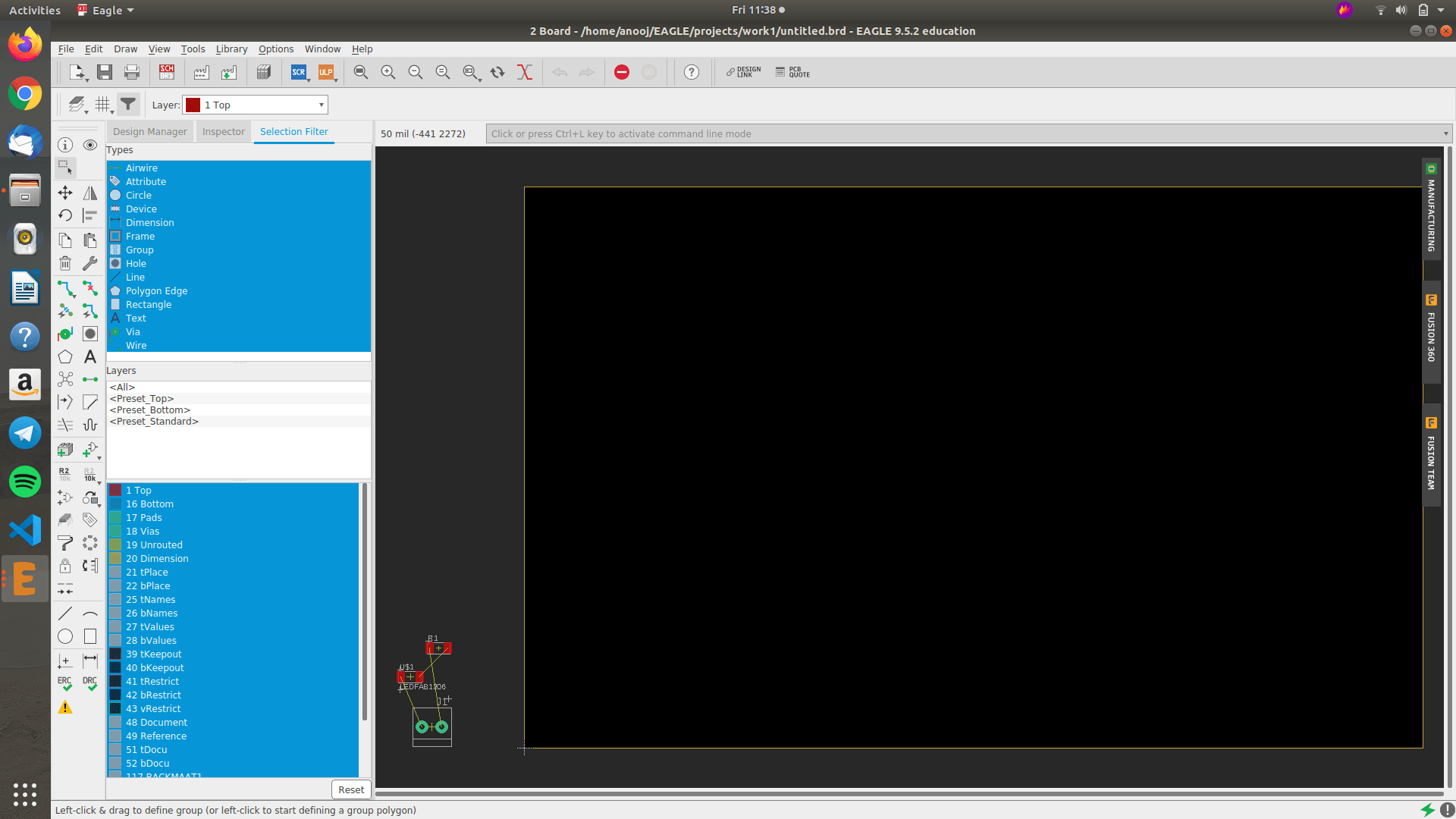

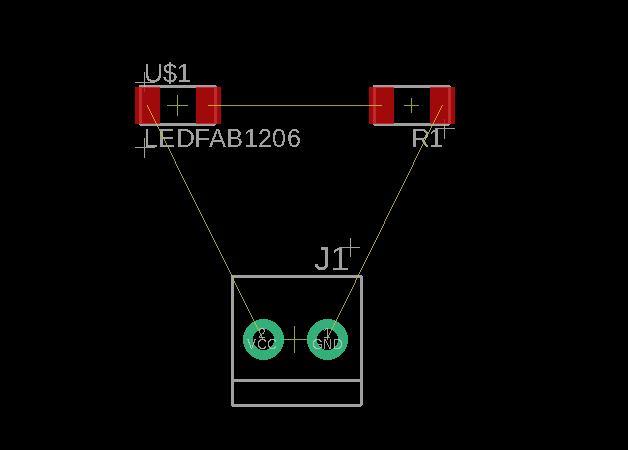

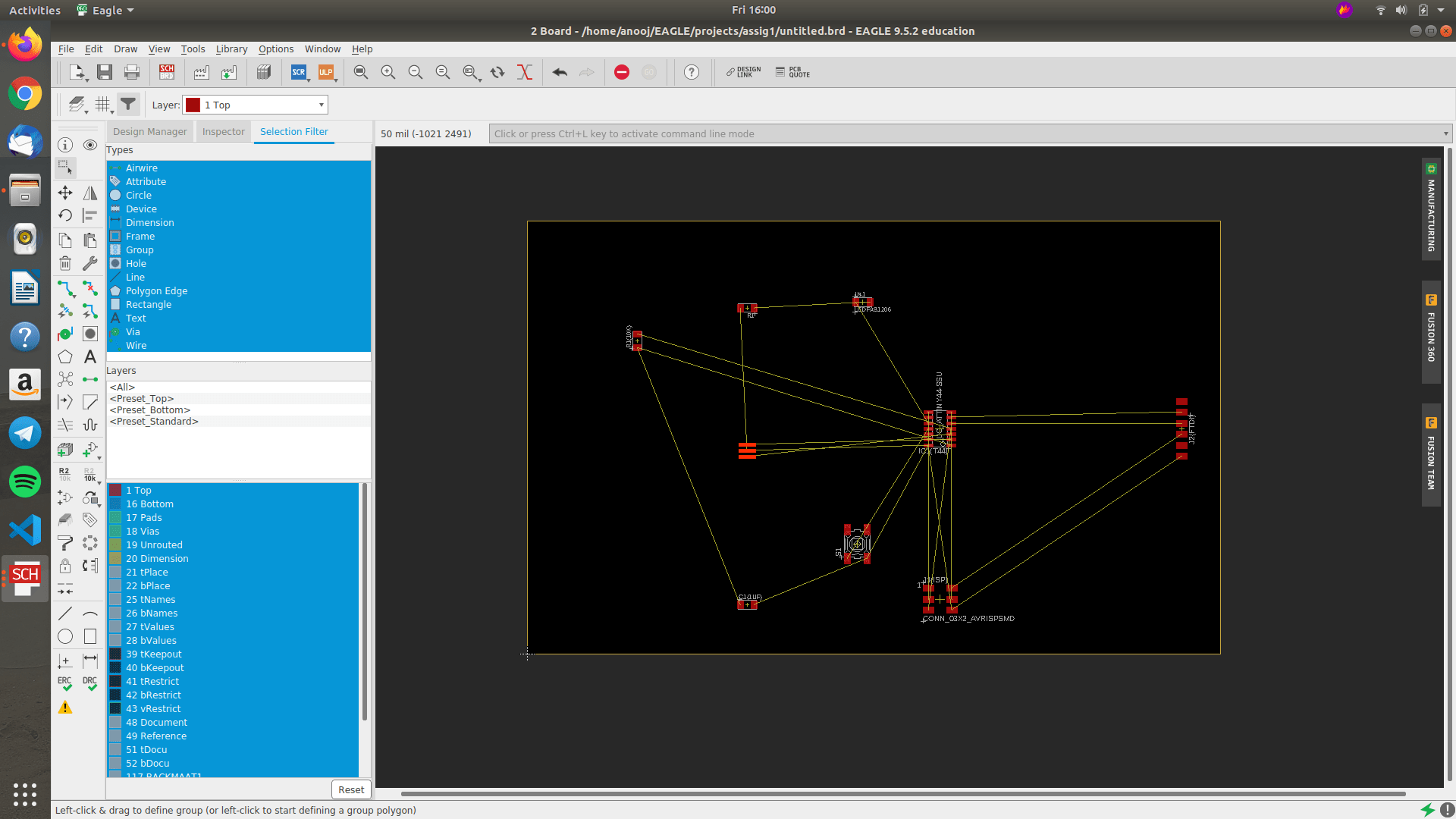

