1

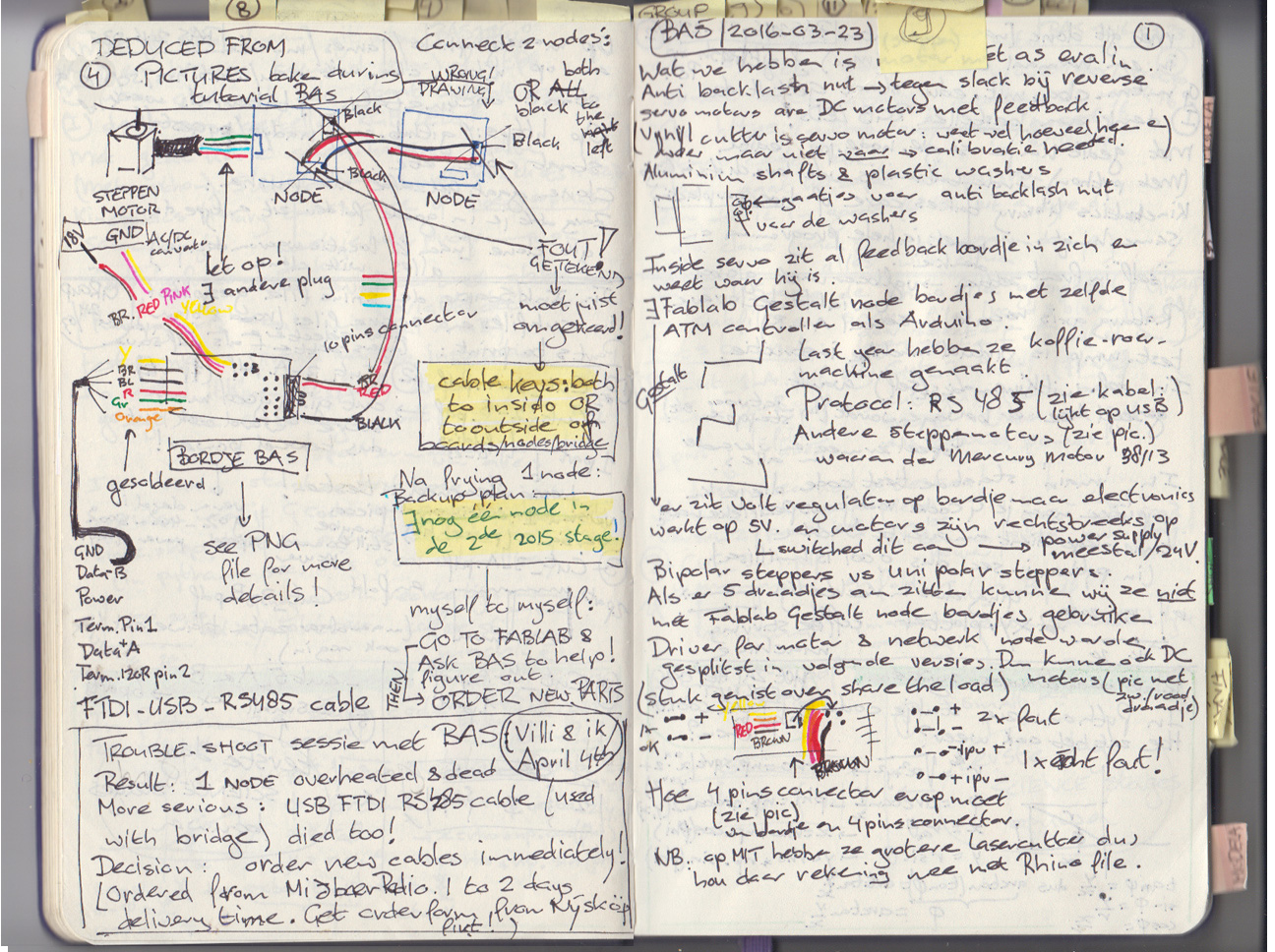

