1. Principles and practices⚓︎

FabAcademy 2021 has started!! Although last week we had some introductory days to the course, it was not until today, Wednesday January 27th, that I felt that the course had begun even so I am still in Madrid. It will be this weekend when I will travel to León to start living there and go daily to the lab, so the experience will get more intense. Also, I’ts been a pleasure to meet all my collegues and instructors that will accompany me during the course and the expectations each of us have for FabAcademy. All of them have plenty of background in lab life so I have a lot to learn to get to their level! This is my squad:

This first week we have two assignments: Principles and Practices and Project Management. In this one, Principles and Practices we have to draw the first sketches of our final project. My colleagues have already decided the projects they want to fabricate, but I have not yet clarified my ideas, so I hope that representing some of them will make me draw conclusions. These are the Assesment Criteria related to the first assignment of the course, Principles and Practices:

-

Individual assignment

- Plan and sketch a potential final project.

-

Learning outcomes

- Communicate an initial project proposal.

-

Have you?

- Read the Fab Charter.

- Sketched your final project idea/s.

- Described what it will do and who will use it.

Concepts⚓︎

I’ve been struggling a lot to decided about an idea to develop on FabAcademy. There are such a lot of interesting topics and awesome past projects that I’m a bit overwhelmed. Many of my ideas are not concrete enough to develop a concept because they would require a lot of research before I could realize them. Others are too complex to cover during the course, and reducing spirals of complexity makes them quite useless. In the other side of the spectrum, much simpler or one fabrication topic projects doesn’t fulfill all the requirements of a FabAcademy project, such as electronics. Complexing them is not the solution either because they would become meaningless.

Apart from all those problems of developing certain ideas, there are a series of criteria that I want my project to meet:

- I would like the project to have a definite purpose, if possible to solve a social or personal problem in my environment.

- I should aim, as recommended by my instructors, to be able to establish growth spirals for my project. From the most affordable basic one, with which I should also be satisfied if it is the only one I reach, to more advanced ones that will turn it into something really interesting for the community.

- Also, trying to develop a concept that suits the assignments itinerary as best as possible so it’s easier for me to develop throughout the course.

Despite all this mental noise about my project, I’ve got some topics that I think would be cool to develop, and some projects I’ve had in the making for a while that could get finished much better with all this digital fabrication tools. Here are some of them:

Cooling laptop dock⚓︎

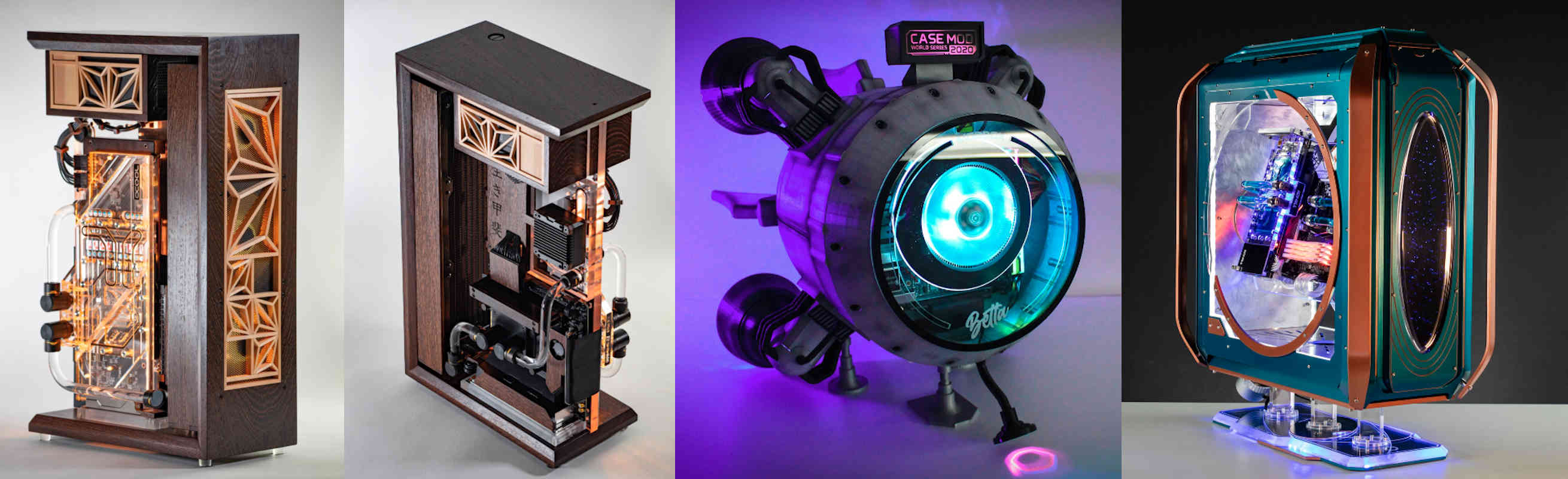

This first idea came out during pandemic, when I was always working with my laptop as a desktop, and temperatures on it got a bit toasty. I though it would be pretty cool to develop a dock with it’s own dedicated cooling and casing, so you could get back home and slide your laptop to transform it in a desktop like experience. Also, part of my Digital Fabrication passion has come from PC modding. Series like Case Mod or Cooler Master inspired me a lot to see the amazing possibilities this world has.

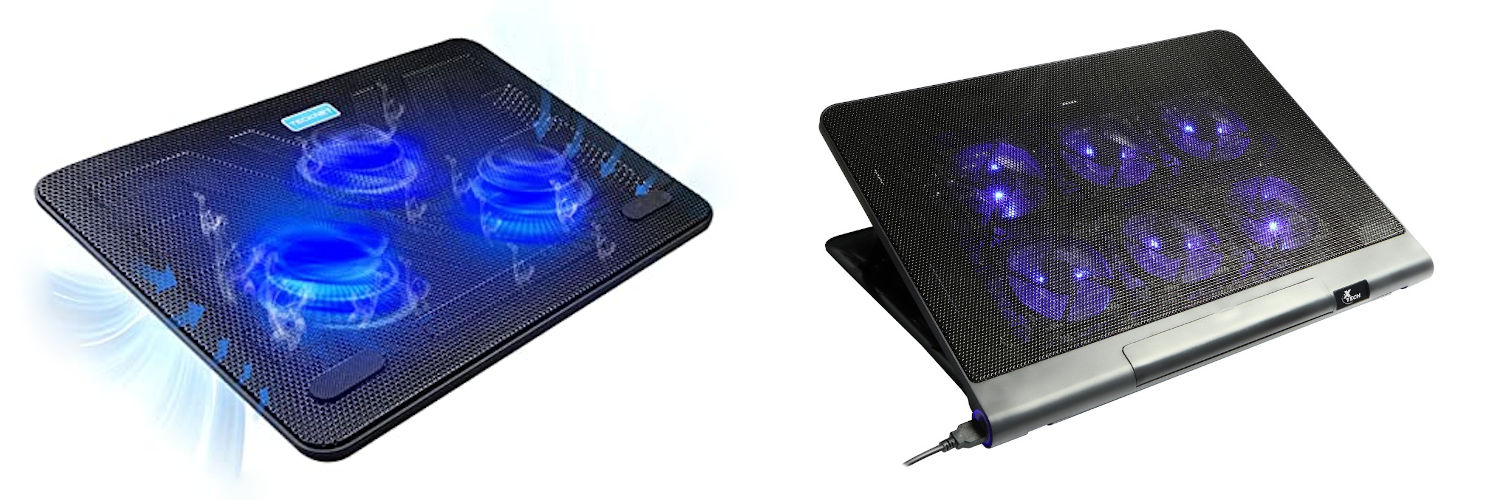

Currently on the market there are some generic basic solutions consisting of a flat platform with one or more fans that provide extra airflow to the top of the laptop, which is where the vents are usually found. This allows to lower the temperature a few degrees but it is far from being a desktop dock. On the other hand, for some specific professional models there are docks where to attach the laptop through a proprietary port, which provide extra connection ports and that feeling of a desktop dock, but without extra cooling. Also for my particular model there is no alternative like this, so the idea was to develop one that merges both possibilities. This are some of the references I just mentioned and other cool projects that inspired me:

Standard dock for bussiness laptops

Standard cooling base for laptops

Extreme cooling solutions develop by manufacturer

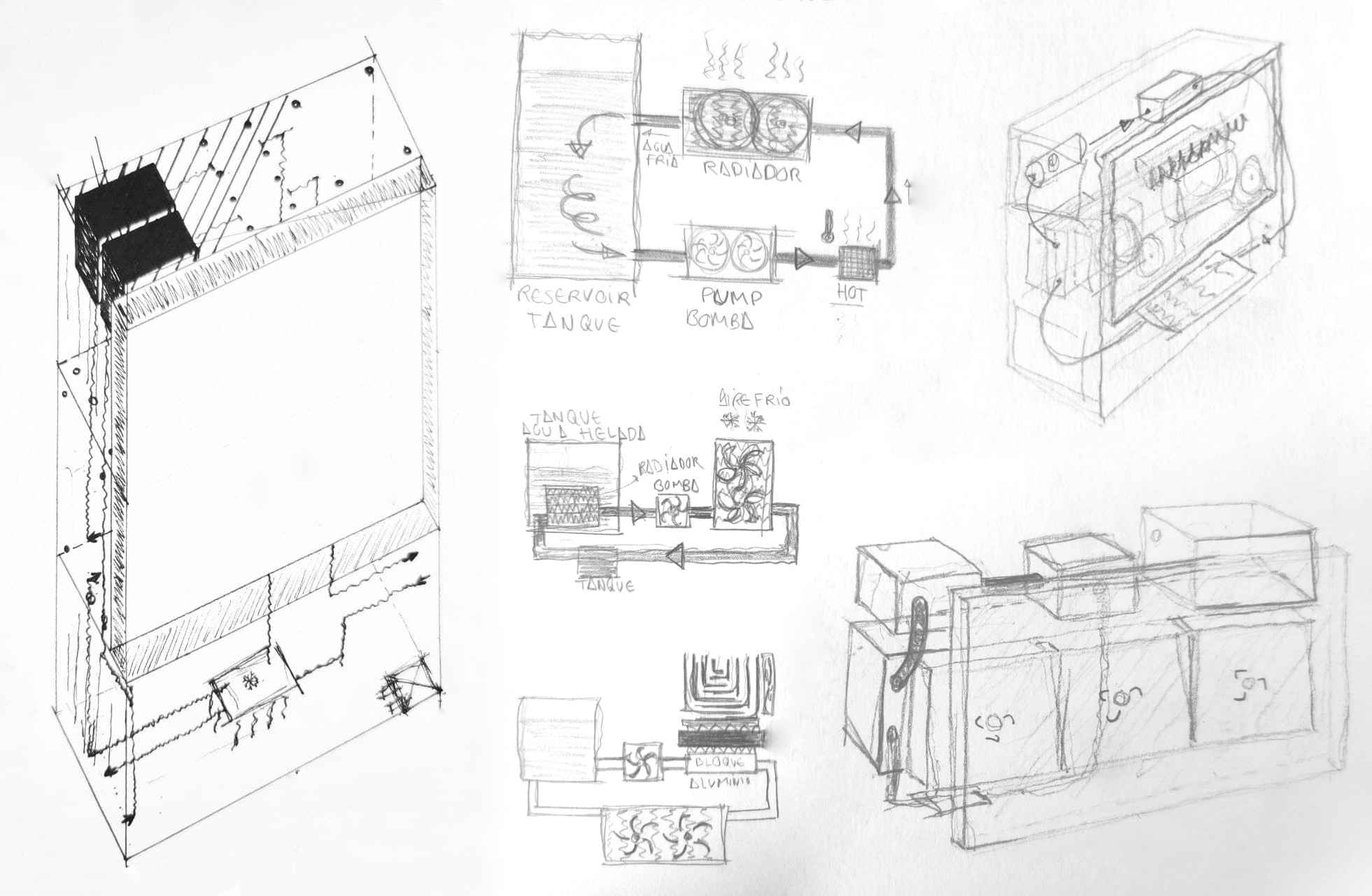

I want a more hardcore cooling solution than some fans blowing room temperature air, as cooler air means lower temps on the laptop and that extends it’s durability. The first idea came working with Peltier cells and other cooling related projects, so I sketched some concepts with 2 water loops. The cold loop can push fresh air to the laptop, while the hot one gets rid of the heat produced by the Peltier because of the thermoelectric effect. This are some sketches I made to figure out the arrangement of the elements.

