4. Electronics production¶

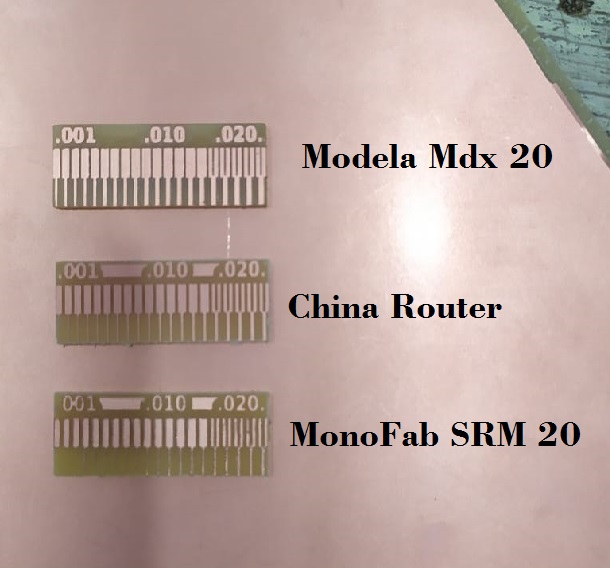

Machnice Characterizing¶

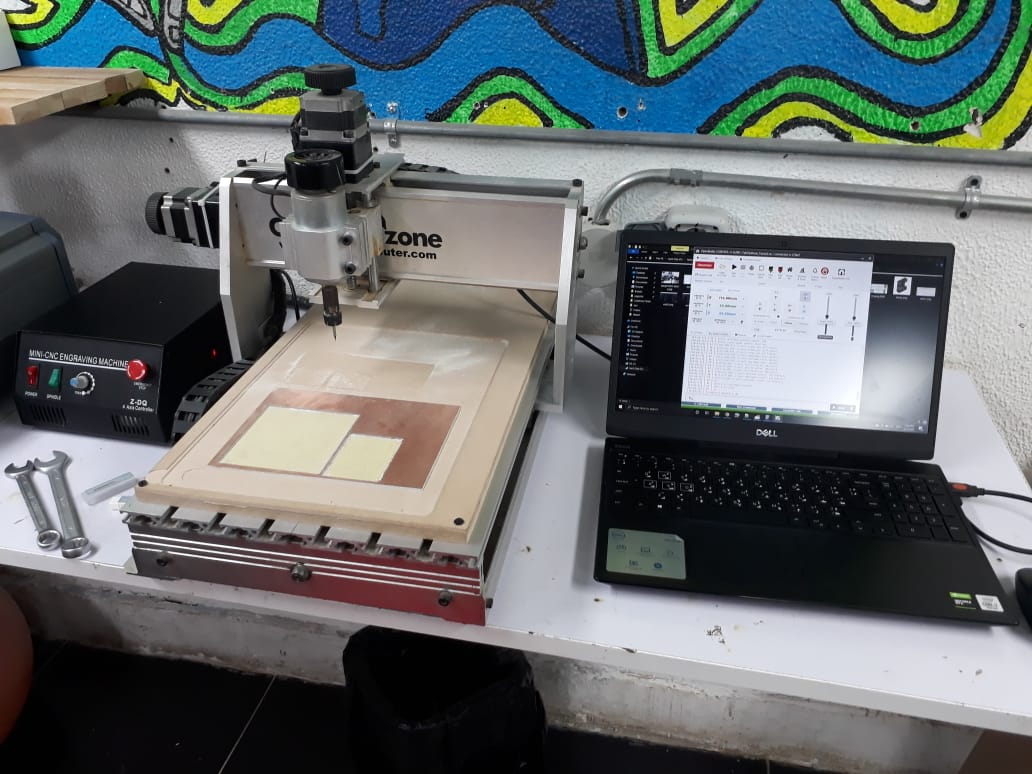

Started with a group assignment of characterizing the machines we had .

Modela Mdx 20 , China router 30*40 & MonoFab SRM 20 .

