Moulding and Casting

Moulding and Casting

Tasks:

- Design appropriate objects of the limitations of 3 axis machining

- Demonstrate workflows used in mould design, construction andcastig

I decide to make a Violin mould that consists of one part, and I willmake Aladdin's lamp mould with two parts.

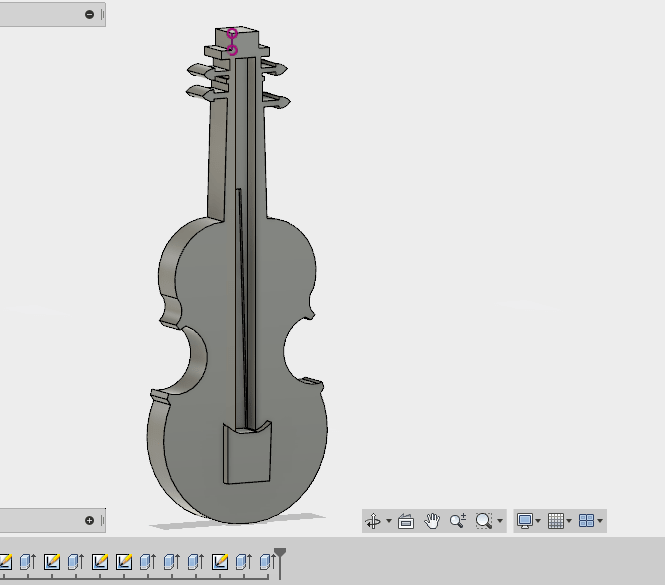

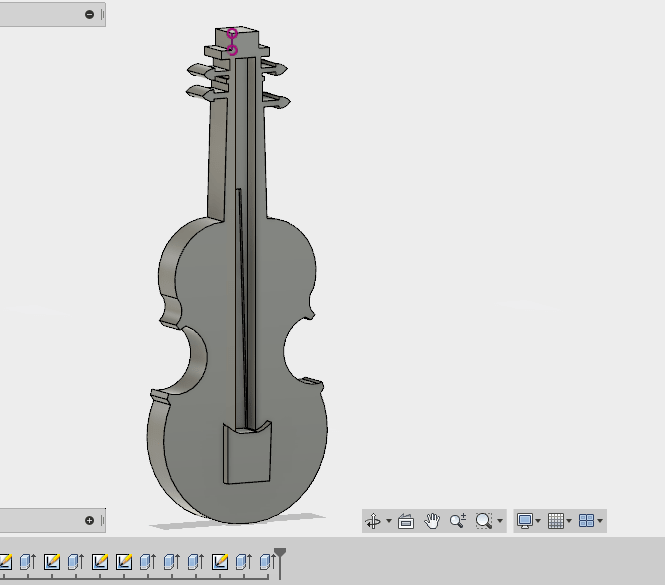

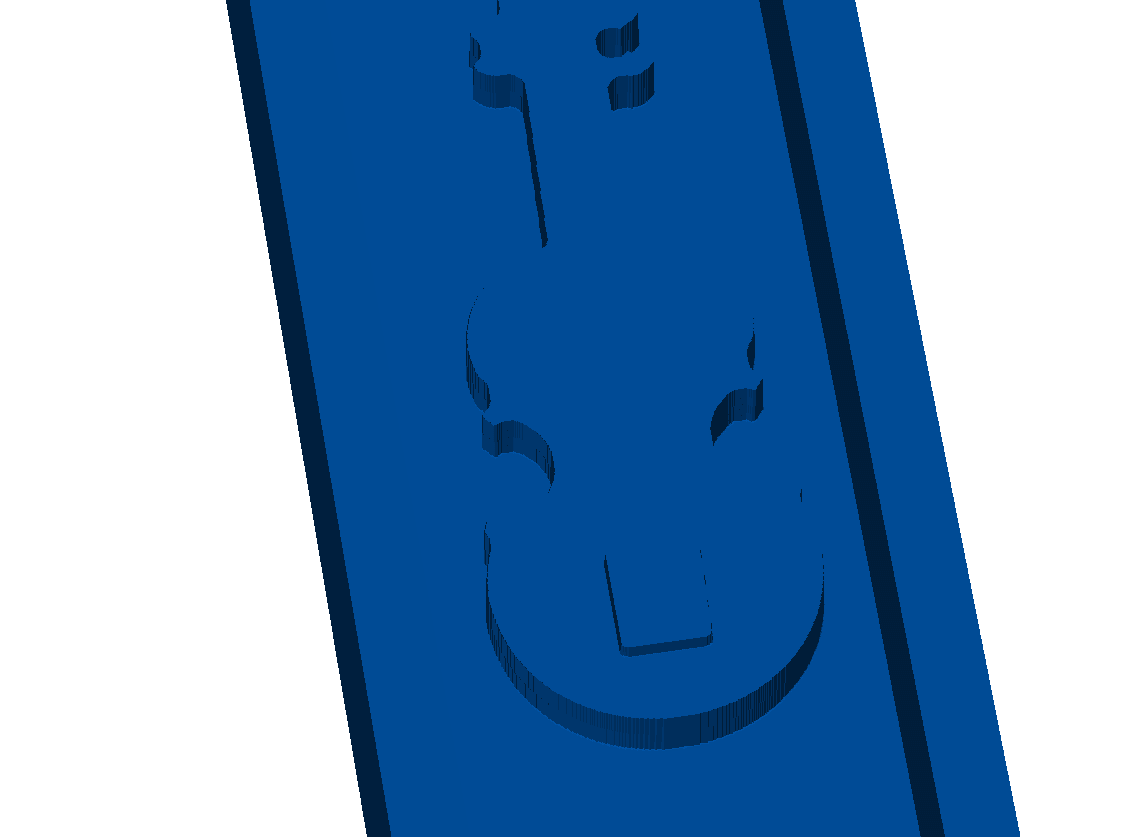

Violin mould.

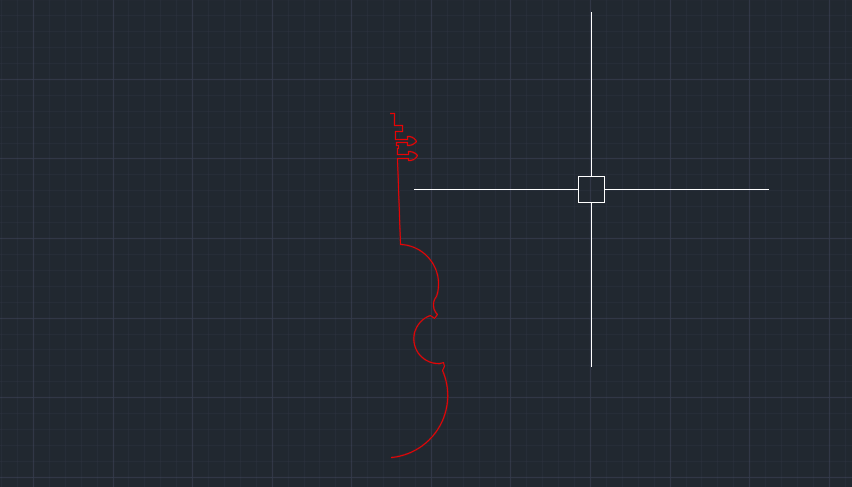

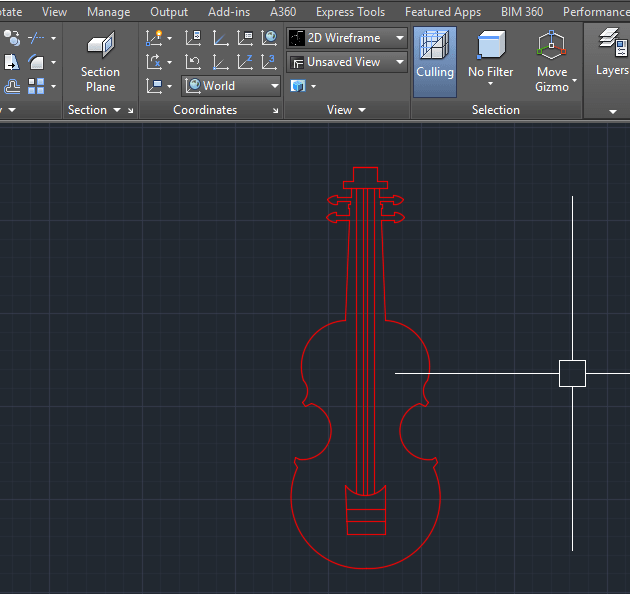

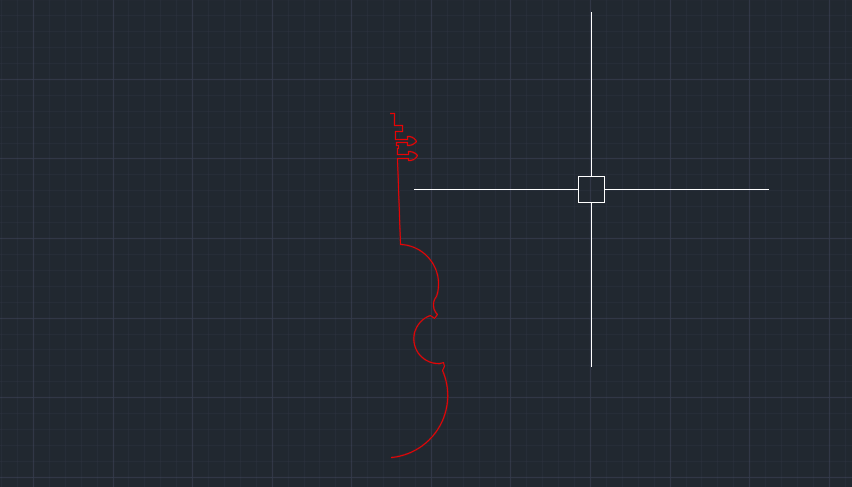

I draw asketch of the violin using Autocad software.

I start with line and arch

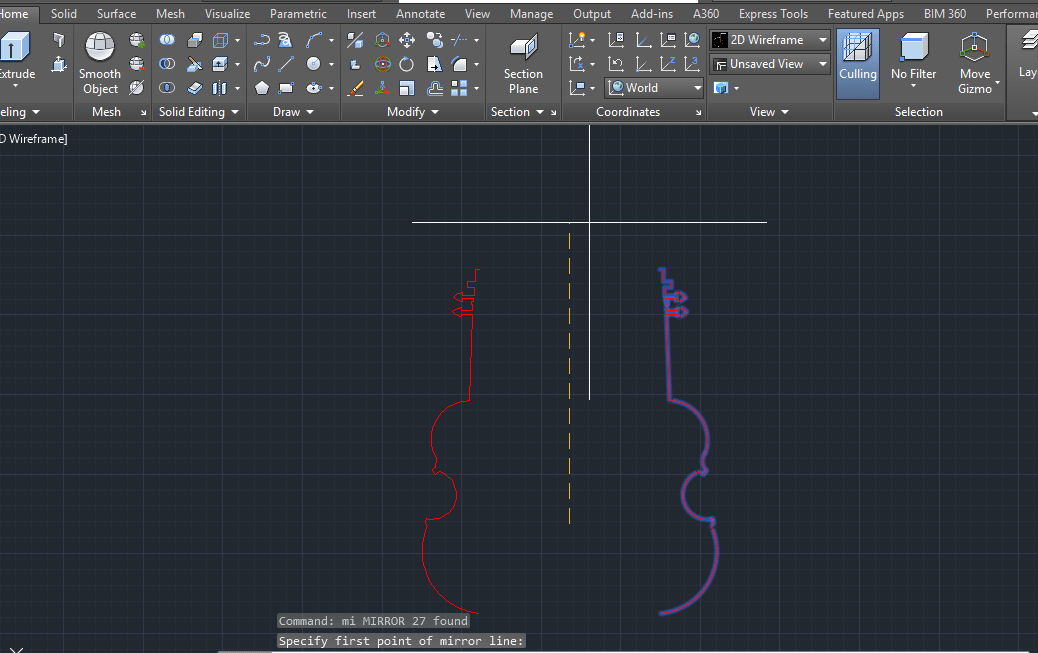

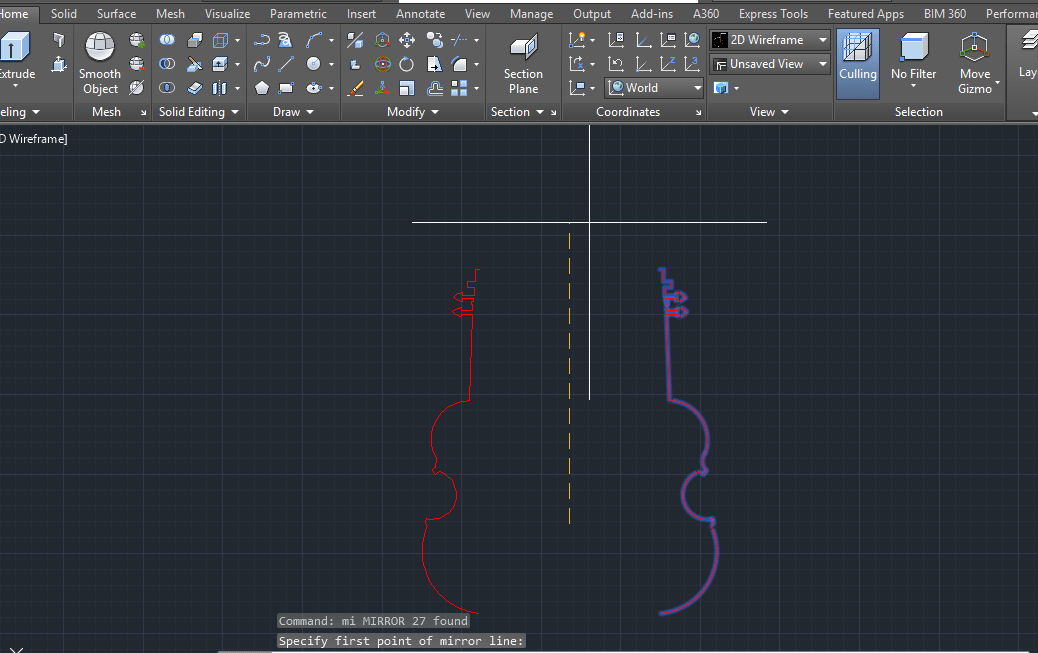

then I use mirror tool .

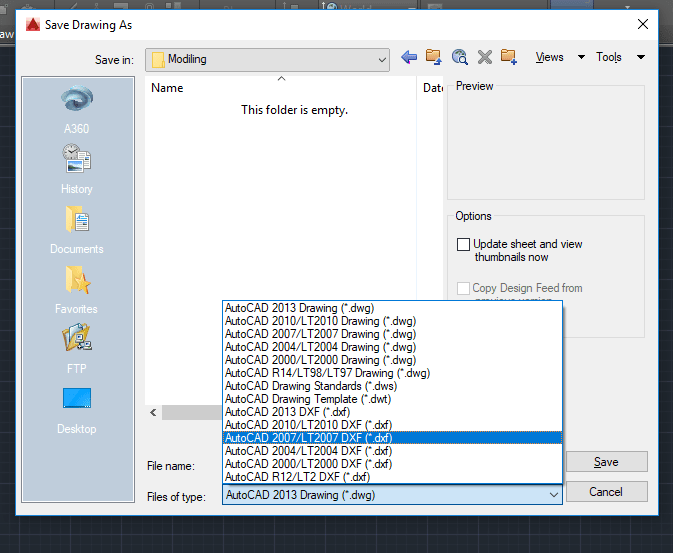

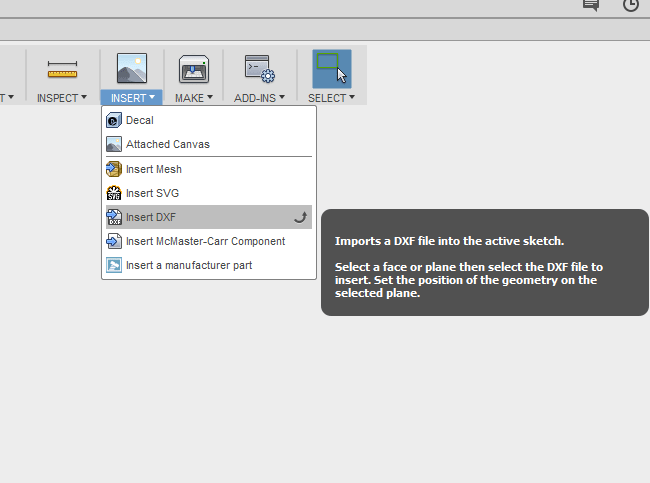

Then I save the file as dxf file. So I can import the file in Fusion to complete the design .

