Week 16: Soft robotics (wildcard week)

This week we followed the composites class as part of the wildcard week. You can see video here.

I decided in this week to touch the topic of soft robotics trying to build some basic inflatable deformable structures the beginner way (…still far away to make soft robots).

Simple design

An easy way to create inflatable structure is to alternate vinyl sheets with baking paper. By heating them, the vinyl sheets will stick to each other leaving a chamber in the surface occupied by the baking paper.

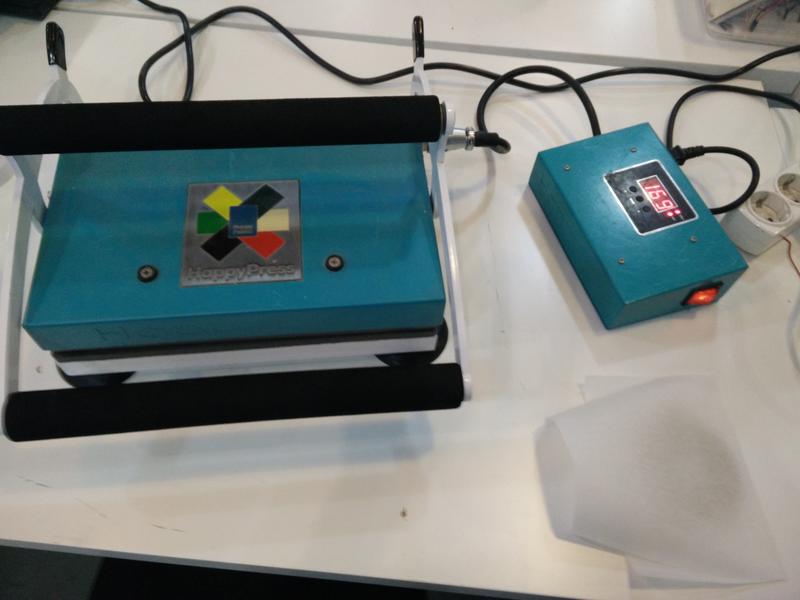

We used foe the initial tests a Happy Press heat transfer press from Happy Fabric.

The material that we choose is made of PU+PET sheets.

PU (or polyurethane) is a polymer used in many applications. It will give to our material a “fake leather” look. The PU film is the part that is going to adhere to the application surface when heated. PET (or polyethylene) is the support layer that will be peeled away after heat-pressing the material.

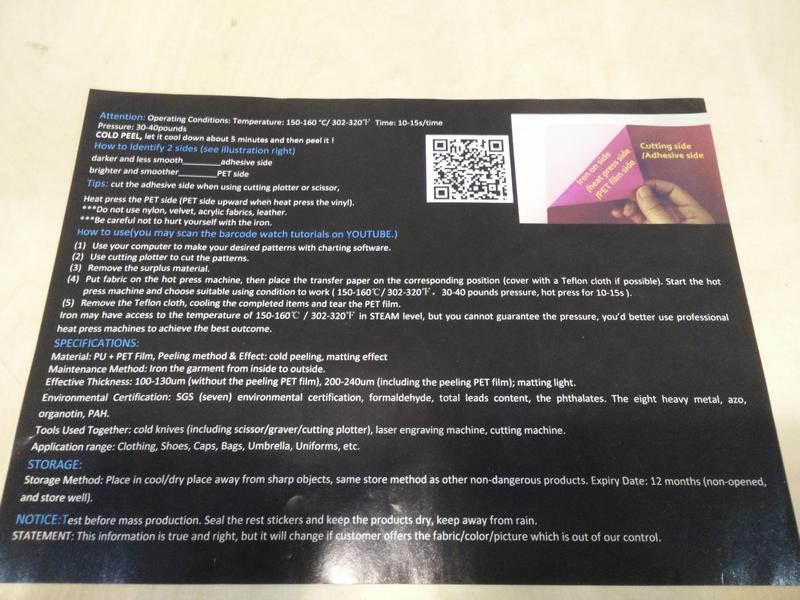

The leaflet below summarises all the characteristics of this material:

Using the control on the Happy press we can set the temperature required for our material 150-160 deg (for around 10-15sec).

