Computer controled cutting¶

Group assignment:¶

Characterize your lasercutter, making test part(s) that vary cutting settings and dimensions

What we have done¶

We deploy three tests:

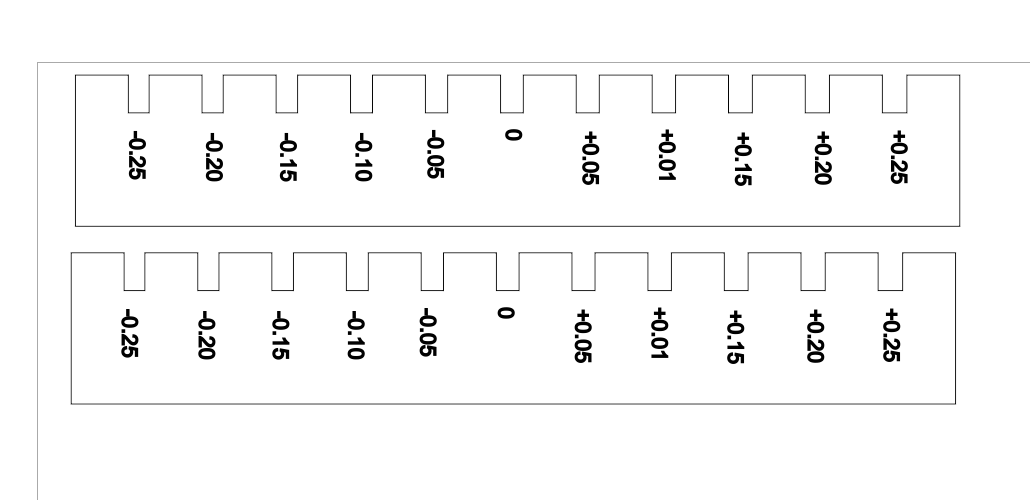

- Press fit, using two combs with different teeth width (Process 1)

- Power and speed parameters, using color mapping to cut rectangles at different settings values (Process 2)

- Kerf width on a straight rectangle of known length cut in 10 equal pieces (Process 3)

Resources available @Fablab ULB:¶

- The laser cutting machine is a CO2 60W EPILOG MINI, with a useful surface of 30x60 cm, interfaced with CorelDraw

- Available material for the test is a 3mm MDF wood plate.