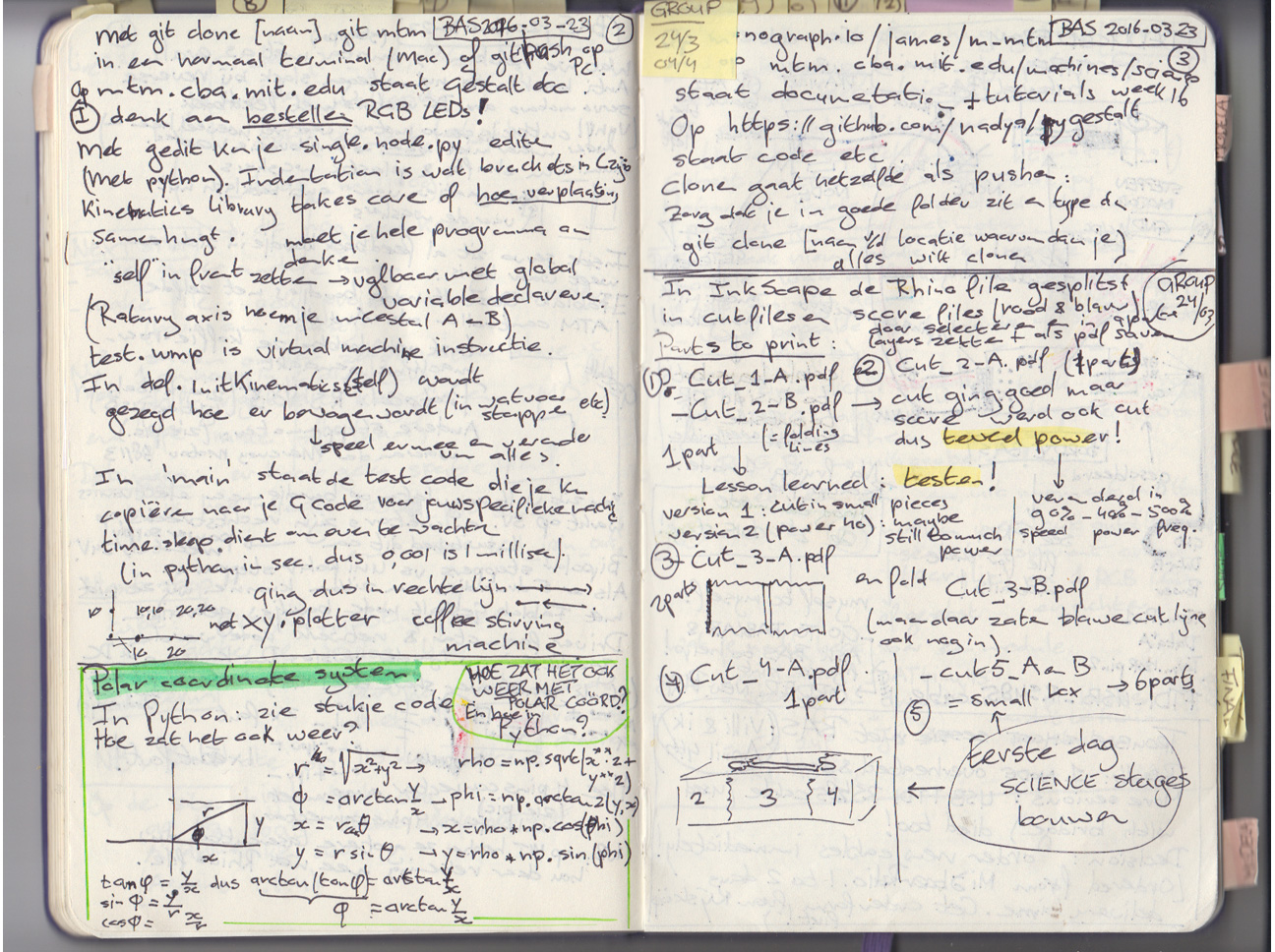

