Computer Controlled Cutting

ASGMT:

group:

characterize your lasercutter, making test part(s) that vary cutting settings and dimensions

individual:

cut something on the vinylcutter, design, make, and document a parametric press-fit construction kit, accounting for the lasercutter kerf, which can be assembled in multiple ways

Software:

Abobe Illustrator

Slicer for Fusion360

AutoDeskFusion360

SVGnest

The most obvious example of a press-fit model appears to be the lego brick, you can make (almost) anything from it, but it has no pre-loaded plans, it becomes what you want it to be.

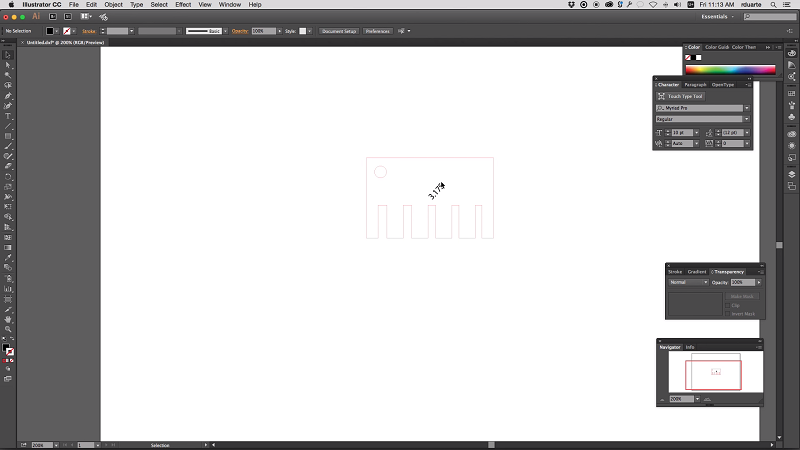

Started off making a simple laser fit gauge via an online tutorial.