Fabrication¶

Design¶

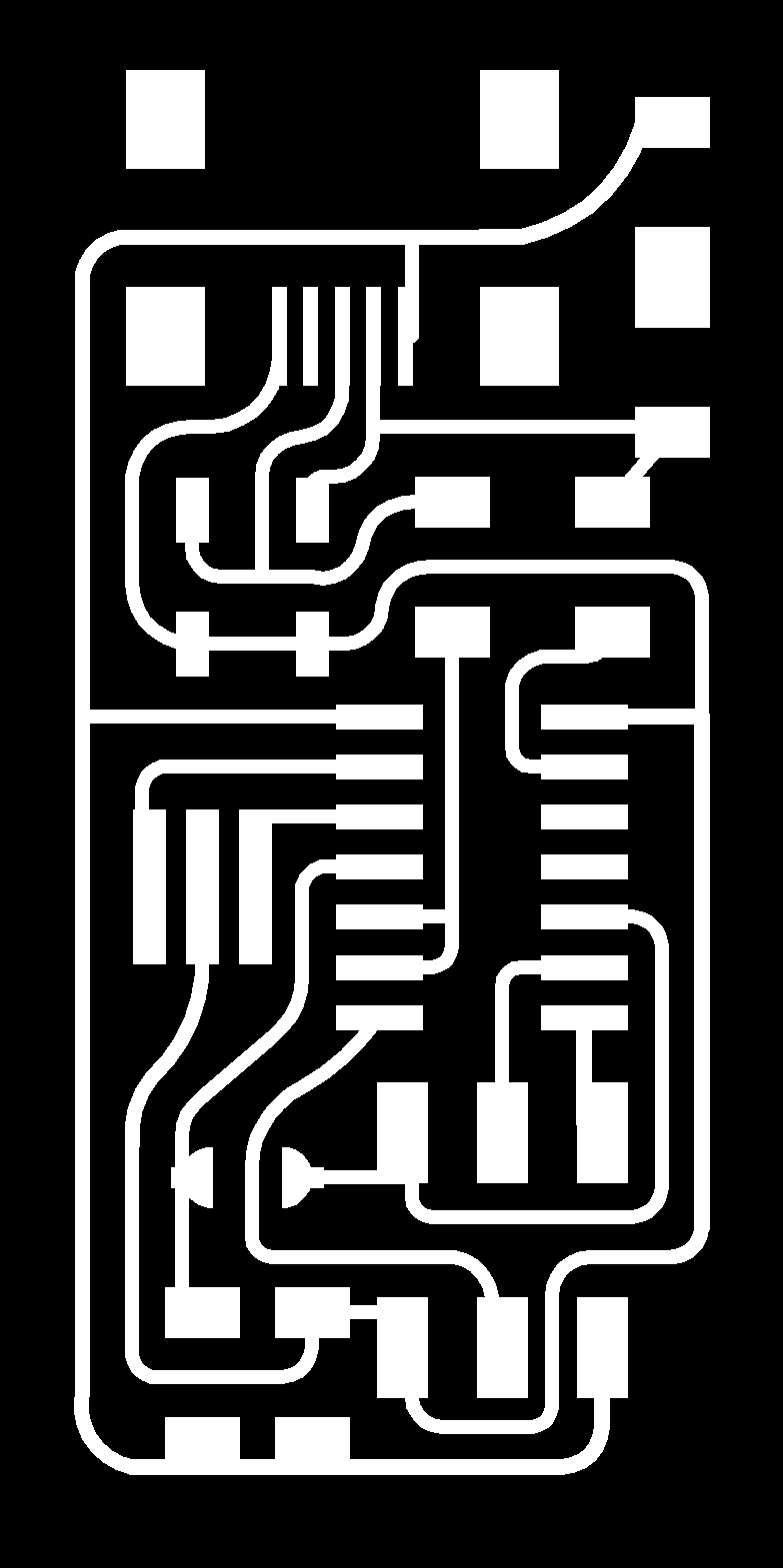

I chose to make Ali’s Board design

I dowloaded the images of the traces and the outer .