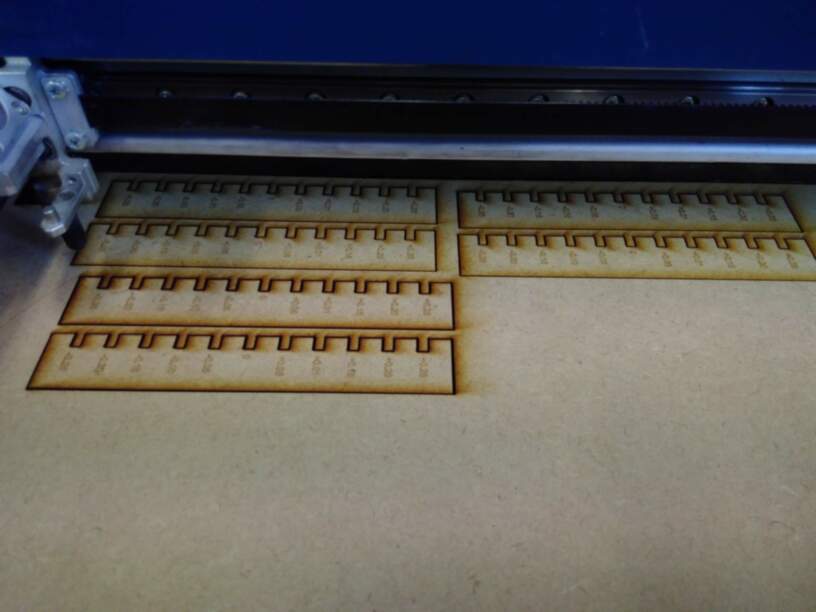

Process 1:¶

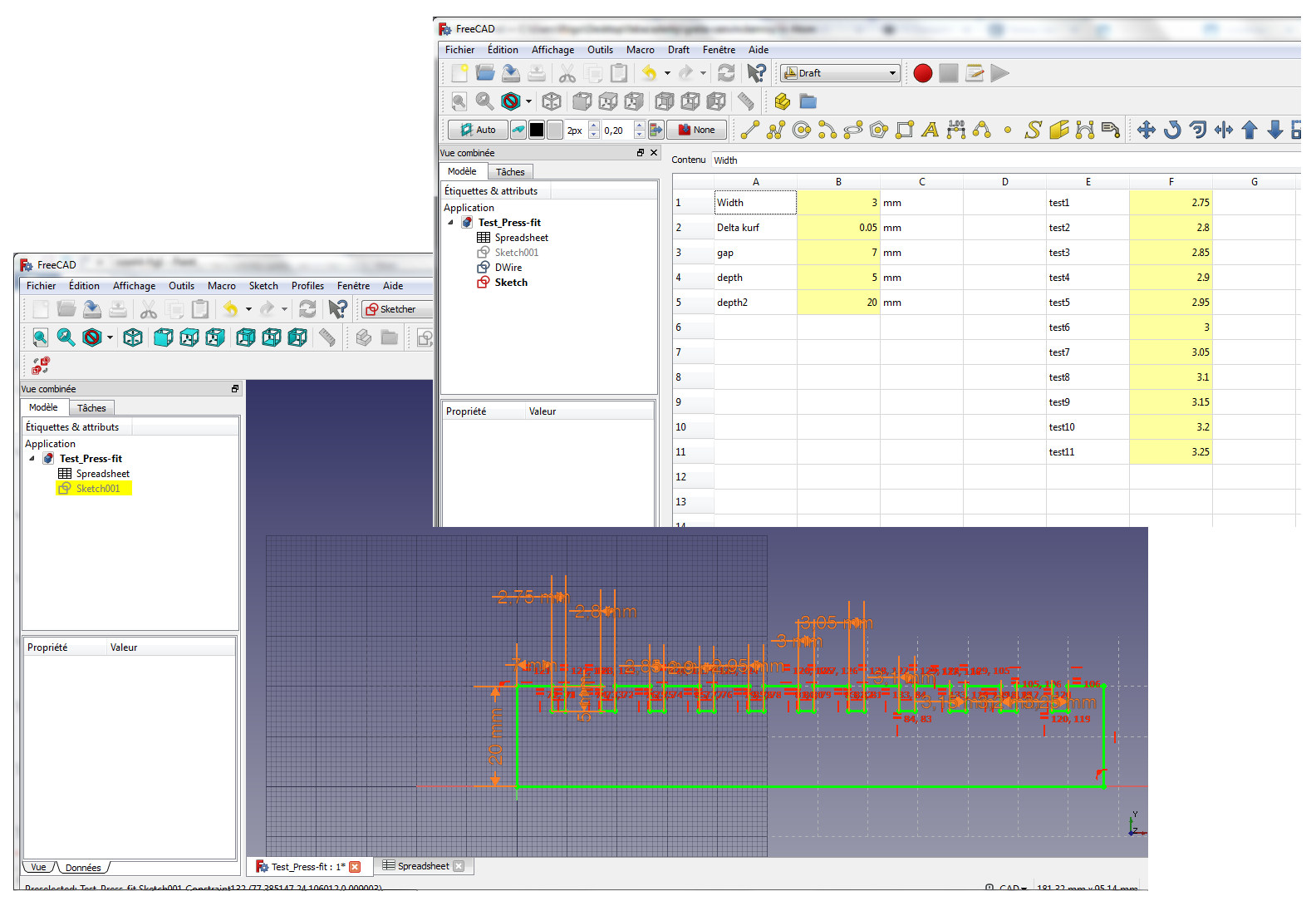

A parametrized comb structure is defined in the FreeCAD Sketcher module, using a parametrization based on the width plate as basic parameter (all parameters defined in Spreadsheet)