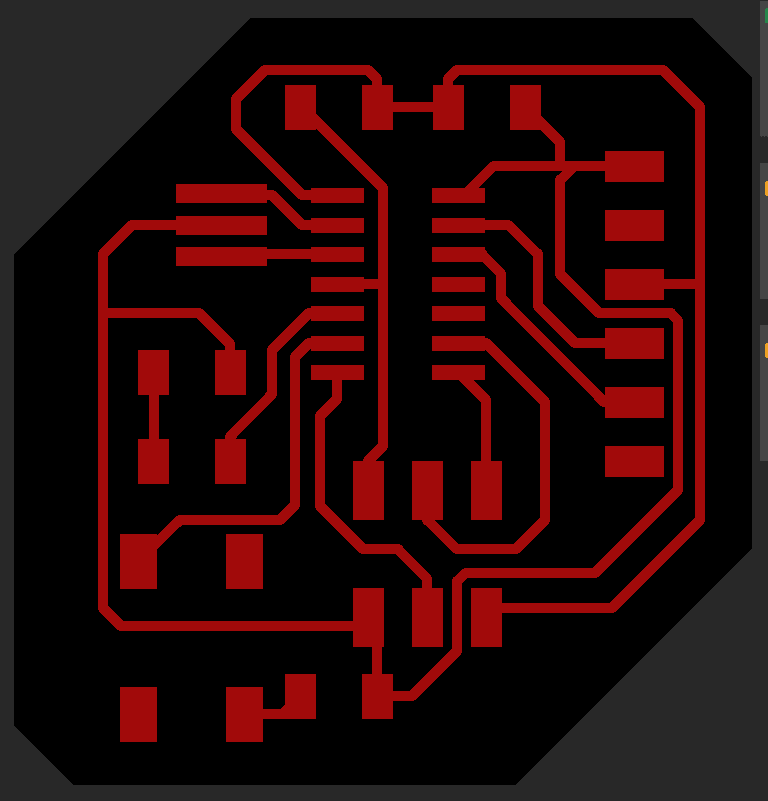

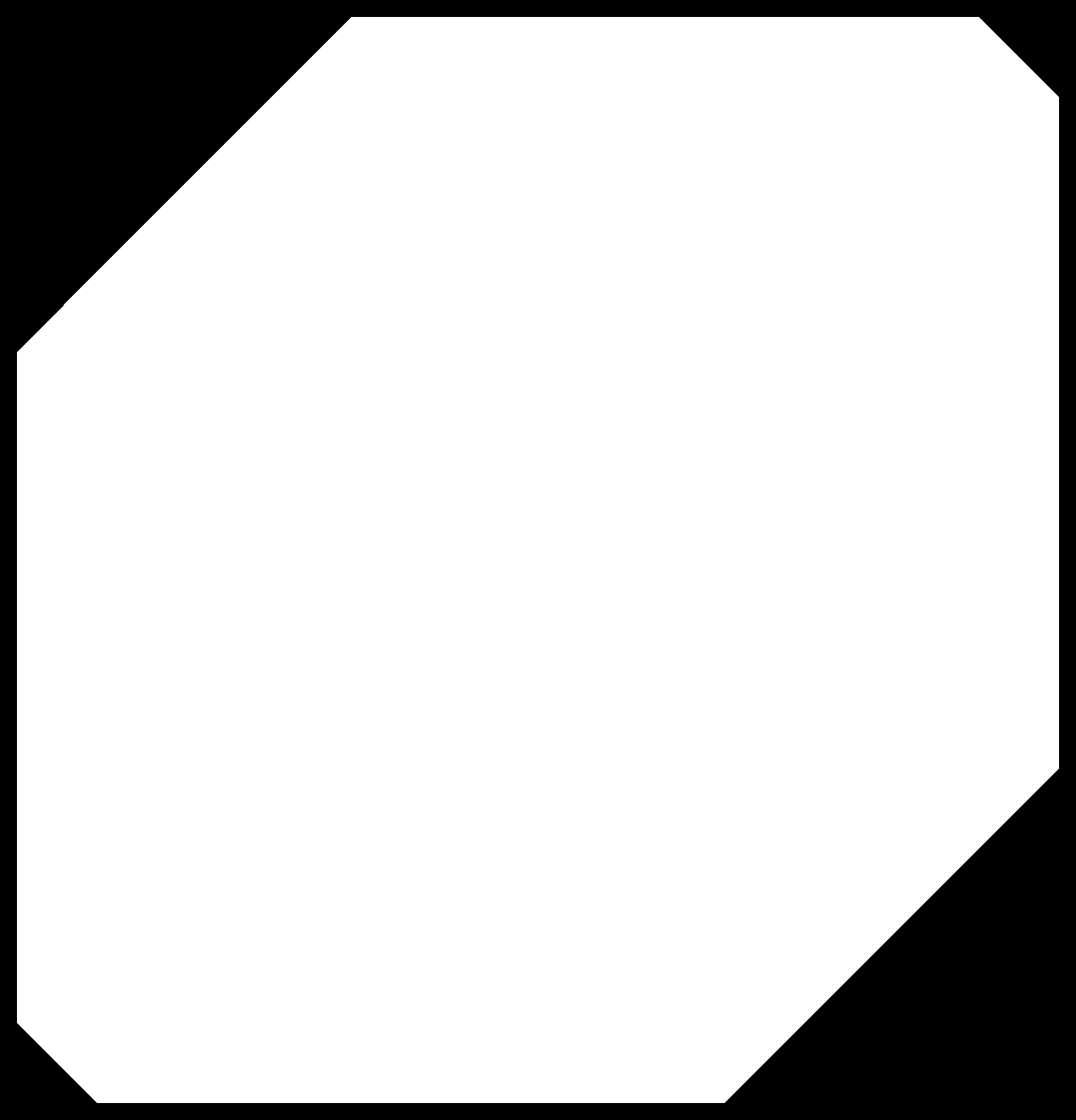

