Week 11

Design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut) and use it to cast parts.

Molding and casting

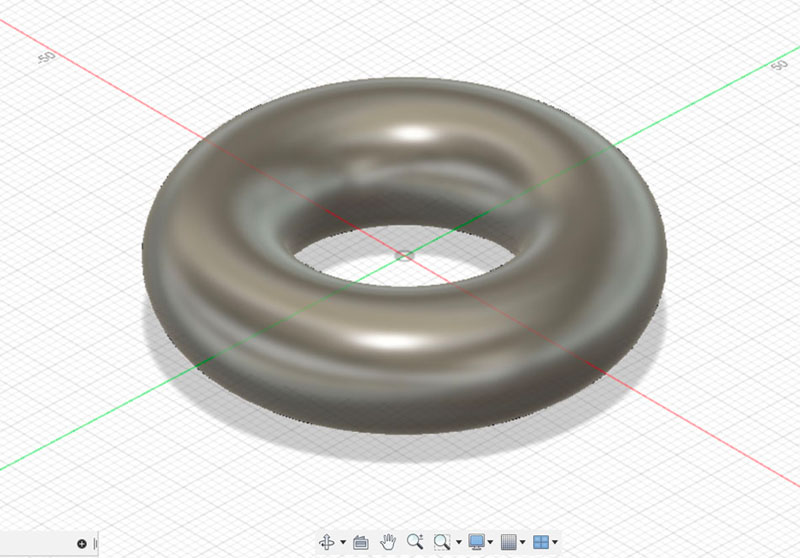

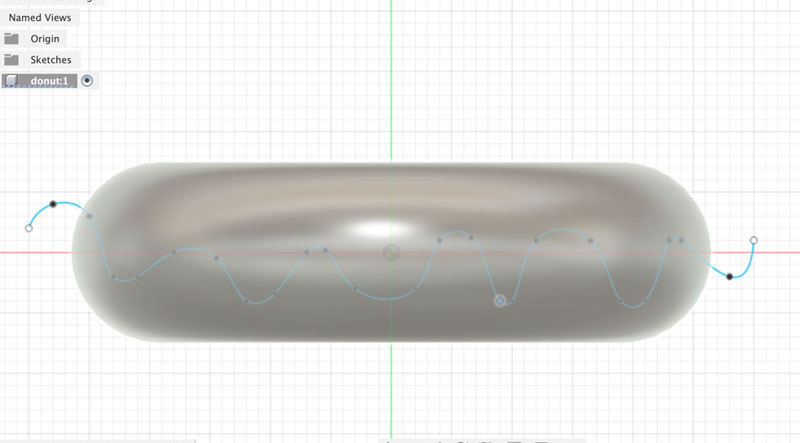

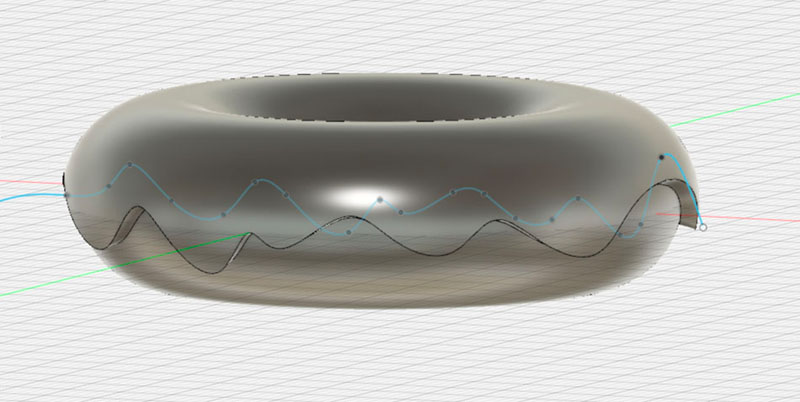

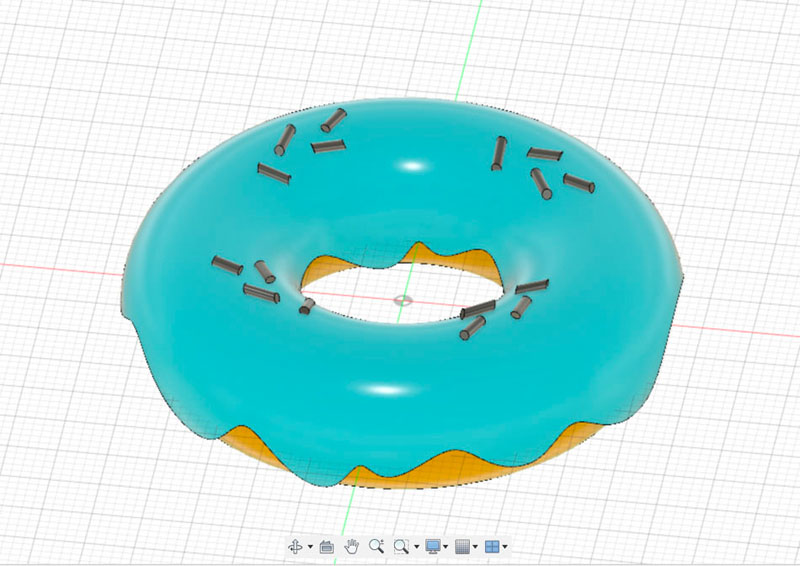

For this week I haven't had idea what to create, after spending a couple of hours browsing I decided to mold and cast a donut. While the main form is really easy, the main question was how to model the icing. So I found info in german how to do it, even though I don't speak german lol. Here below the first steps taken, the icing finally was done creating a line on the profile and then just using the tool Trim on both sides.