To meet the Fabacademy standards for a final project, we need some electronics, and this can lead to a deeper control of the cooling so it’s a win win. Using some sensors to control the surface temperature of the back of the laptop, where the processor and graphic dies are, should allow to controll the fan and pump speeds in correlation. This means less noise and power draw when not all the cooling potential is needed.

There should be some problems to deal with. Condensation is a common thing when using Peltier cells, and water doesn’t go well with electricity, so there should be good ventilation for the area where the cell is and have great isolation. Also, efficiency should be under control, because this type of electronics consume lots of power and maybe the lower temps for the laptop aren’t worth it.

Update

During week 2 of the course, in the Computer Aided Design assignment, I 3D modeled the design and most of the parts for the project, planned the loops based on the sketches, measured the dimensions and figured out some things in the making. First of all is the size, as it’s getting a bit bigger than expected. I wanted a compact solution and tight spaces are not the best frind for heat and ventilation. Second thing is wire management, as it needs lots of design work and intention to finish it clean.

This idea is a viable option for a FabAcademy project but, I’m not quite sure why, it doesn’t generate too much engagement on me.

Time management device⚓︎

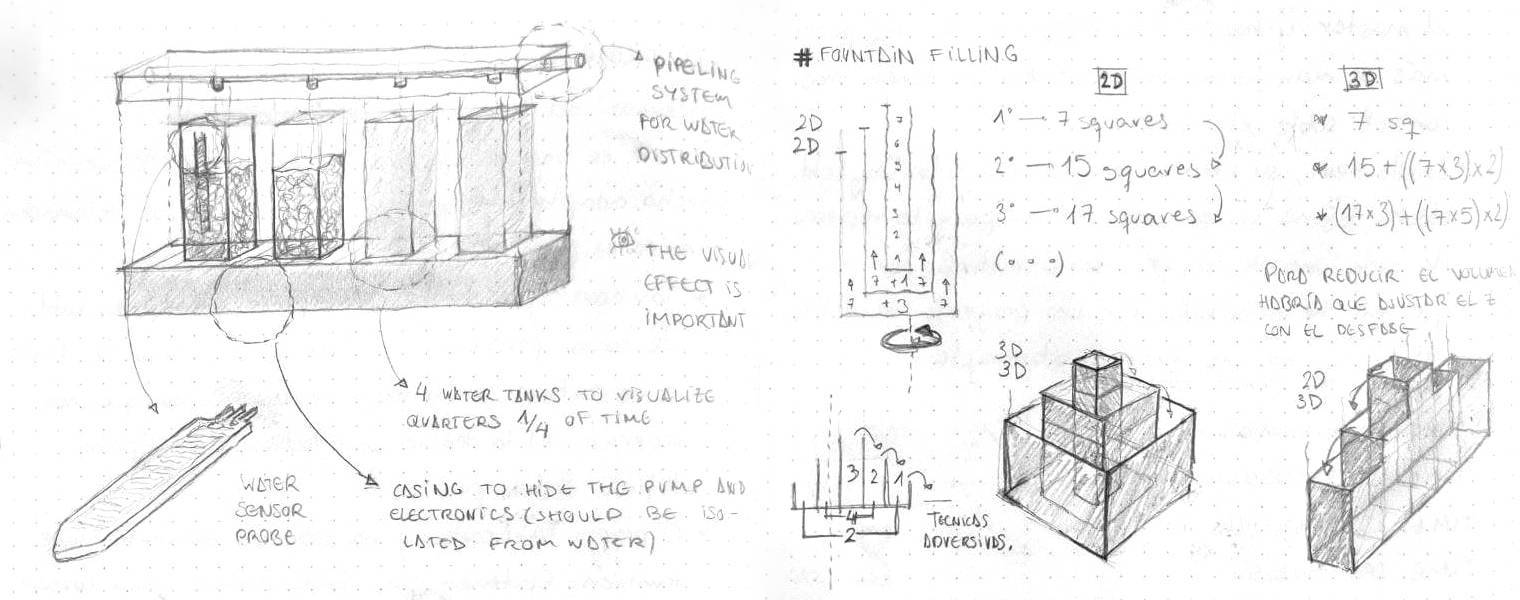

This second idea is given more by a personal conflict than by an external need, time management. Time has always been an element that has caught my attention. Both trying to handle and represent it allows multiple iterations and interpretations of it. For this reason, I think it would be interesting to address this issue, with the possibility of making an element that represents it in a creative way to reflect on its meaning, and as a device that allows a greater awareness of it.

This is perhaps the project that attracts me the most, due to the creative possibilities it offers and the flexibility of choices when it comes to meeting the course standards. Electronics could range from sensors dedicated to measuring an element of the representation, to devices that make a mechanism work. In this line, I have decided to make some initial drawings of a prototype whose purpose is to represent a period of time in a visual way. In this case, it would be through water as an element that determines the progress of said period, trying to convey the concept of fluidity also present in time.

As I mentioned before, the viability of the project is good. The electronics would consist of a level sensor as input and a water pump as output, and a possible interface through a screen and buttons, or an application and a bluetooth module. The design and finish is totally dependent on the development of the different topics that we deal with during the course, although working with water first complicates things a bit.

Extra ideas⚓︎

-