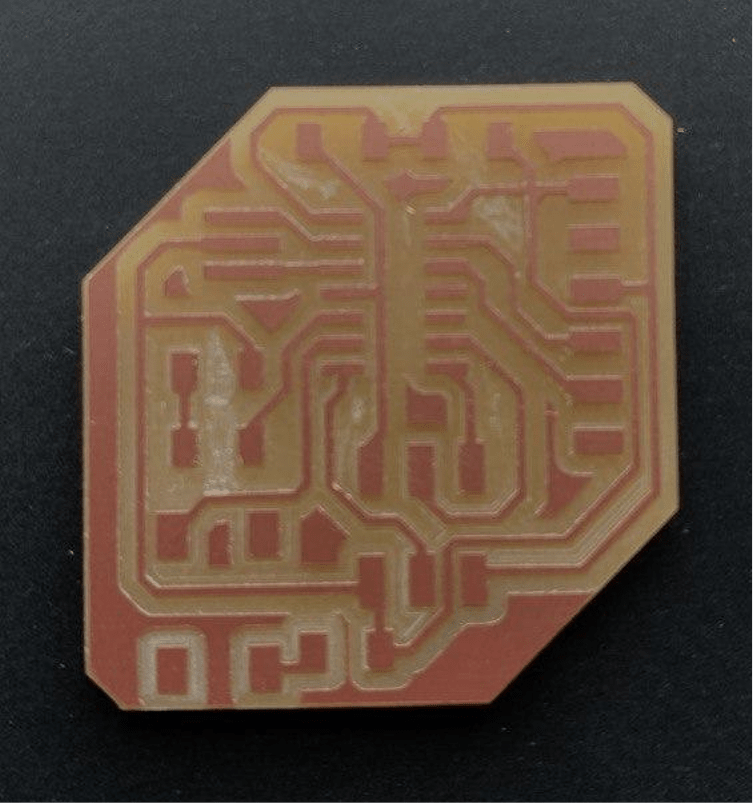

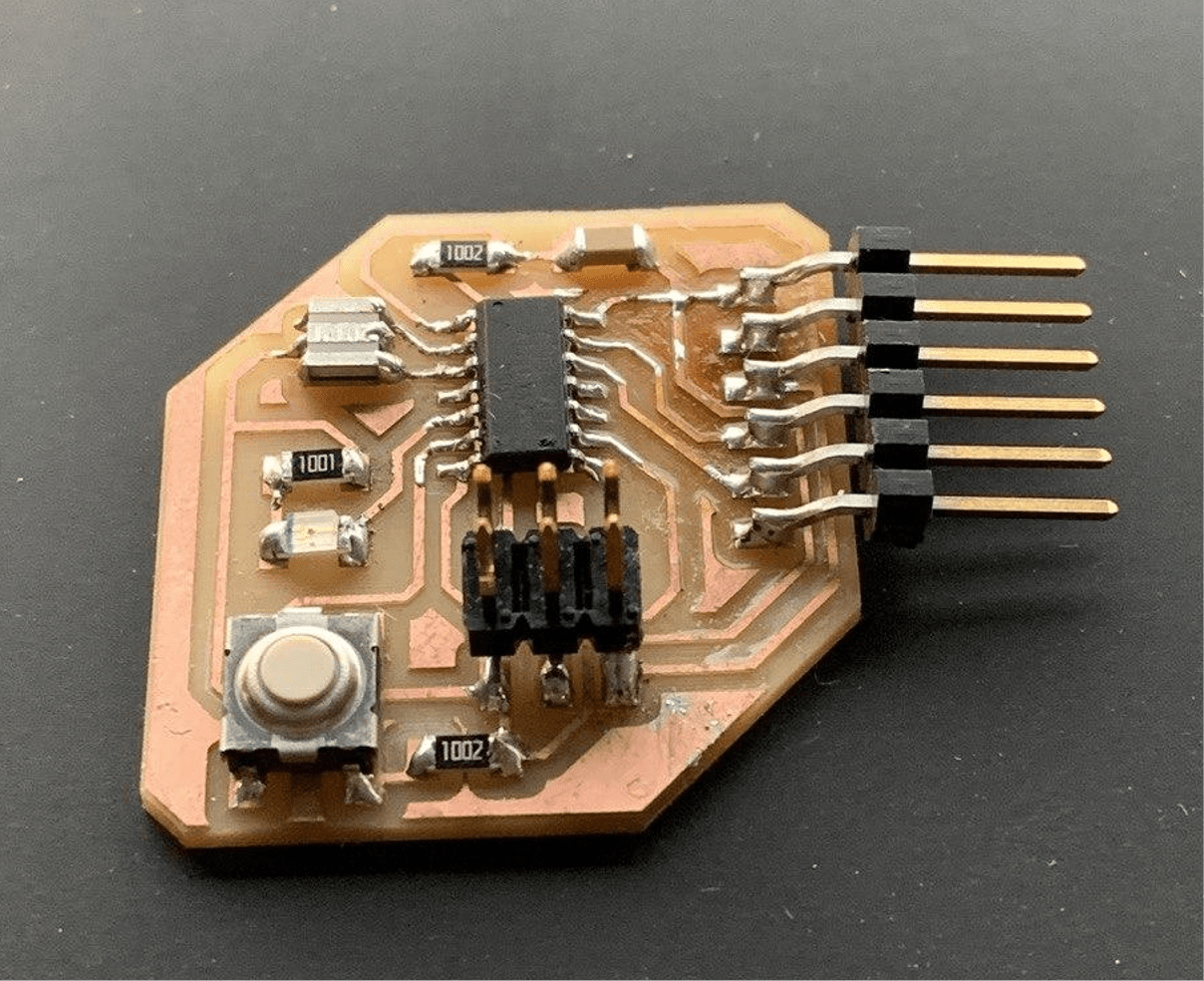

2) Make it

1)ATtiny44 - 1

