Week 16

Assignment: Design and produce something with a digital fabrication process (incorporating computer-aided design and manufacturing) not covered in another assignment, documenting the requirements that your assignment meets, and including everything necessary to reproduce it.

Biomaterials

Our lab gave us green light, but we focused mainly on composites. So I did a small research to find what I would like to create and decided to compose at least two biomaterials and hopefully to make bracelets with them. I searched mostly on materiom website where I found some recipes that I liked. In particular, I wanted to try clementin gelatin plastic, nettle leaf composite and a biomaterial with activated charcoal.

Into the wild

Since the main problem there was to find nettle leaf, I went to find it outside of our small town. Fortunately, there was nice weather even though at certain point I was fed up looking for this plant and as I found out later the one that I got was not even nettle leaf at all lol Well, I tried.

The recipe required 100gr of leaves, I guessed it was a lot, but still tried to get as much as I could.

When I came back home, I needed to dry the leaves as fast as possible. Another recipe required clementine peel, I had oranges and in the end did not reach 150 gr anyway. Firstly, I selected the leaves and prepared orange peel. Then to dry it all I put it into oven at 50 degrees circa with ventilation (it turned out essential for fast drying). In fact, after an hour and a half it was ready to be used. I forgot to put peel, so I waited a bit more, but generally it took less time than I imagined. Once I got it all out, I distributed materials into jars. Since the leaves were really dry, it was easy to turn them into powder. In order to make composites it is important to use dry materials mostly in form of a powder because in this way it amalgamates better and after time does not create mold due to natural process of decomposition.

I did not calculate properly the mass of gelatin needed, even though I bought some extra packages of it, I would be able to composite just two materials and that is what I did.

Cooking activated charcoal

I decided to start with the one I was more curious about because of the color and possibilities the material offered. On the website of Fabtextile it is possible to see a brief research on this material and doses to use depending on the desired outcome. In my case, I wanted it to be flexible and shiny, so I used:

- 100 ml of water

- 25 gr of gelatin

- 14 gr of activated charcoal

- 25 ml of glycerol

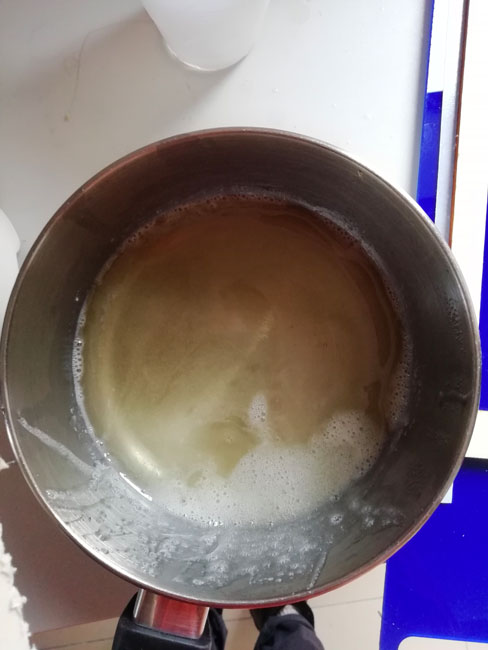

The steps to follow are described here, in the step one they suggest to mix gelatin powder with water off the heat. In my case, I had gelatin sheets and it was too hard to melt them without any heat supply, so from time to time I would put my pot back on the heat in order to melt all the substances properly.

Besides, it was hard to identify the white deposit forming that was to be eliminated following the instructions, because this foam, visible a bit in the picture started to form almost since the beginning. Anyway I tried to get rid of it.

When the time came to add activated charcoal I realised that it does not melt in the hot water by itself (realisation that I could have made earlier, I know..now). So quite urgently I needed a mortar to pound all those tablets of charcoal. I did not find anything better than a wax block that we use for molding (I cleaned it afterwards, obv) and fortunately it worked!

