A Home for my CNC and Ender 3D Printer

This page contains the continued work of the After Make Something Big (aka Computer-Controlled Machining). The first attempt failed, as you can read on that page. And I still want a home for these machines, so I am going to do a second attempt. Let me repeat the most important steps.

Feature list:

- connection to a ventilation system that sucks away any airborn particles created by either machining operation.

- holes for power and other circuitry

- acrylic see-through front that snap nicely into the home.

- a little protruding tab on the front of the machine home with a 3mm deep pocket to temporarily store milling bits, SD-cards and other little utensils.

- a hole in the top of the 3D printer box to guide filament from outside the home into the box.

- a kick space under the box that leaves room for future drawers in which I can save all tools needed for machine operation.

- rubber feet to reduce vibrations between the home and the surroundings

- LED strips inside the box that illuminate the machines from all sides for a clear view on the working area.

Steps to achieve this are:

- Make a sketch with all the right dimensions.

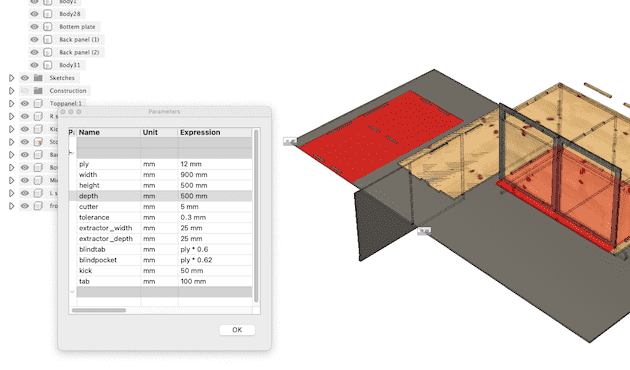

- use the sketch to make the design in Fusion360 (following a Youtube tutorial

The video explains how to do the following steps

- Create sketch with through cut of all parts.

- use extrude and mirror to create all parts

- add tabs to the different planes to extend them into other planes

- use these tabs as cut tools to make pockets and profiles in planes

Stuff I will add myself are:

- I added a bunch of fillets to make corners more rounded and pleasing

- I added a front plane (not normal in a bookshelve) and created a profile in that front pane so that a acrylic window can be added at a later stage.

- The bottom shelve is extended outside the box and has a pocket. This feature can serve as a little workbench to temporarily store stuff

- the kick is (much) deeper then in the original video. I want to make some small drawers underneath to store machine related tools.

- the top contains a little hole for 3D filament to pass through

- the back contains an extra hole for power to the 3D printer

- the right side contains 2 holes. These are for future connection to the CNC home. It is for ventilation purposes and allows extraction of fumes into the ventilation system.

Considerations

I am pondering wether I should make one big box, with a divider wall, to hold both machines, or two seperated boxes; one for each machine. The benefit of two boxes is that they can easily be moved to another location. The benefit of one box is that they both can use the same suction mechanism...

In the end I decide to make two identical boxes; the CNC will also fit in the EnderBox. But I will make holes in the sides of the boxes so I can connect them. The Ender3D produces super tiny airborn particles that will probably be easily sucked away, whereas the CNC will likely produces clouds of fine-dust that need to be removed asap. So the suction machine will be connected to the CNC box first and secondary to the Ender box.

Sketch

The dimensions of the Ender 3D printer are 50x50x60cm. I use the parameters of a previous design to get started:

Dogbone issues.

The add-in to create dogbones that I used previous, no longer seems to work. I am now going to try a freemium version of Nifty Dogbone that I can use for 30 days and will cost me $20,- after that.

It does throw some errors, but the dogbones seem to be created anyway, So for now I can go along with this...