2)ISP -1

3)FTDI - 1

4)XTAL 20MHz -1

5)Red LED - 1

6)Tactile switch - 1

7)10k resistor - 2

8)499 resistor - 1

9)1uF capacitor - 1

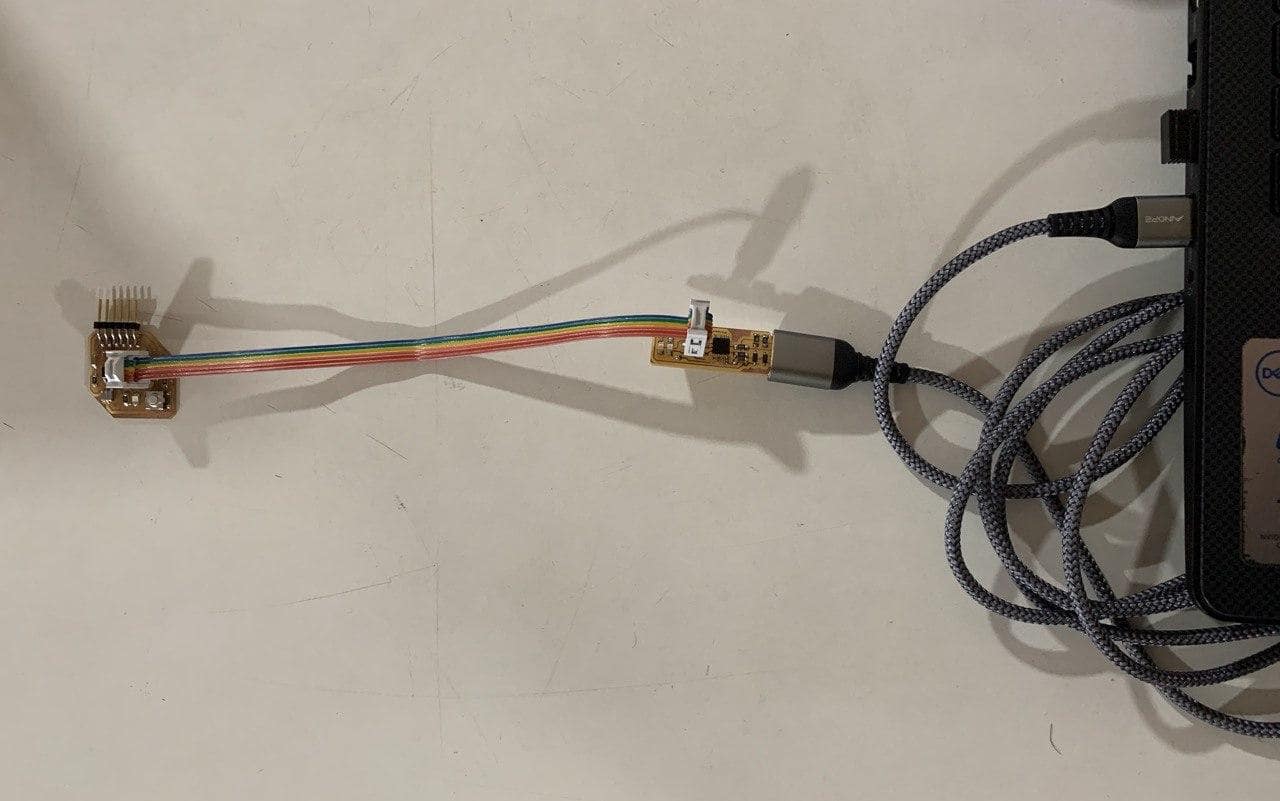

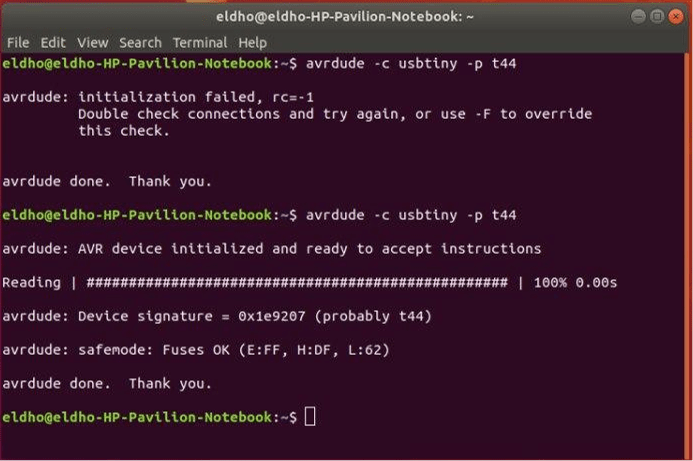

3) Test it

Make sure that the ground (GND) of both the boards are connected to each other.