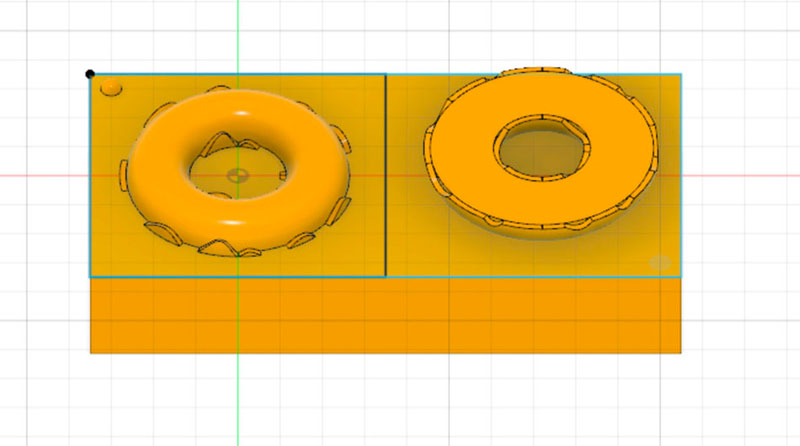

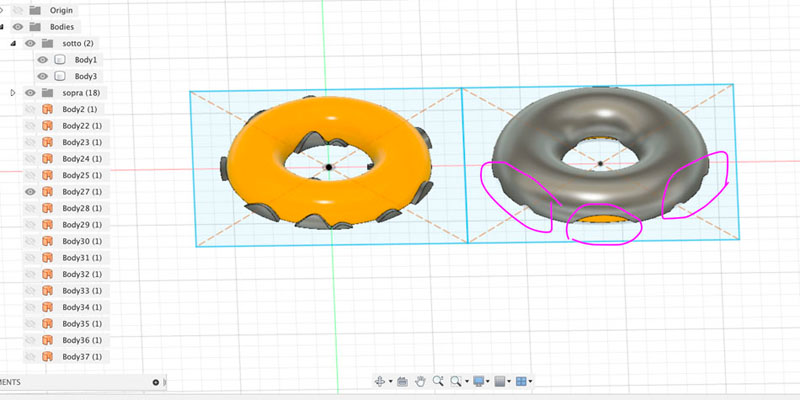

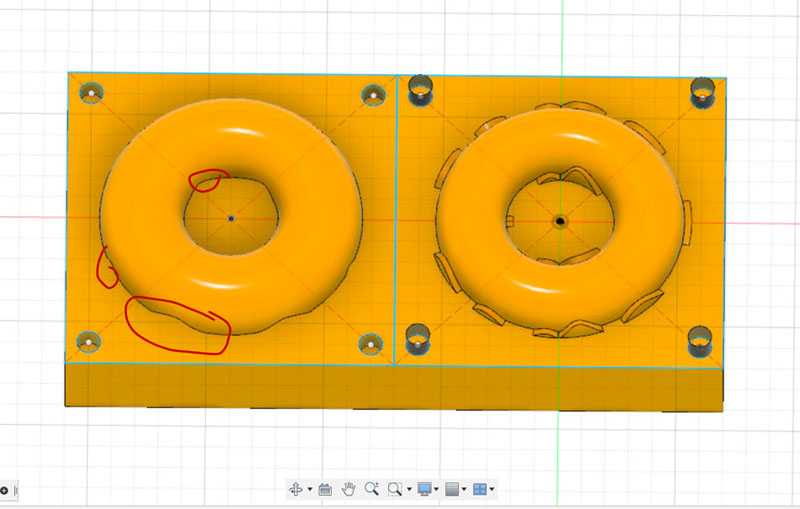

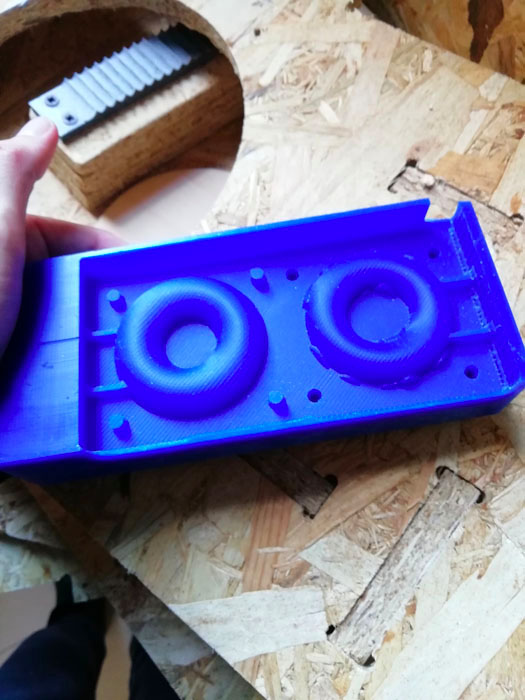

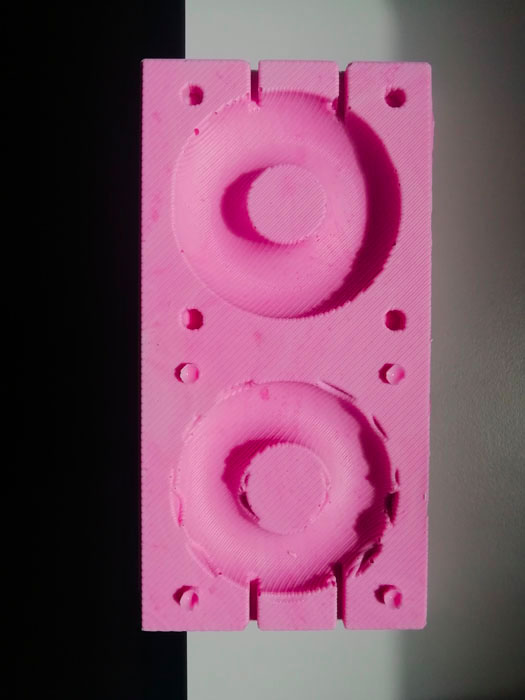

The sugary thing I've decided not to mold, because the whole object was quite small. The icing presented some issues as well, in the pictures below I colored the parts that were not possible to be milled, this "undercut" is just physically impossible to mill with machine that has three axes. I also made a mistake in the beginning with the model on Fusion360, that is the parts that were to be mold were upside down, so I have to turn the second part of the donut in order to create a vessel for silicone. So I made the registration keys and two tunnels for air, too.