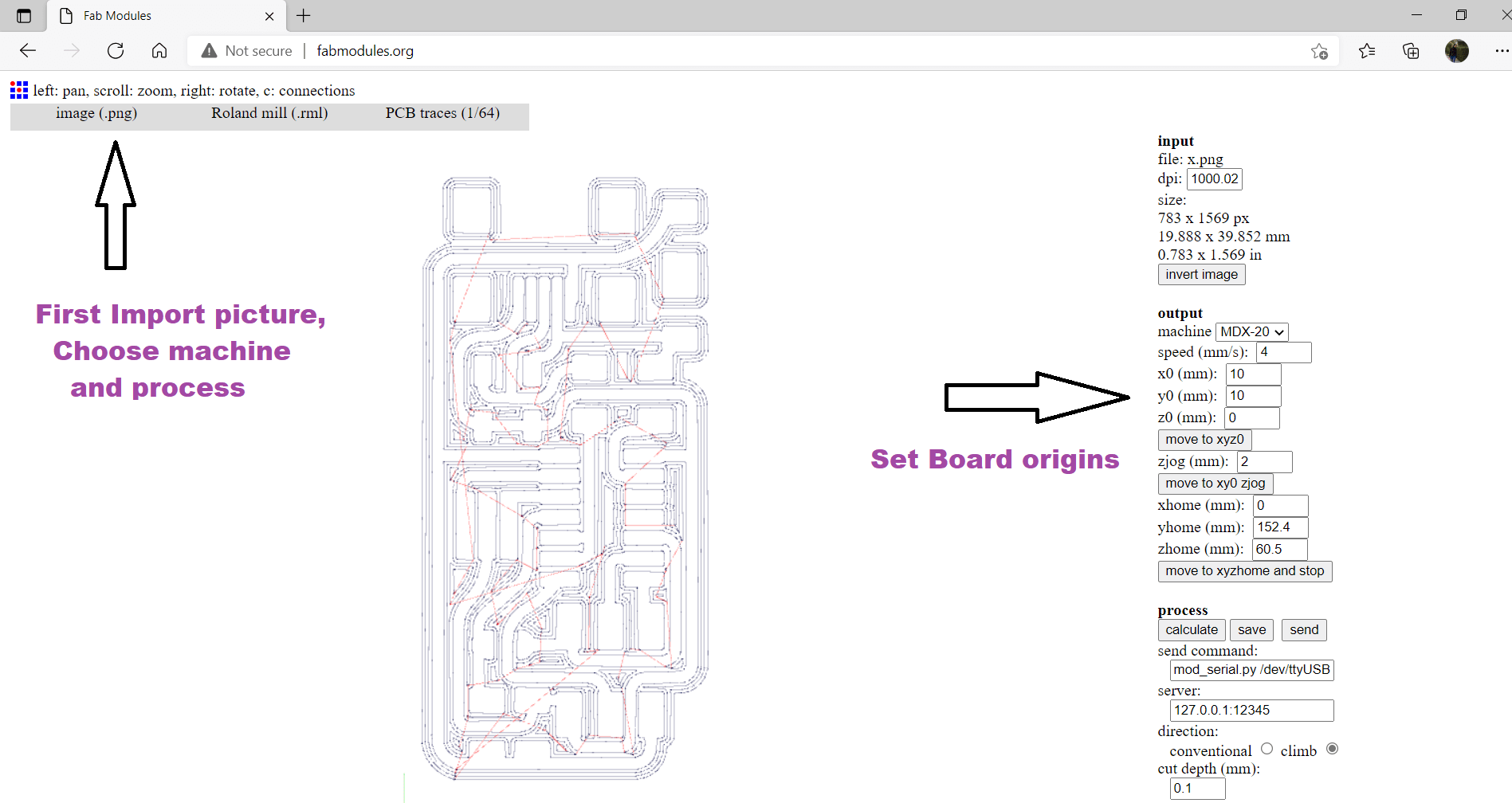

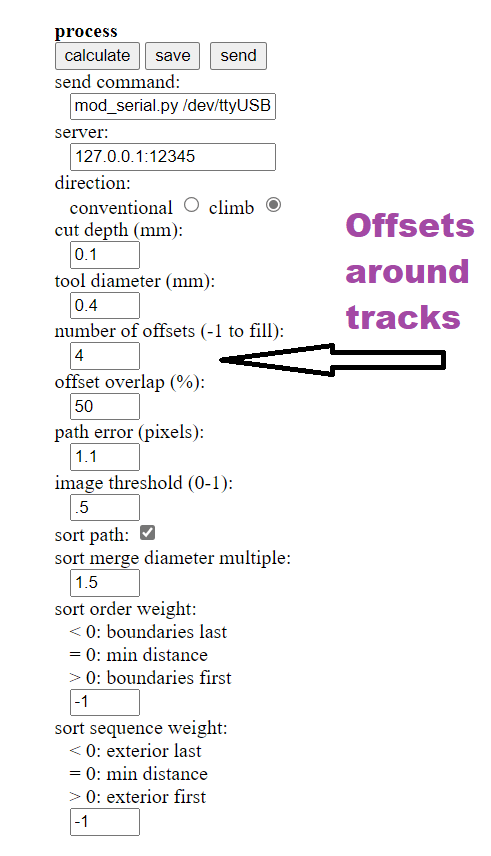

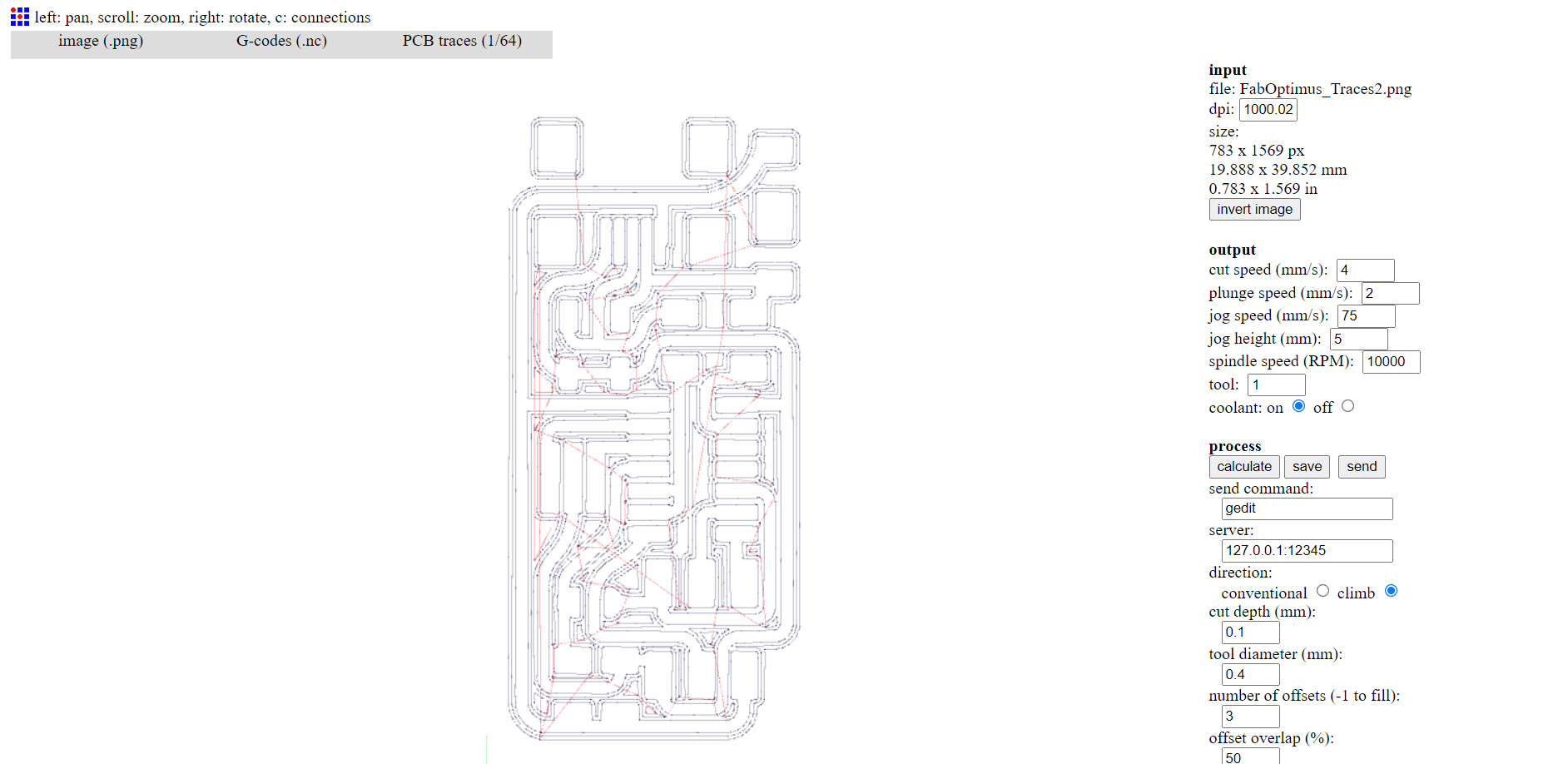

Imported to Fab Modules and edited setups , The machine and the process

and from the setting on the right , I sat the origin of my board .

