11. Molding and Casting¶

Sounded as a fun week , yet I got happy too early . I tested positive for Covid so I had to stay home quaranteening with Bomba (the cat) and Sodawy (the laptop).

In 2 weeks I got better , thank God , and went to get back on track .

Reviewed the Group Assignment .

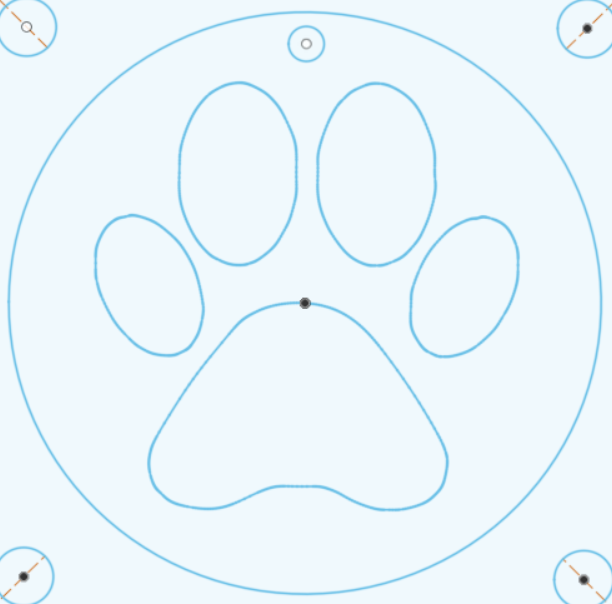

Design¶

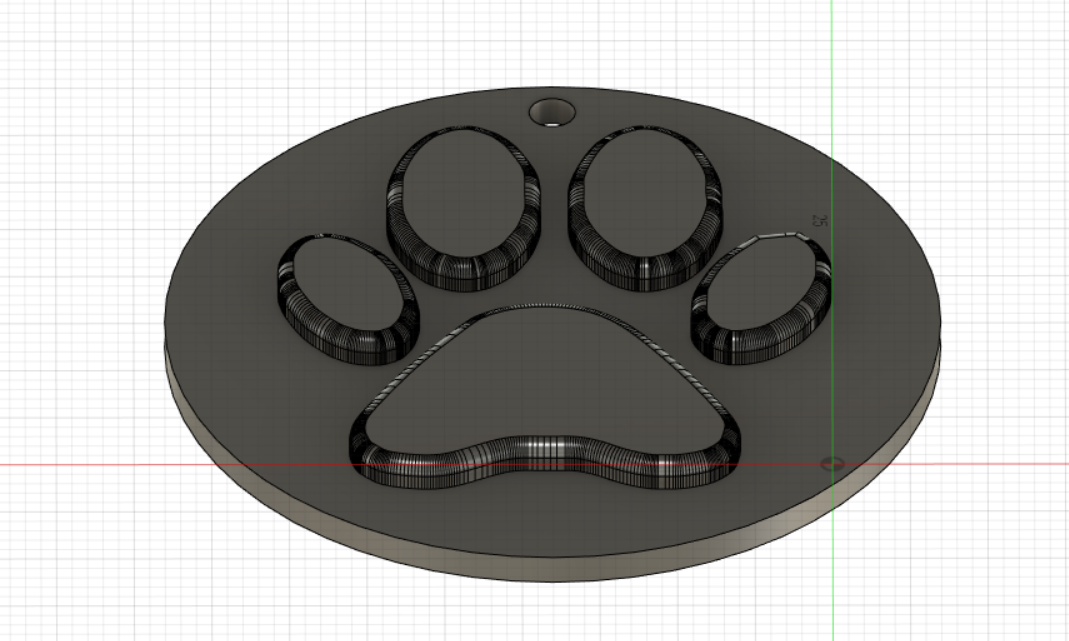

Working on Fusion360 , I had a sketch of a cat paw .

Did some extroding to get the final Medallion I wanted .