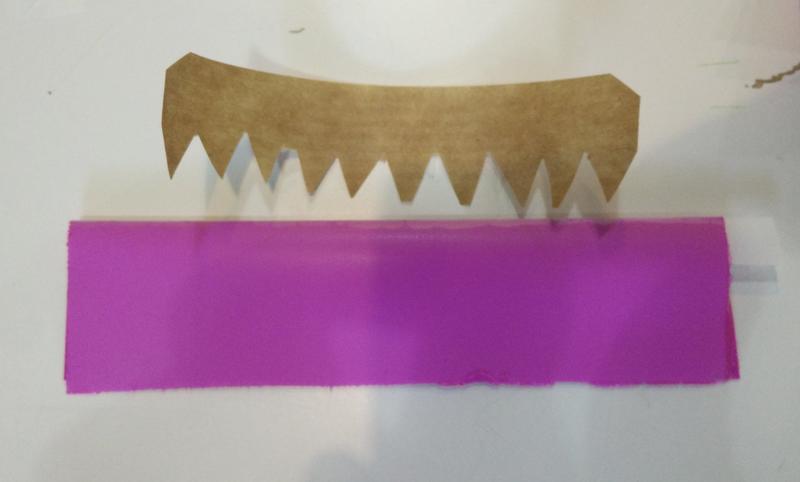

The first test I did was to check how a saw type of structure bends and test the use of the material.

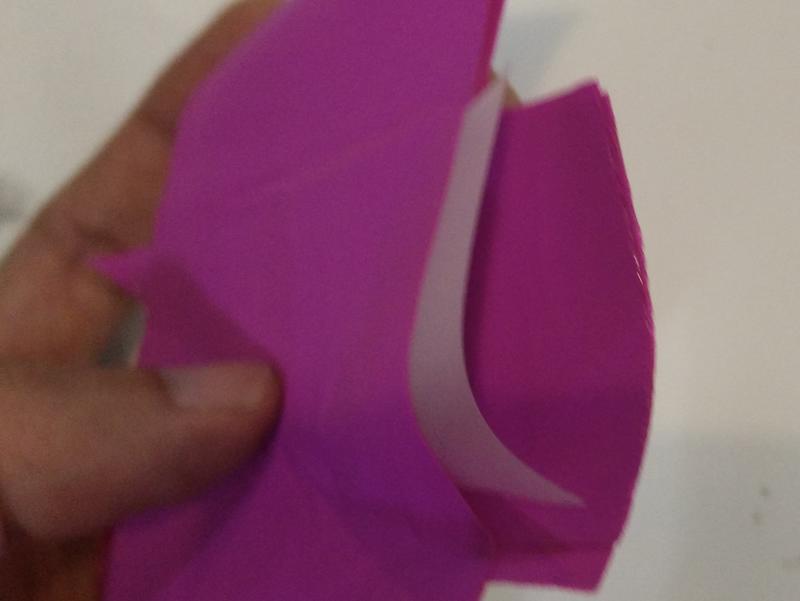

Unfortunately using a single sheet of vinyl fabric is leaking air. Folding the same sheet of material causes bends along which air tend to leak.

I created a new simple examples just to test the sealing.

And it works! :)

Multiple layers folds

As a second test I wanted to create a structure with holes created by overlapping 4 sheets of vinyl material (and two of baking paper)

After presssing I unfortunately relaised that becomes almost impossible removing the vinyl support material from the iternal parts of the holes.

Circle structure

Finally I wanted to create a structure that could be used to grap objects like a circle that changed diameter.

