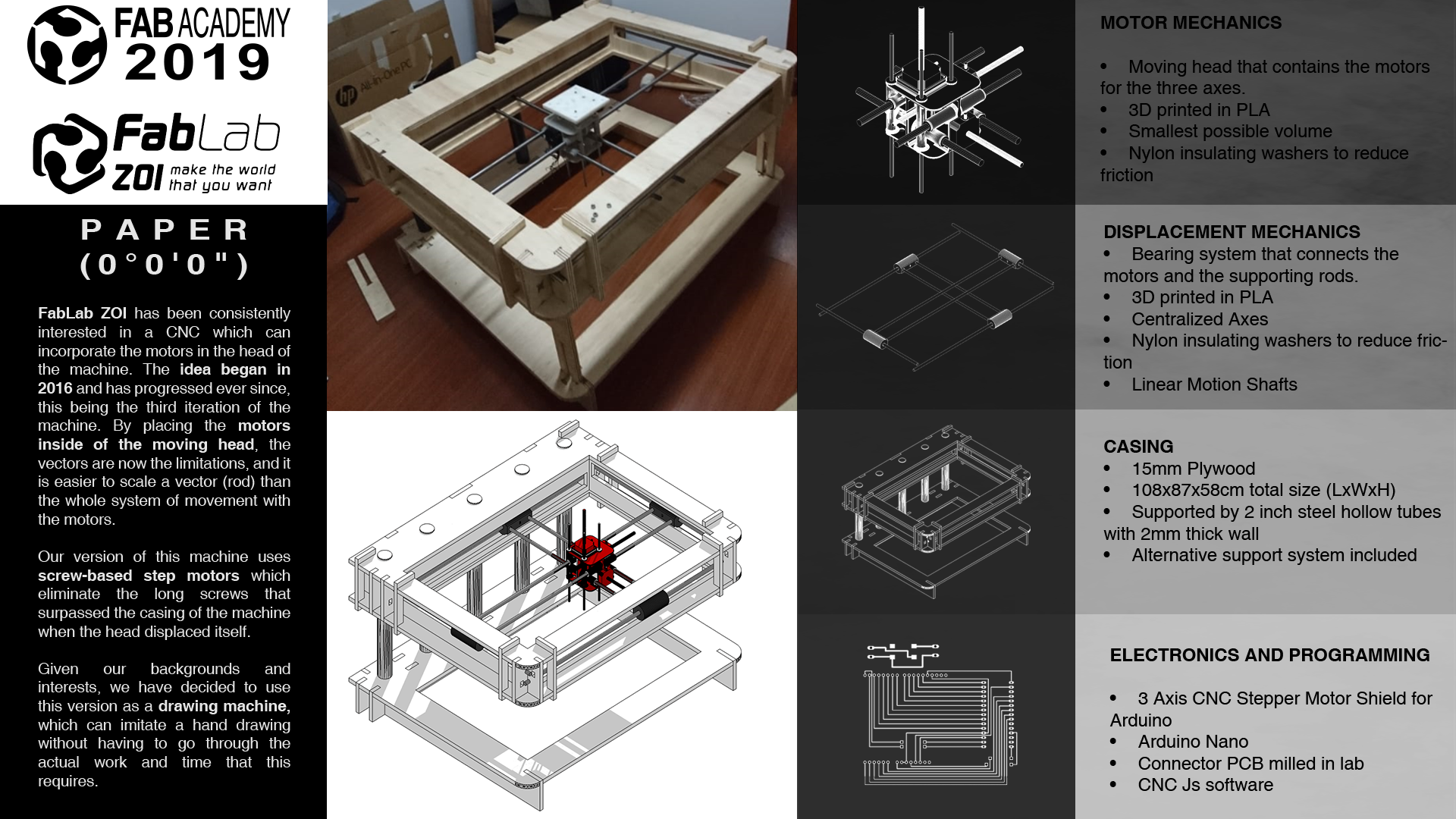

Motor Positioning System

-by Jorge Correa

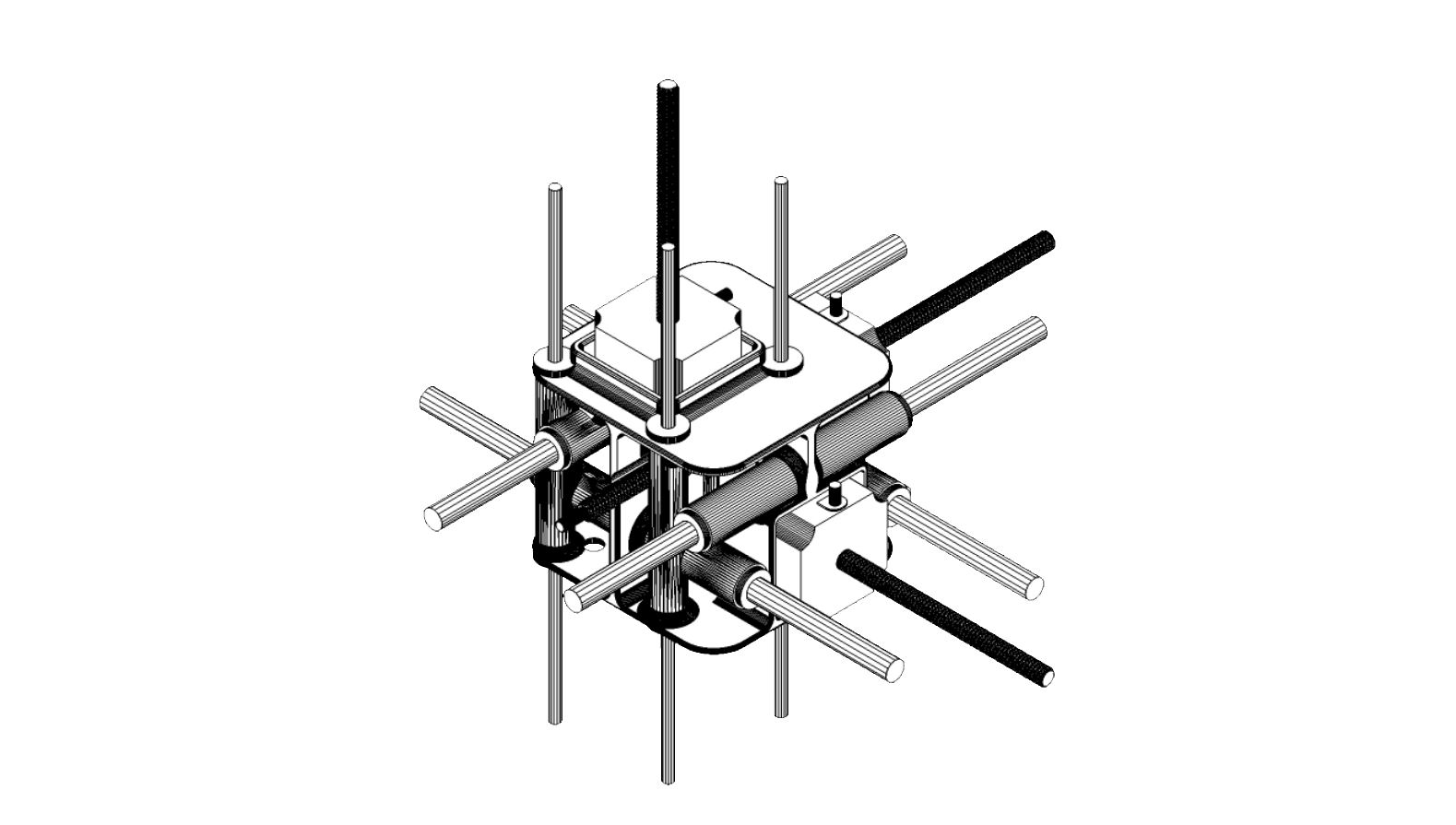

The "head" of the machine, containing the three motors and the tool.

FabLab ZOI has been consistently interested in a CNC which can incorporate the motors in the head of the machine. The idea began at the end of 2016, by identifying the problem in most CNCs which is the limitation of the movement of the machine because of the location of the motors that generate the movement. By placing the motors inside of the moving head, the vectors are now the limitations, and it is easier to scale a vector (rod) than the whole system of movement with the motors.

FabLab ZOI has been consistently interested in a CNC which can incorporate the motors in the head of the machine. The idea began at the end of 2016, by identifying the problem in most CNCs which is the limitation of the movement of the machine because of the location of the motors that generate the movement. By placing the motors inside of the moving head, the vectors are now the limitations, and it is easier to scale a vector (rod) than the whole system of movement with the motors.

In the year 2017, the first 0 CNC was created as the machine week project in FabAcademy by the students of FabLab Yachay. This machine had the motors in the moving head and worked via a system of rods that was easily transportable and could be assembled quickly.