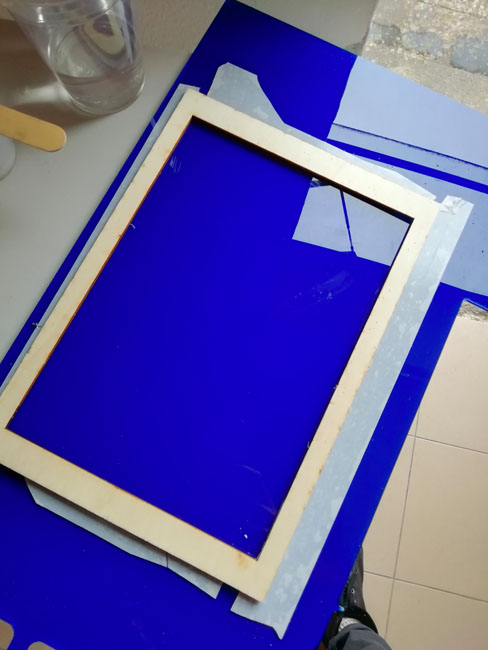

One of the important things specified in the instructions is to prepare a mold before starting all the cooking. So I prepared a simple mold for the substance, although the wood frame eventually would not resist under the pressure of black biomaterial. I should have glued it better.

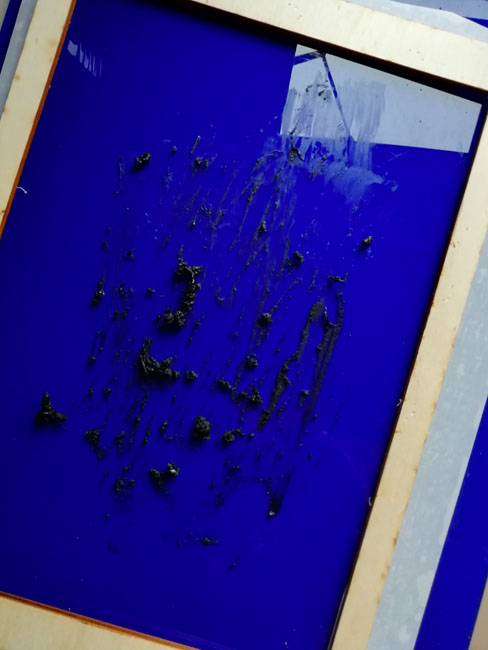

While I was pounding the charcoal all the mass was getting harder and harder. It is one of the main features of this recipe I guess: it gets solid very fast. In fact, I believe in three days it must be completely dried. So when I put it on the mold it was just a hard black ball that was impossible to spread on the surface. It's safe to say that I panicked during all the process and this moment was not an exception, so I don't have a picture of it, but just of glued pieces of composite that was left on the mold.

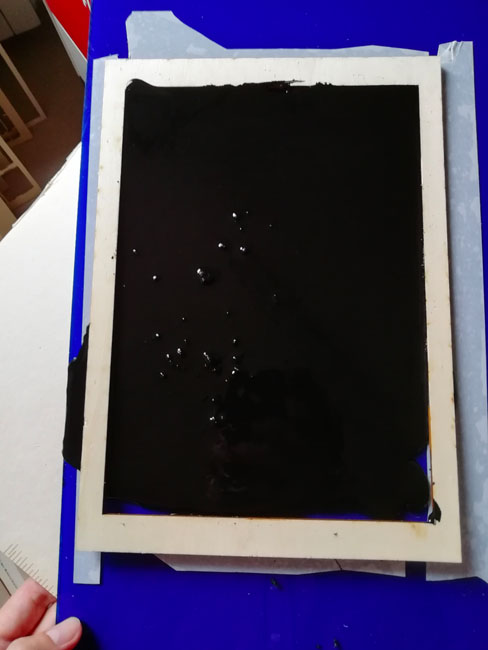

Basically, I just scratched it out of the surface and put back into the pot and on the heat. And that was the right thing to do cause it melted again, that permitted me to distribute the material evenly on the surface.