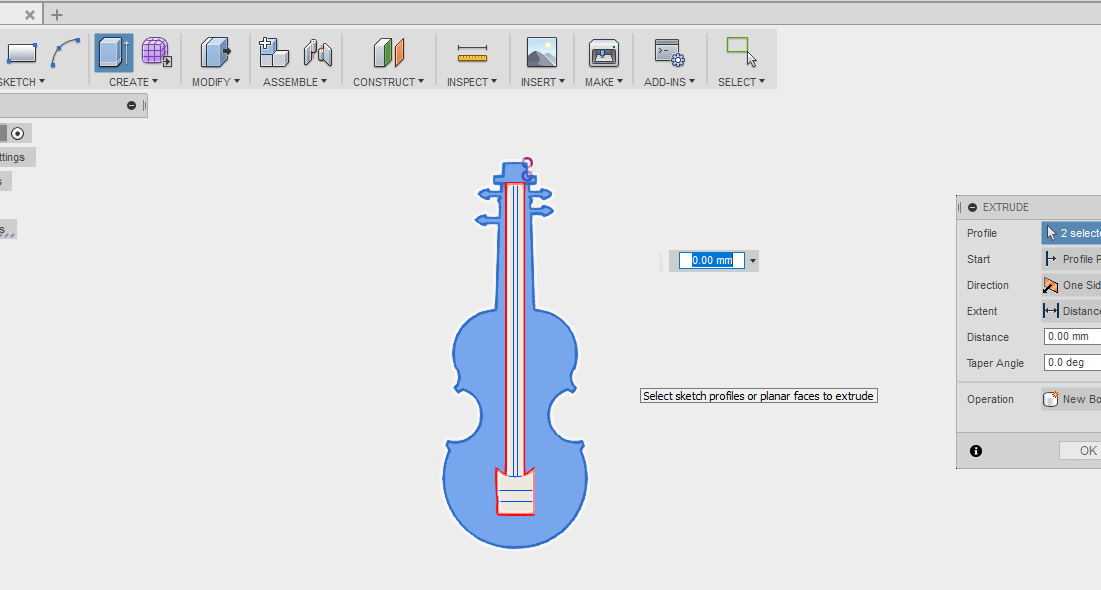

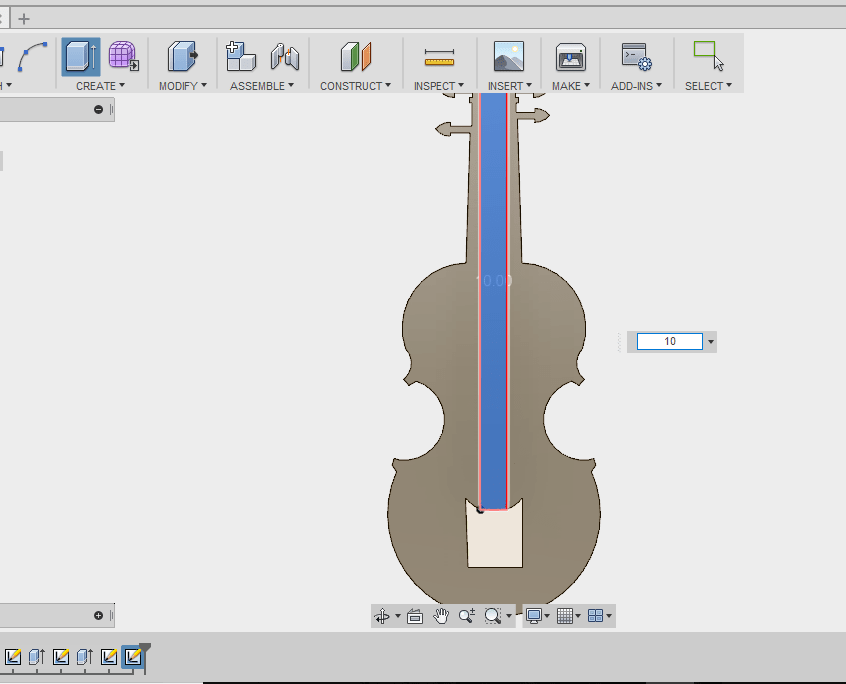

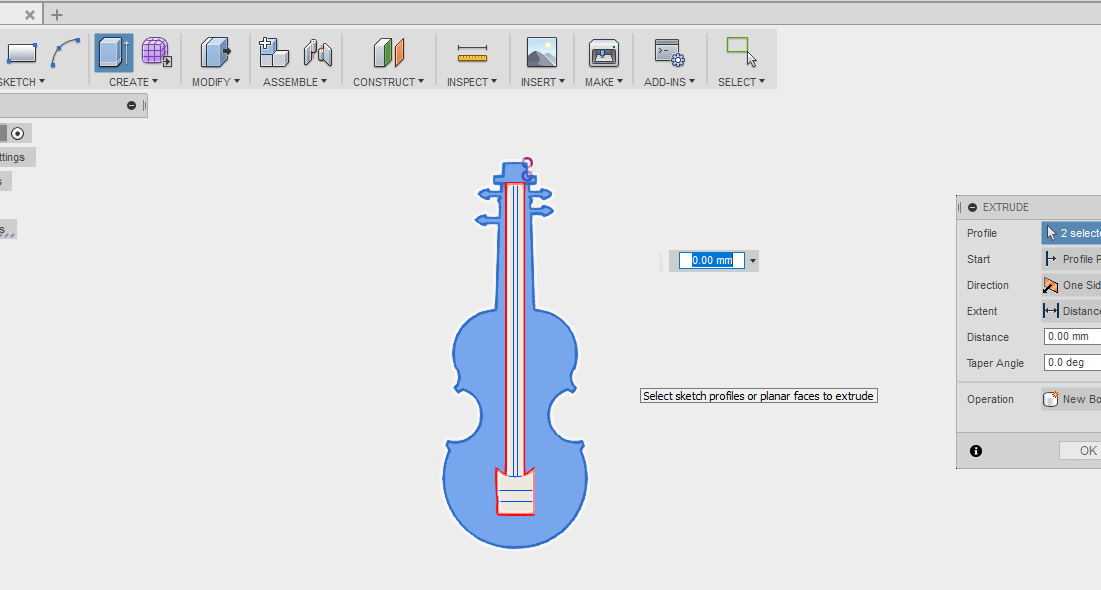

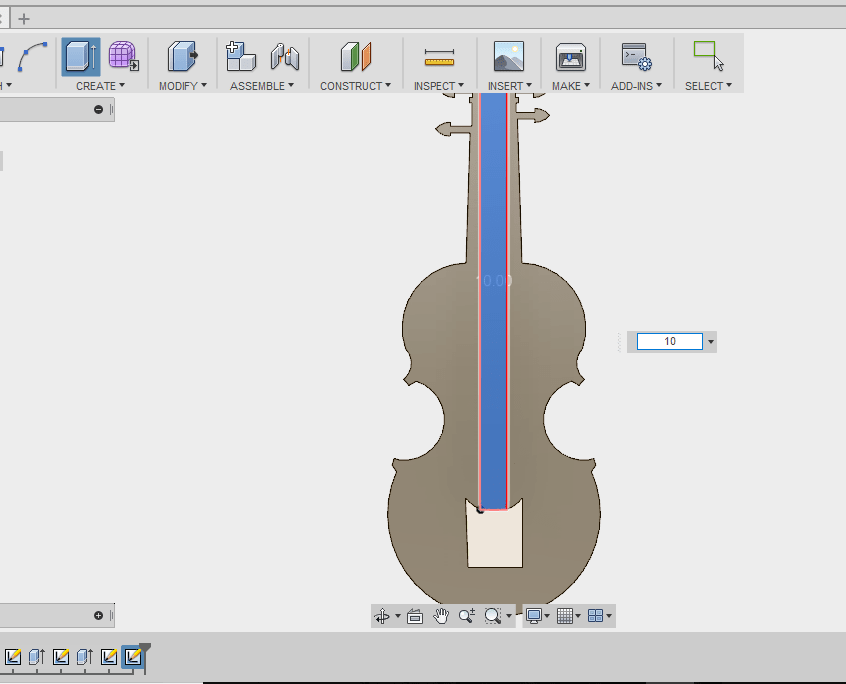

Extrude the exterior shape 10 mm

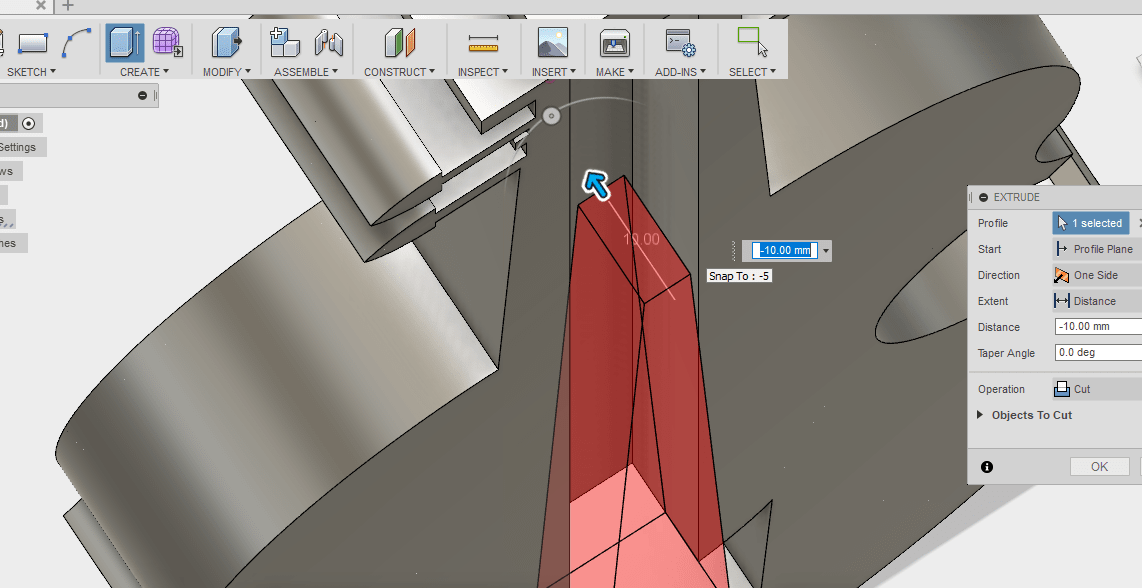

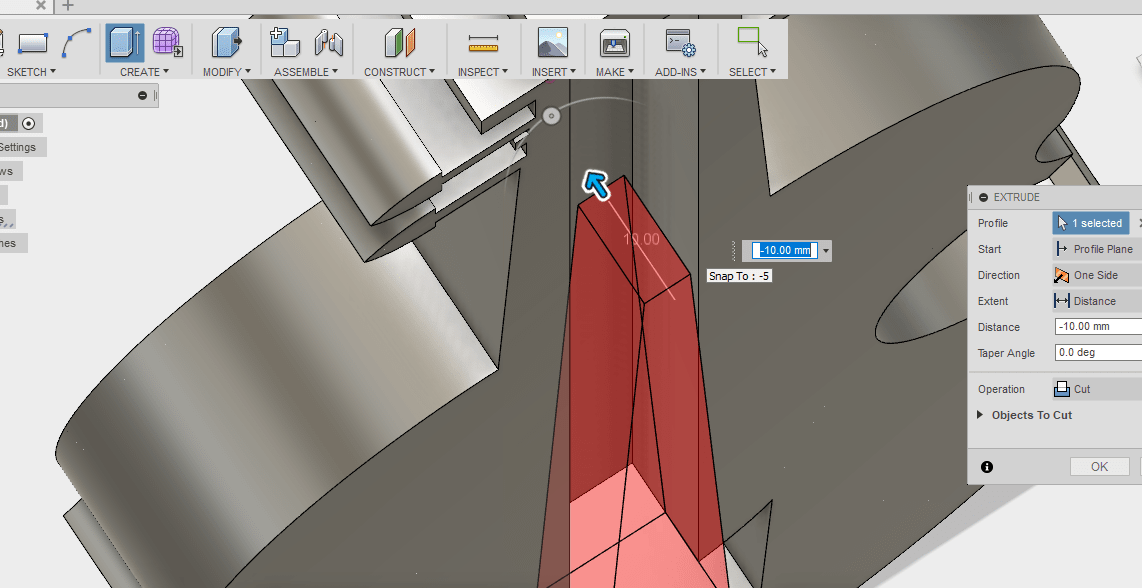

Extrude the center of in opposite direction of the basic shape .