Then , editing milling settings

After all is set , we click Calculate to process and prepare the gCode

then Send , and the machine starts milling .

Milling & Soldering¶

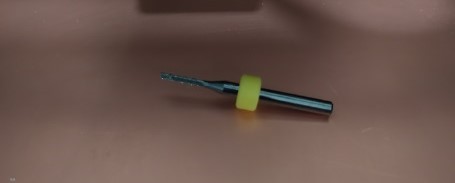

For Traces , I used the V cut

For Outline , I used the 2 mm Endmill

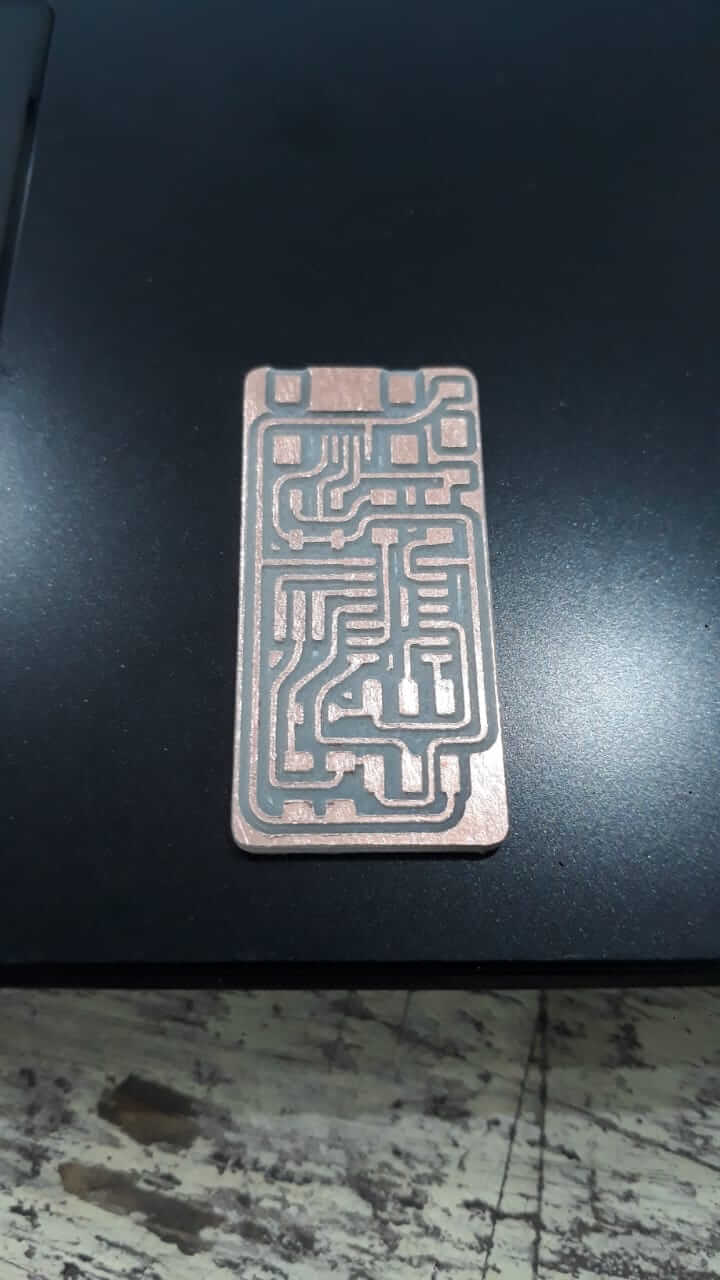

Sweet output of a milled board on Modela Mdx-20 .

Stuffing wasn’t very hard but I’m happy with the final look . Gonna need more practise .