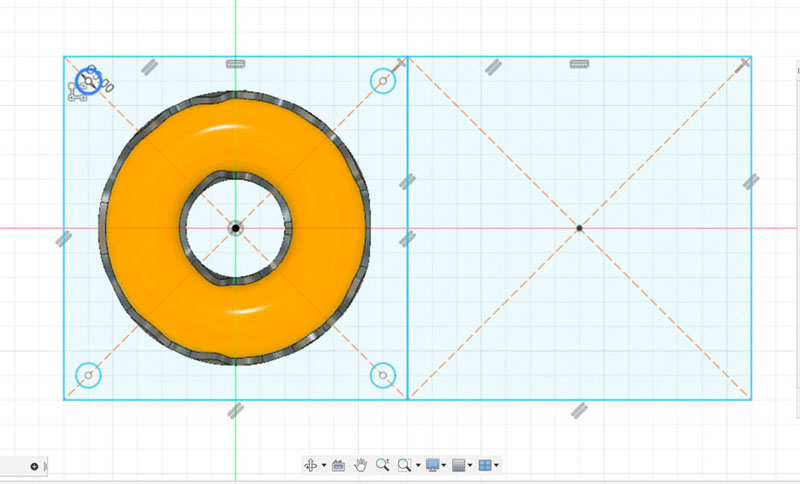

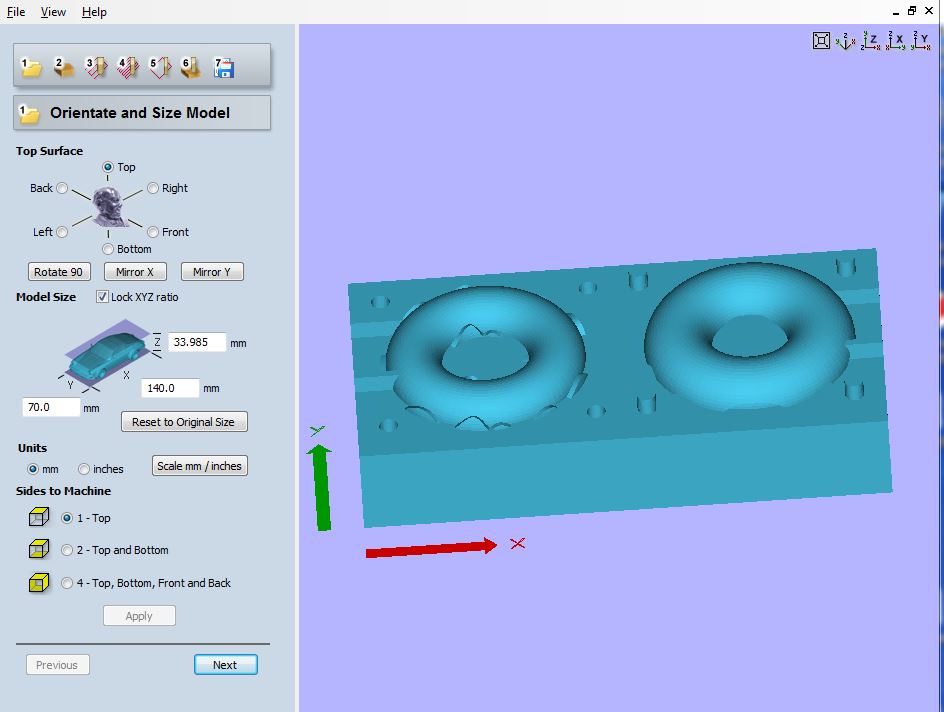

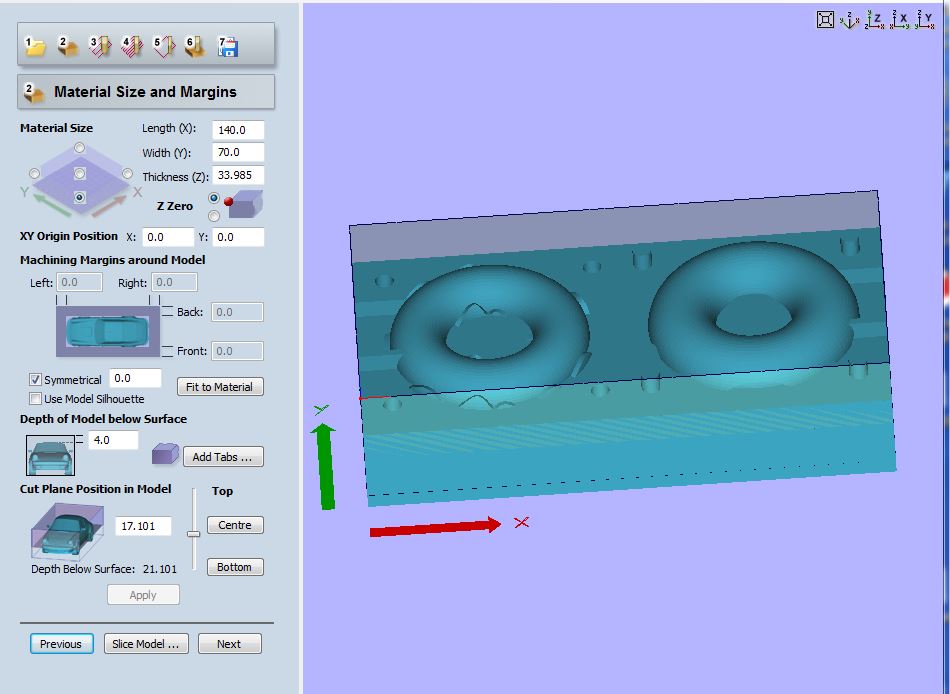