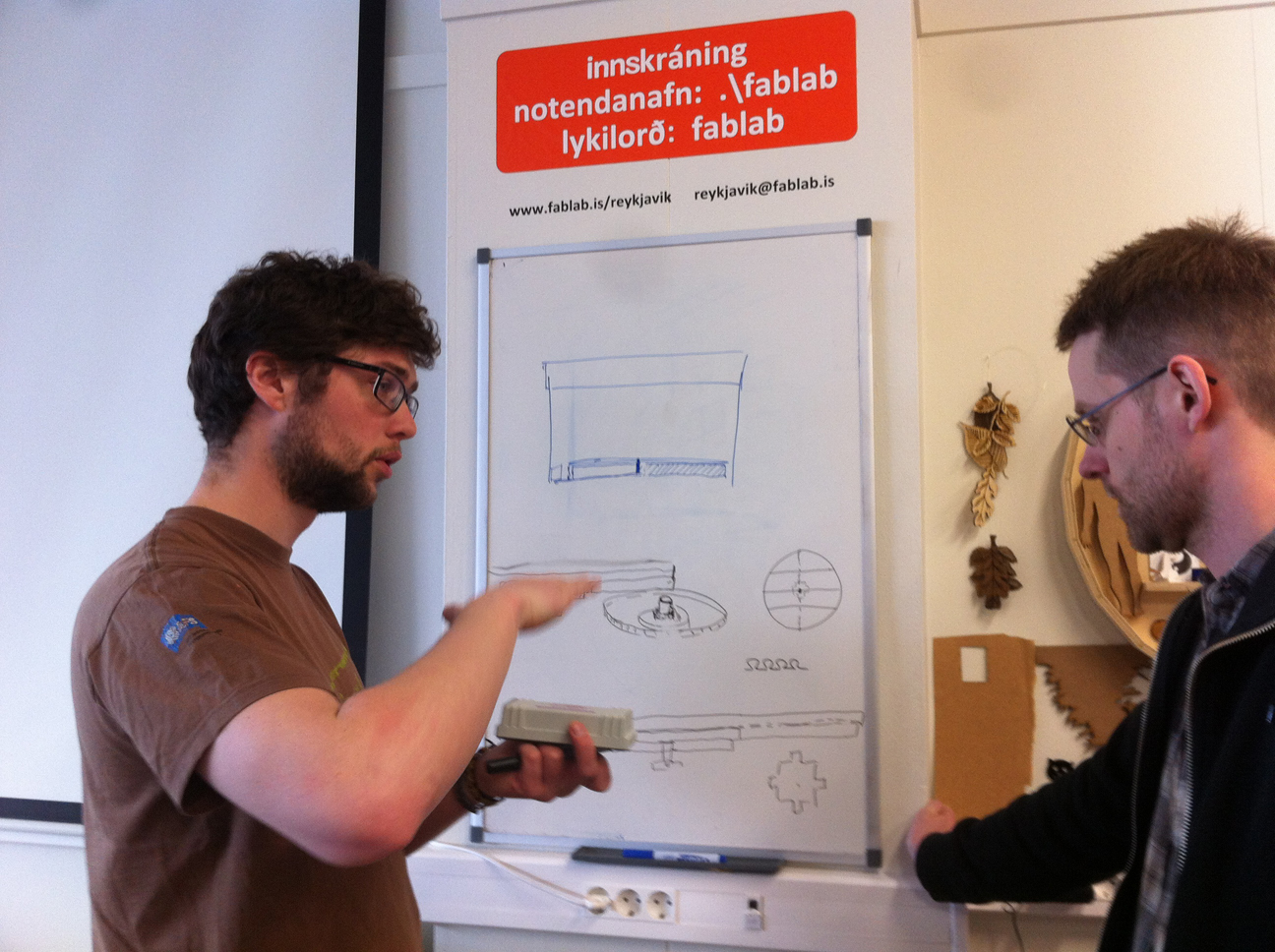