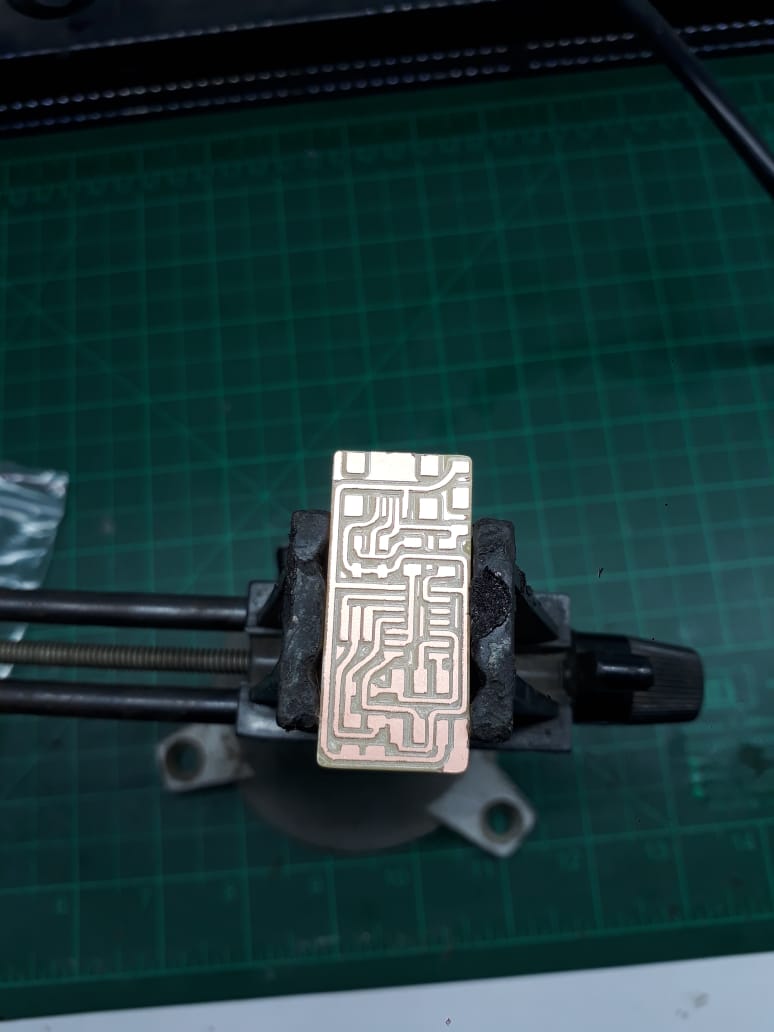

Sadly , I lost this board so I milled another one on the China Router .

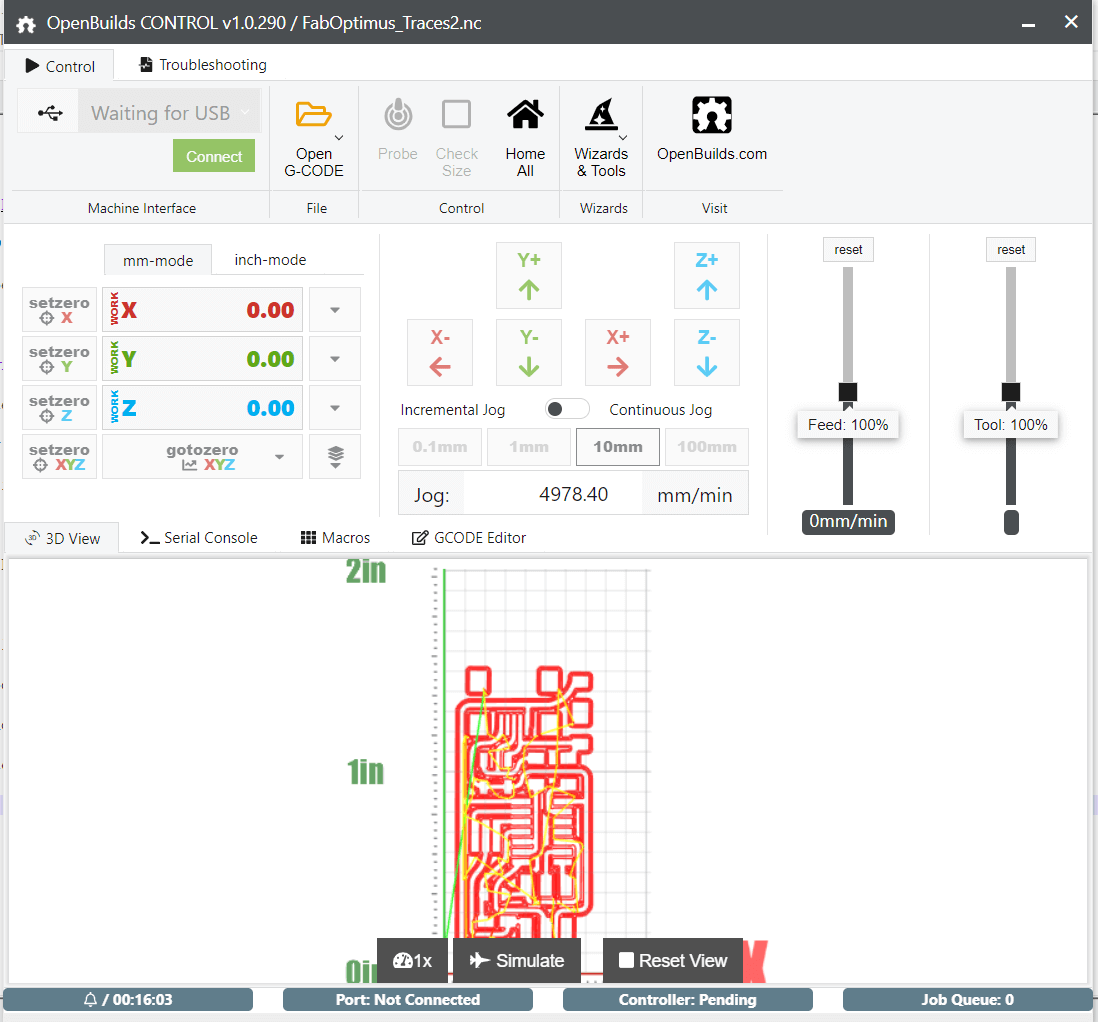

I used Fab Modules to generate Gcode

Then Used OpenBuilds Software to control and cut my board .