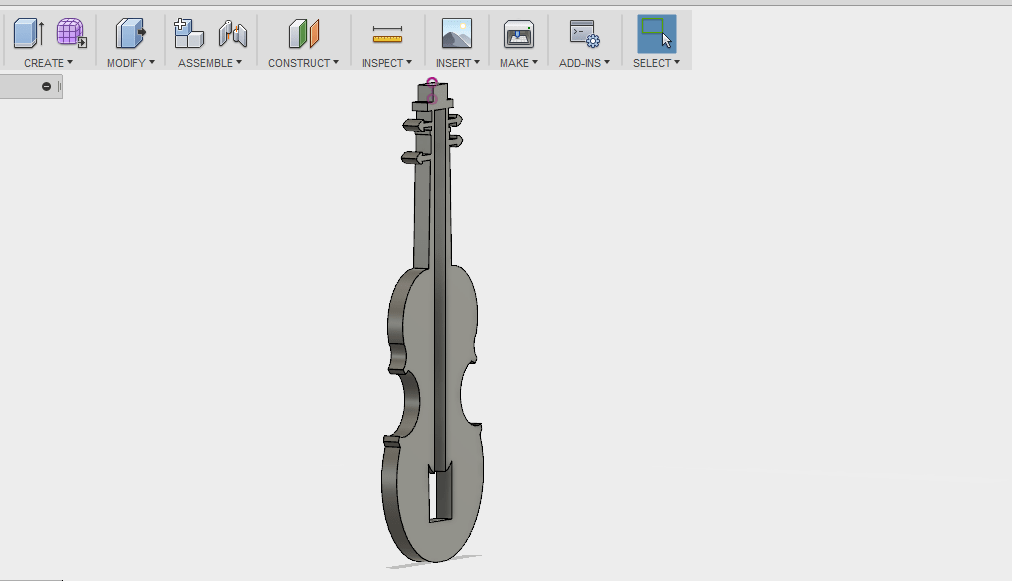

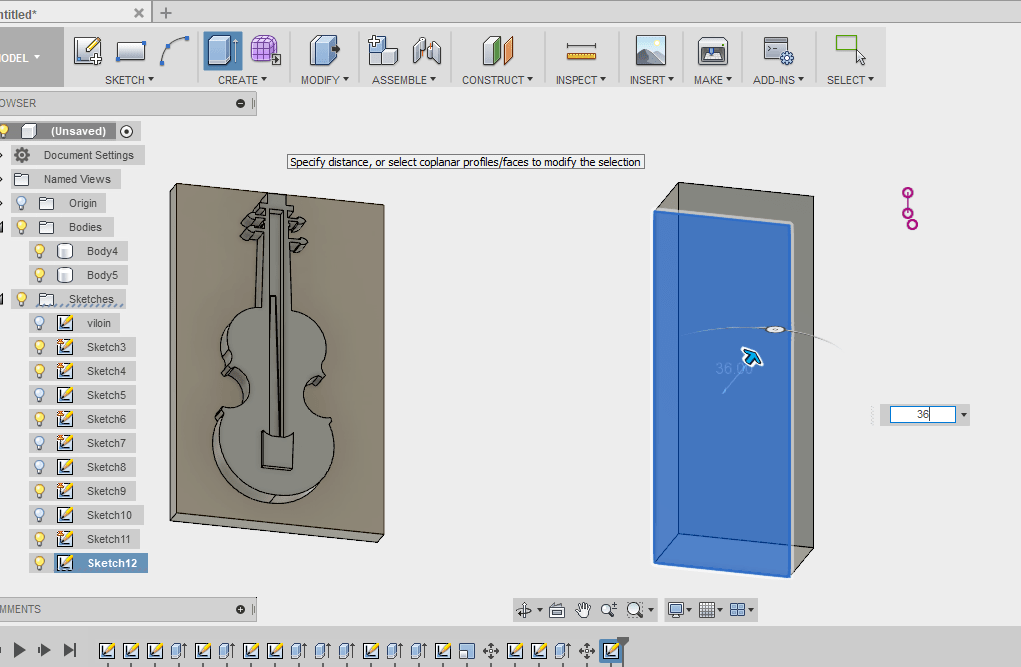

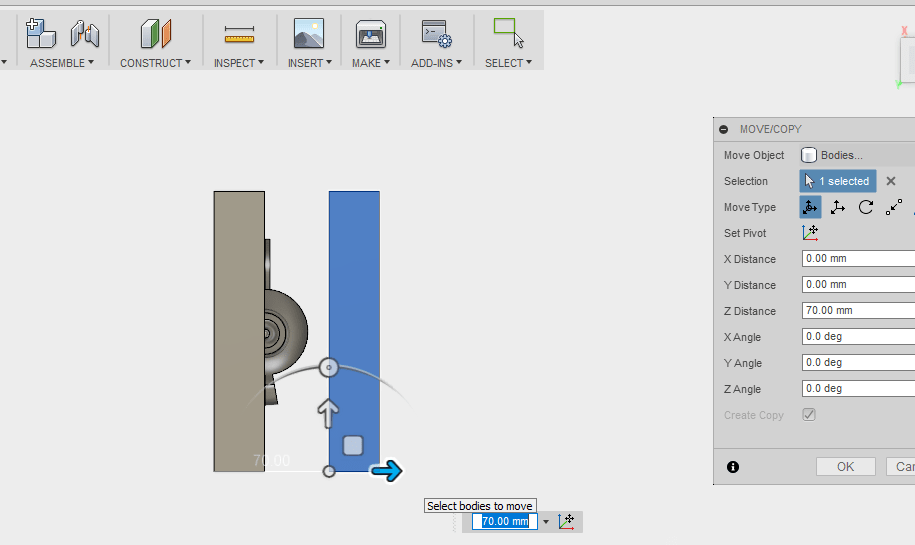

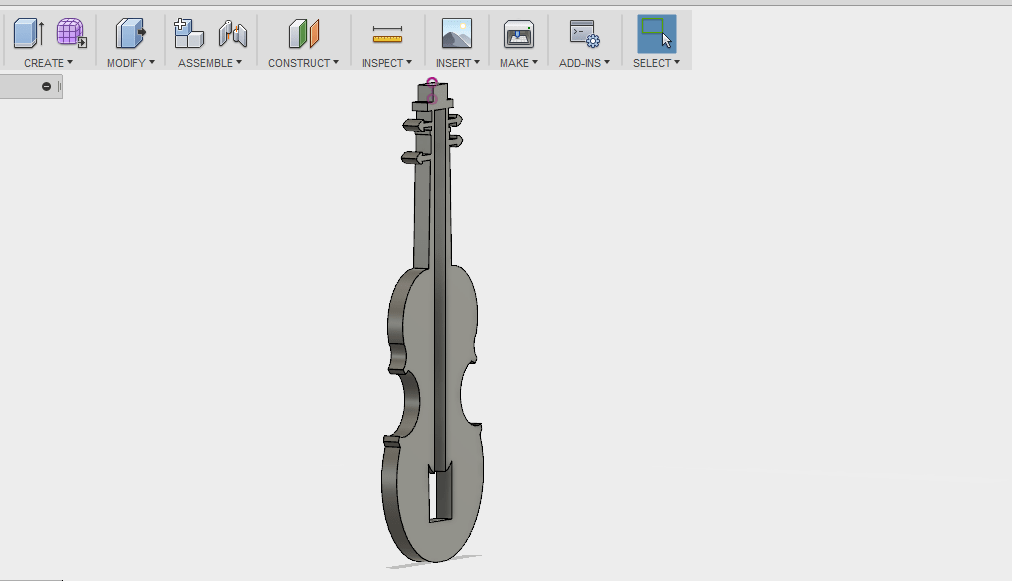

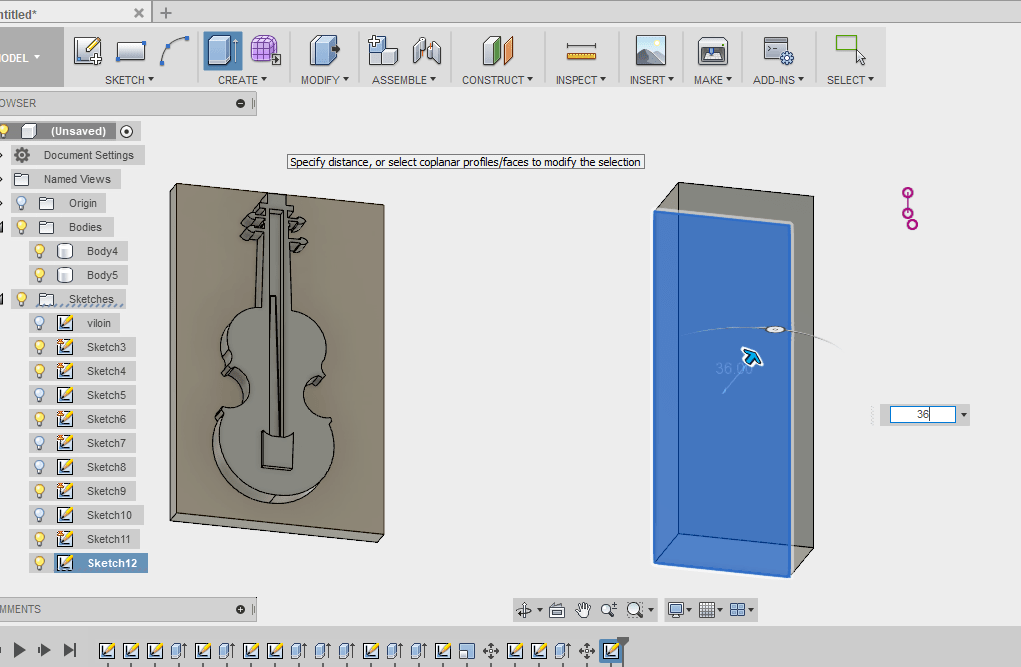

Then I draw a rectangle with the dimensions of my wax block

width :170mm - Depth : 70mm - Height : 36mm and extrude it .

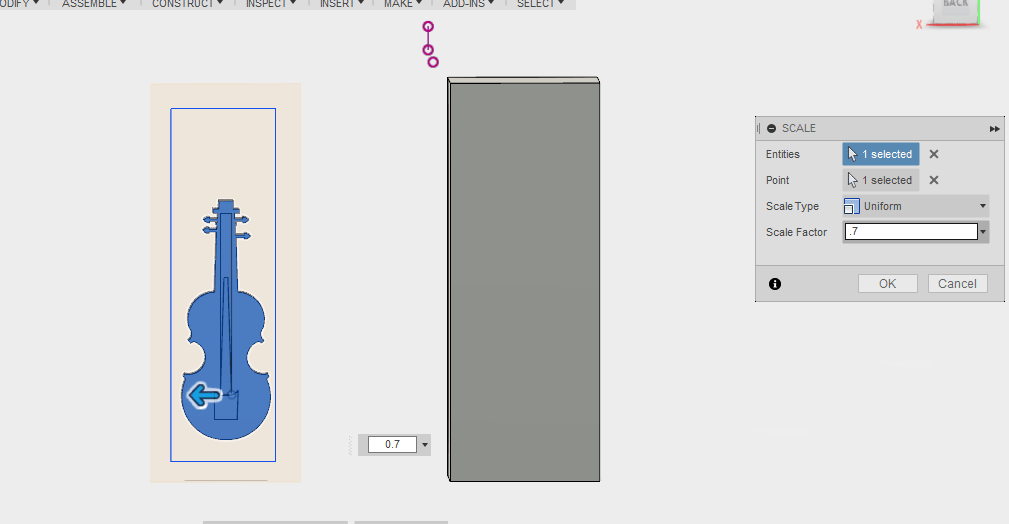

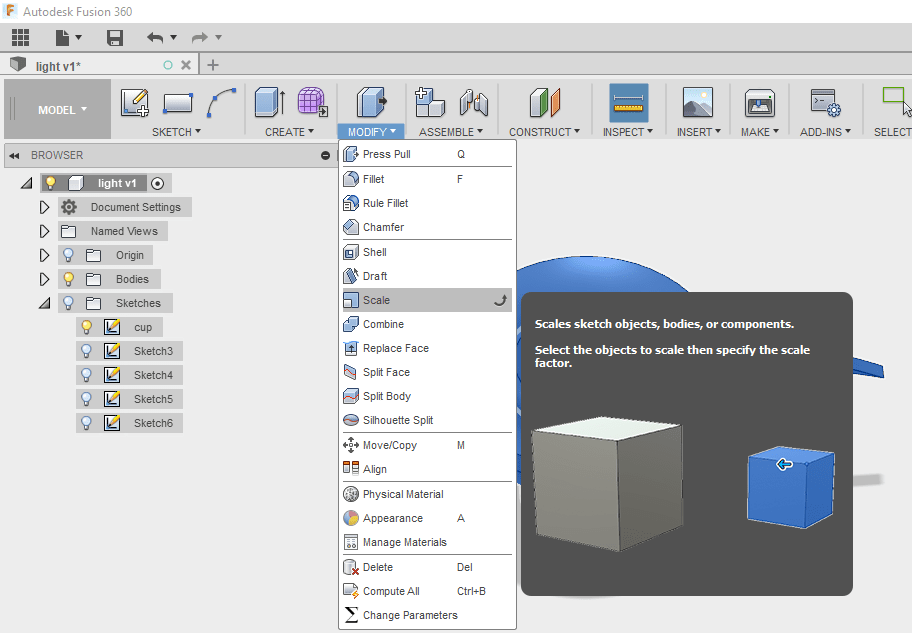

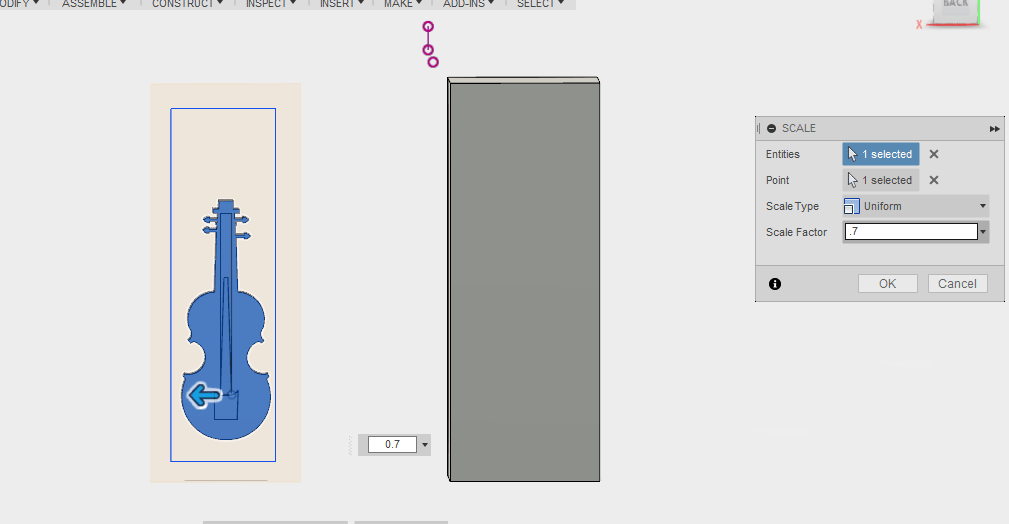

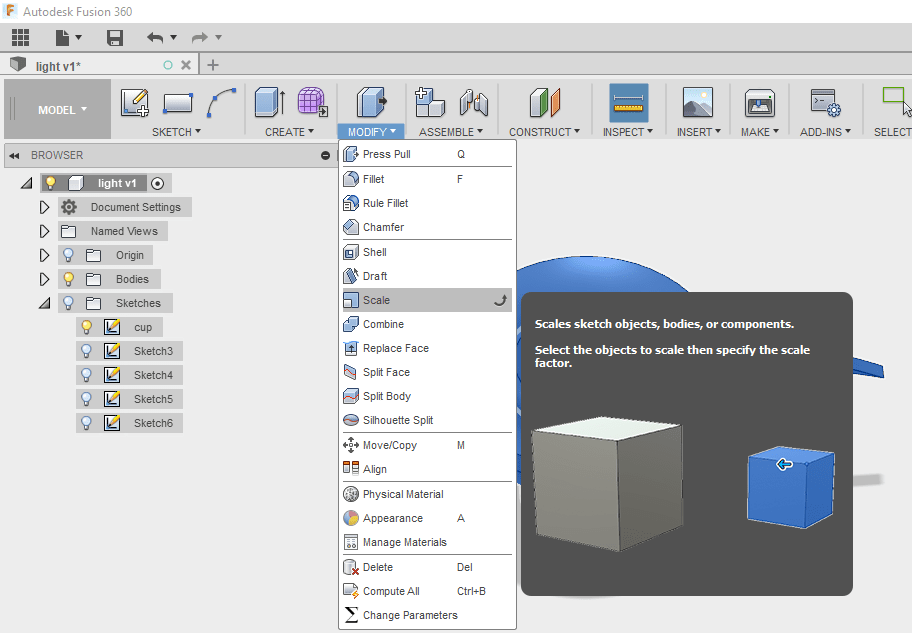

I change the scale of the violin . So it can fit the block

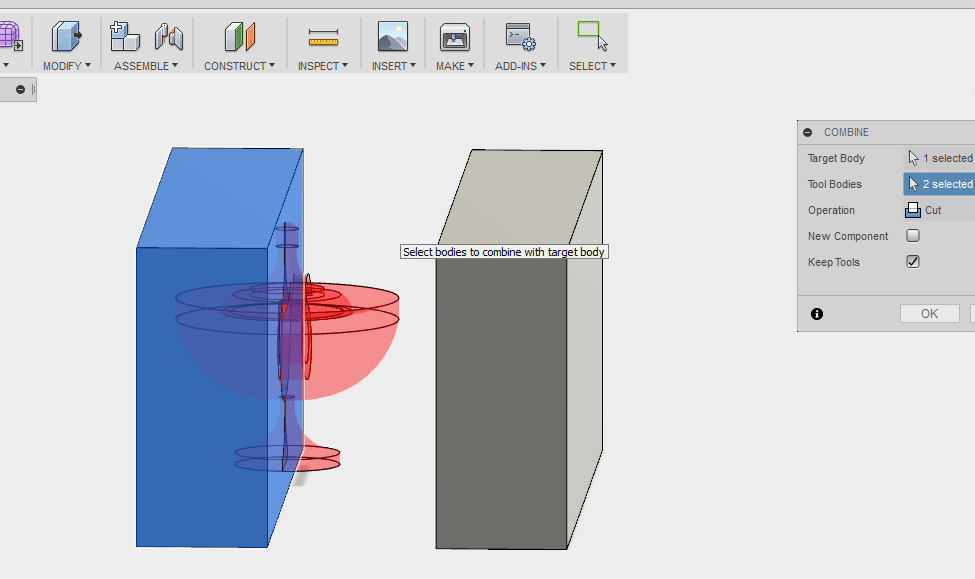

Then I make a subtraction using the combine tool .