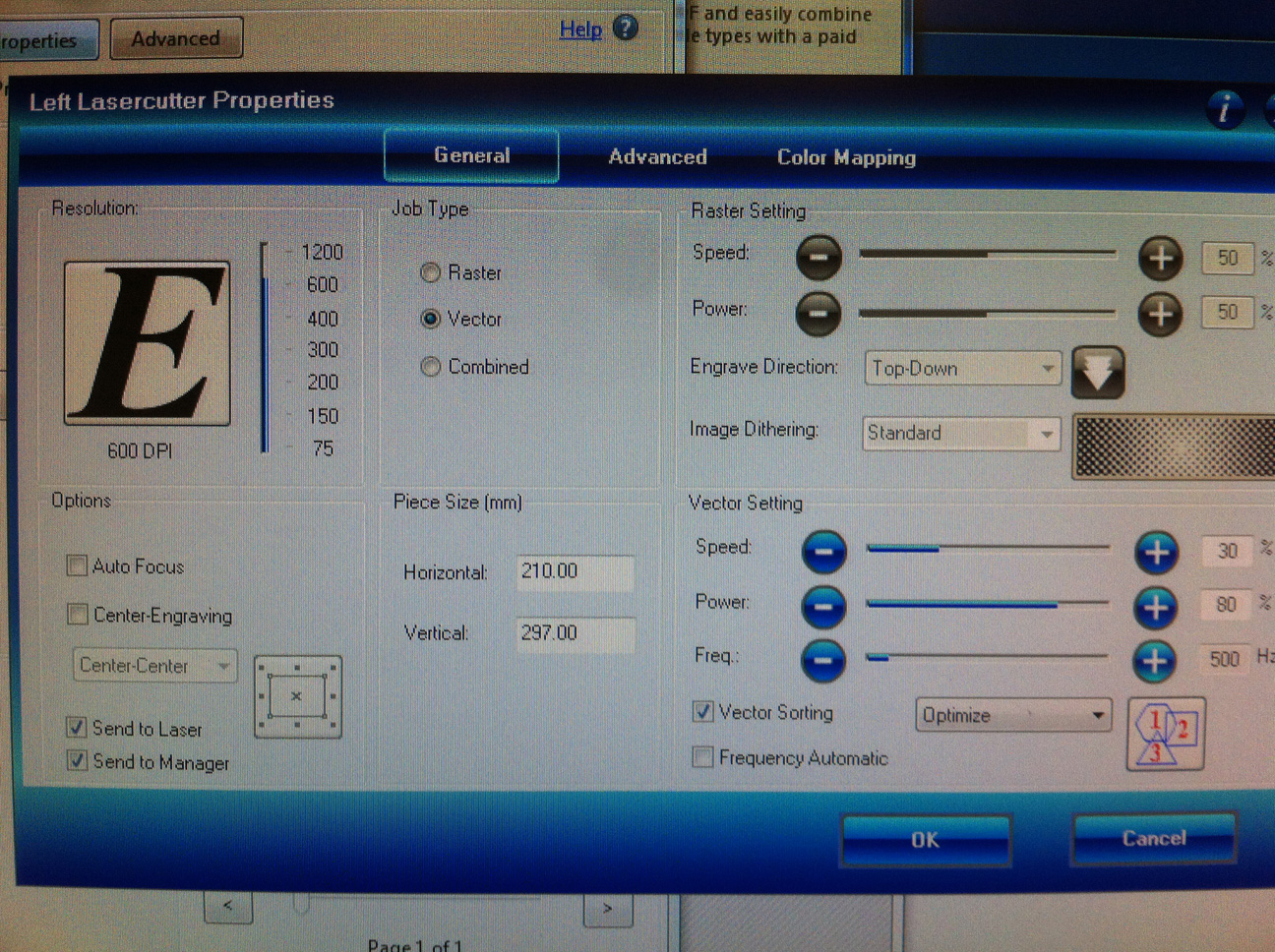