Then I had just to clean all this mess up, yea

Nettle leaf + orange peel cooking

The main idea was to follow the recipe with nettle leaf, because I liked the color. Despite I got a lot of leaves I did not reach 100 gr, but just 9 gr lol After drying all mass got light , so I decided to mix it with orange peel that was also not enough to use any specific recipe. I tried to follow the recipe of the latter, calculating the proportion, but it was evident that the mass was too liquid, like water, so I was adding some glycerol, then water and gelatin again. More or less, I would say I used these propotions:

- 130 ml of water

- 12 gr of gelatin

- 12 ml of glycerol

- 30 gr of leaves, orange peel, flowers

Since I quite improvised during the process and with propotions there is no point to describe it. I just mixed first glycerol, gelatin and hot water. Then I added the mix stirring all it and when I was satisfied with solidity of the substance I put it on the surface.

Result

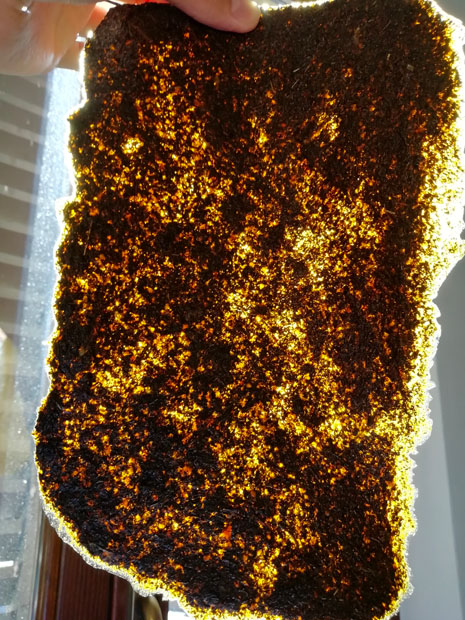

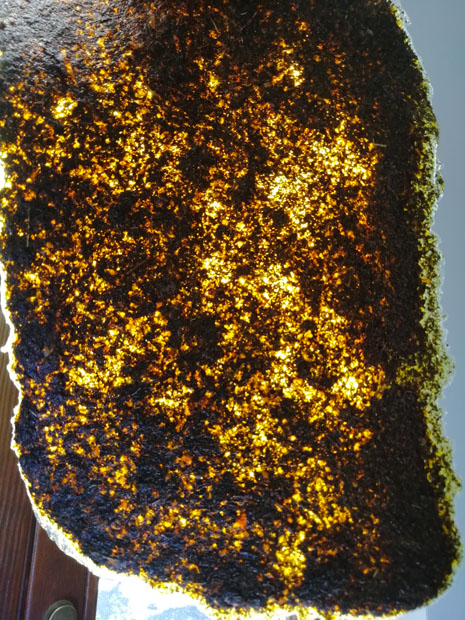

So After 4 days my stuff was ready. I guess that biomaterial with charcoal was ready actually after a couple of days already because it gets thick very fast. And here there is the result below:

CNC cut and ingraving

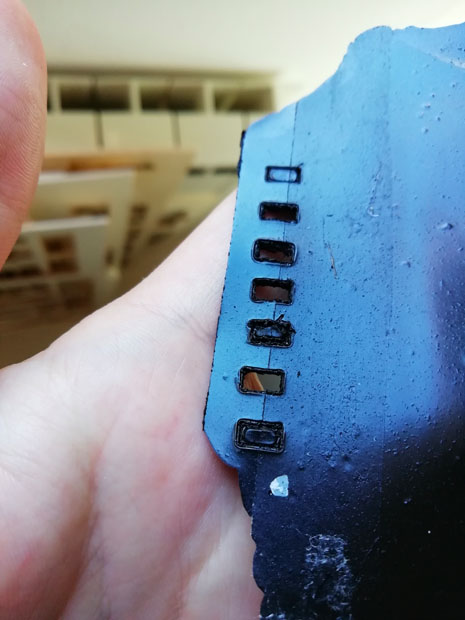

My main idea was to make bracelets with bioplastic, so I tried different parametres in order to find best ones for cutting. At certain point I tried also to ingrave even though I did not believe to get a nice result, I did. Surprisingly, on black matter there came out a white ingraving that looked quite nice. The main issue was that in some parts the thickness of material is higher, so the cut wasn't uniform everywhere and I had to finish the cut manually.

Finally, some friends asked me to personalise bracelets, I believe they did not like them completely but at least I was happy to experiment with this stuff :)

I got some elastic thread to allow the two sides of bracelet to put on the wrist.