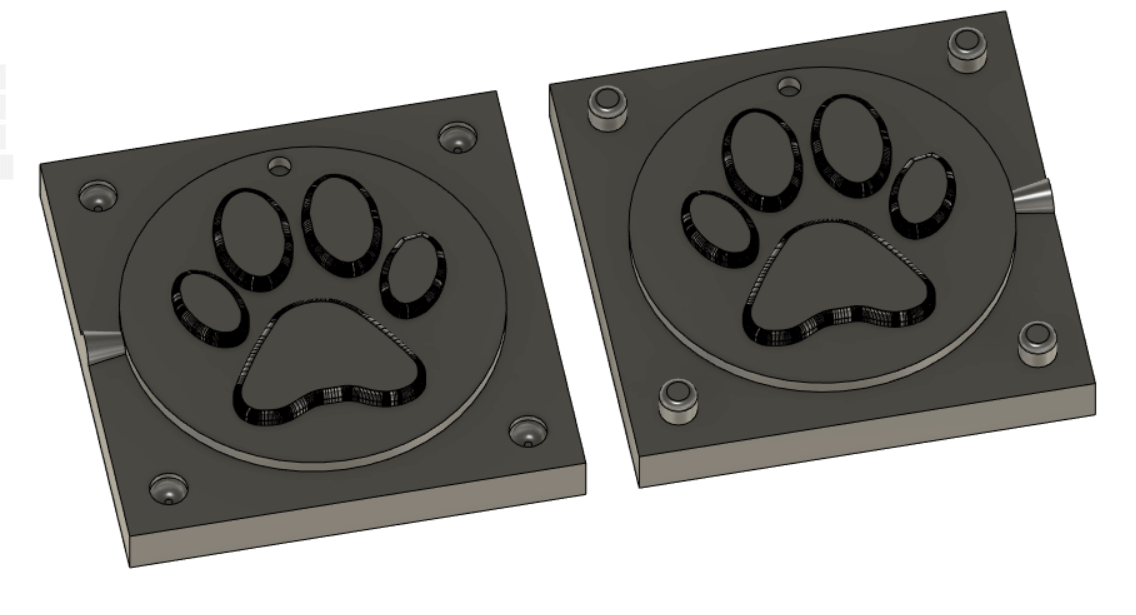

Added the frame , registeration pins and pour

Milling¶

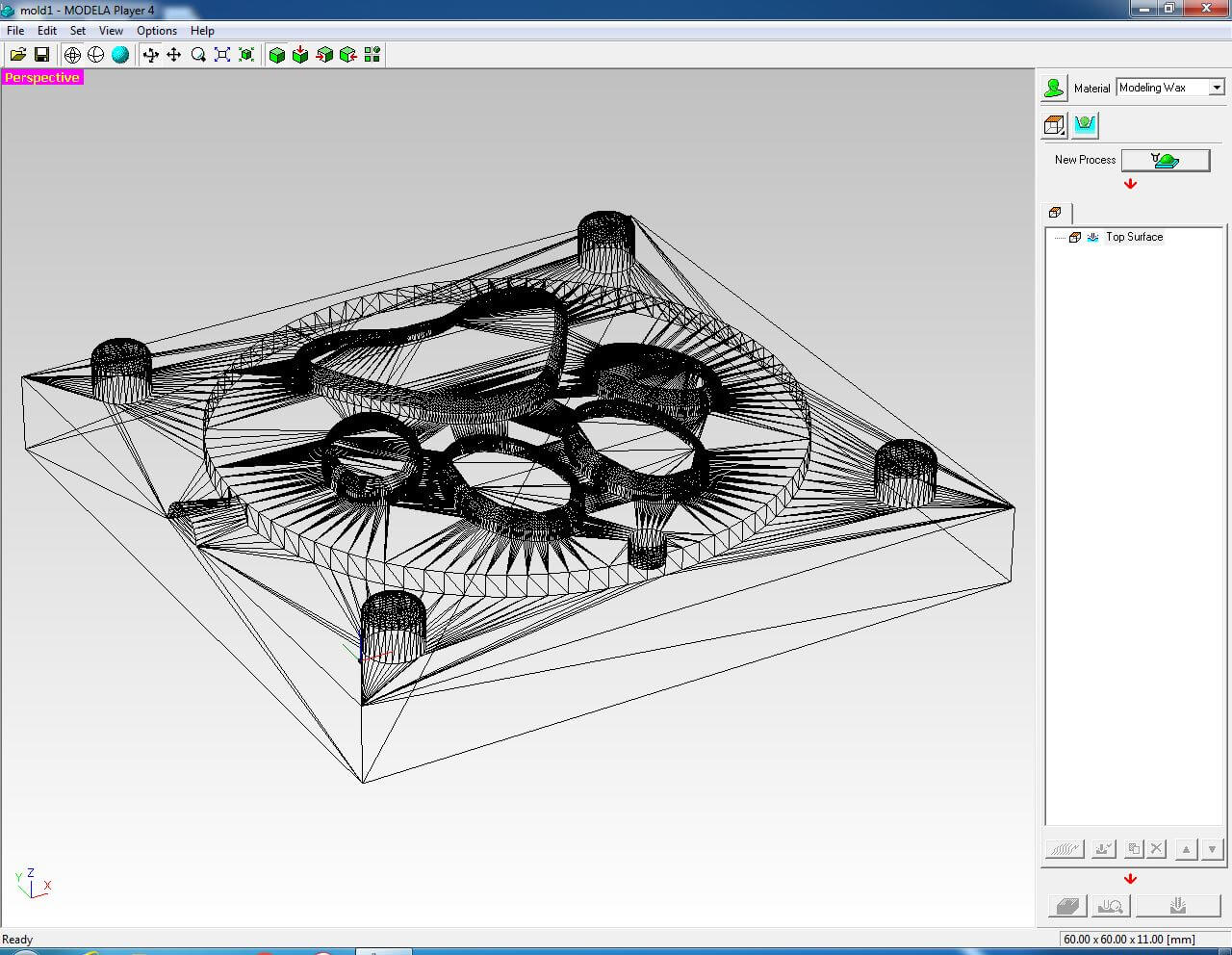

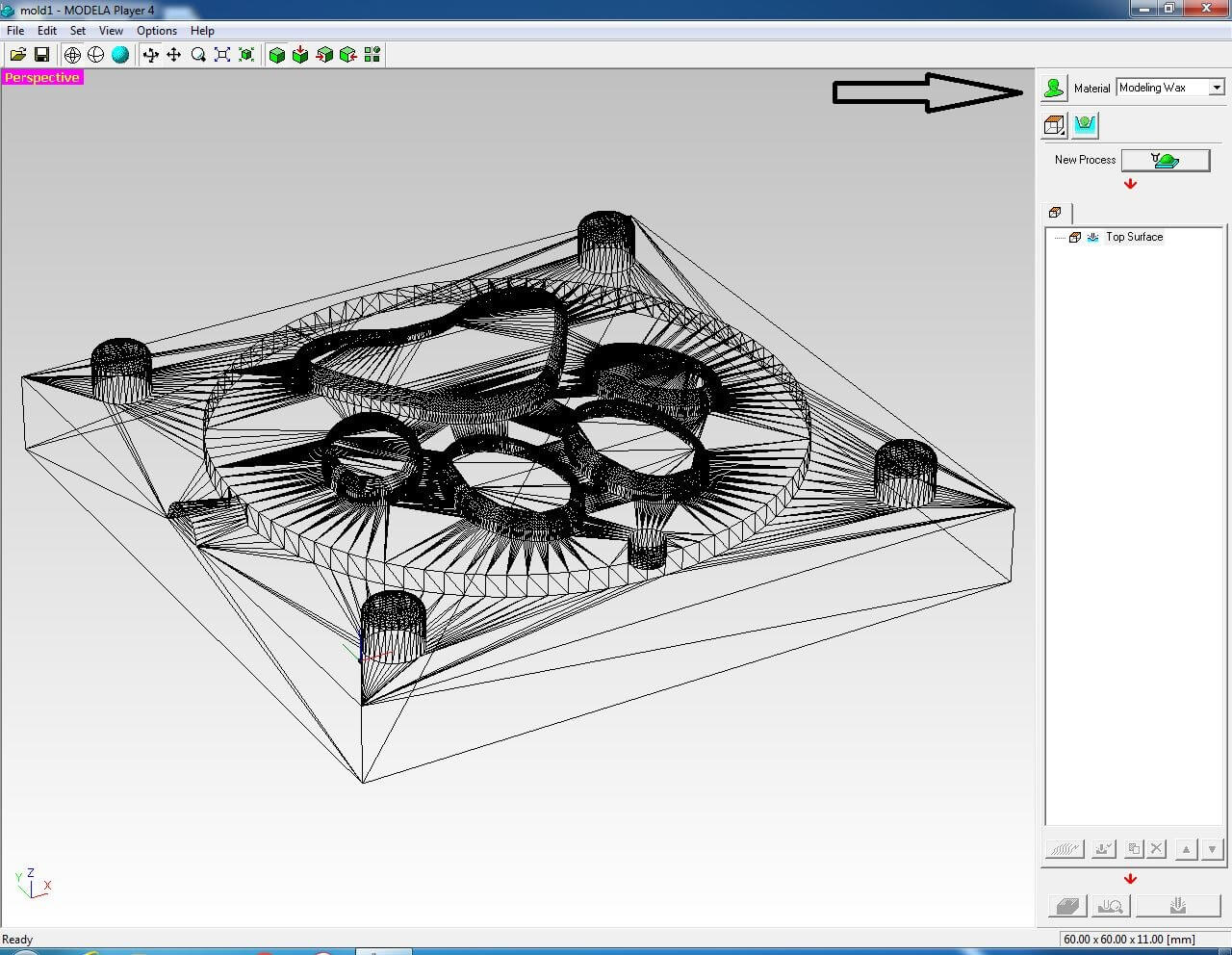