CAM Process

I use Modela player 4 to make the file .

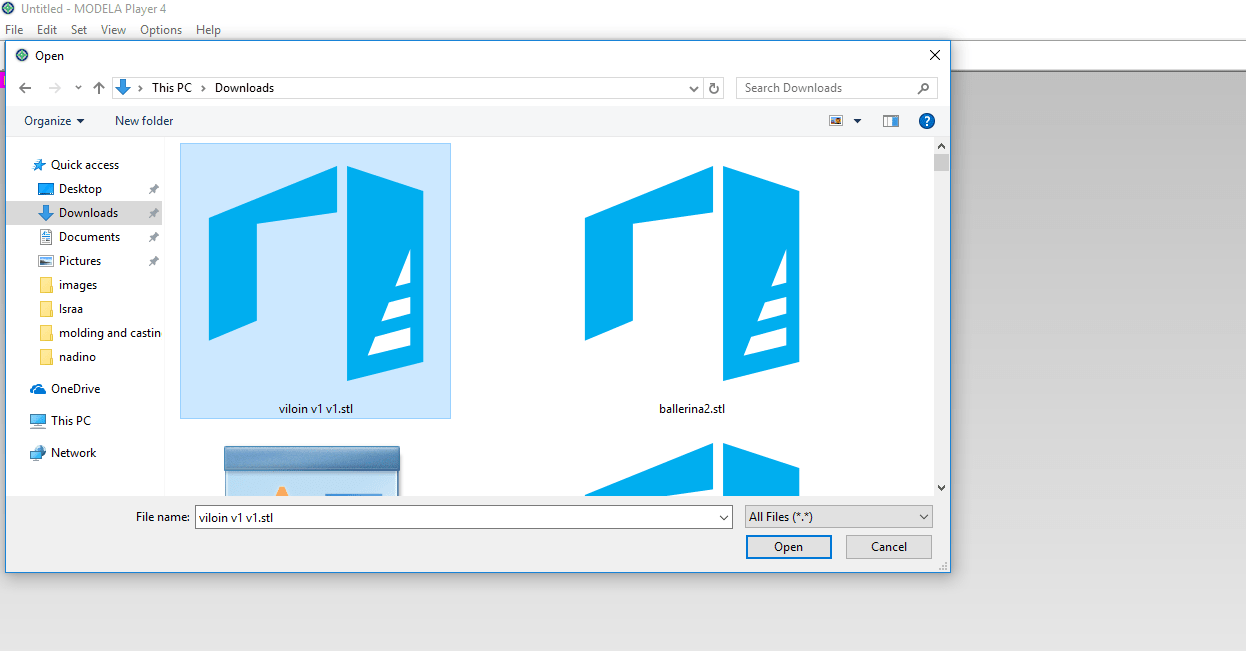

First I import the design

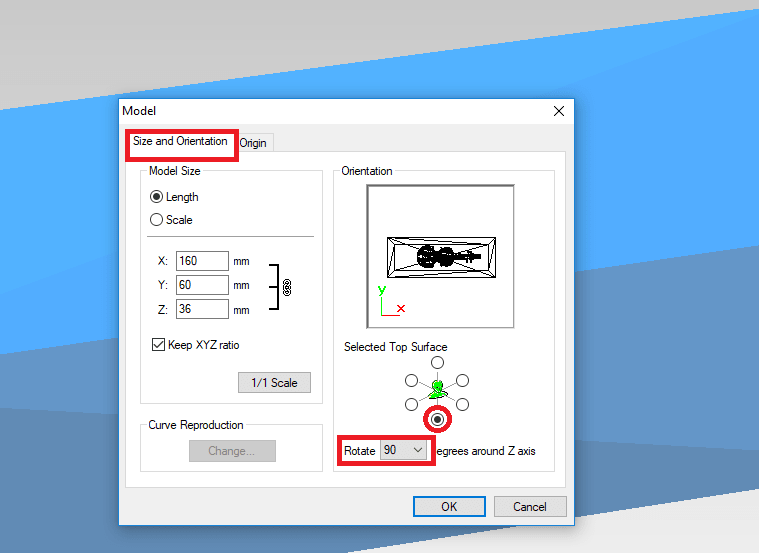

To rotate the object I press on set menu then I chose Model.

Then specify theX , Y , Z coordinates .

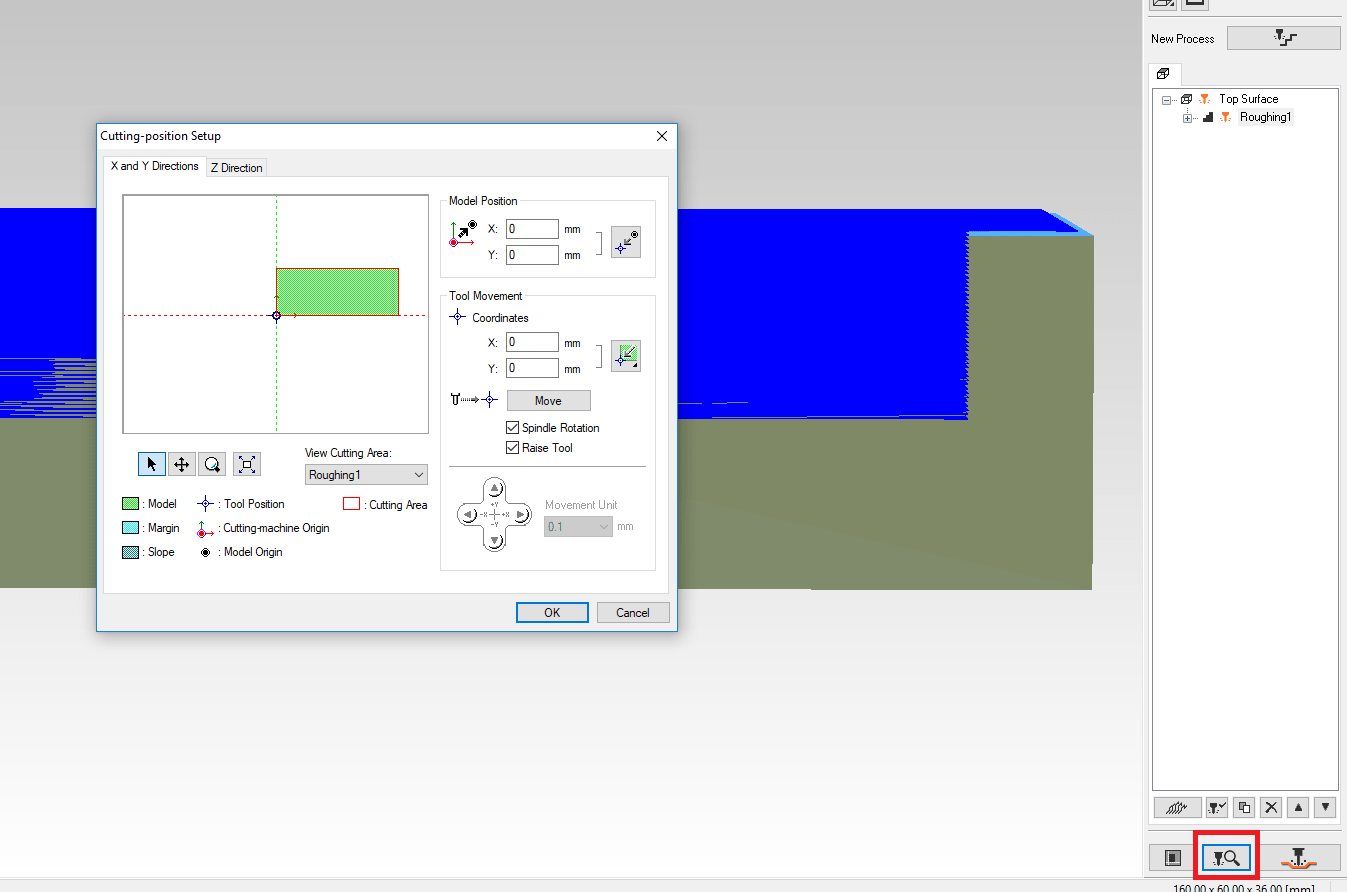

From set menu I chose process click on Roughing

The tool diameter we used is the 3.175 mm

It comes in two types:

- Ball nose : Used for finishing

- Flat : used for roughing.

I chose3.517 square tool .

1. X-Y Speed: To mill wax, you need smaller drill bits, with high RPM

and high feed rate

because the wax is rubber material and the relationship between tool diameter

and RPM is inverse relationship .

2. Z-Speed : Z-speed should always be low.

3. Cutting in amount: The maximum valur for Cutting in amonut should always be equal to the radius of the drilling bit.

To avoid an error occurring, we chose it to be evem less for safety reasons.

4. Path Interval: Which is the overlap between two layers when milling

Should be less than the raduis of the drill bit.

Then I save the file and click on review tosee the simulation.

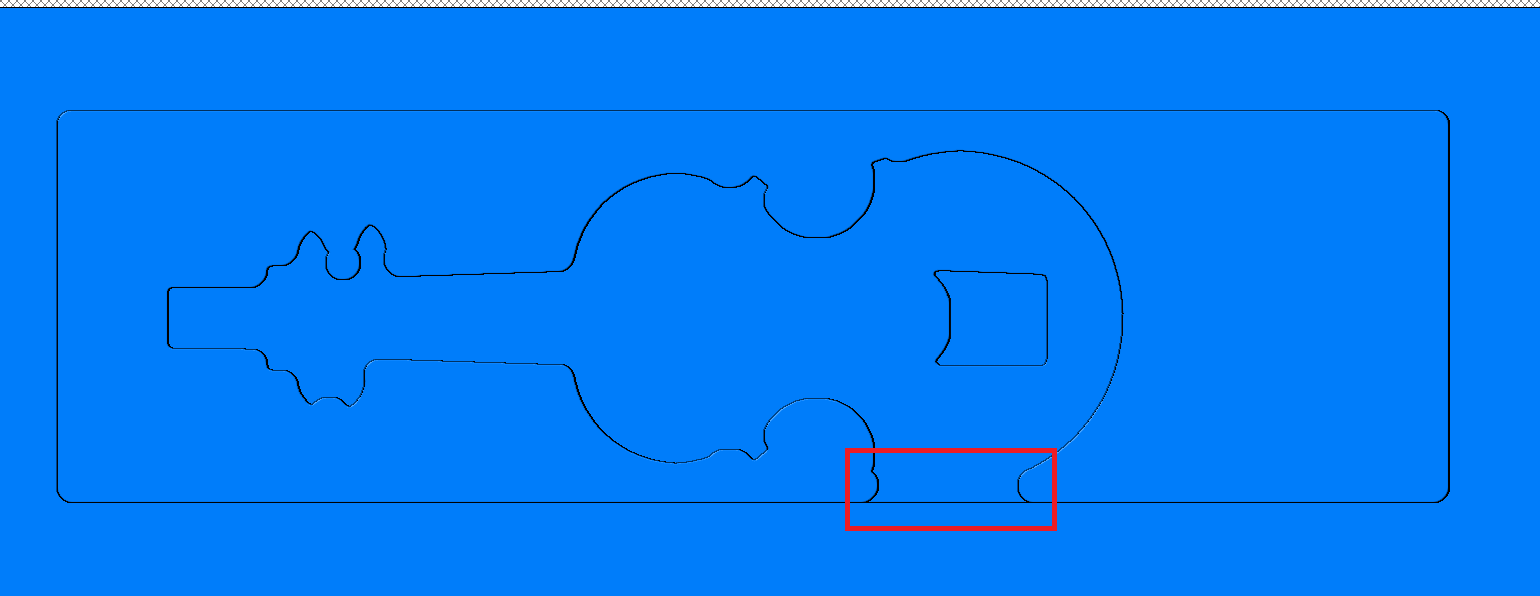

The problem was there!

I go to my file and edit the size of the rectangle which contain the object then i press again in simulation to see the result.

Now I upload the G. Code to the Roland 20 SRM software.

Finish cut

For finish cut I press on set menu I chose process click on finshing

I chose 3.517 radius tool .

Let's cast it !

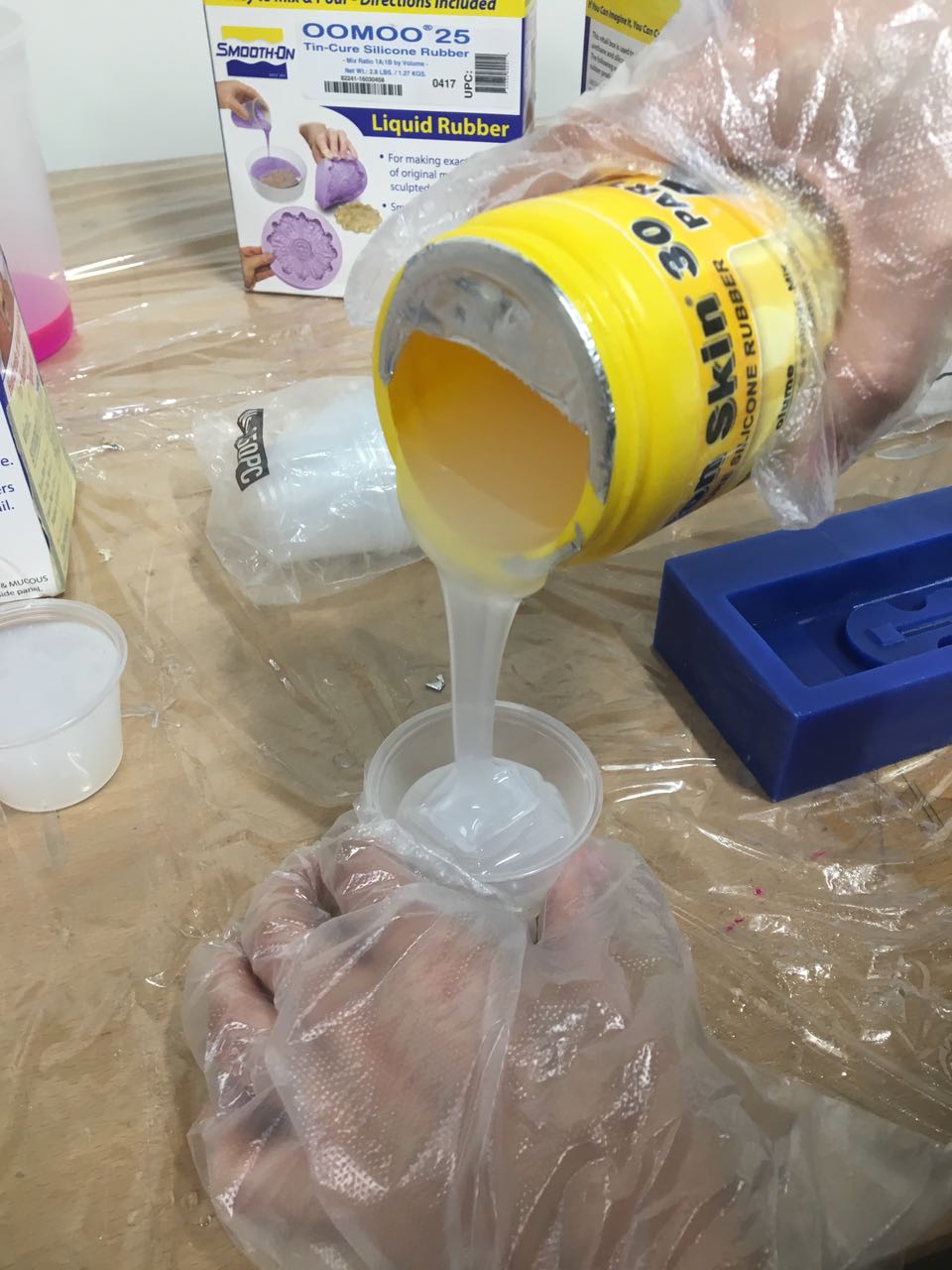

First, I have to make the mold out of silicon rubber .

