Molding and casting¶

Group assignment:¶

Review the safety data sheets for each of your molding and casting materials, then make and compare test casts with each of them

Result¶

Choice of materials¶

We decided to work with four materials available @FablabULB, of different kinds:

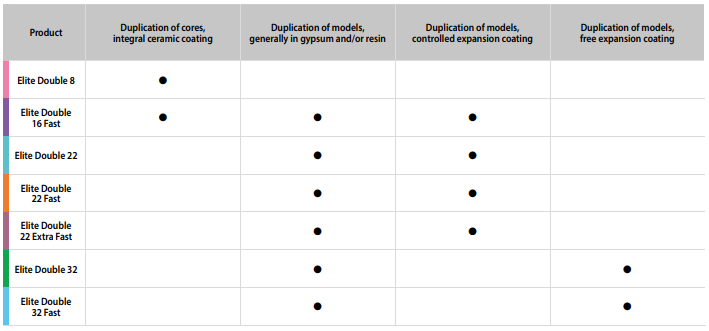

* silicone with short cure times ( Elite Double 8, Elite Double 16 FAST, Elite Double 22, Elite Double 32) from Zhermack

* PDMS (polydimethylsiloxane)

* CLV

* polyurethane

* Smooth-on Ecoflex 0030 and Ecoflex 0035 fast

Dental Silicone (vinylpolysiloxane (addition silicone)):¶

Looking at the datasheets of the several products available here, we see that the Elite Double range of silicone consists of several coloured products, final hardnesses (4) and setting times (3). Compatible with stones, polyurethane resins, acrylic resins and phosphate and alcohol-based investments (note: a dental casting investment is a material applied as a soft paste to a pattern that hardens to form a mold for casting)

Our choice: Elite Double 32, Silicone, 32 A (Zhermack). It is a good compromise between manual mixing time (1min), working time (10min) and setting time (20min), at room temperature, to be used with materials with free expansion casting

Instructions for use: 1. Measure or weight equal amounts of Catalyst (white) and Base (coloured) in a graduated container. 2. Mix the two components well, until colour is even. 3. slowly pour Elite Double, preferably from a height of about 30cm above the flask. If the quantity measured out is not sufficient to complete the process, wait until the silicone has hardened completely and then add more material the same way.

Safety requirements:

There is no specific safety document available on internet!!

So the minimum requirements is definitely to wear gloves when handling these chemicals.

PDMS (polydimethylsiloxane)¶

Sylgard 184, a Dow Corning Corporation (now DOWSIL) product, is a silicone elastomer (PDMS) kit. The kit contains two chemicals: Base (part A) and Curing Agent (part B), that are mixed in 10:1 mass ratio. Both the chemicals are transparent, but quite viscous in nature (mixed material viscosity is 3500 cP).

At room temperature, Working time is approximately 1.5 hours and full cure will take 48 hours to achieve optimal performance.

Heat cure time at 100° Celsius is 35 minutes, at 125° Celsius is 20 minutes and at 150° Celsius is 10 minutes.

Sylgard is designed to cure into a flexible elastomer that is well suited for the protection of electronic applications.

Safety requirements

Please don’t use pipettes to draw the chemicals as they are pretty thick. Also, wear gloves when handling these chemicals.

SuperSap CLV Bio-epoxy¶

From the reseller page: SuperSap CLV is a special formulation of the highly regarded SuperSap resin system from Entropy Resins. SuperSap CLV has been formulated to provide a clear, low viscosity bio-derived epoxy resin that is suitable for both hand laminating and vacuum resin infusion.

Safety requirements

Available here

Xencast PX90 Polyurethane¶

From the reseller page: Xencast® PX90 is an industry leading semi-flexible polyurethane casting resin which cures to a firm yet still slightly flexible 90 Shore A hardness whilst retaining unbeatable abrasion resistance and resilience.

Xencast® PX90 is ideal for product applications requiring a semi-flexible yet highly durable material including hand tools, skateboard wheels, engine bushes, props and training weapons.