In the year 2018, the second version of Zero CNC was created by the first class of newly created FabLab ZOI. This version reduced the moving head, and used a system made of wood instead of rods and plastic. The idea was that it was going to be an easily transportable machine, as the rods and pieces could be removed and (along with the central motors) transported in luggage. The pieces of the “casing” of the machine could then be fabricated on another lab per arrival, as it was a press fit kit.

For this iteration of the machine (version 3) we use the same system of movement on three axes via the motors in the moving head, but we have the advantage of using screw based step motors, which eliminate the long screws that surpassed the casing existent on the previous version of the machine.

Given our backgrounds and interests, we have decided to use this version as a drawing machine, which can imitate a hand drawing without having to go through the actual work and time that this requires.

-by Jorge Correa

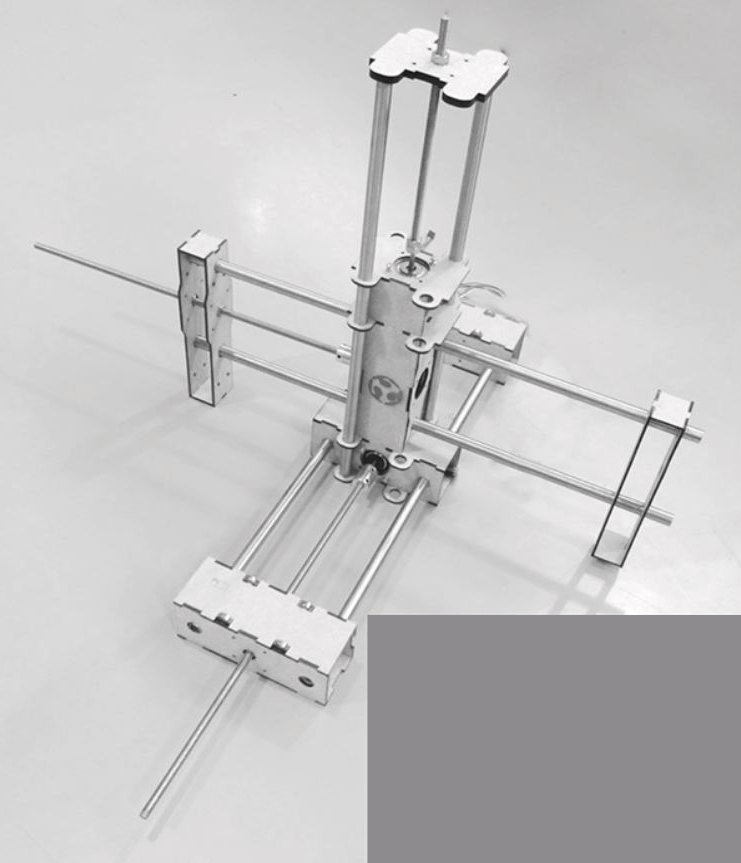

The "head" of the machine, containing the three motors and the tool.