I use Dragon skin. Description of how to use it can be found Here

The features for this material:

- It can be used to make exceptionally strong and tear resistant molds for casting plaster, wax, concrete, resins and other materials.

- Soft, super-strong and stretchy

- Cures at room temperature (73°F/23°C) with negligible shrinkage.

Vacuum degassing is recommended to minimize air bubbles in cured rubber.

After mixing the silicon, we placed it in the Vacuum Machine for about 10 minutes until the air bubbles came out .

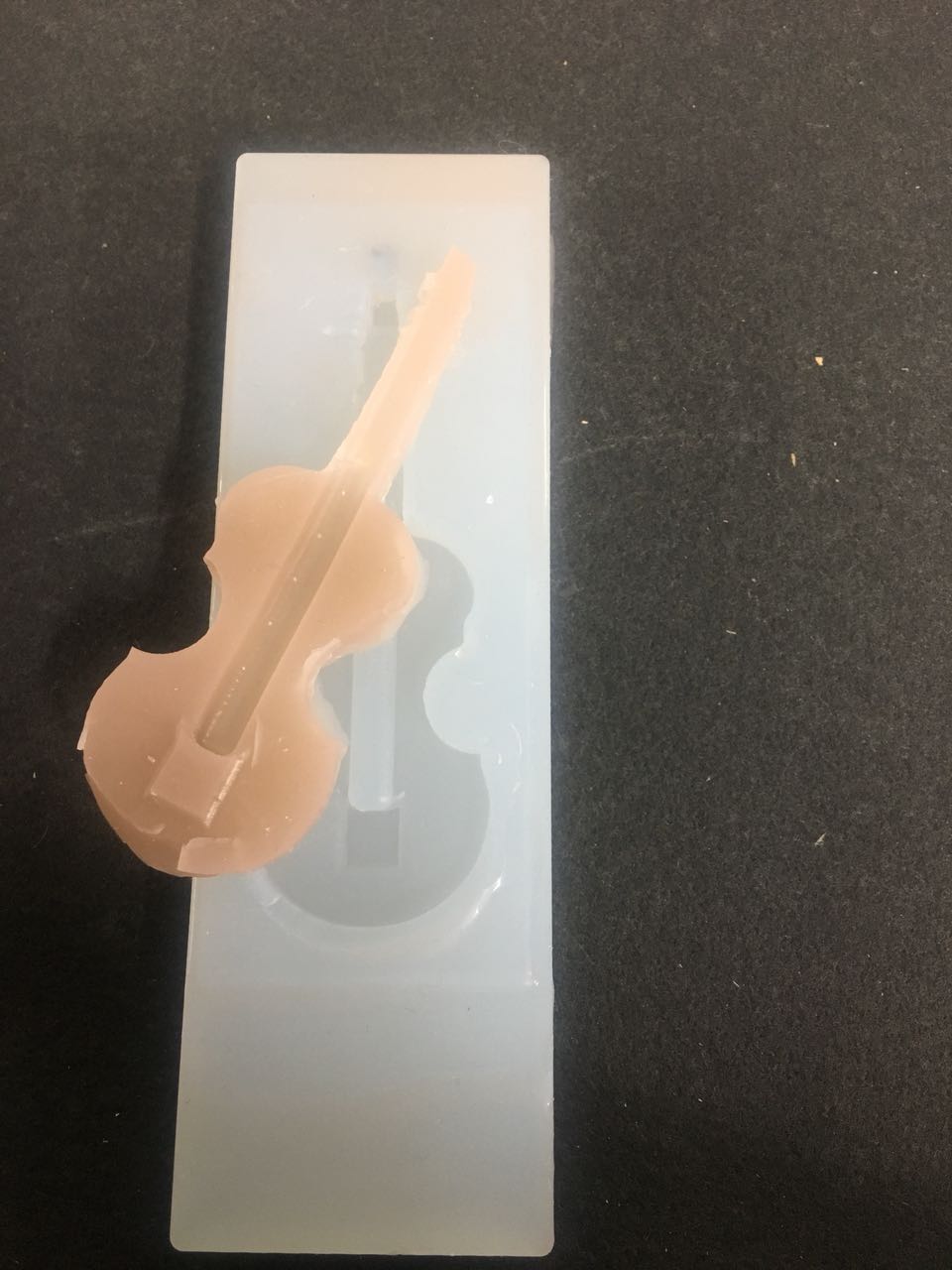

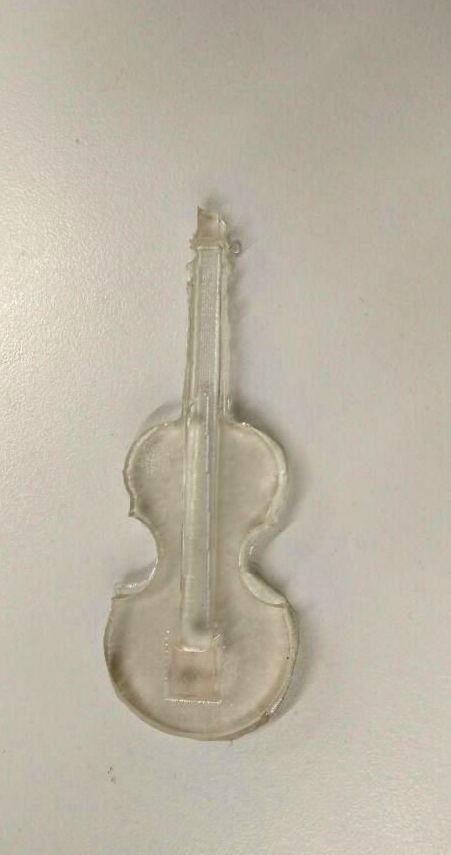

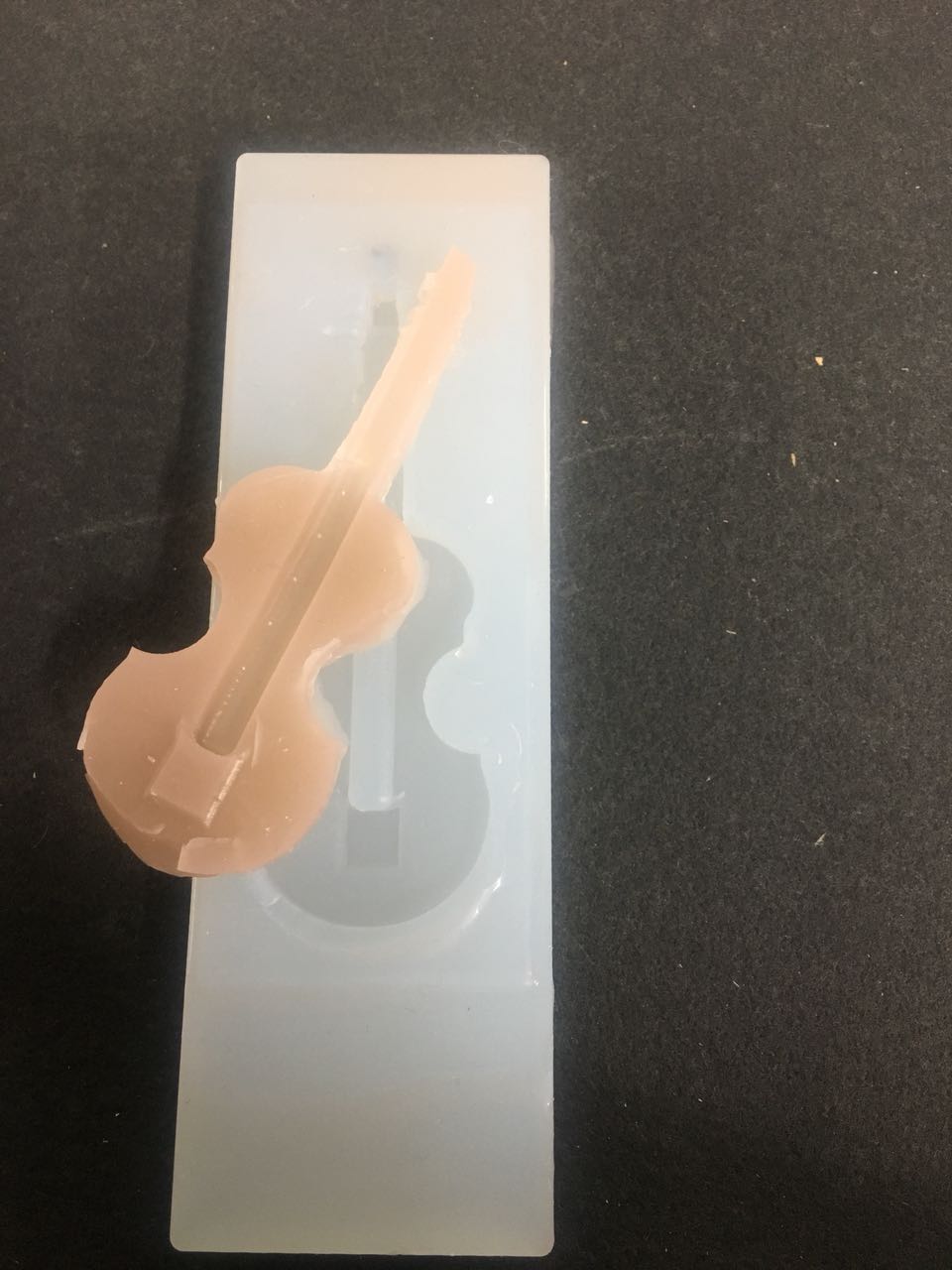

Casting the Violin

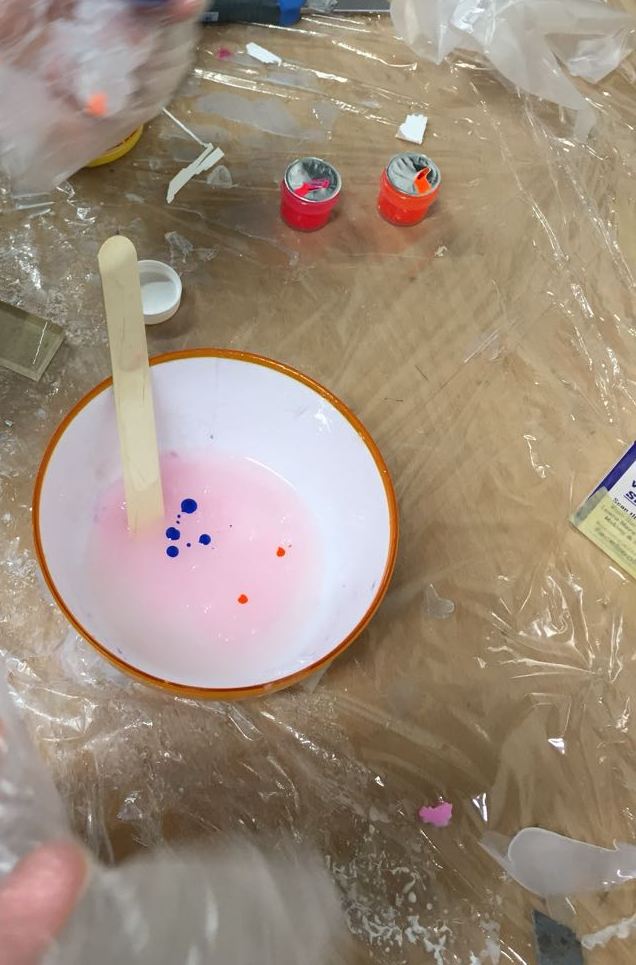

Here I also use dragon skin material and mix it with some color

I left the material overnight after i put it in the violin module.

I also cast it using resin material, I think this material looks more beautiful.