- Plate width: 3mm (alias: width)

- 11 variable slots sizes varying from with-0.25mm to width+0.25mm, by step of 0.05mm (aliases: test1 to test 11 variables)

- depth of the teeth: 5mm

- overall depth of comb : 20mm

- distance between teeth (gap): 7mm

Here is the result:

In a second stage, the file is exported to DXF format (File > Export > Autodesk DXF 2D ) to be read by CoralDraw, the softawre used to communicate with the laser cutter. Note that the preference Allow FreeCAD to automatically download and update the DXF libraries must be turned on in FreeCAD.

In CoralDraw: * The width of each slot is added as text, to be engraved on the MDF plate. Do not forget to convert text to curve, and to change the text thickness to 0.2mm to make it more readable.

- Lines to be cut need to be defined as “ligne très fine” (very thin lines)

- Lines to be engraved do have a defined thickness

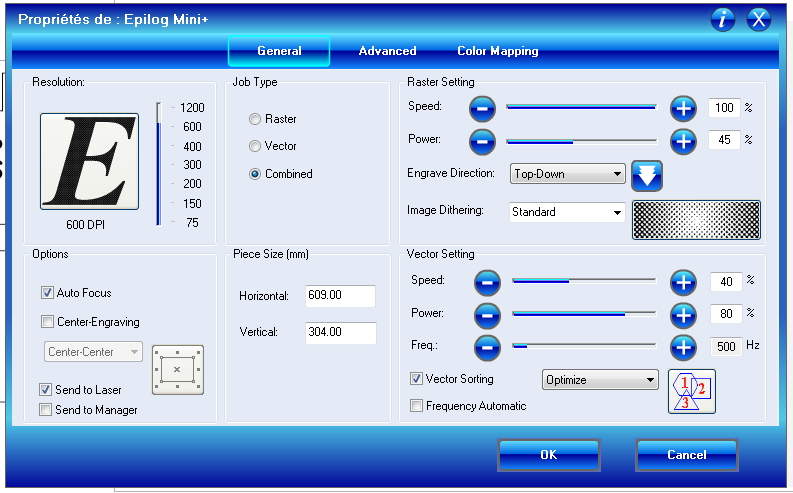

- When file is ready to be sent to printer, define the settings in the EPILOG driver in CorelDraw:

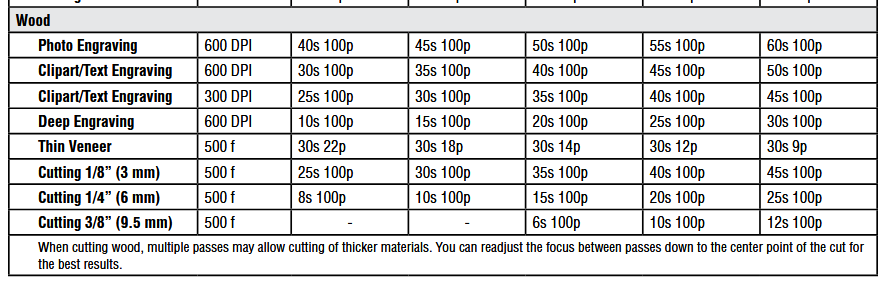

The standard settings for wood are given below (extract from EPILOG manual):

For a 60W machine:

- Text Engraving: raster, 600DPI, speed: 45, power 100

- Cutting 3mm: vector,pulse frequency: 500, speed 40, power 100

As both engraving and cutting are used, do not forget to check the option combined!