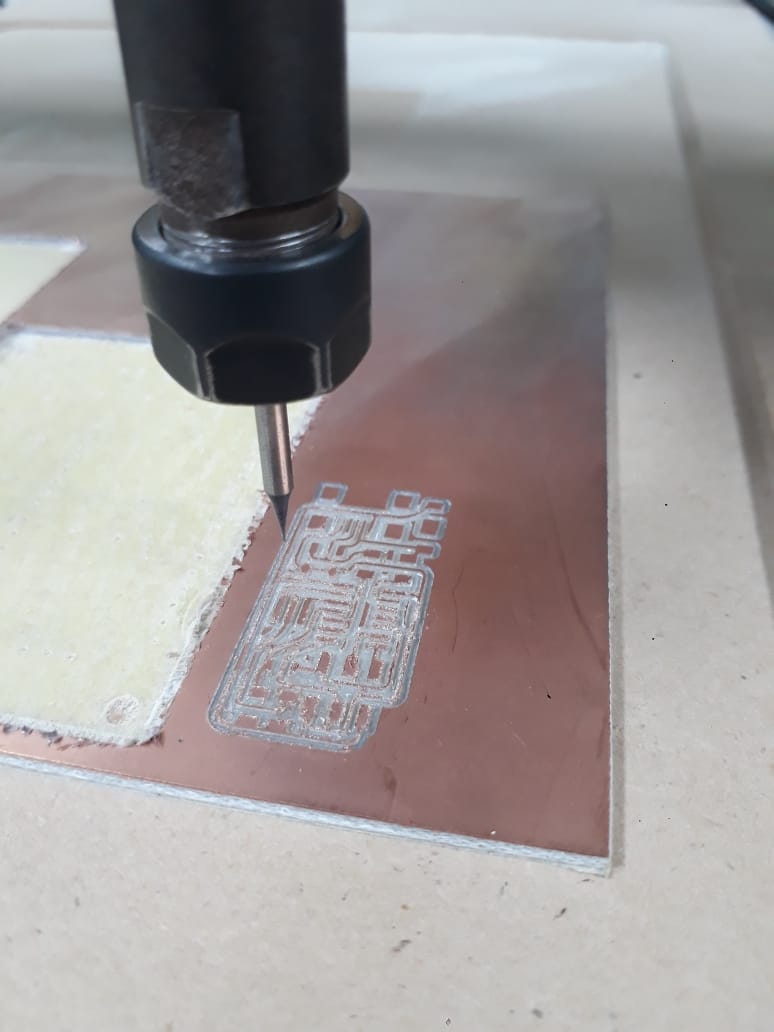

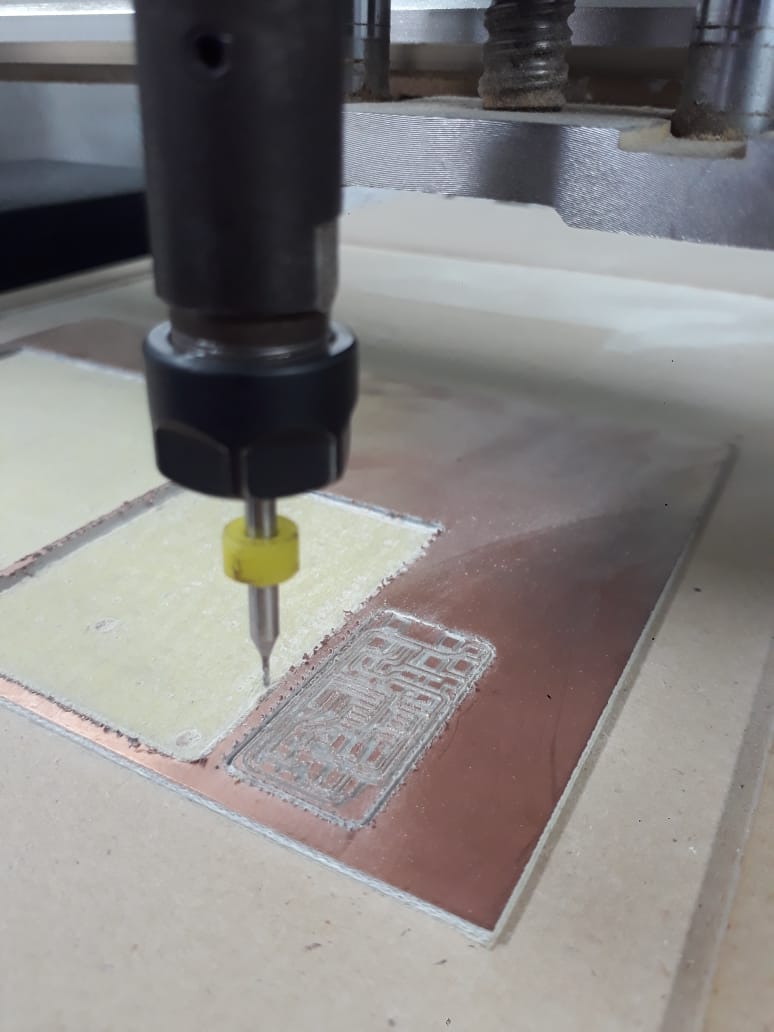

And on to milling

Traces :

Outline :