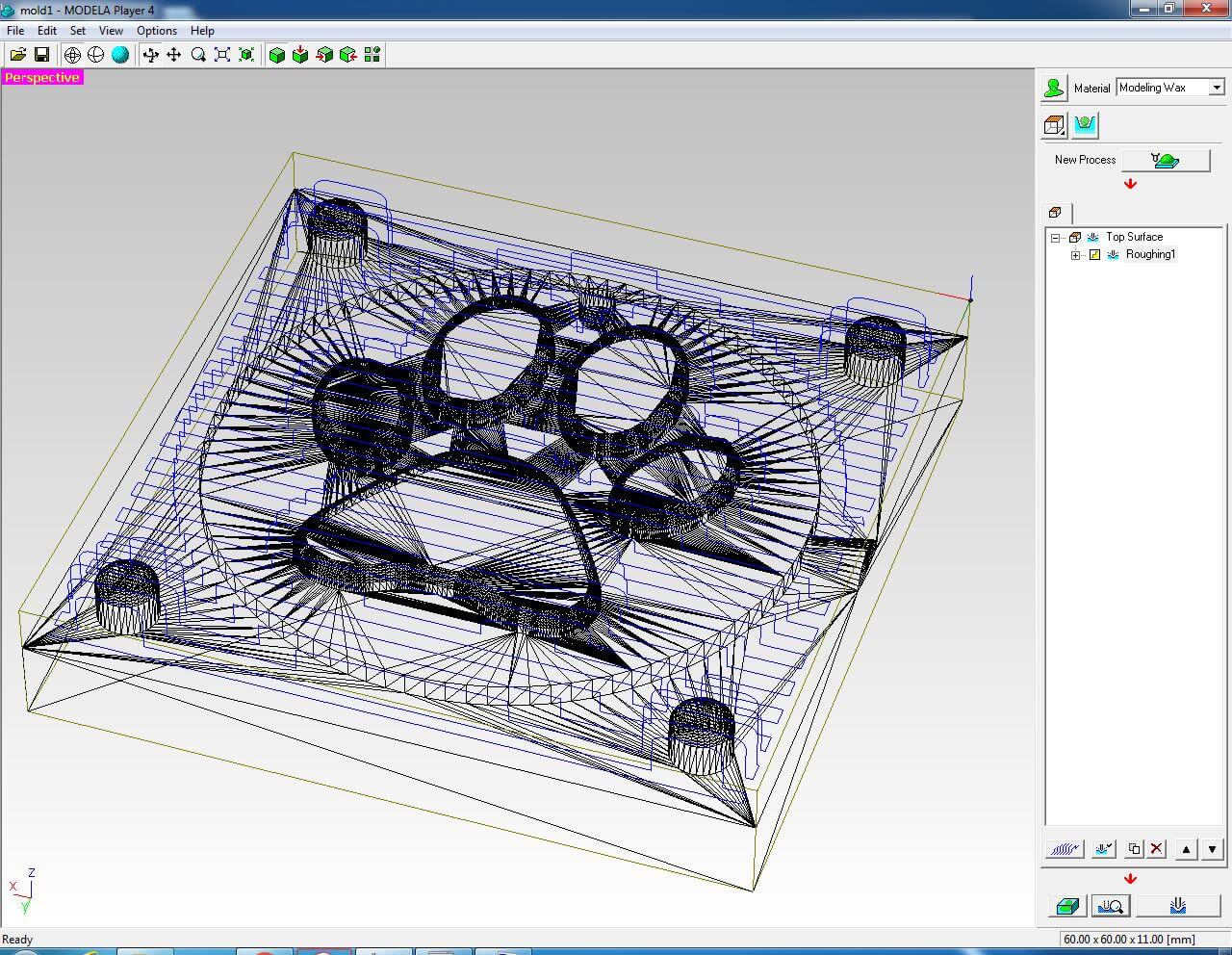

Worked Modela player

Open my design

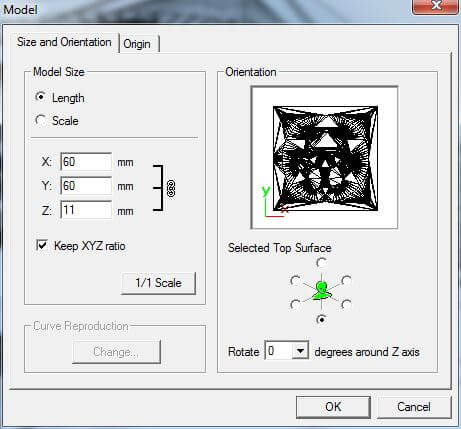

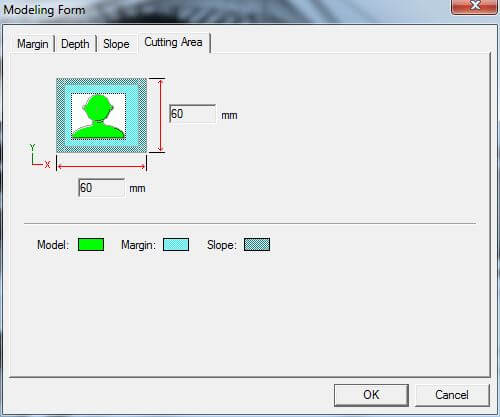

Set design orientation and Scale

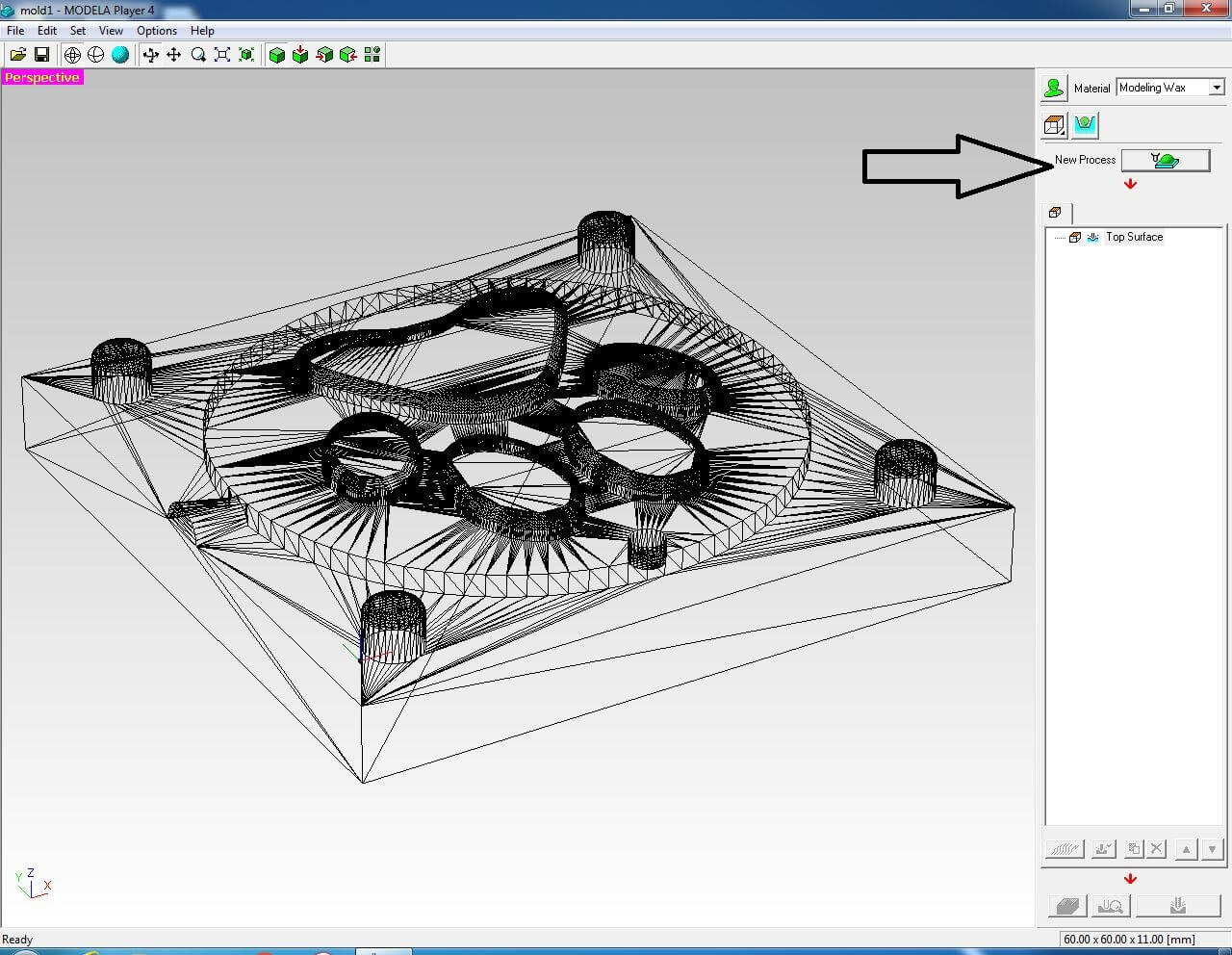