Laser Gauge

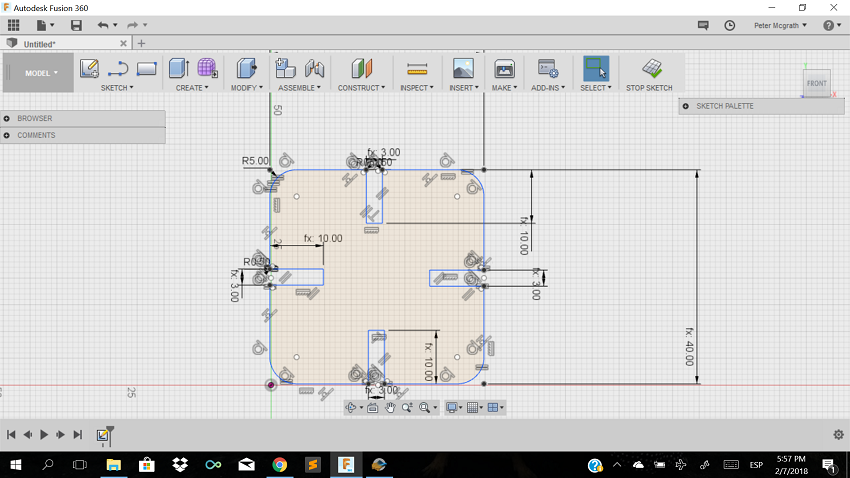

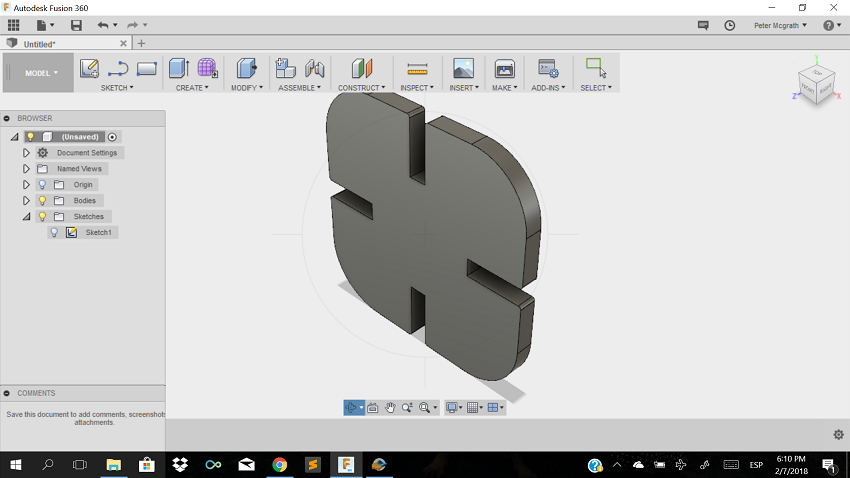

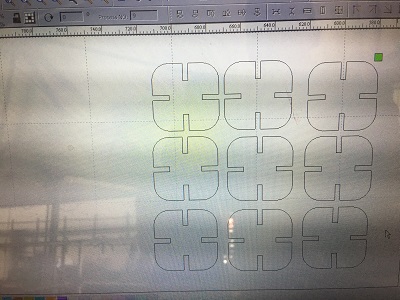

Went on to modelling various parametric components in Fusion360

Lots of difficulties getting the constraints right, so that the model would respond parametrically.

This is a simple shape with tapered slots to allow multiple components to press together.

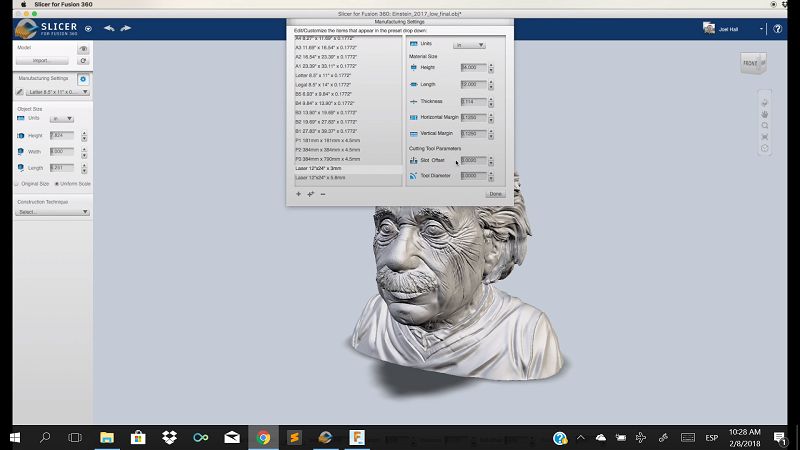

Slicer appears to be a very powerful piece of software and capable of doing some interesting things with 3D models. An excellent application for prototyping, but beyond that it just seems like a bit of fun.

The above is from an online tutorial for usind slicer with fusion.

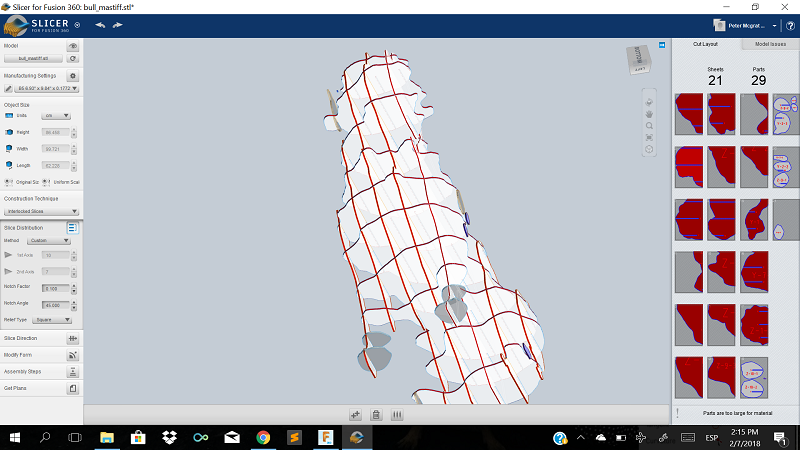

Slicer for Fusion360

The group project involved taking a 3D image of my Bullmastiff dog, uploading it into Slicer, manipulating the slicer controls to get a reasonably accurate rendition of what the model would look like, downloading these files as dxf, converting these to svg with an online dxf converter, sending these files to SVGnest to enable some semblence of budgetary constraint within the cutting process.