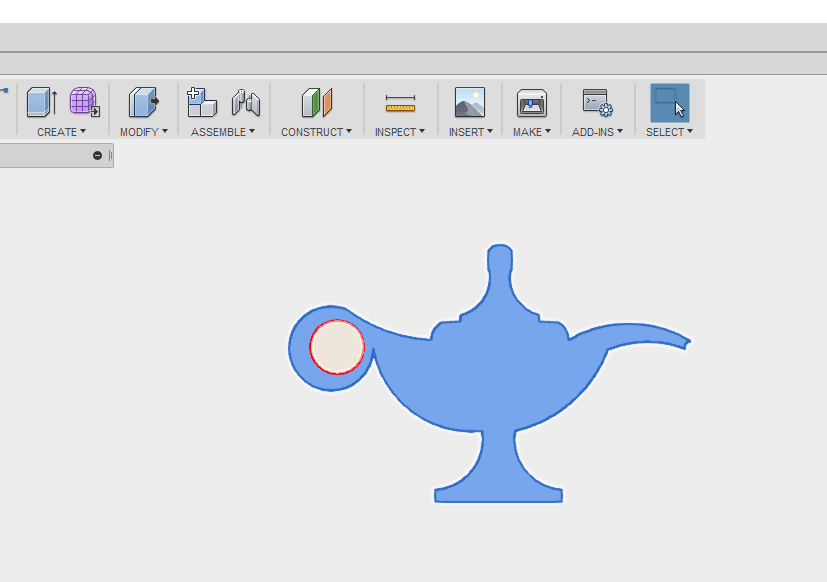

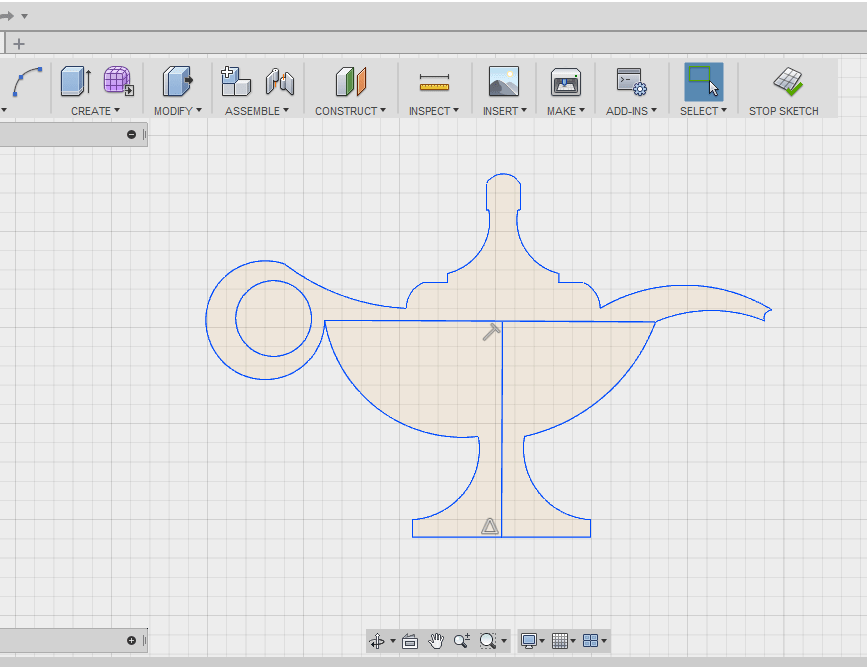

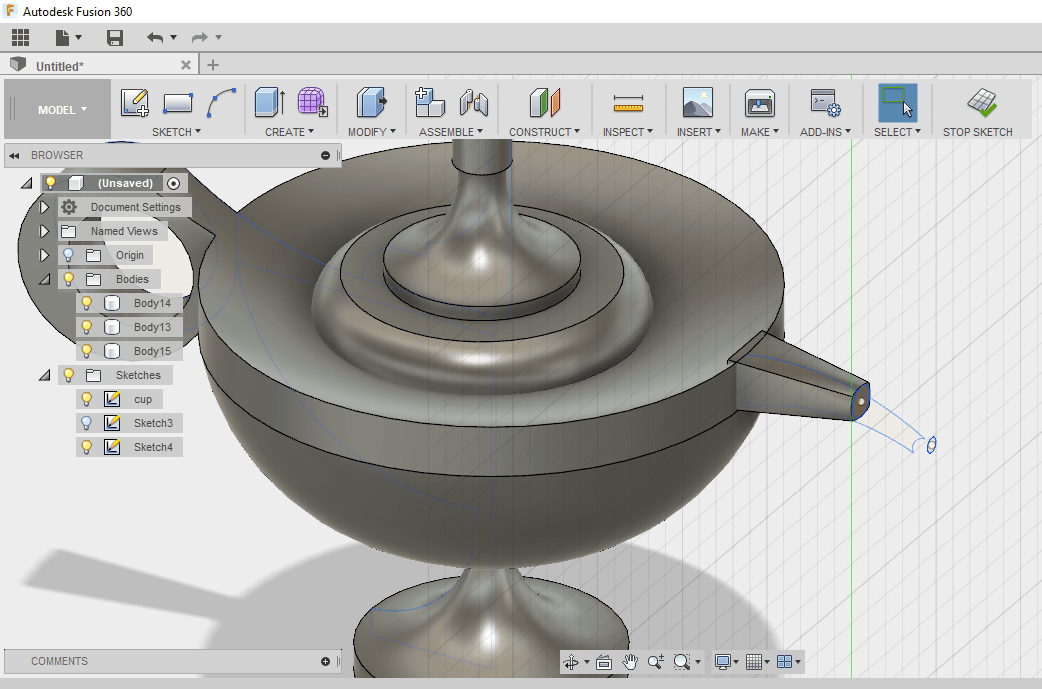

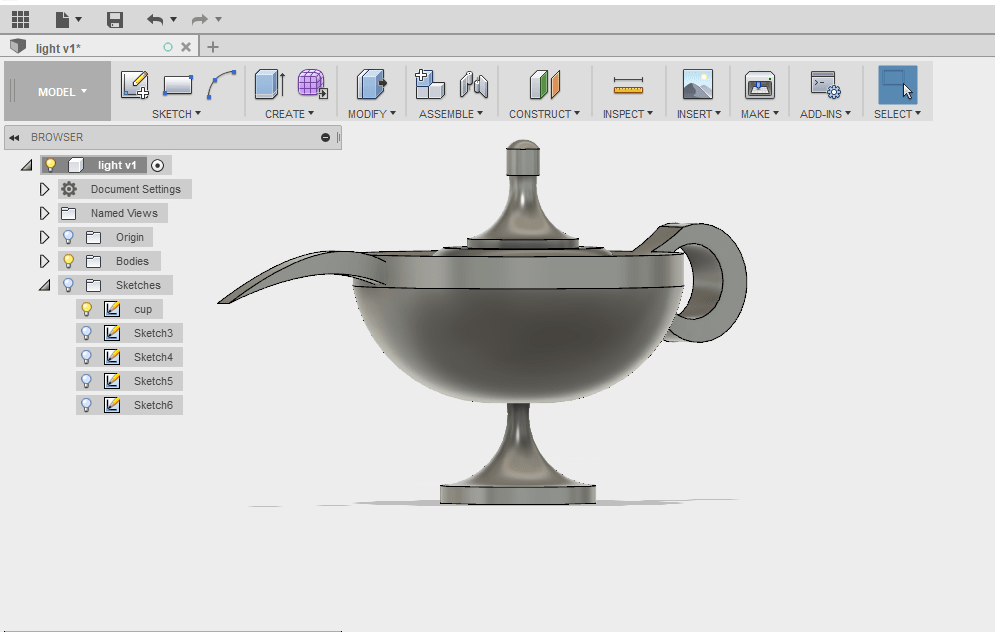

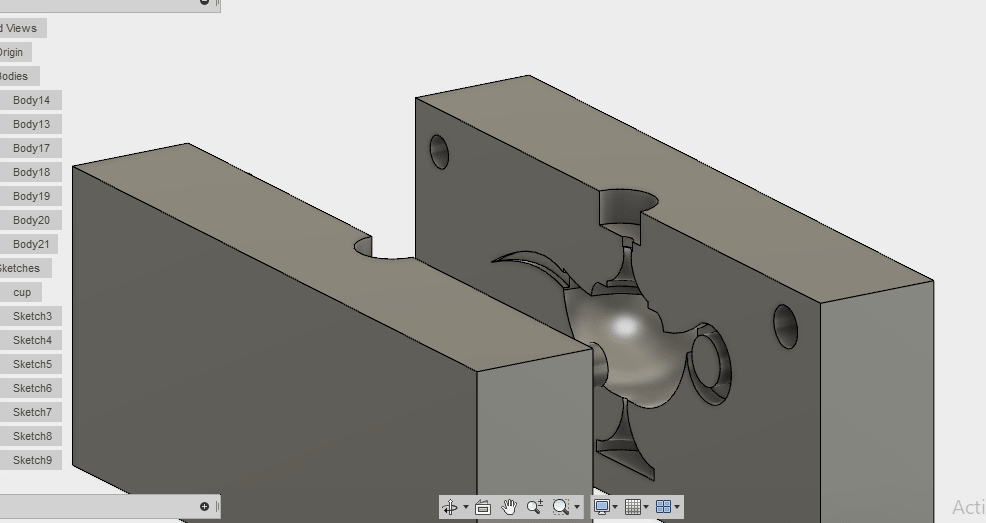

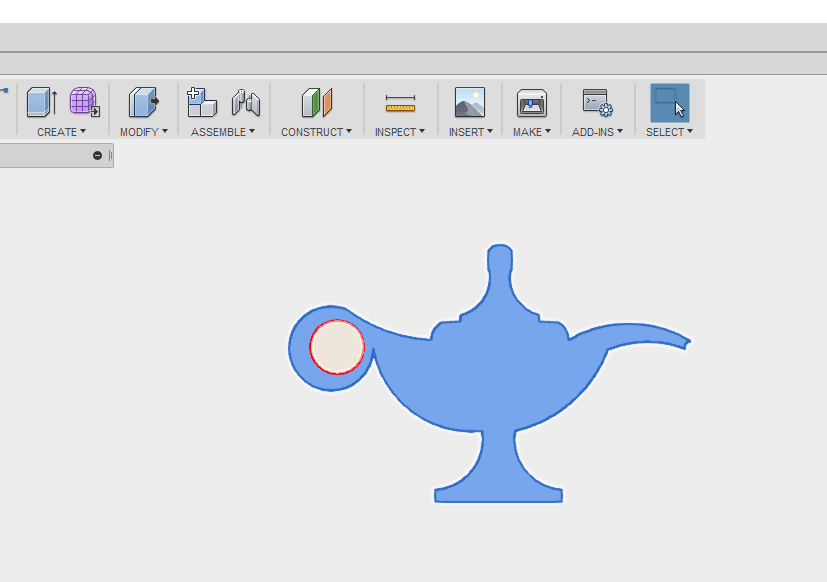

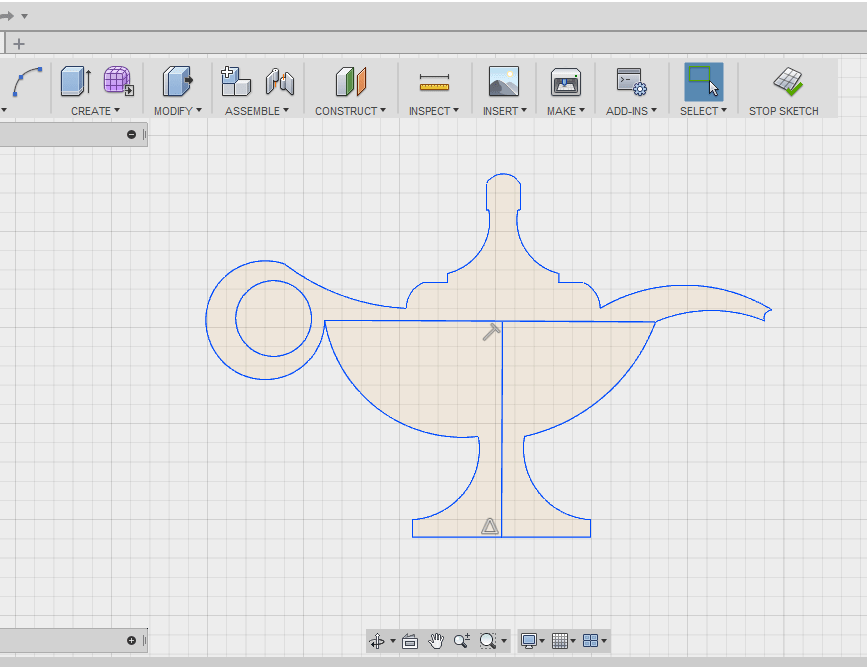

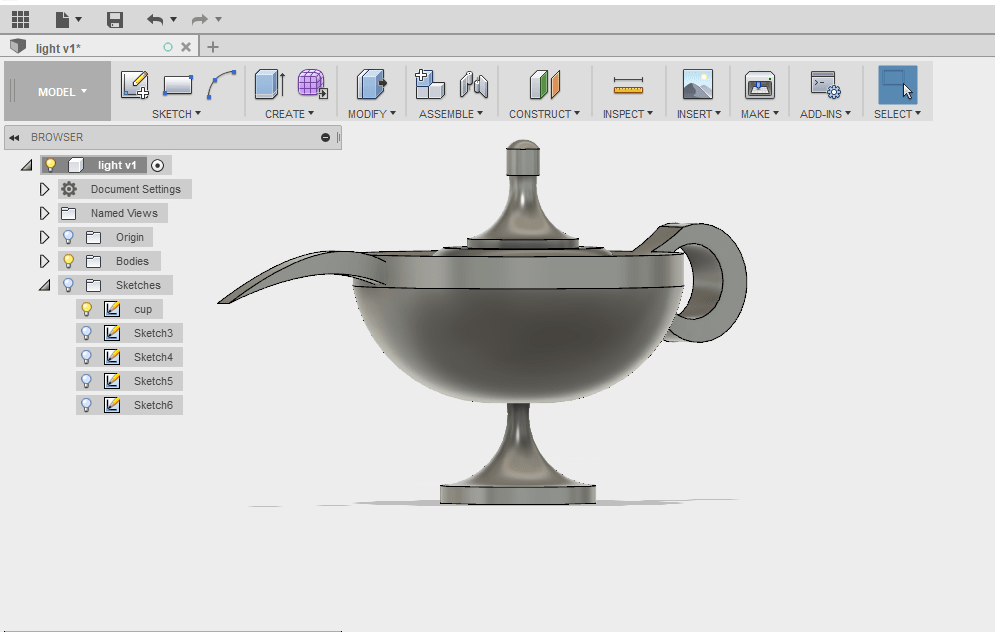

Aladdin's lamp

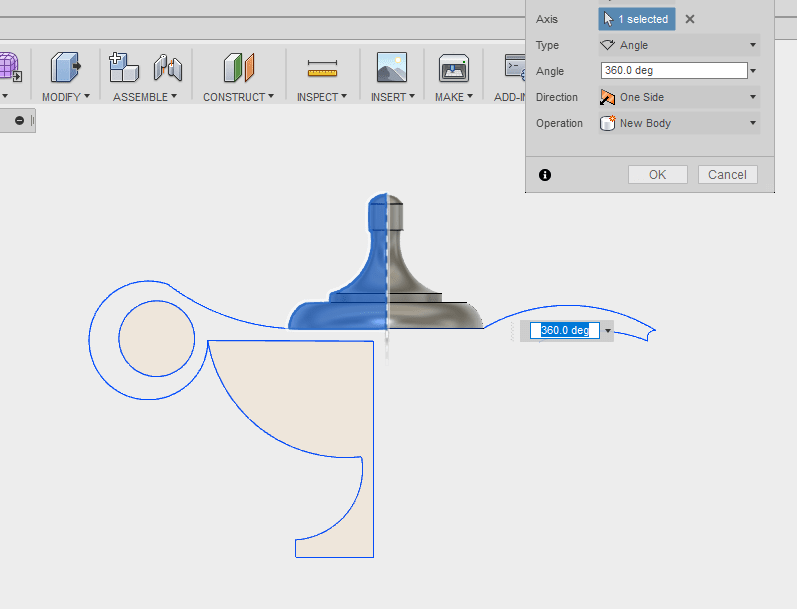

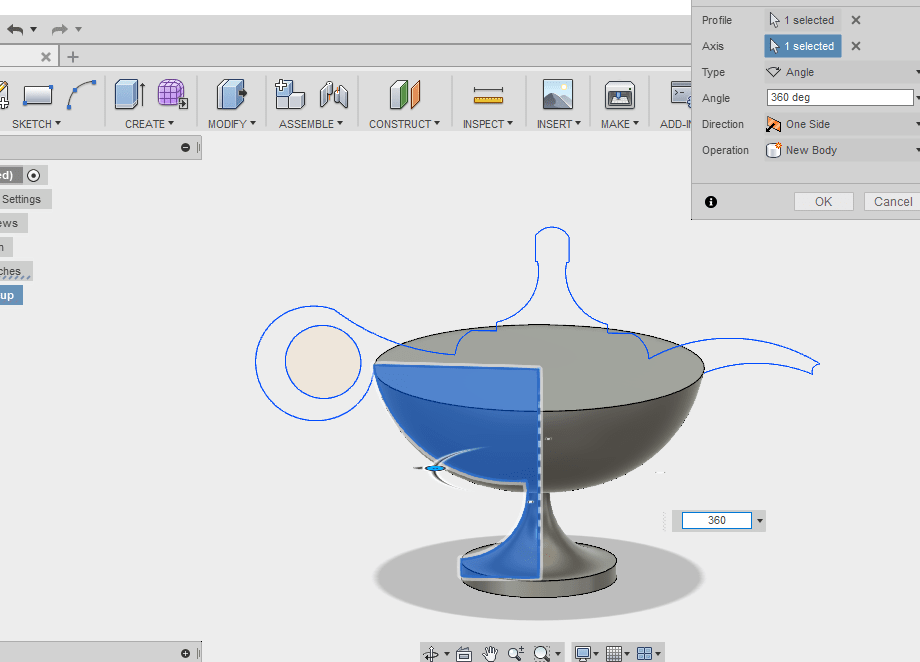

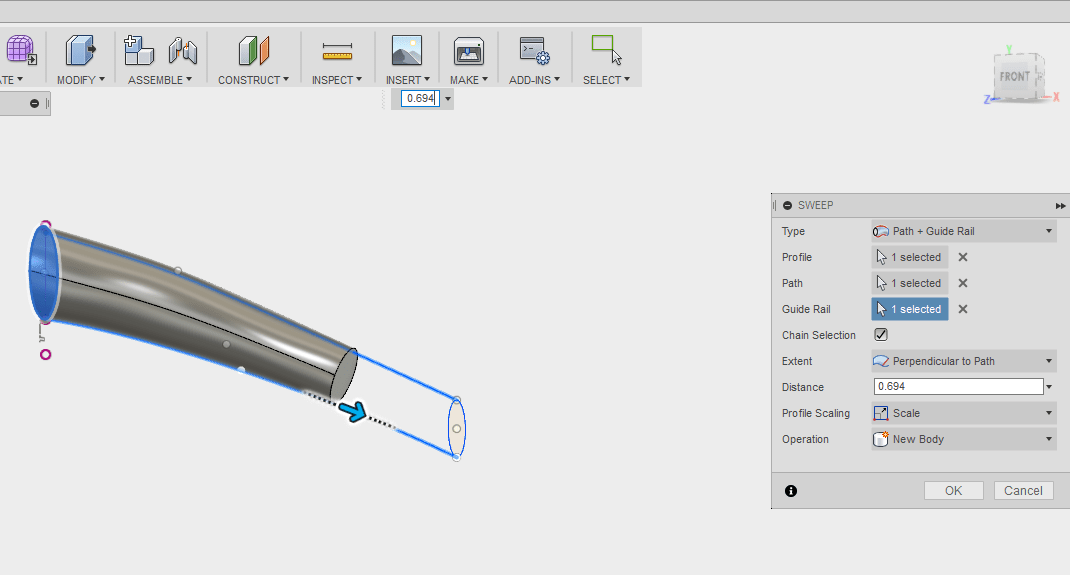

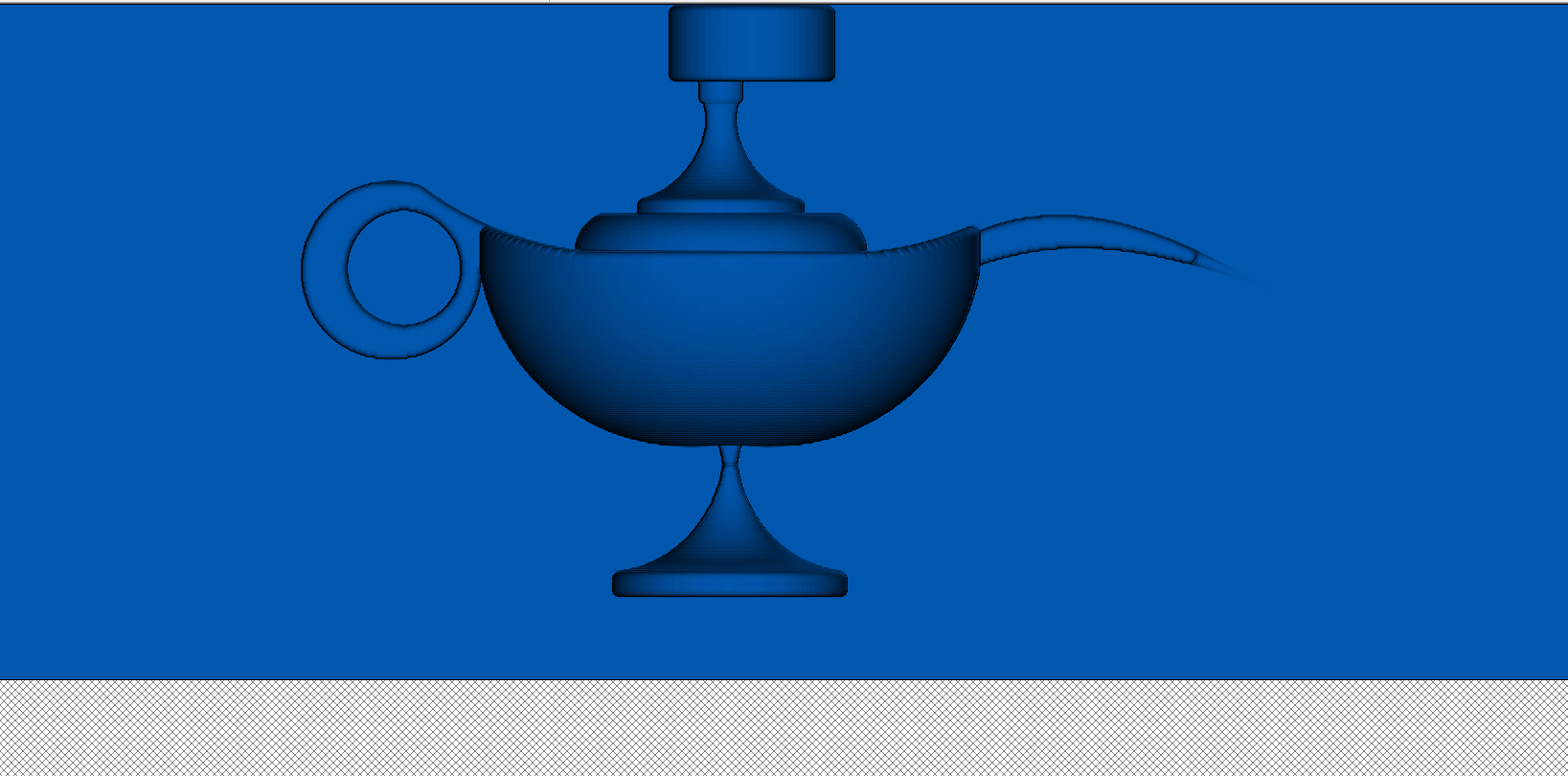

First I insert a picture in inkScape and used Trace Bitmap to have the outline, then I save the file as dxf file and insert it in Fusion360