At room temperature, working time/pot life (5min) and setting time (7 days), at room temperature, to be used with materials with free expansion casting

Safety requirements

Available here

Smooth-on silicones¶

Ecoflex 0035 fast and Ecoflex 0030 are very similar, excepted that the first one cures in 30 minutes while the second cures in 1 hour! Their specificity is their extreme softness and large deformations capabilities (up to 900 %).

Safety requirements

Available here, those product are certified skin-safe!

Plaster¶

Christophe also used usual construction material plaster for his tests!

Safety gloves:¶

Why use Nitrile gloves and not latex? When working with epoxy resin premium quality tough Nitrile gloves should always be used instead of latex because latex gloves can allow the transport of harmful amines through the gloves. These tough Nitrile gloves block these amines which is why they should always be used when working with epoxy resin.

Mold shape¶

Axel and Greta made 2 different types of moulds to test different materials.

Axel’s molds¶

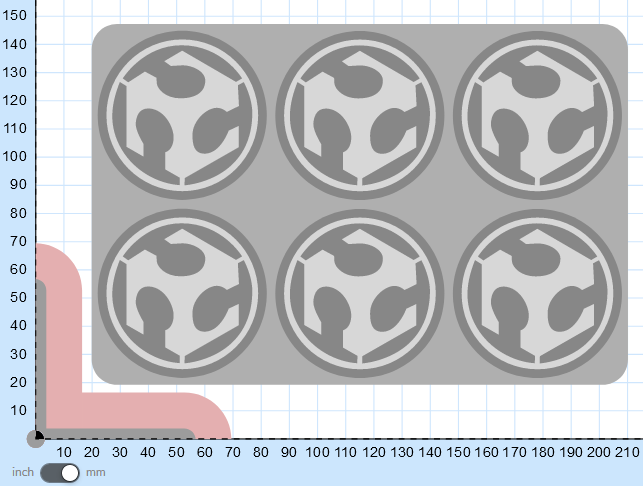

I wanted to make a mold that can be used to cast 6 identic coins (for up to 6 differents materials). I choosed to use the Fablab logo, so I searched for a .svg drawing and I found it in this Thingiverse files. Then I imported the .svg into Easel, I added a larger circle (for deeper outline cut), then I added 5 copies. Finally, I added a rectangle for the bottom of the mould. This is how it looks like in Easel :

- Light grey (logo) is 2mm deep.

- Medium grey (rectangle) is 4mm deep.

- Dark grey is 6mm deep.

Here is the link for the g-code files. There is the original logo and 3 g-code files :

- Fablab_single.nc that is meant to be milled with a single 1/8” end mill.

- FabLab_roughing.nc to make a rough milling with a 1/8” end mill (before the detail pass).

- FabLab_detail.nc to make a clean milling with a 1/16” end mill (after the roughing pass).

This is the simulated toolpath for the single pass version :

From the milled positive is moulded a silicone negative using AS40, to be use as effective mould!