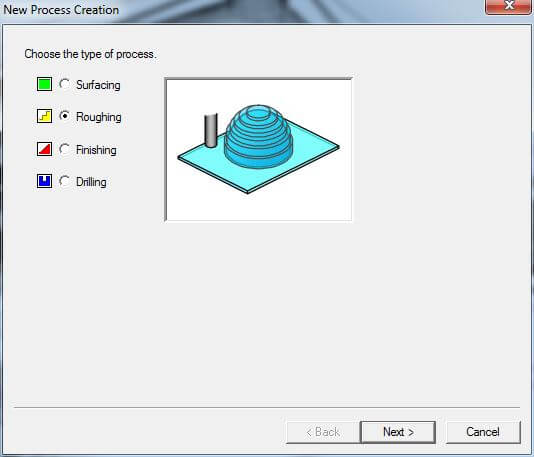

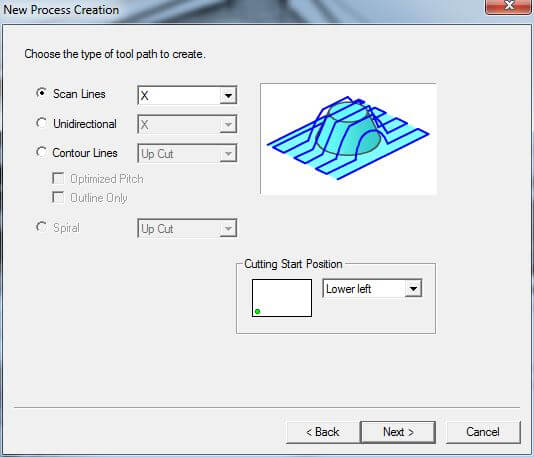

Define a new process

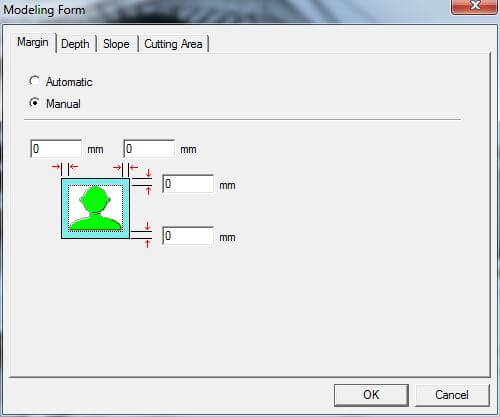

Margin

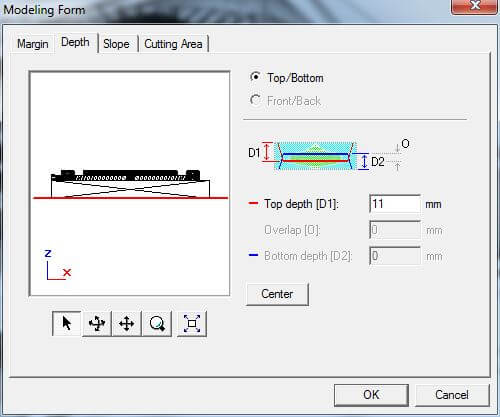