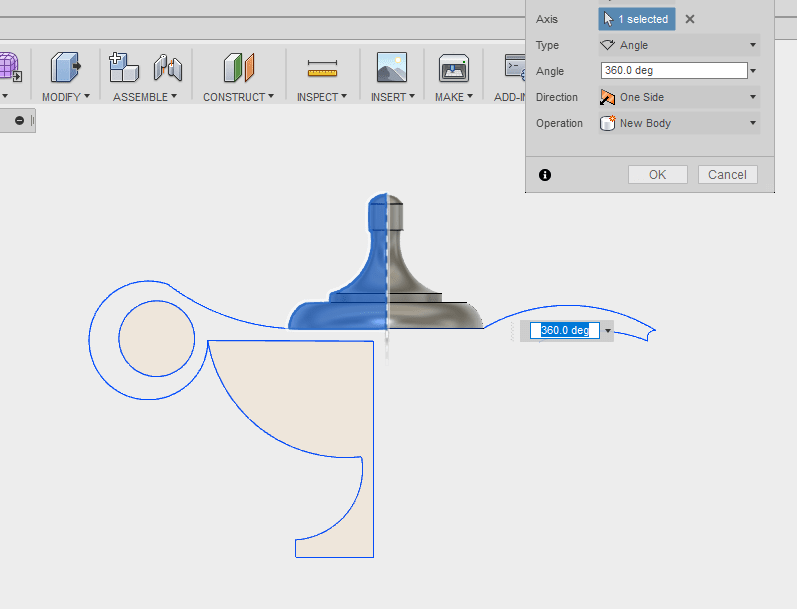

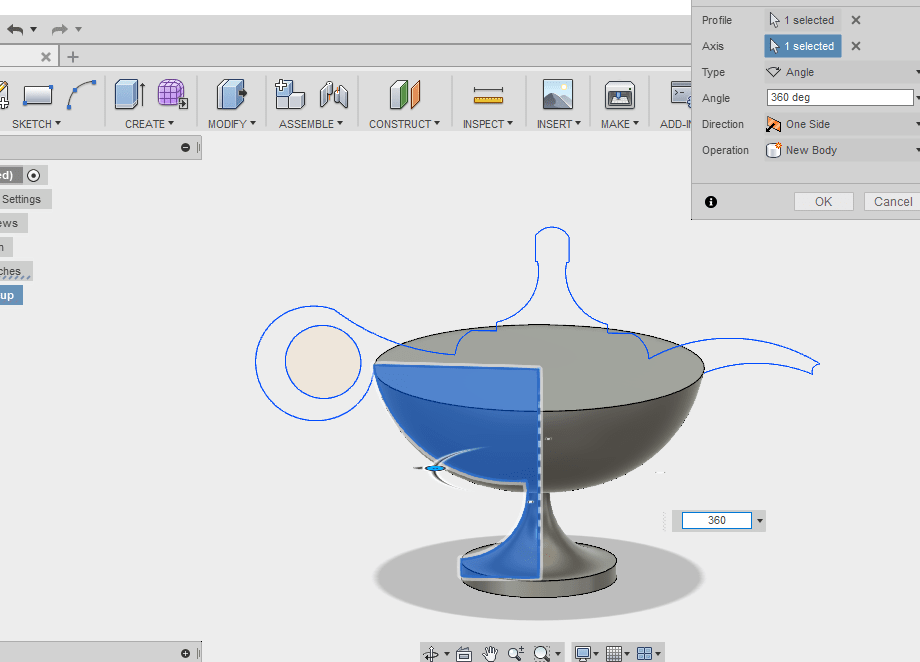

Then I draw a line in the object to revolve each part,

I chose from create menu revolve to revolve the body and the cover (360 degree)

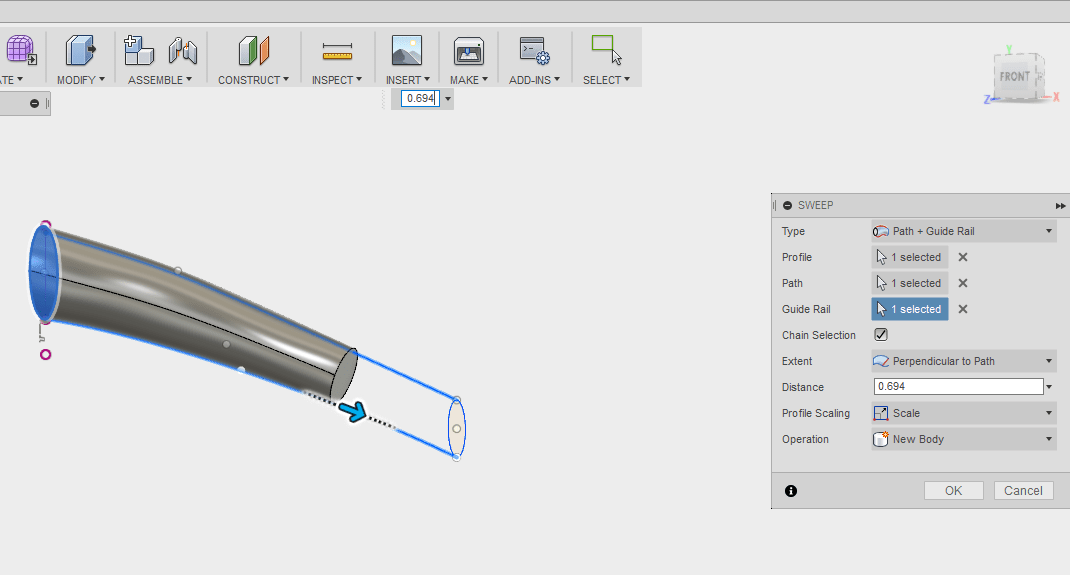

Extrude the hand of the object.

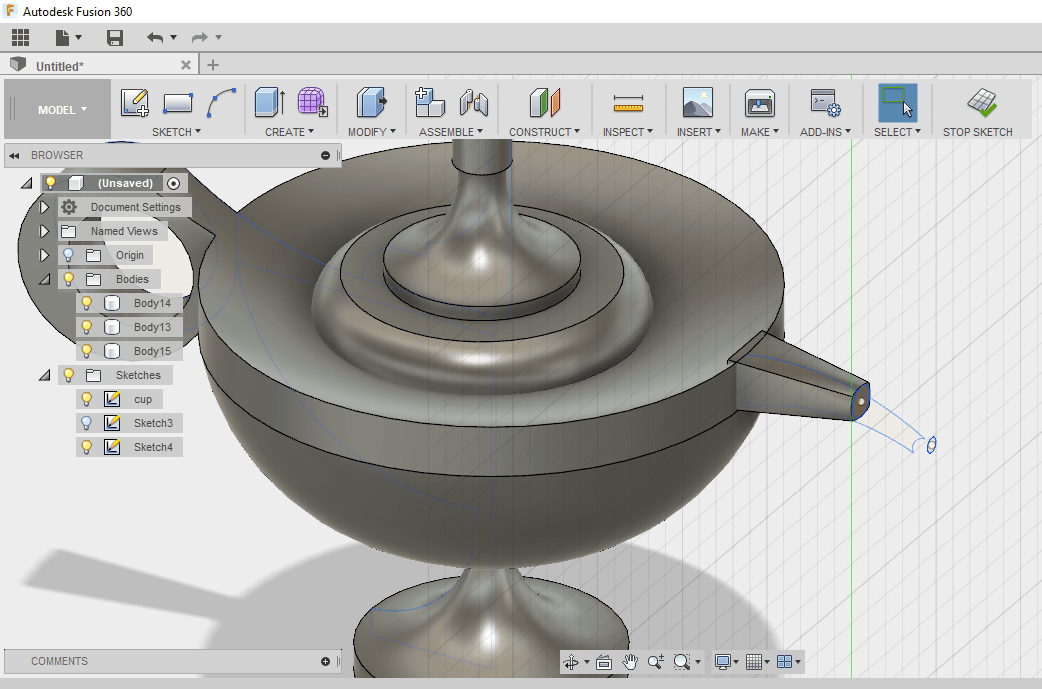

And this is Aladdin's lamp

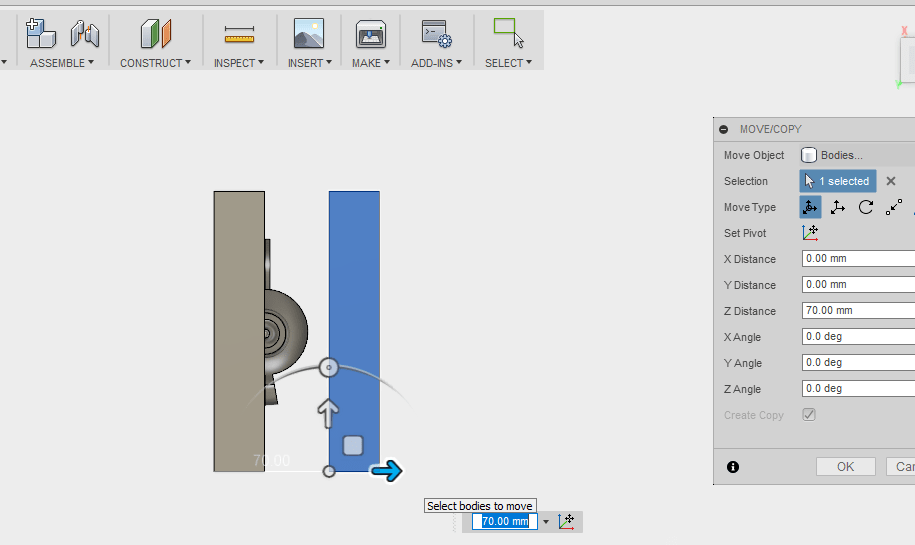

Then I edit the scale before I draw the blocks.

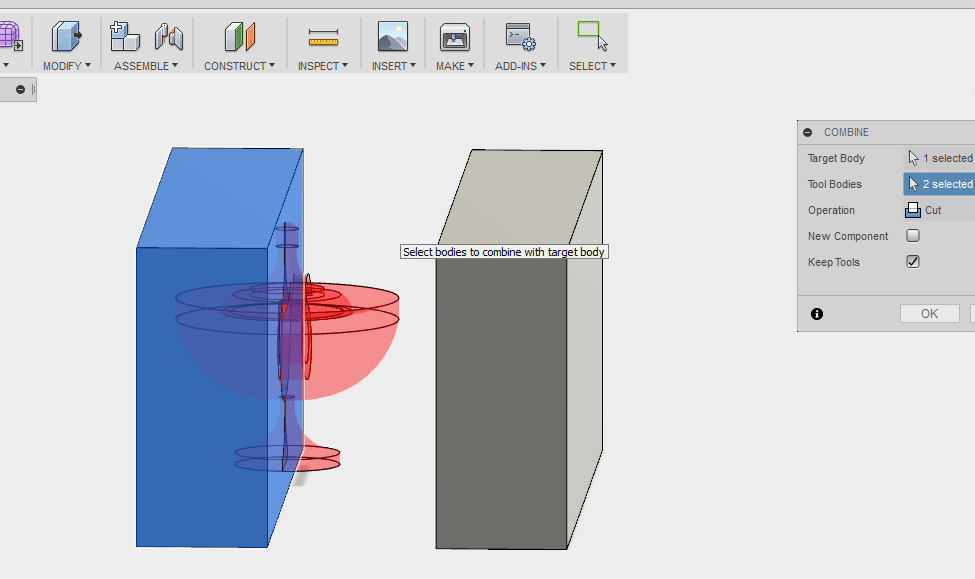

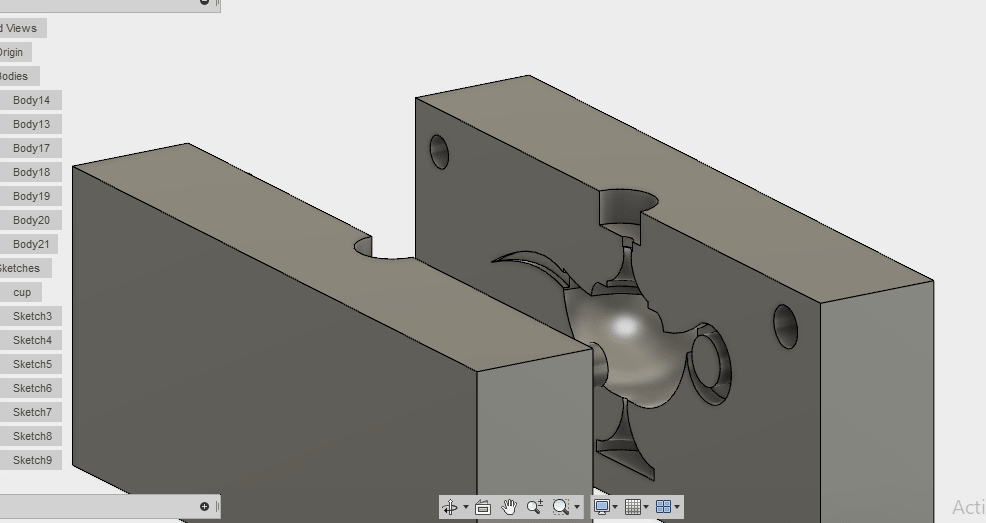

I make two cubes then subtract the object from them.