- by Danny Vallejo

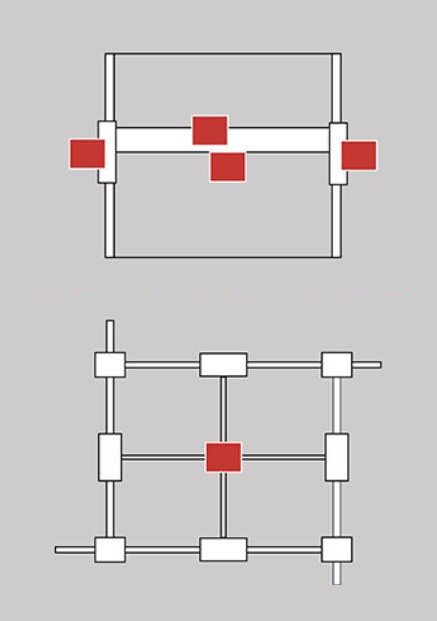

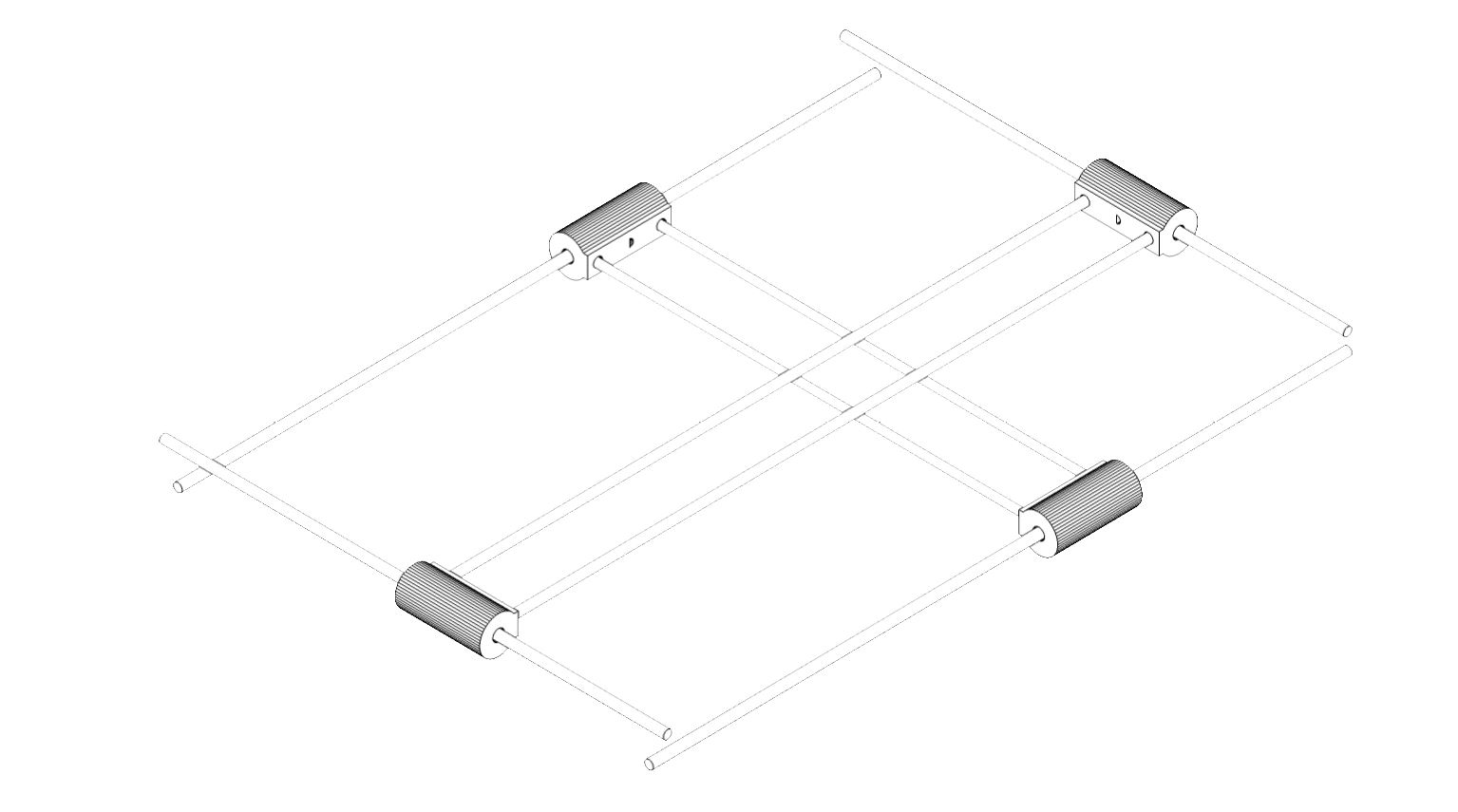

Bearing system which enables the movement of the machine

- by Alejandra Loaiza