Depth

Process : First time roughing then Finishing

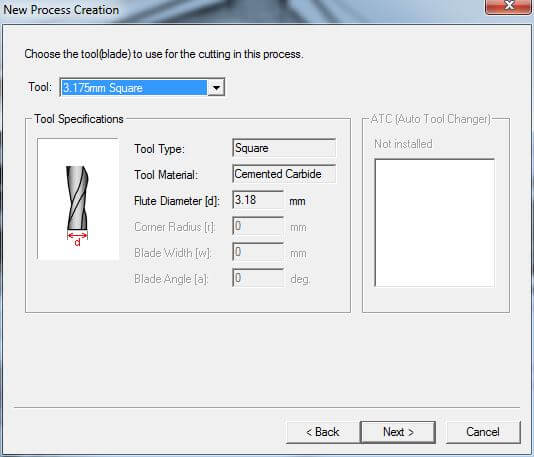

Set Tool

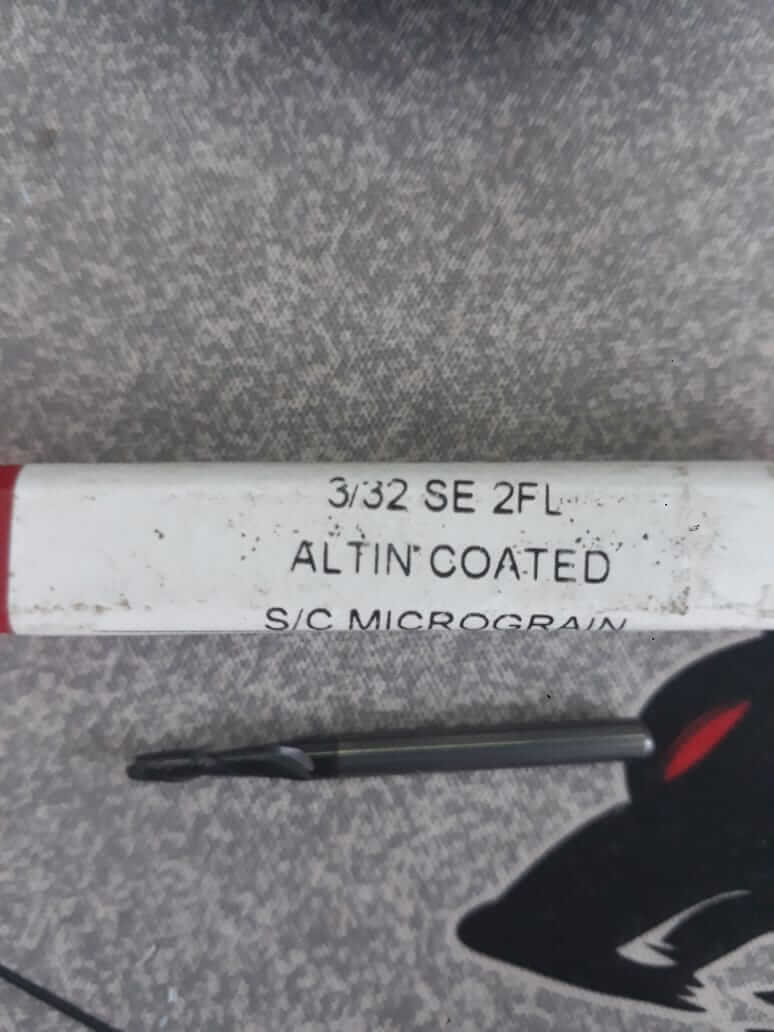

For Roughing I used the 3/32 Square .