A shiny-looking board

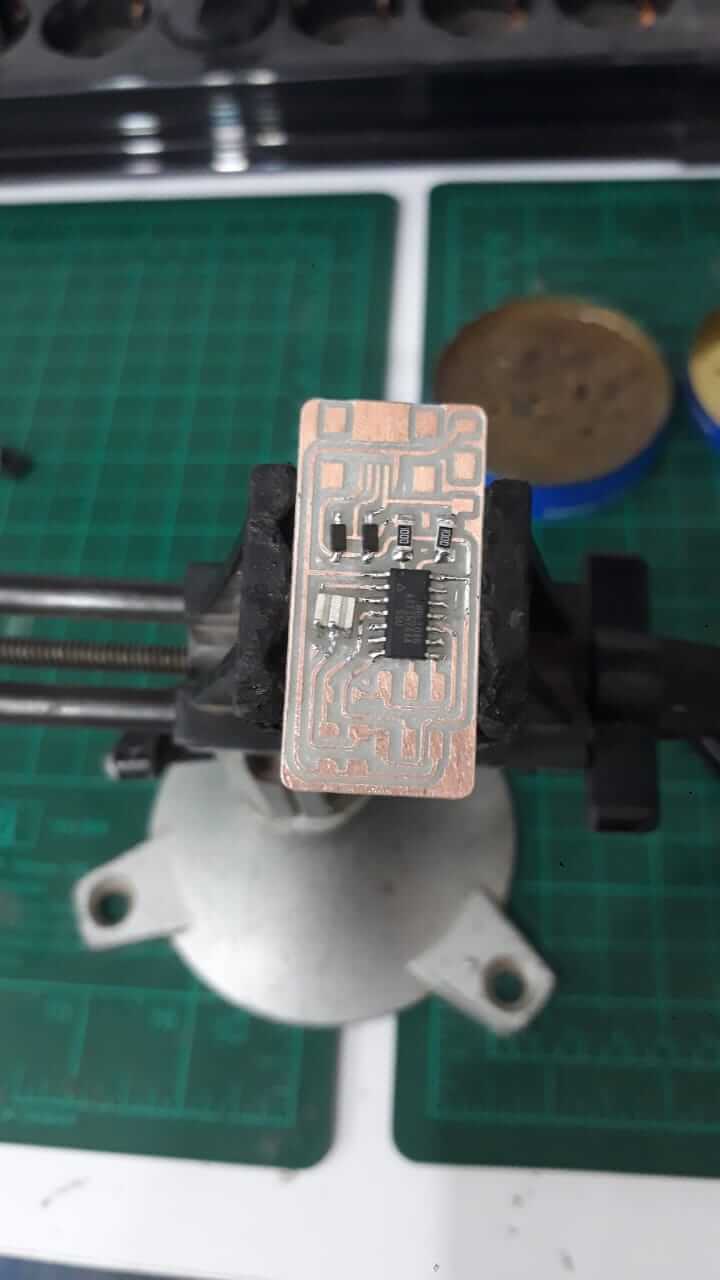

Time to trying not to make a mess while placing components

Starting from the inside and lower height components

Towards outside

Finally high components

Programming¶

Following this great Documentation

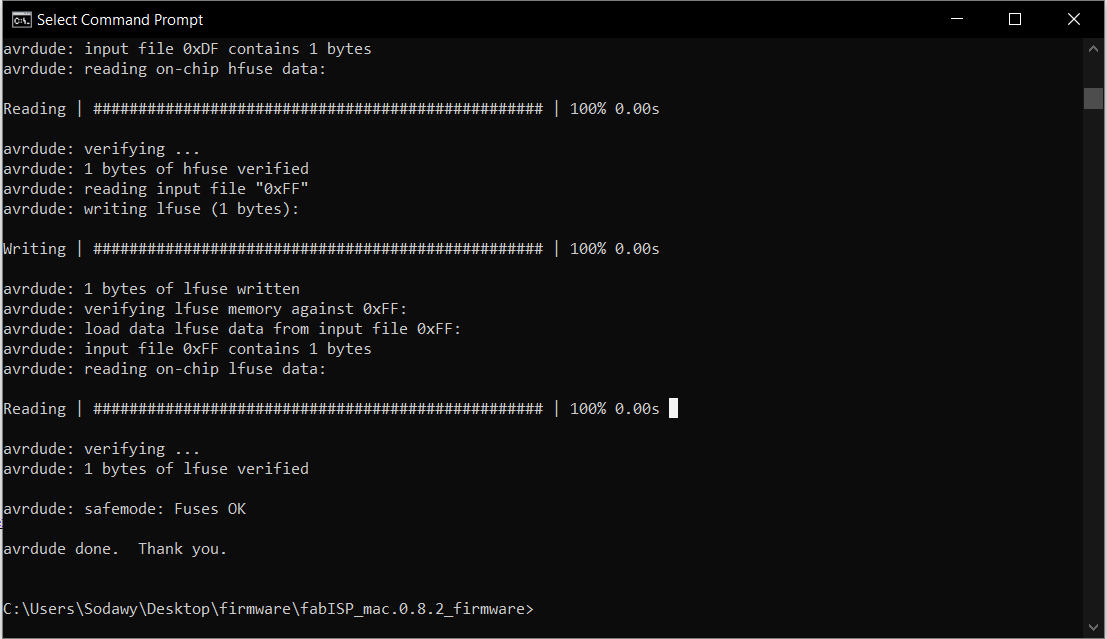

And using the USBasp programmer , I made my FabISP .

