Molding and Casting

Group members

This week we were supposed to review the safety data sheets for each of our molding and casting materials, then we were supposed to make and compare test casts with each of them

Work description

We started to learn about molding and casting at 23.3.2018 with our local instructor Iván Sánchez Milara. We studied the basics of mold making, milling of the mold and different types of mold and cast materials. After we had learned the basics, we read the safety data sheets for each material and also read the instructions for their use.

Some interesting information we got from the different Safety Data Sheets

In Smooth-Cast 305 Safety Data Sheet we could read:

- Handling Precautions: Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment. If ventilation is not sufficient, wear proper respiratory equipment. Avoid moisture contamination.

- Respiratory Protection: Follow OSHA respirator regulations 29 CFR 1910.134 and European Standard EN 149; wear an MSHA/NIOSH or European Standard EN149 approved respirator.

- Protective Clothing/Equipment: Wear chemically protective gloves. Wear protective eyeglasses per OSHA eye and face protection regulations

In Ooomo 25 Safety Data Sheet we could read:

- Precautions for safe handling: Use good general housekeeping procedures. Wash hands after use

- Respiratory Protection: Should a respirator be needed, follow OSHA respirator regulations 29 CFR 1910.134 and European Standards EN 141, 143 and 371; wear an MSHA/NIOSH or European Standards EN 141, 143 and 371 approved respirators equipped with organic vapor cartridges.

- Hand Protection: Wear any liquid-tight gloves such as butyl rubber, neoprene or PVC.

- Eye Protection: Safety glasses with side shields per OSHA eye- and face-protection regulations 29 CFR 1910.133 and European Standard EN166.

- Other Protective Clothing/Equipment: Additional protective clothing or equipment is not normally required.

In Smooth-Sil 940 Safety Data Sheet we could read:

- Handling Precautions: Minimize breathing of vapors and avoid prolonged or repeated contact with skin. Wear proper protective equipment.

- Ventilation: Provide general or local exhaust ventilation systems

- Protective Clothing/Equipment: Wear chemically protective gloves. Wear protective eyeglasses per OSHA eye and face protection regulations

To follow the instructions given, we are working in a properly ventilated room. We are using nitril gloves and safety glasses.

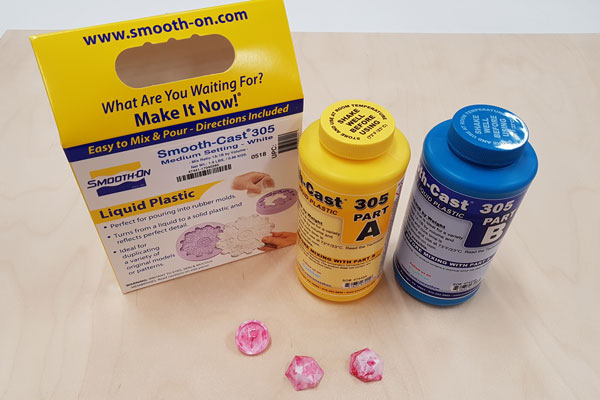

Smooth-Cast® 305

First, we experienced casting a Smooth-Cast® 305 liguid plastic, which is ultra-low viscosity casting resin that yield castings that are bright white and virtually bubble free, so there is no need for vacuum degassing.

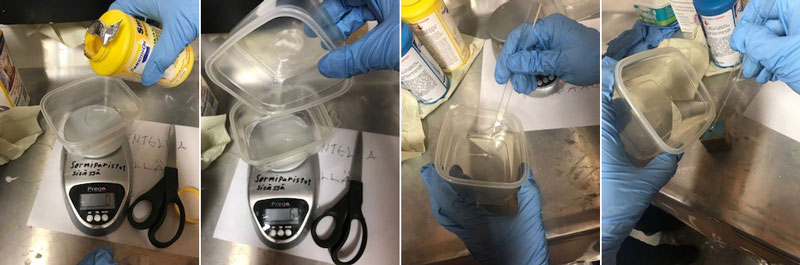

We put nitril gloves and safety glasses on and we started the work with Smooth-Cast 305. We and pre-mixed both Part A and Part B thoroughly, weighted them separately using a gram scale, and mixed them together (mixture was 10 parts of A and 9 parts of B. Total weight of the mixture was 40 g. Then, we stirred them by horizontal movements trying to avoid adding bubbles into the mixture.