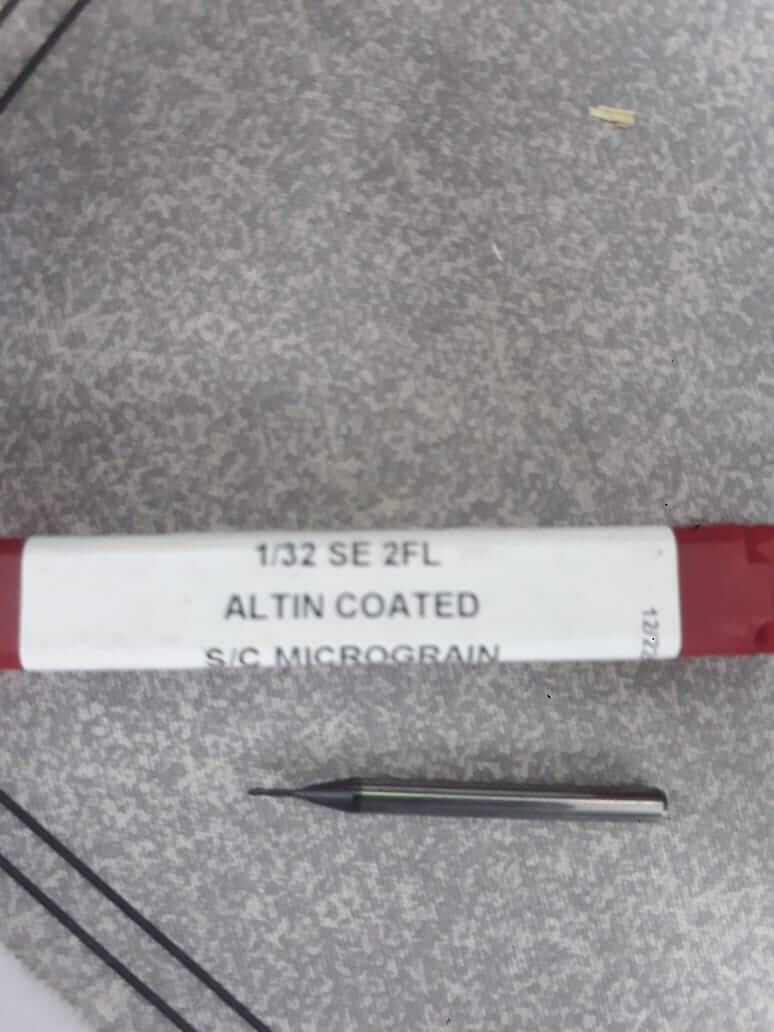

and for Finishing I used the 1/32 BallNose .

Continue setting , Lines type

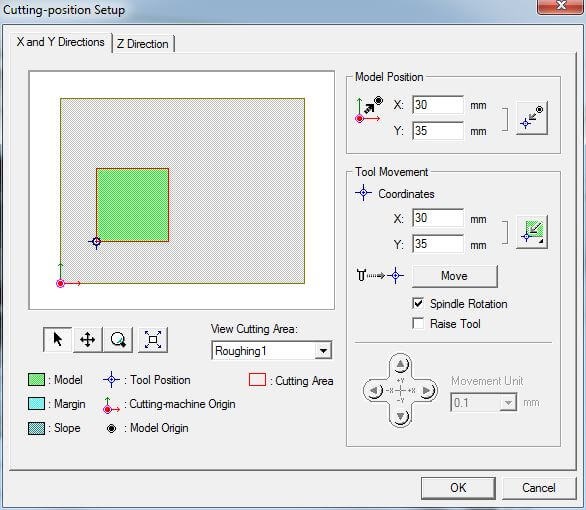

And before starting , I set my origin

After pressing Preview , I get to know estimated time for the process and I can see now the machine route