For the CAM process I chose Modela and make the previous setting of this program

BUT THE PROBLEM

when I chose simulation the small details of the object was hidden.

So I decide to use a small tool which is not define in Modela software,

to define the tool I chose add tool from option menu.

Now I can choose the tool.

This is the result of the finishing simulation

The result of roughing job

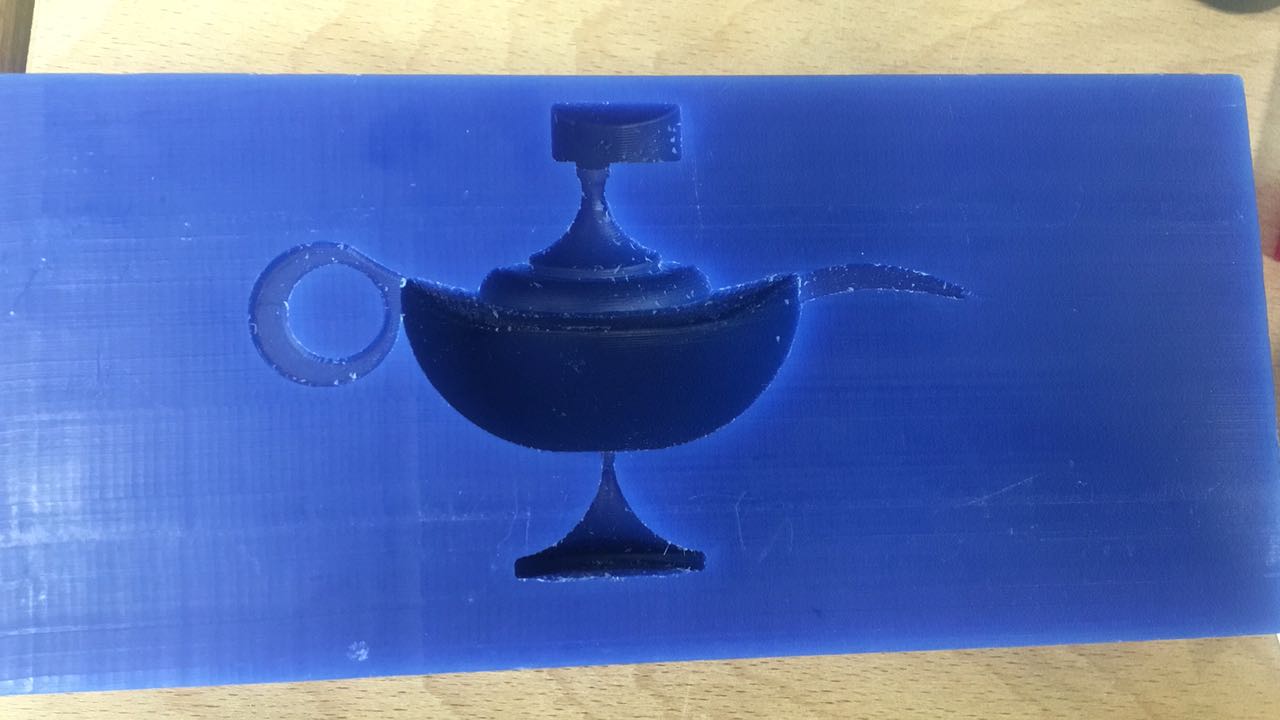

And here is the result of the finish cut.

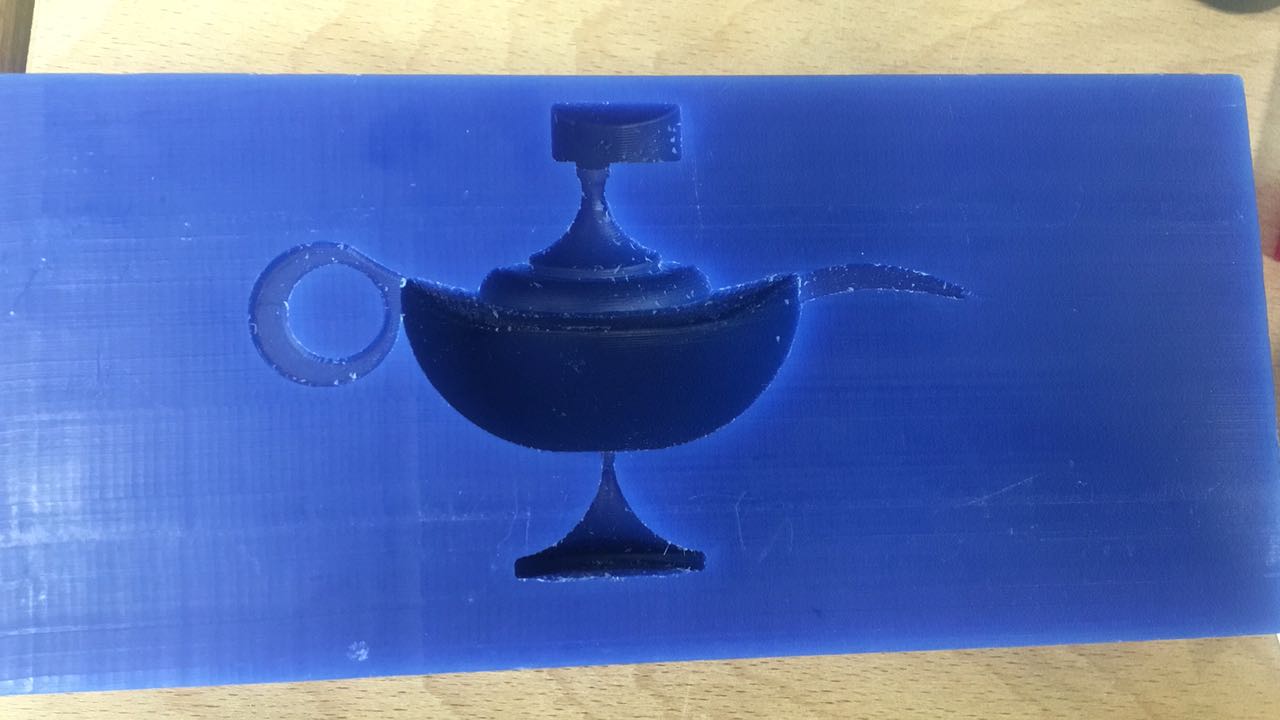

Casting Aladdin's lamp

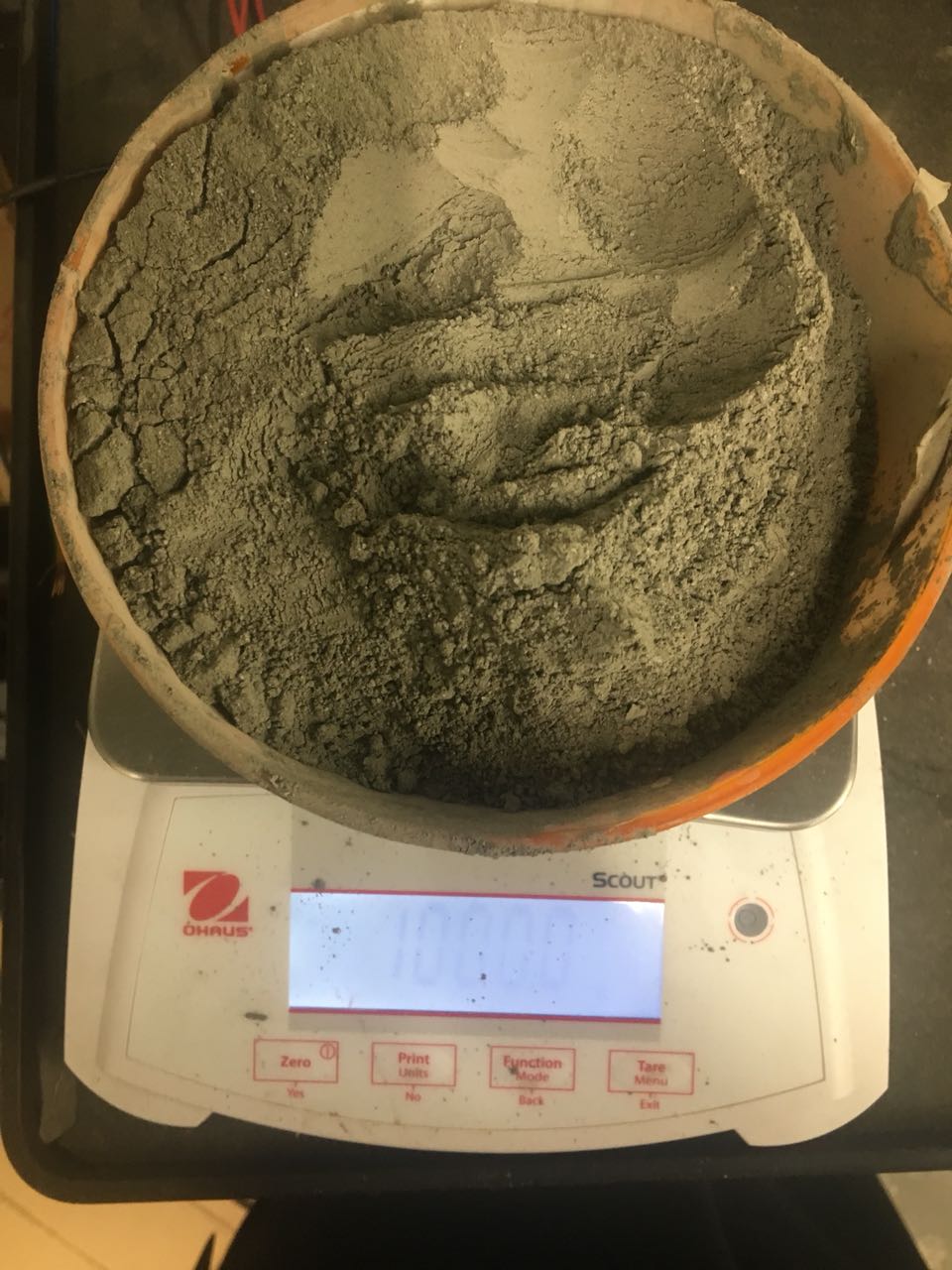

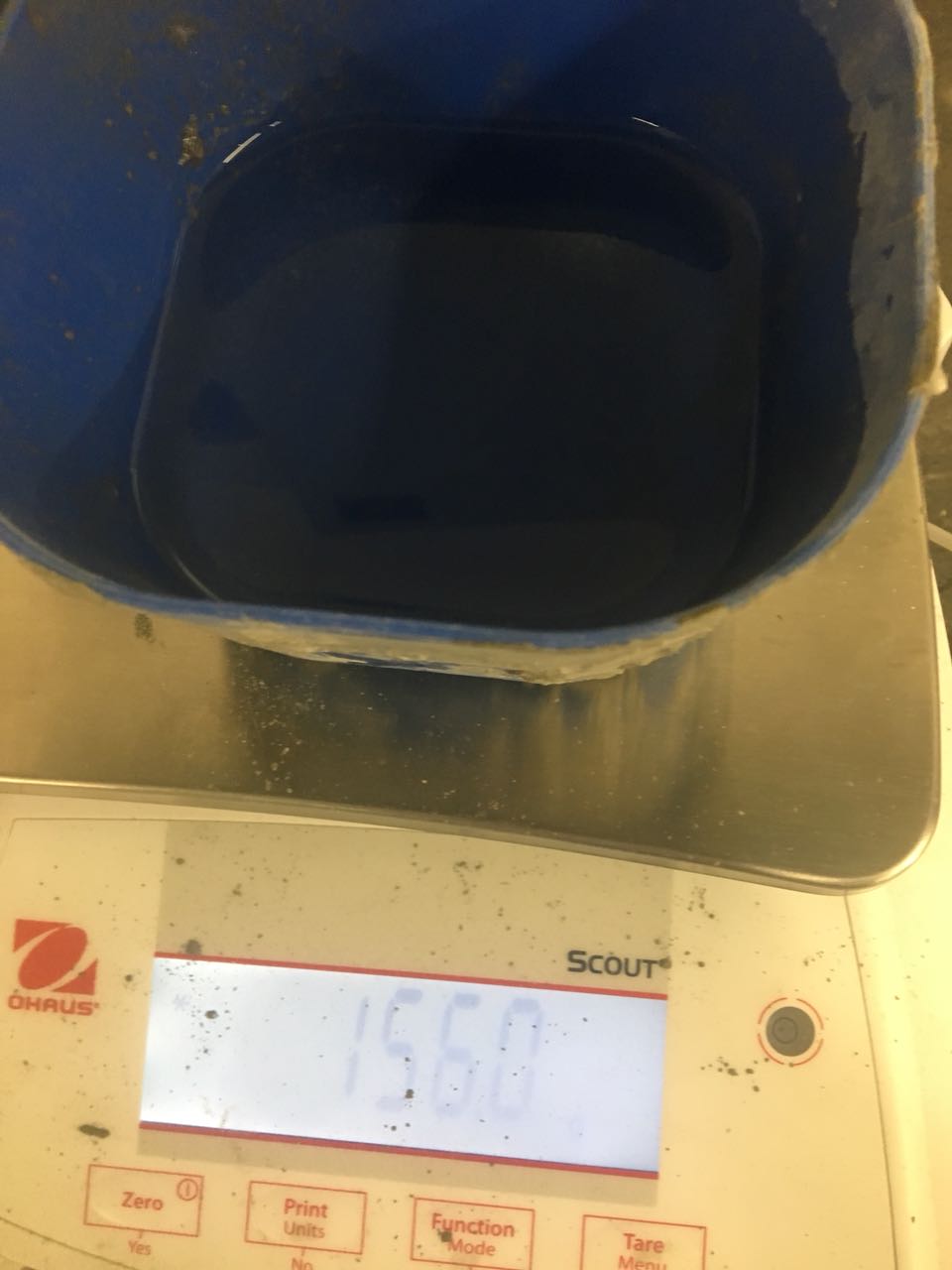

I decided to use a material called Grout

Grout is a particularly fluid form of concrete used to fill gaps. Grout is generally a mixture of water, cement, and sand"

By following the data sheet of this material

I put 1 Kgof Grout and 556 g of water and mix it together.

Unfortunately this is the result !!!

The possible reason for the problem

I left the mold 24 hours. But when I read the data sheet I think that I should should leave it Minimum 24 hours and the cure time may be extended

depending on caulking thickness and ambient conditions.

So maybe I should leave it more than 24 hours to avoid this problem.

Download the Files:

Violin Design

Aladdin's lamp