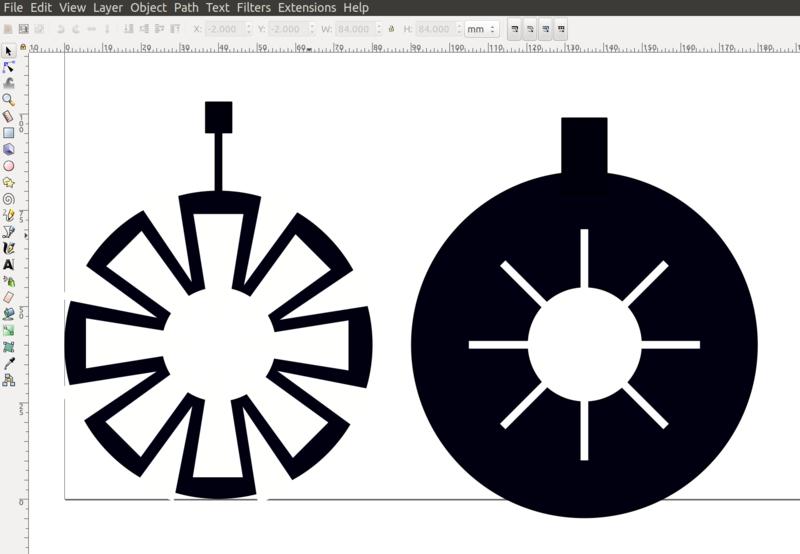

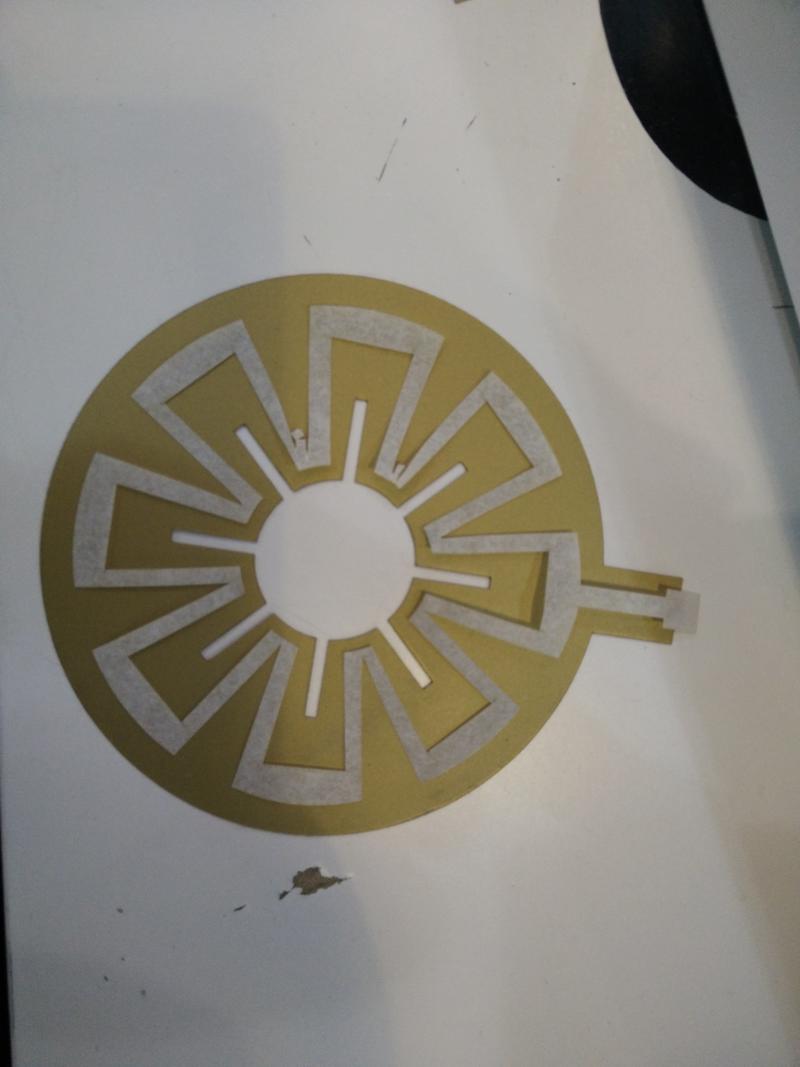

I designed for this purpose the following structure.