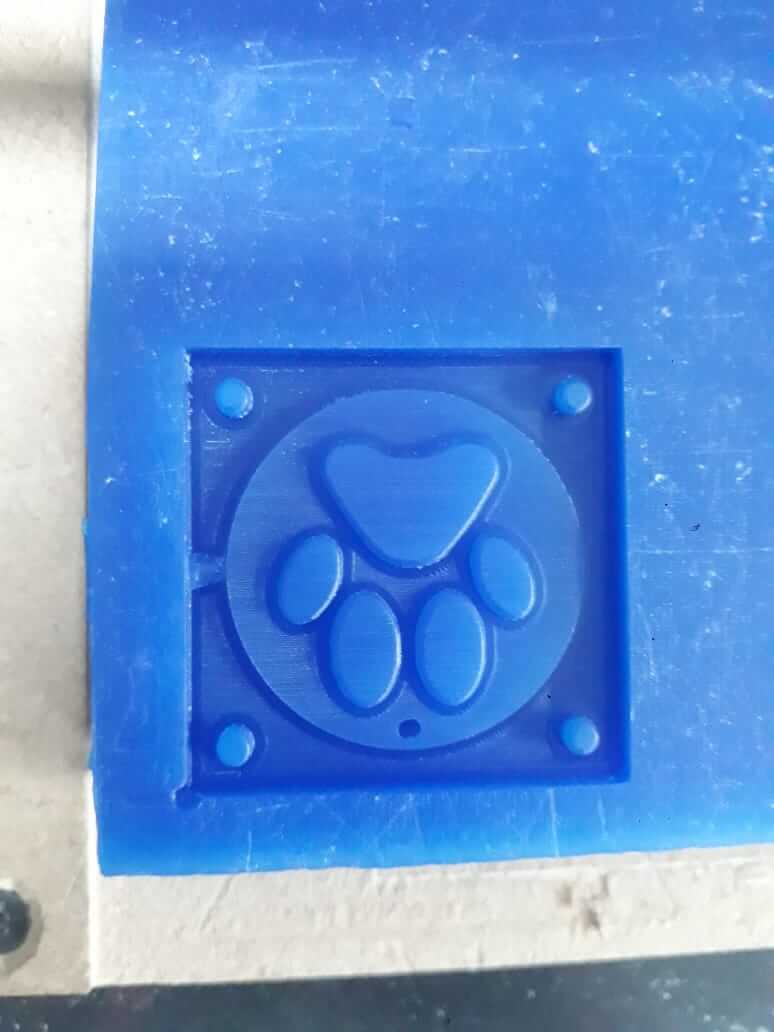

Roughing Done

And Finishing

and off to Mold2

Silicon¶

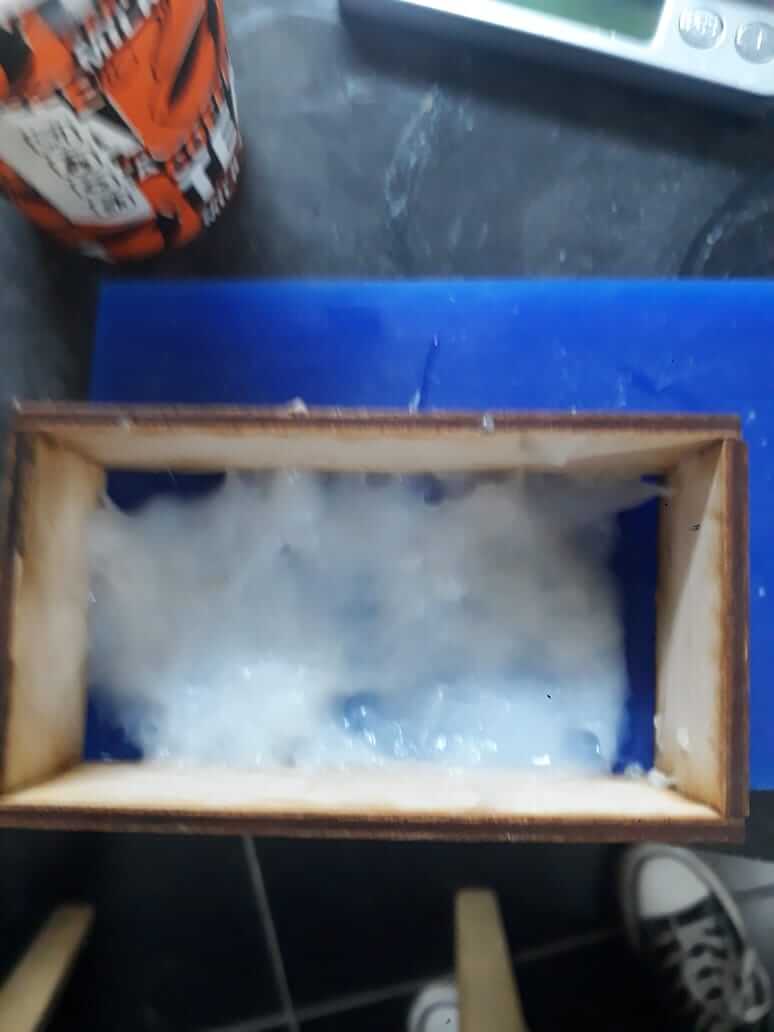

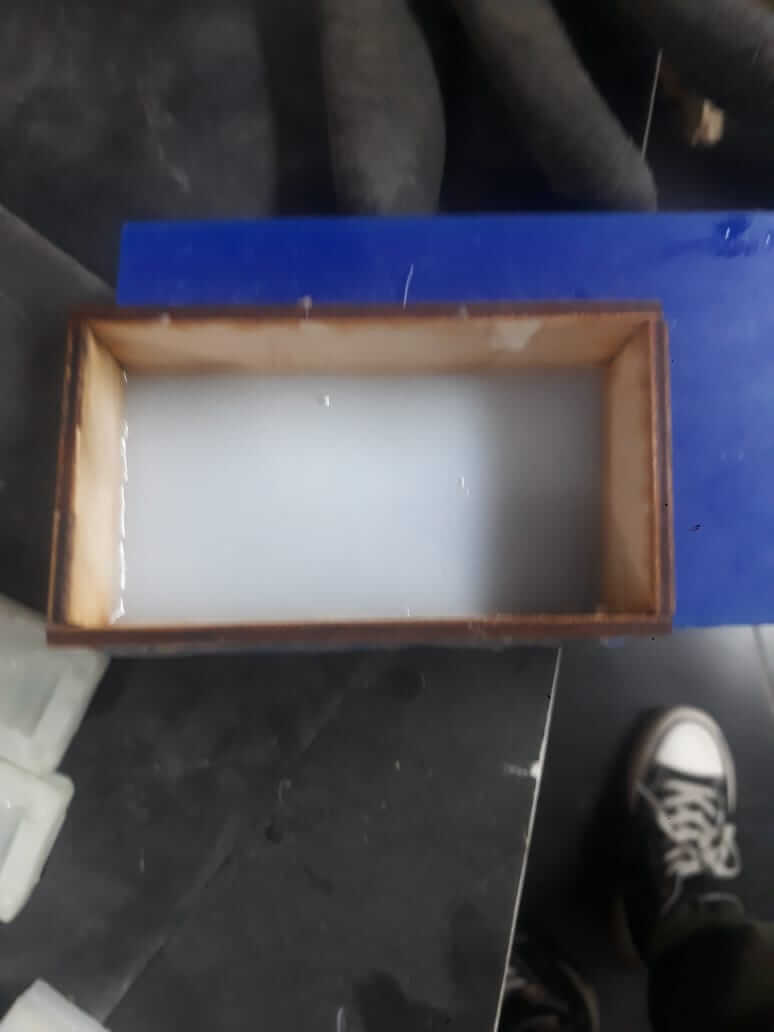

I made a mistake in the desing , Didn’t make walls . and the mold wasn’t deep enough .