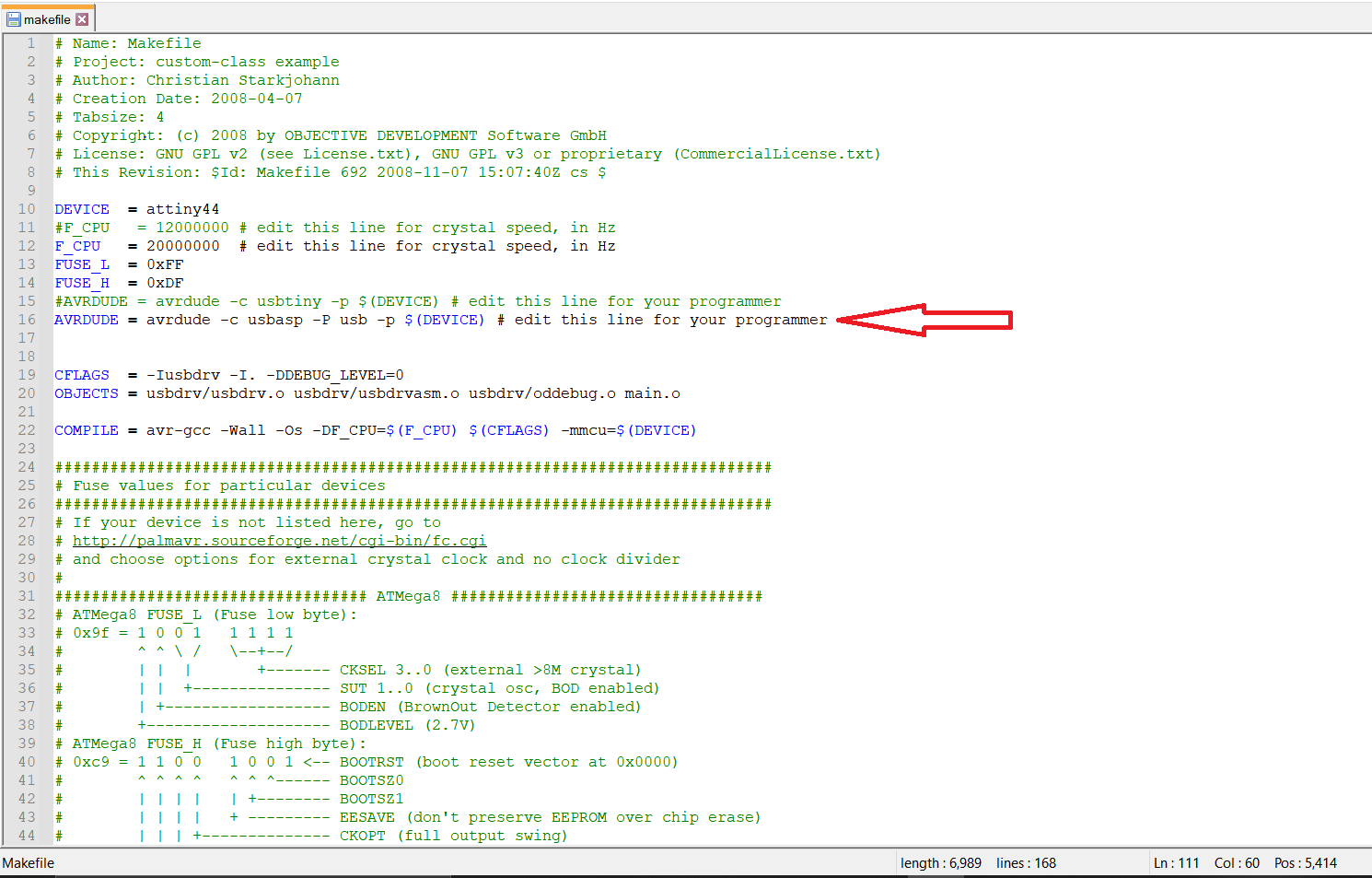

First , I edited the Makefile as shown

in a command prompt : Make hex , Make program and Boom : you’ve got your programmer !

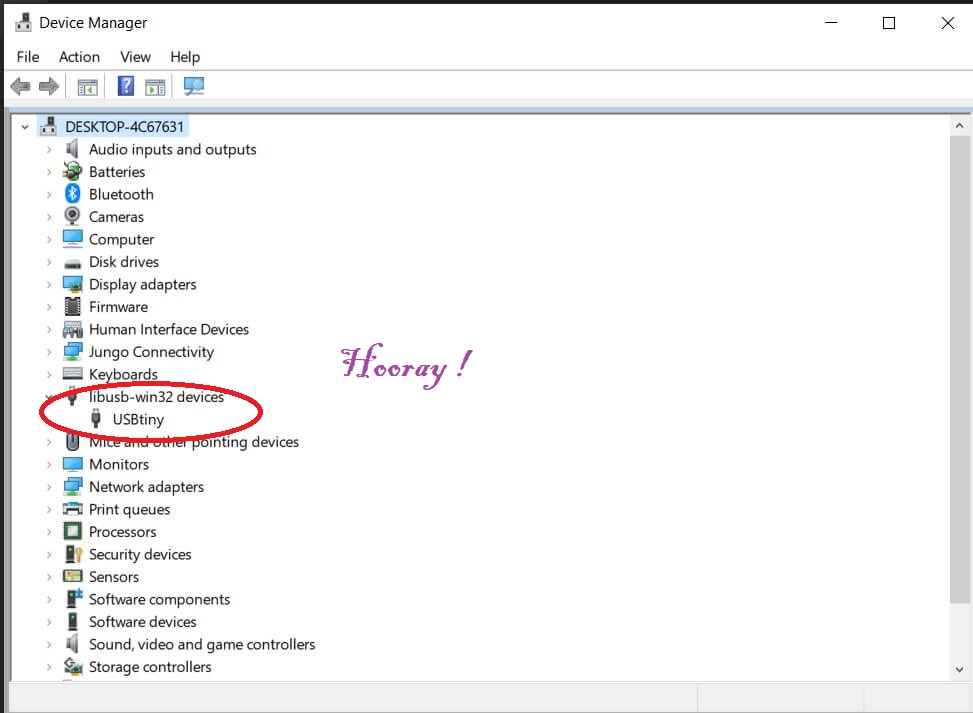

After programming was done successfuly , My board wasn’t recognized by the Device Manager , Turned out that I had my Zener diodes soldered the other way ,Anode switched with cathode, Just had to fix that and I got my board ackonwledged .