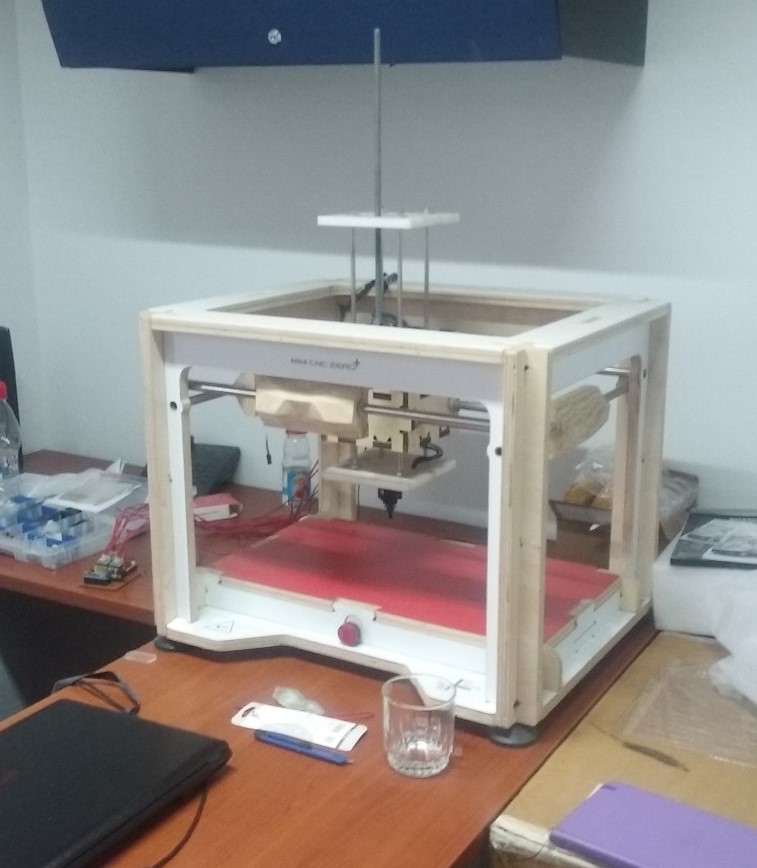

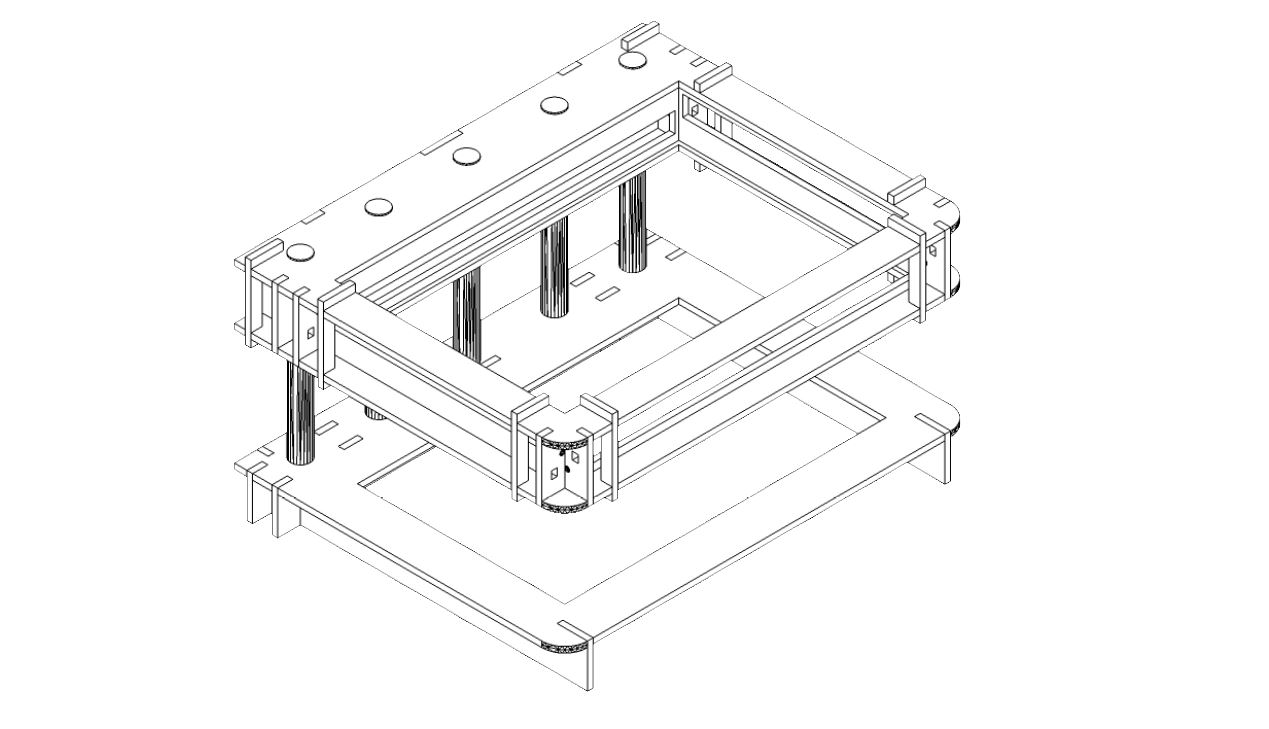

The shell of the machine, which holds the bearing system and the motor.

- by Danny Vallejo

Electronic System of the Machine