Printer setup : Place the MDF wood plate on the honeycomb support in the printer Caution: take care to start the design by defining the origin point through manual settings if needed ( On Epilog mini dashboard: set manually zero position (pointeur > x/y off > (move manually the laser pointer) > définir origine)) Do not forget to start the gas extractor and its pump, altogether with the laser printer itself! Press Go on the dashboard when Job, sent from the controlling PC, can be started…

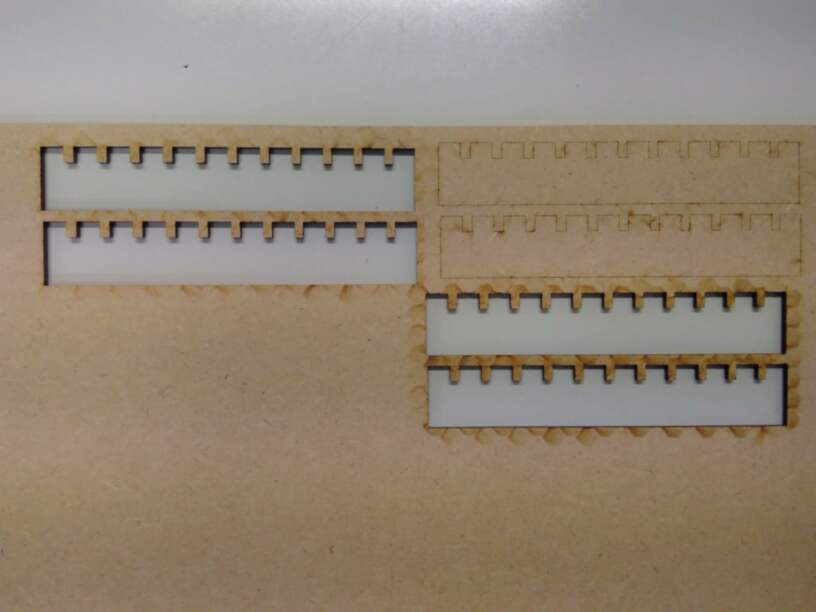

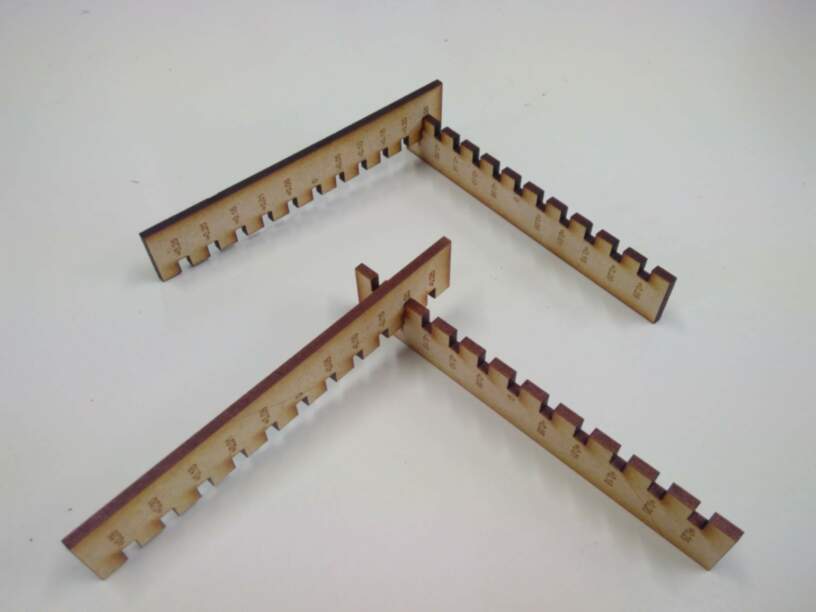

We’ve tried three sets of tests: * First test (top left): Power 80, speed 40 : comb is not completely cut (power too low) * Second test (top right): Power 100, speed 20: comb is completely cut but wood is burnt (speed to slow) * Third test (bottom): Power 100, speed 40 (standard settings): comb is cut and wood is in better state!!! Definitely the best choice!