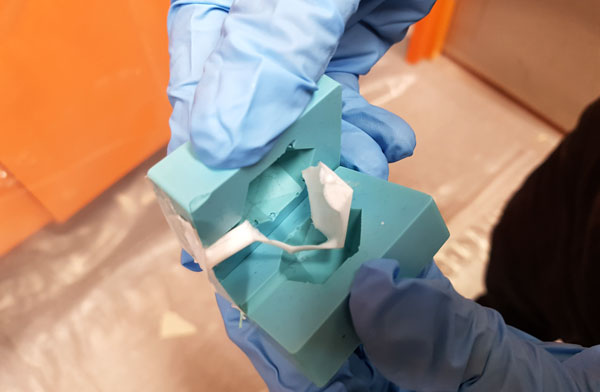

The other part of the group worked on preparing the mold by taping the front and backside of the mold tightly together. However, the tape didn't stick too well, and we finished preparing the mold too late for pouring the material into a silicone mold, and Smooth-Cast was already started to harden so it didn't went well. Moreover, because the air bubbles were coming out the same way that the liquid plastic was poured, it was hard to know if the mold was full or if the material was just sticking on the neck of the mold.

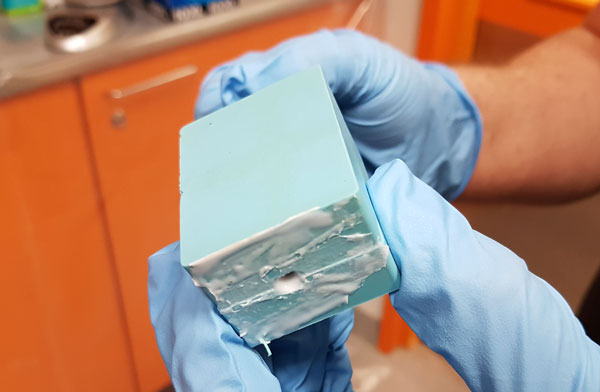

We allowed the liquid plastic to cure on the mold at room temperature for 30-40 minutes. When it was time to check the result we noticed, that only a little bit of material had went in the mold, and the casting failed miserably.

Here is the product and Kati's result on casting (and coloring) Smooth-Cast® 305.

OOMOO™ 25 Liguid Rubber

OOMOO™ 25 is an easy to use silicone rubber compound that features a convenient one-to-one by volume mix ratio. It has a low viscosity for easy mixing and pouring.

We had bad luck with OOMOO™ 25, because it had all gone bad (5 new packages) and the material itself was only 2 months old and sealed in the bottles. The whole shipment had gone bad and the material provider promised to send a new batch, but we were not sure, if it would get here in time. In the end it arrived 29.3.2018.

This time we had prepared everything really well for the group work casting, but since the whole batch had gone bad, we couldn't work with it and we wasted a lot of time.

However, afterward Marta, used OOMOO™ 25 on her project. Here is the product and the result:

OOMOO™ 30 Silicone Rubber

Moreover, Kati experieced using OOMOO™ 30 on her project. The main differences between OOMOO 25 and OOMOO™ 30 is the pot life and cure time of the materials, which the former has way more shorter. Here is the product and the result:

Smooth-Sil™ 940

We had Smooth-Sil™ 940 in the shelf, but didn't make the casting with that one. The other group worked with it, but we used it in our own projects.

It was easy material to use. The pot life of the Smooth-Sil 940 is 30 min and cure time 24 h, so there is no hurry to cast it in the mold. The silicone part A was very viscous and required part B to make it more like fluid and less like rubber. The mixture according to instructions is 10 parts of part A and 1 part of part B.

Here is the product and Kati's result on experiencing Smooth-Sil™ 940.

Technical Overview of Materials

| Material | A:B Mix Ratio by Volume | A:B Mix Ratio by Weight | Pot Life | Cure Time |

|---|---|---|---|---|

| Smooth-Cast® 305 | 1A:1B | 100A:90B | 7 min | 30 min |

| OOMOO™ 25 Liguid Rubber | 1A:1B | 100A:130B | 15 min | 75 min |

| OOMOO™ 30 Silicone Rubber | 1A:1B | 100A:130B | 30 min | 6 hours |

| Smooth-Sil™ 940 | 100A:10B | 100A:10B | 30 min | 24 hours |