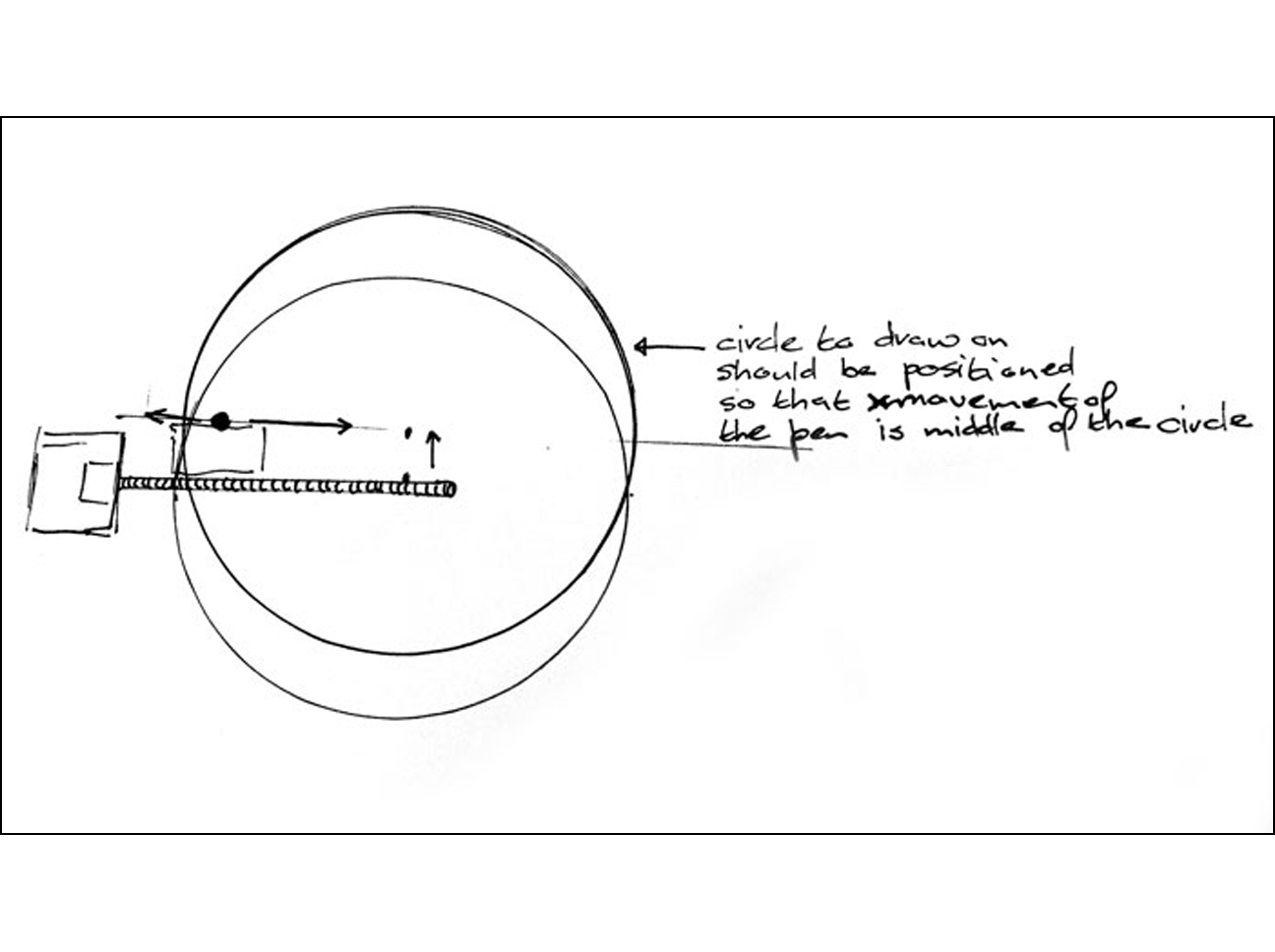