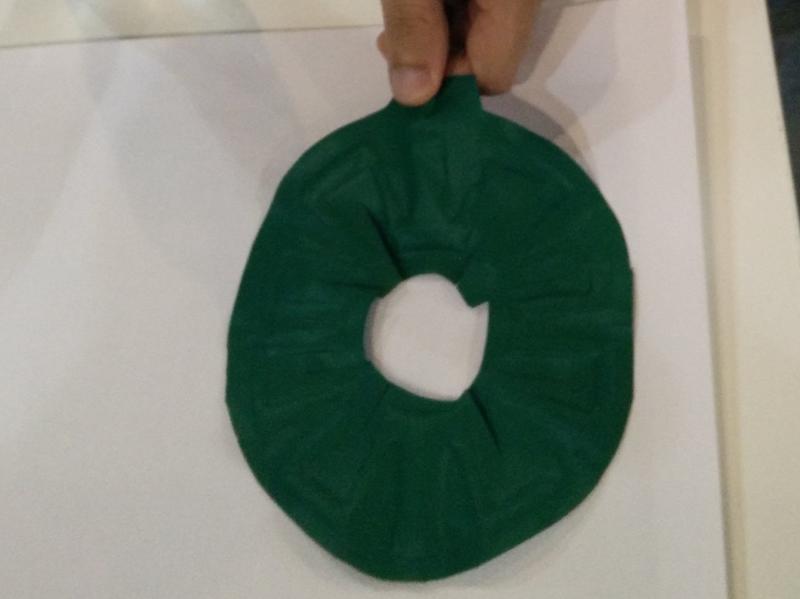

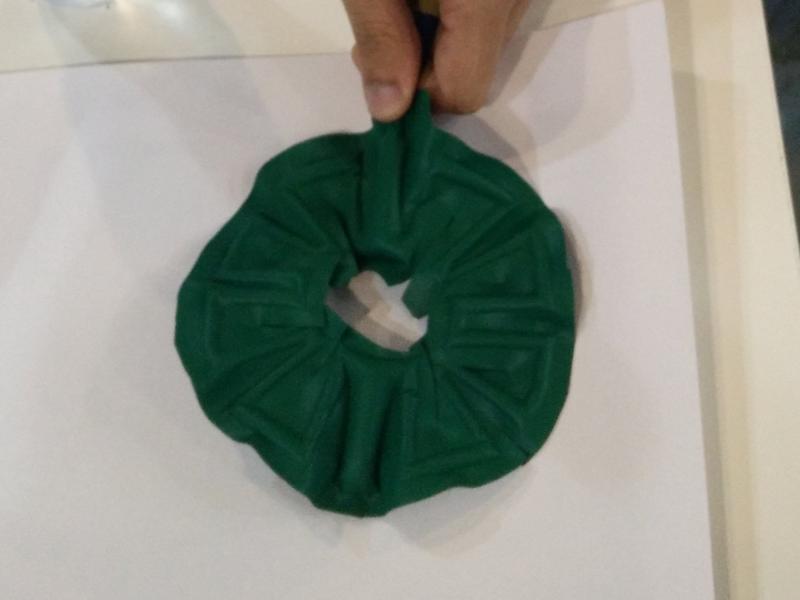

The inflatable at rest  …and under pressure! :)

…and under pressure! :)

You can notice that the internal circle has a smaller diameter and can be used to grab light objects,

Model

I designed the model in inkscape to be used with a laser cutter machine.

The design was easy to make combining circles and triangles and rotating them by +45 degrees.

After overlapping them accordingly we can transform objects to paths and use Path->Union and Path->Difference until we get a single contiuous path.

Download .svg file (.zip archive)

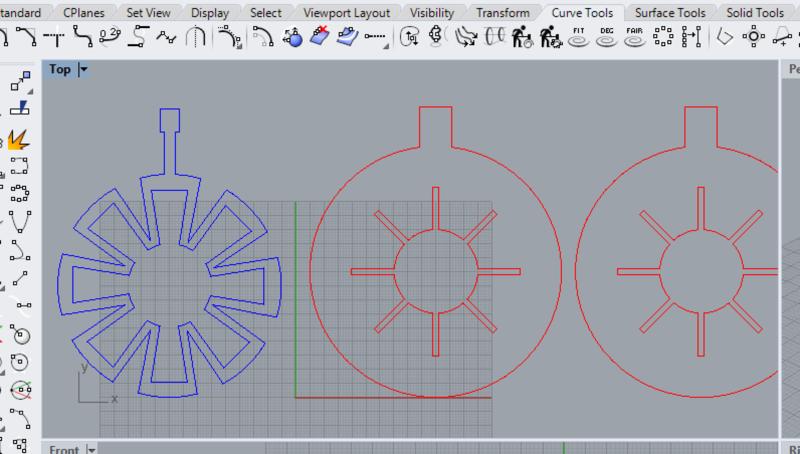

We then just import the .svg files in Rhino for processing them with the laser cutter machine.

The materials can be used in a laser cutter with the following settings:

Baking paper:

| Power | Speed | PPI/Hz |

|---|---|---|

| 6 | 0.9 | 1000 |

Vinyl:

| Power | Speed | PPI/Hz |

|---|---|---|

| 20 | 0.9 | 1000 |

The baking paper was hard to cut because it tends to bend and wrinkle when heated. The paper was also too light and easily blown away by the laser cutter air aspirator: I decided to turn it off for this specific cut.

The vinyl cut was easier, I I realised I had made a design dimension error and had to do it twice to get the correct result here:

After pressing two sides together in the heat press machine and removing the protection layer here is the result ready to be tested:

In the video below you can see the object shape changing when the structure is inflated with a manual pump.

Personally I was expecting a bigger effect… not very impressed.

I realised the bigger air chambers are needed to have a bigger effect like on the one I manually cut.

Lessons learned

- Avoid folding the same sheet of material

- Avoid multiple layers of fold overlapping the air chamber

- Probablyy I have to design the air chanbers bigger to produce bigger displacements

Next steps

- Try silicone and fibers based structures combining materials with different elastic characteristics.

- Experiment the same structure in dofferent sizes of the circle radius and air chambers diameter to find optimal result.

- Work with electronically controlled pumps to inflate the objects