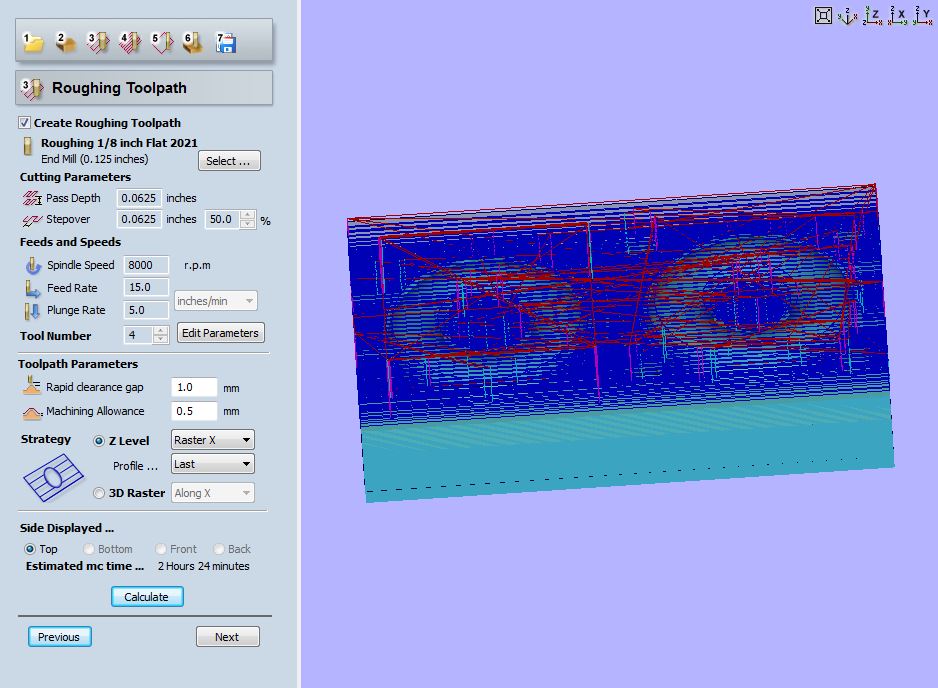

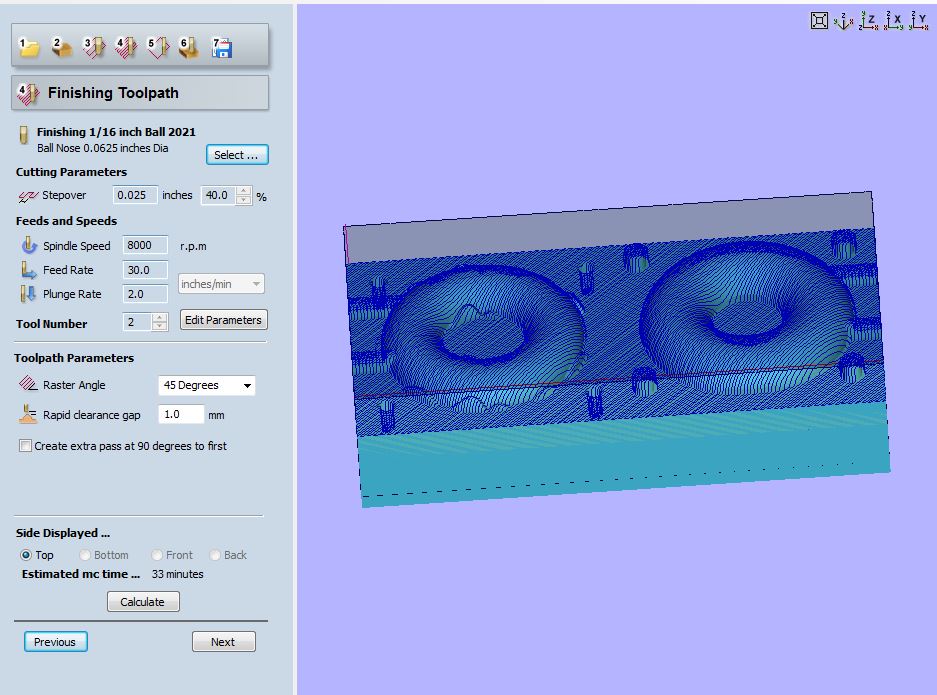

Then I prepared the file on 3DCut software to mill.

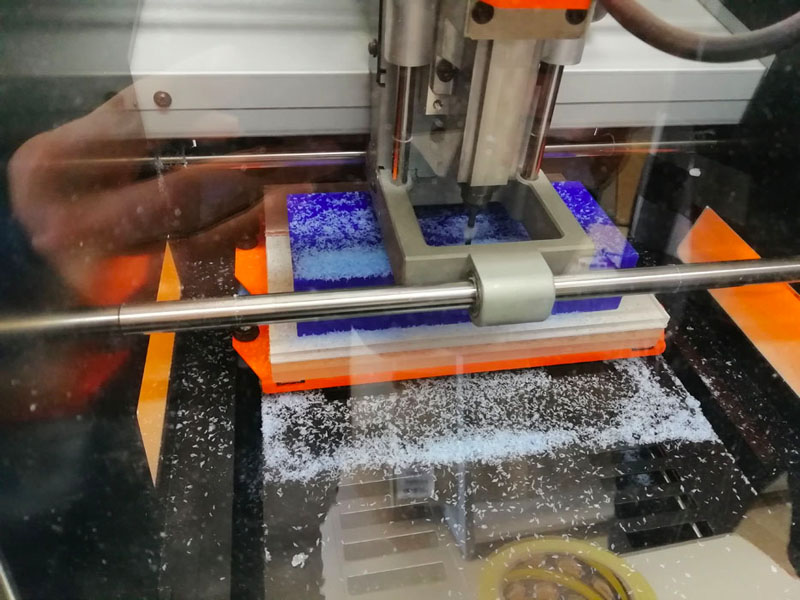

While milling I noticed that one side just fell down, because the available width was 8 cm, while my donut frame was 7 cm.