So I made walls of wood , sealed by wax gun

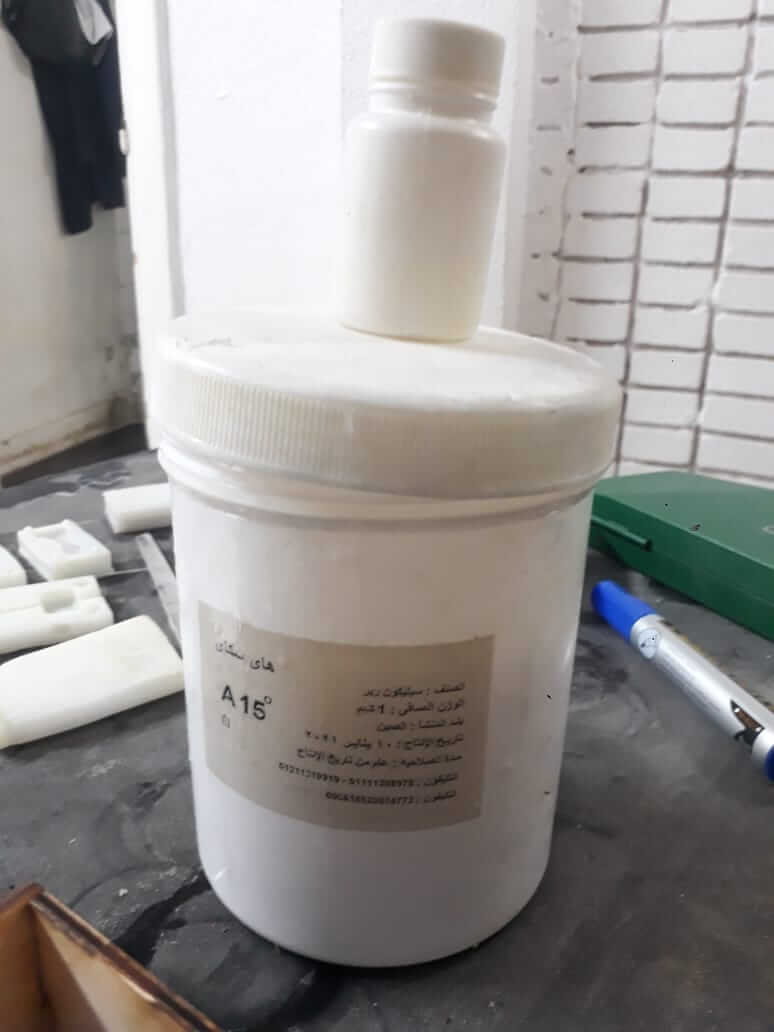

Preparing the mixture with a ratio of 1:10

Probably I over-stir it as it came out very thick and mold wasn’t successful .

Try 2 , with 1:15 ratio , As I don’t want it to dry fast

This time it came out much nicer

Resin¶

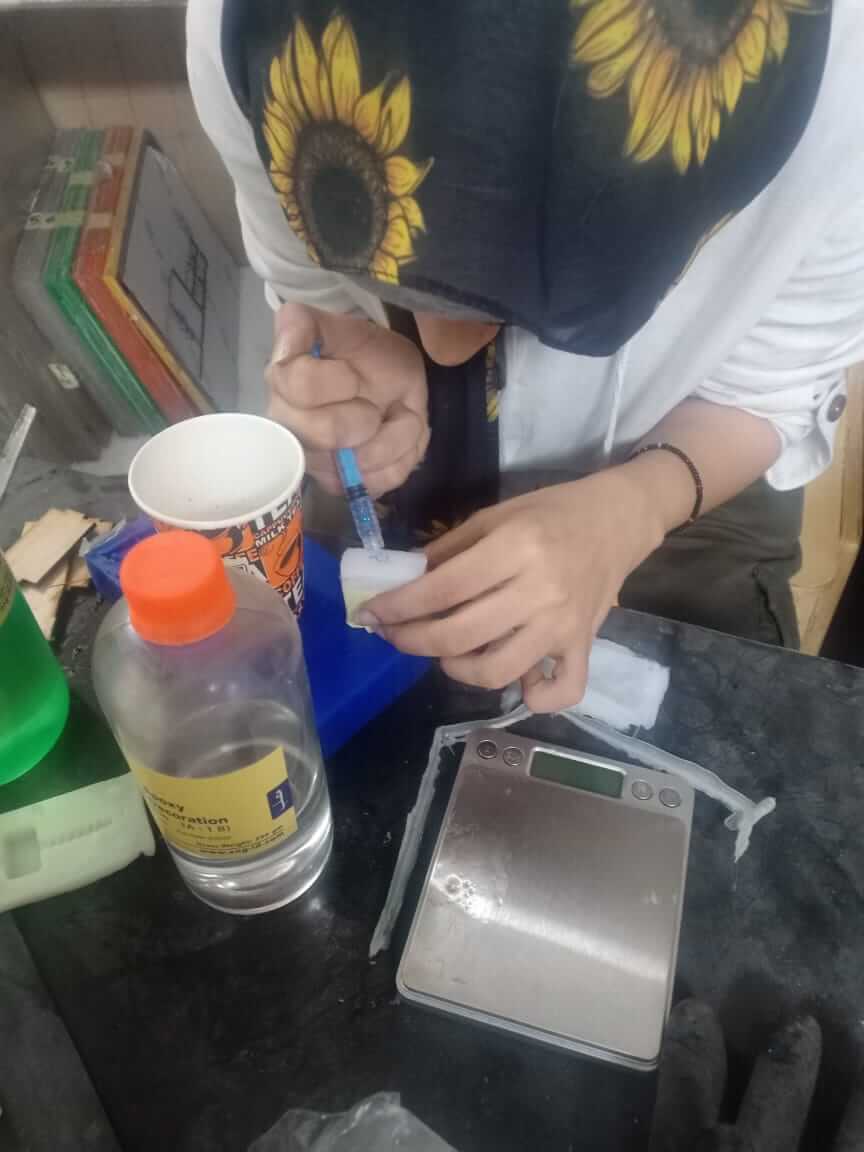

Secured my two molds together using tape .

Prepared my resin with a ratio of 1 : 2 and a sprinkle of glitter .

And poured inside using a syring .

A lot of bubbles , yet I love it