Concerning the best press fit, we see that for the second test, it is the slot -0.25mm, whereas for the third test, the best fit is -0.20mm. In this latest case, we can then estimate the kerf width to 0.10mm.

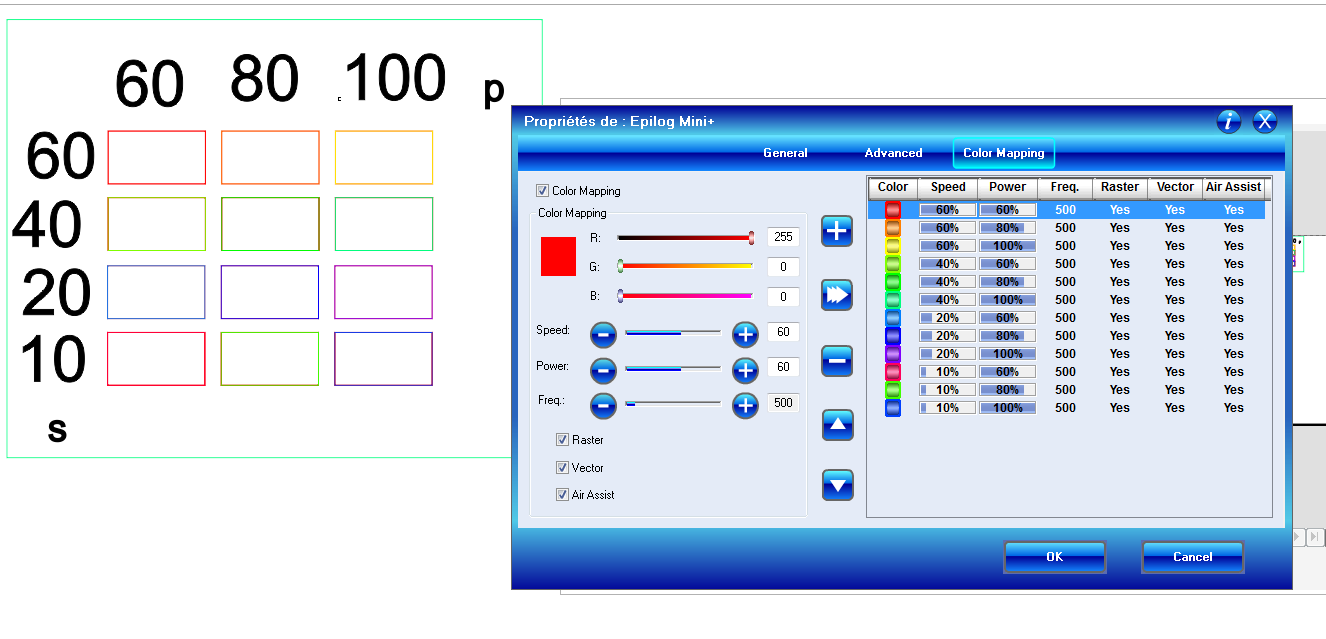

Process 2¶

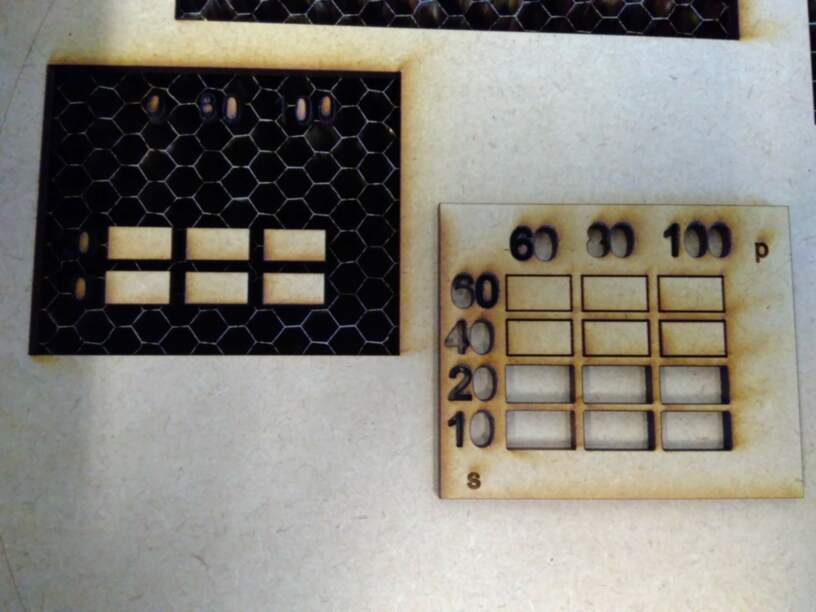

In this test, a simple structure of a 4x3 rectangles is directly drawn in CoralDraw, with power (p) and speed (s) as parameters of the color mapping

The result is that for speeds 10 and 20, all rectangles are really cut, for speed 60, no rectangle is cut. For speed 40, only the rectangle cut @ 100 is cut (standard settings!!)

Difficulties encountered : there has been a superposition of rectangular frame at creation that lead to two passes of the laser! Failed! The combination of raster, vector and color mappings is more difficult than expected, and