Greta’s molds¶

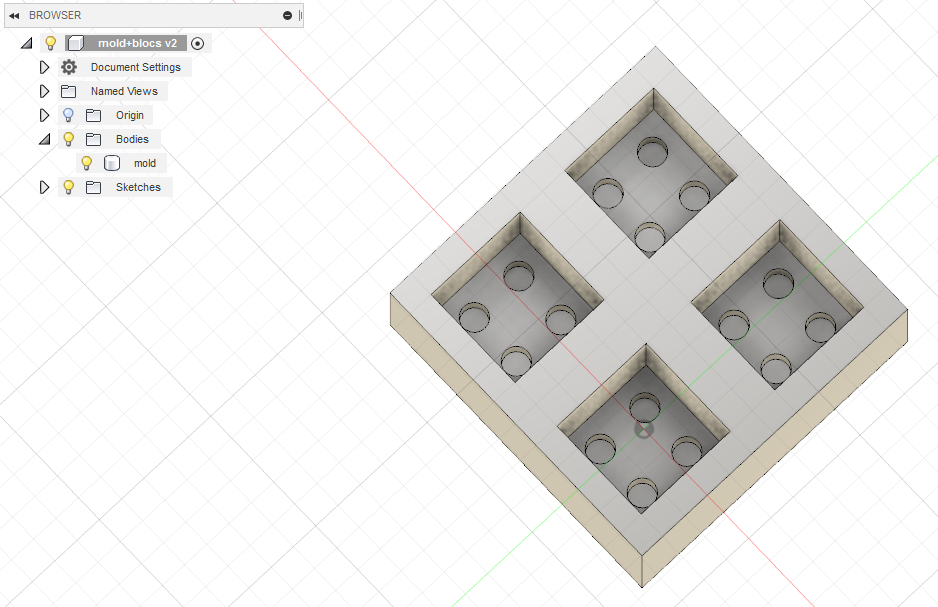

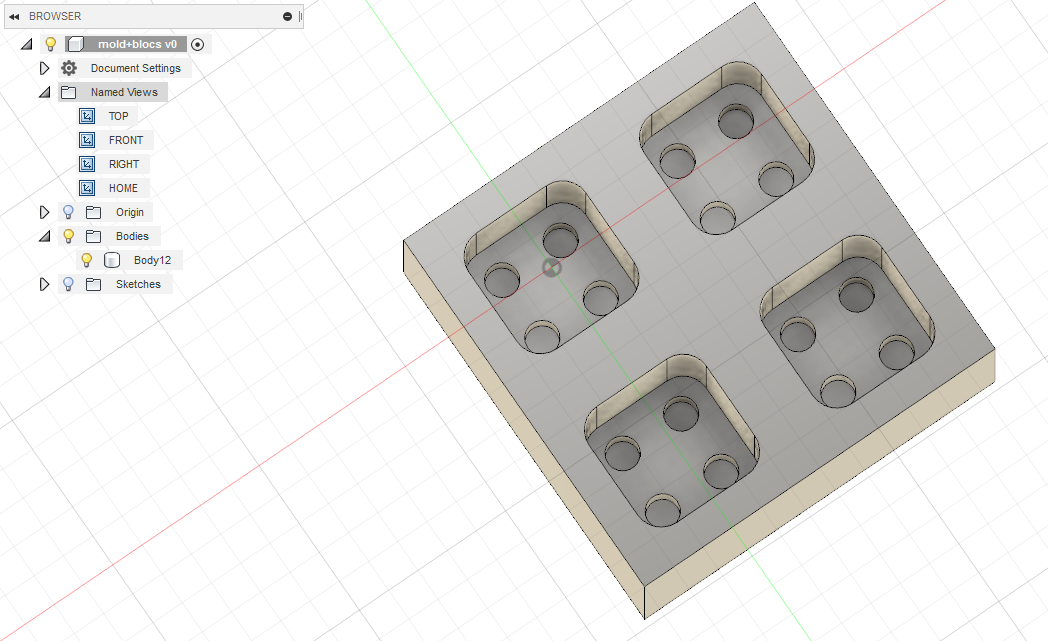

Concerning the shape to form, we opted for a simple structure, that we create with FUsion360 (on Windows7). The idea is to compare the behaviour of those materials, not to make a real mold yet. In order to test all materials at the same time, we decided to go for a unique mold with four cavities, in which we will pour the materials

Of course, this model needs some revision to take manufacturability into account; sharp corners aren’t acceptable for the CNC machine… So here is the new version:

Molding results¶

Axel’s mold and Plaster¶

The demolding was easy but the plaster broke, probably because it was not dry enough. Silicone was good for the mould.

Axel’s mold and Ecoflex¶

We made three tests, one using a demolding agent](https://www.easycomposites.co.uk/#!/wax-and-mould-release-agents/PVA-mould-release-agent.html) and the others without. We first tried to unmold the one with demolding agent, supposed to be easier. Indeed, the release agent helped, but this remained very difficult, seeing the adhesion between the two silicone!

Seeing the difficulty and the bad results for the first one, the two others without release agent were not even tried to demold! Conclusion: moulding silicone on silicone is not a good idea (as expected).