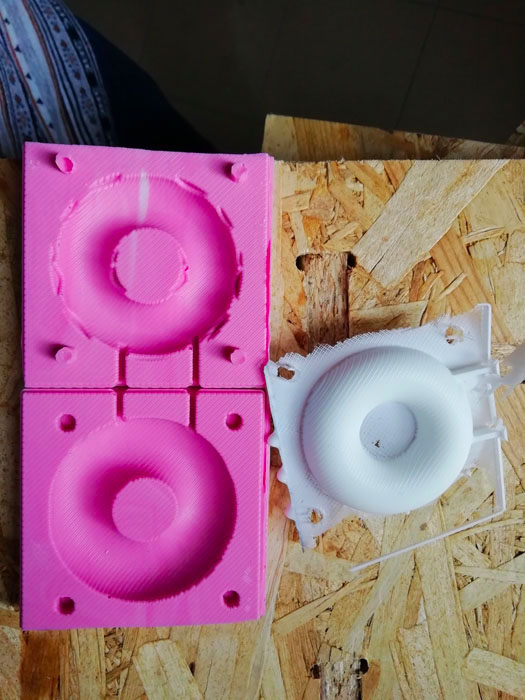

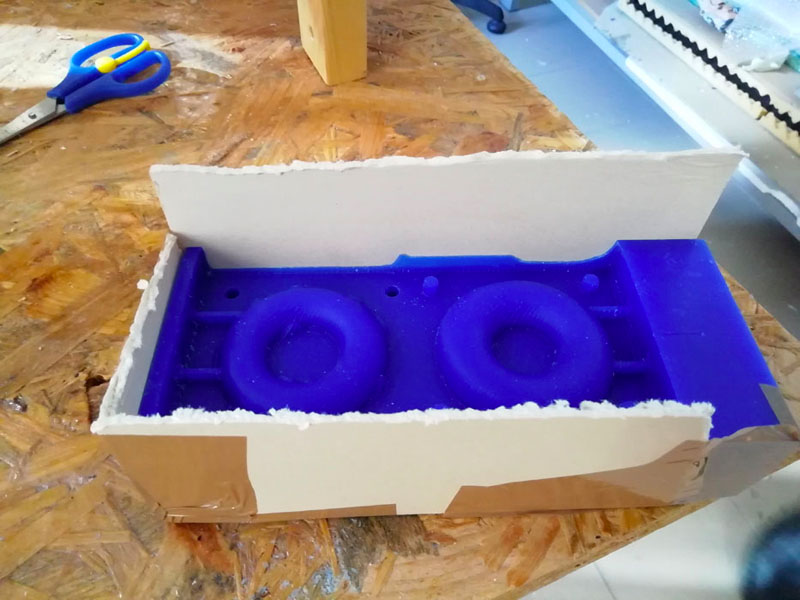

The first cast didn't come out perfectly well, I tried to mix the silicone veeery slow, but at certain point it got too solid, so I just poored it. In the registration keys some of the air was trapped, so they came out not very high, although, high enough to be used anyway. In fact, there were some bubbles in the silicone, too. I used talc powder as release agent, in the second cast I didn't use it at all and there was no evident difference. So the first material for casting was liquid plastic.

It did not come out very nice, cause apparently the model got switched when it was pressed and as you can see the icing undercut part didn't come out as it had been foreseen.

So I redid the whole silicone mold and tried the first one with hydrostone and the second, new one, with plastic again. It came out much much better, that good that the registration keys were too high this time :D I cut them and poored plastic in the mold. Once dried it was completely covered in it, I cut it all out and it was ok:)

I had some problems with hydrostone though. I read the instructions just till the proportions (20 parts of water to 100 parts of powder) and just later noticed that it also said to add powder into water, not the way around as I did. Read the instructions!:)

Anyway the mass created was not enough for my model and very quickly I tried to compensate it other hydrostone substance without really following the instructions anymore. For this reason probably it still looks like wet, but it worked!