Defibrillators for drones: Cardiac arrest is one of the most common causes of death in Spain. It is not only necessary to detect the problem as soon as possible but to act in less than 5 minutes after the collapse, something extremely complicated if the defibrillators are limited exclusively to hospital spaces. Experts warn that early defibrillation is essential to saving lives. Recovery of the heart rate is 90% when it takes place one minute after the heart attack. However, every minute of delay will limit its effectiveness by almost 10%, so after 10 minutes the chances of survival are slim. You can find more info here

Therefore, under this idea it is intended to use the mobility and speed of a drone adapted to autonomously transport a defibrillator equipment, offering a very fast response capacity and a greater range of coverage of these devices in public spaces. Handling them is extremely simple, and it would be enough for a user to alert emergencies of the situation to activate the device, and for it to arrive at the place in a few minutes. This is a concept that I have found searching on this idea:

The idea serves a specific purpose, but the realization makes the project extremely difficult to manufacture during FabAcademy. Developing a drone for this purpose would not make much sense, since there are already models with high capacities, and matching the necessary speed and power benefits that are required for this case would be extremely complicated. The logical development would be to develop the system that allows cohesion between the drone and the defibrillator, but this could be solved in a simple way with a 3D design and the manufacture of the model, so it would be an incomplete project.

-

Radon Meter: Radon is a colorless gas (it has no color), odorless (it does not smell), tasteless (it has no taste) and invisible that is generated naturally in the subsoil by the decomposition of the minerals in the subsoil. It is present in almost all types of soil, but calcareous soils are more isolated than granite ones. For this reason, some areas of Spain present higher levels than others. Radon leaks into homes through cracks and holes in the walls, through capillary action in the walls. It is more evident in rooms in contact with the ground, such as basements, but it can accumulate throughout the house, especially if there is no proper ventilation.

The project would consist of a Radon gas meter, including the manufacturing processes of the encapsulation using additive and subtractive techniques and the development of the electronics with the corresponding input and output sensors. Currently there are numerous devices that allow these measurements to be made as we can find here, and in this case we would not be contributing any innovative concept to the project, more than a replica. In addition, the creative part is quite limited so it does not attract my attention too much.

Conclusions⚓︎

Many purposes confront in the choice to get a valid idea, but I would like to stay true to them, because I think it will be the key to feel satisfied with the course and enjoy the process. I know FabAcademy would open my mind and bring new purposes through the project so I’m excited for what is to come.

If you know any related ideas, references, past projects or inspiration that could fit my intentions, feel free to text me up in Mattermost to expand my view! It will be really helpfull for me.