forms that were meant to be engraved were finally cut ( the numbers, colored in black, not used in color mapping were thicker than expected!!). Be carefull in this case!

Process 3¶

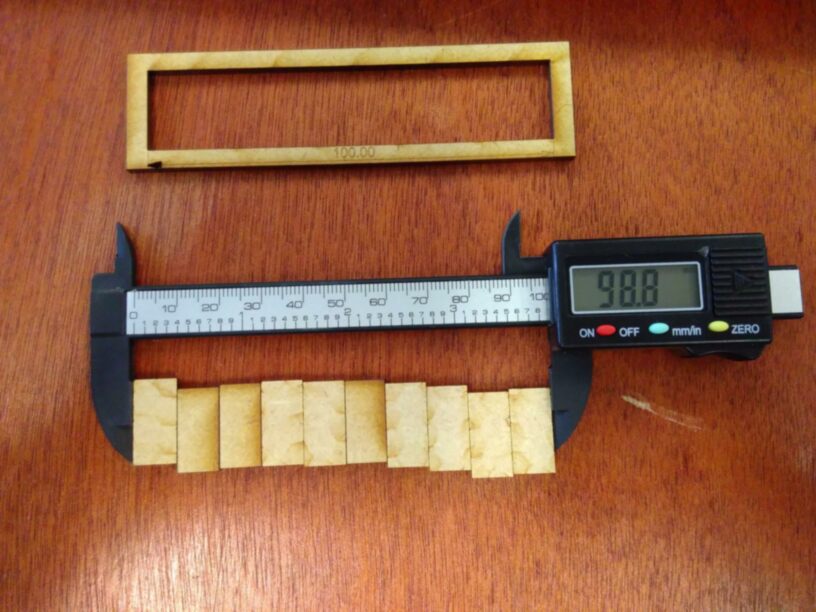

In this test, a rectangle of 100mm is drawn in Coreldraw, and then cut in 10 equal pieces.

Measuring the remaining width (98.8mm) on small rectangles after cut,kerf may be estimated to: width(1.2mm) divided by 11 : 0.11mm

This latest test didn’t bring any specific difficulty.

Job done!

Summary¶

Optimal parameters for 3mm MDF wood plate cutted with a CO2 60W EPILOG MINI

| Parameter | value |

|---|---|

| Cut power | 100 % |

| Cut speed | 40 % |

| Cut frequency | 500 Hz |

| Engraving power | 100 % |

| Engraving speed | 45 % |

| Engraving quality | 600 DPI |

| Kerf width | 0.11 mm |

| Optimal fit | 3 - 0.20 mm |