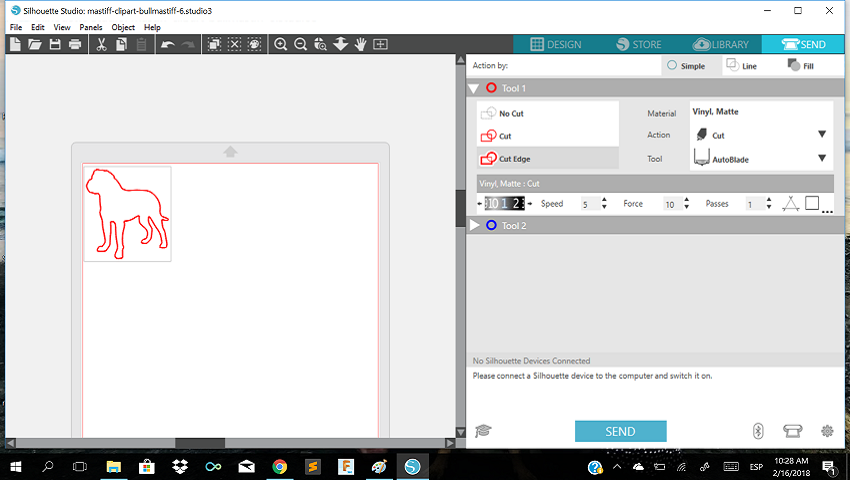

Vinyl Cutting

Found a vector image of a bullmastiff dog via the web. Imported this to SilhouetteStudio for the Cameo vinyl cutter. Had to make an outline of the image as only the frame of the image was vectorised. Selected black matt vinyl to print to(cut). Adjusted blade to recommended depth and cut out the image. Fairly straight forward procedure.

This method provides a wide range of possibilities for cutting out images, logos, decals, etc. A nice transformation from something that has been designed on the computer to piece of hardware to fulfill some need or desire.

The machine we used was fairly basic, a Cameo Silhouette, but I imagine the higher spec cutters have even greater application abilities.

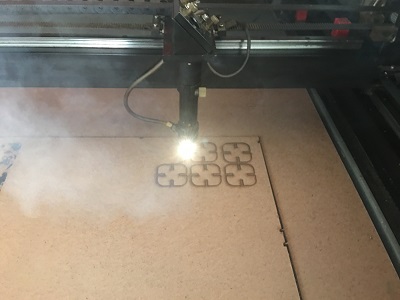

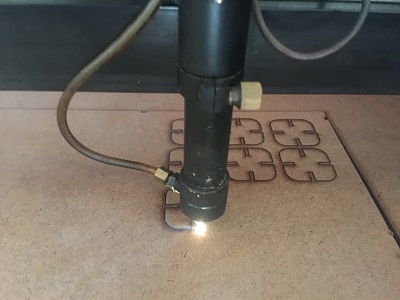

On close inspection here you can see uneven cutting across the mdf surface.

On close inspection here you can see uneven cutting across the mdf surface.

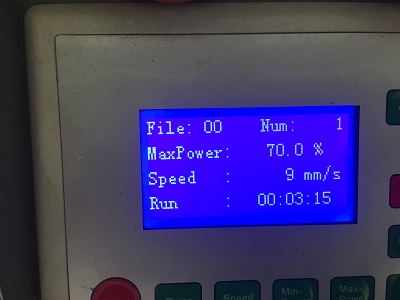

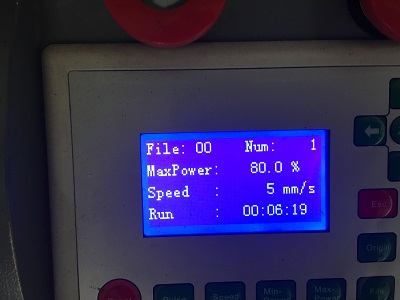

Even by increasing the power and lowering the speed of the cut, the cutting was inconsistent and failing to get through at some parts of the board. The power was also such that there was a large risk of fire from this cut.

Even by increasing the power and lowering the speed of the cut, the cutting was inconsistent and failing to get through at some parts of the board. The power was also such that there was a large risk of fire from this cut.

This is just showing the laser cutters display panekl for power and speed.

This is just showing the laser cutters display panekl for power and speed.

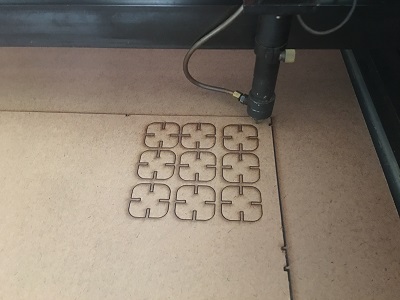

The results are not particularly pleasing, but the press-fit shape did work and was able to form various models. Further slots in this simple component would have added to the degrees of freedom and enabled even more variety of nshapes to be formed. It is easy to see on the lower model the difference in cutting depth.

The results are not particularly pleasing, but the press-fit shape did work and was able to form various models. Further slots in this simple component would have added to the degrees of freedom and enabled even more variety of nshapes to be formed. It is easy to see on the lower model the difference in cutting depth.