Assignment 2: Add (at least) a button and LED (with current-limiting resistor)

Assignment 3: Check the design rules

Assignment 4: Make it

What went really wrong.

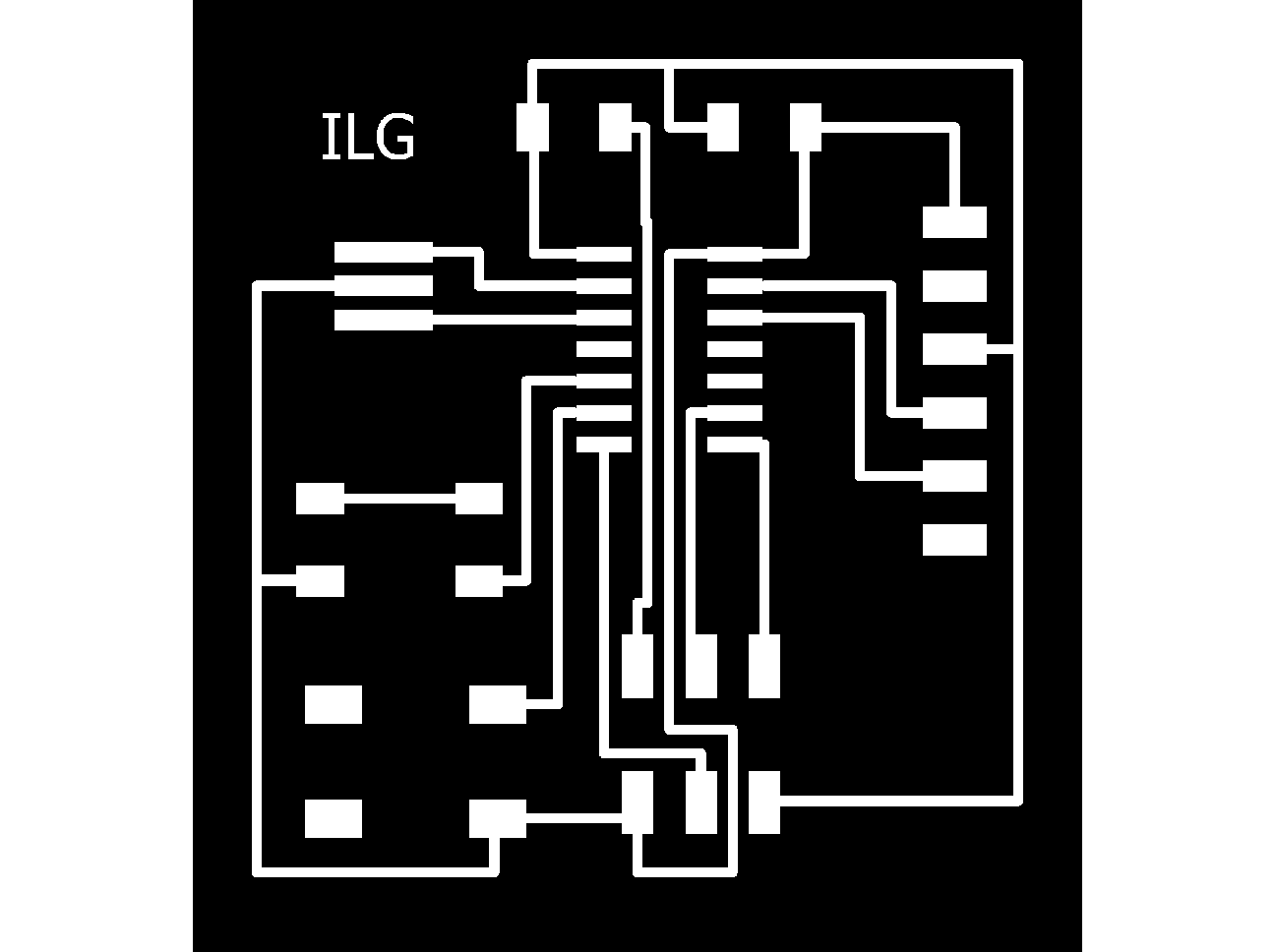

I got an error message. After switching cables, programmers and laptops the conclusion was: faulty board. Bas immediately saw a connection was missing between IC1's pin PB3 and the R1 resistor (or RST pin of J1). How could this happen, since in the schematic drawing the connection is visible. It also is visible in the board layout as it was BEFORE I started juggling with the routes to solve DCR issues. A tiny yellow line apparantly had reappeared that I did not notice, resulting in ...

Other lessons learned

First I forgot to CALCULATE before pressing SEND. The Modela is then going to do the same job it did before. After following the procedure described in the 6.2 part. I wanted to continu and then found out I forgot to invert the Inside file. It might be better to make a check list, because there is so much one can forget.