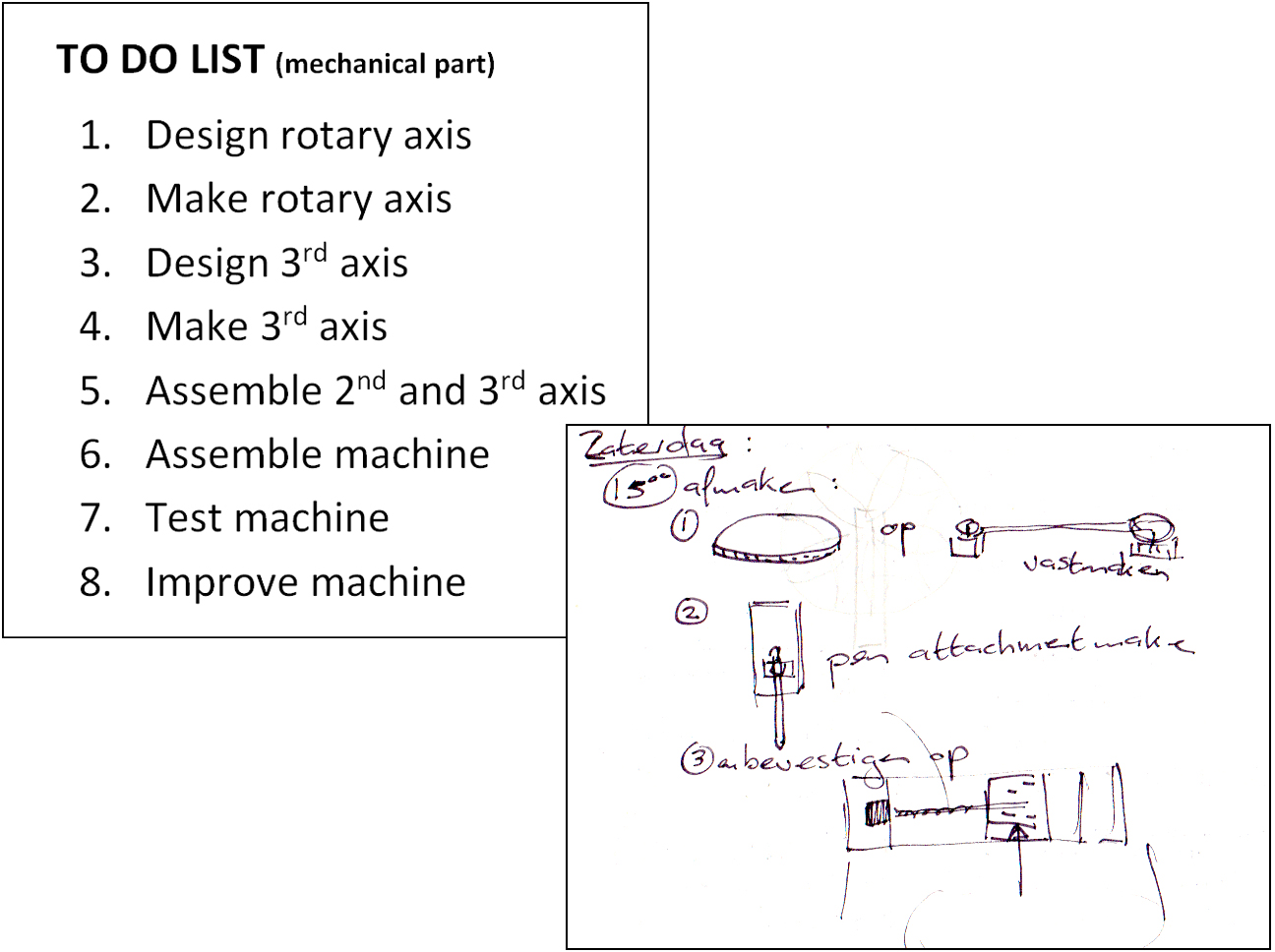

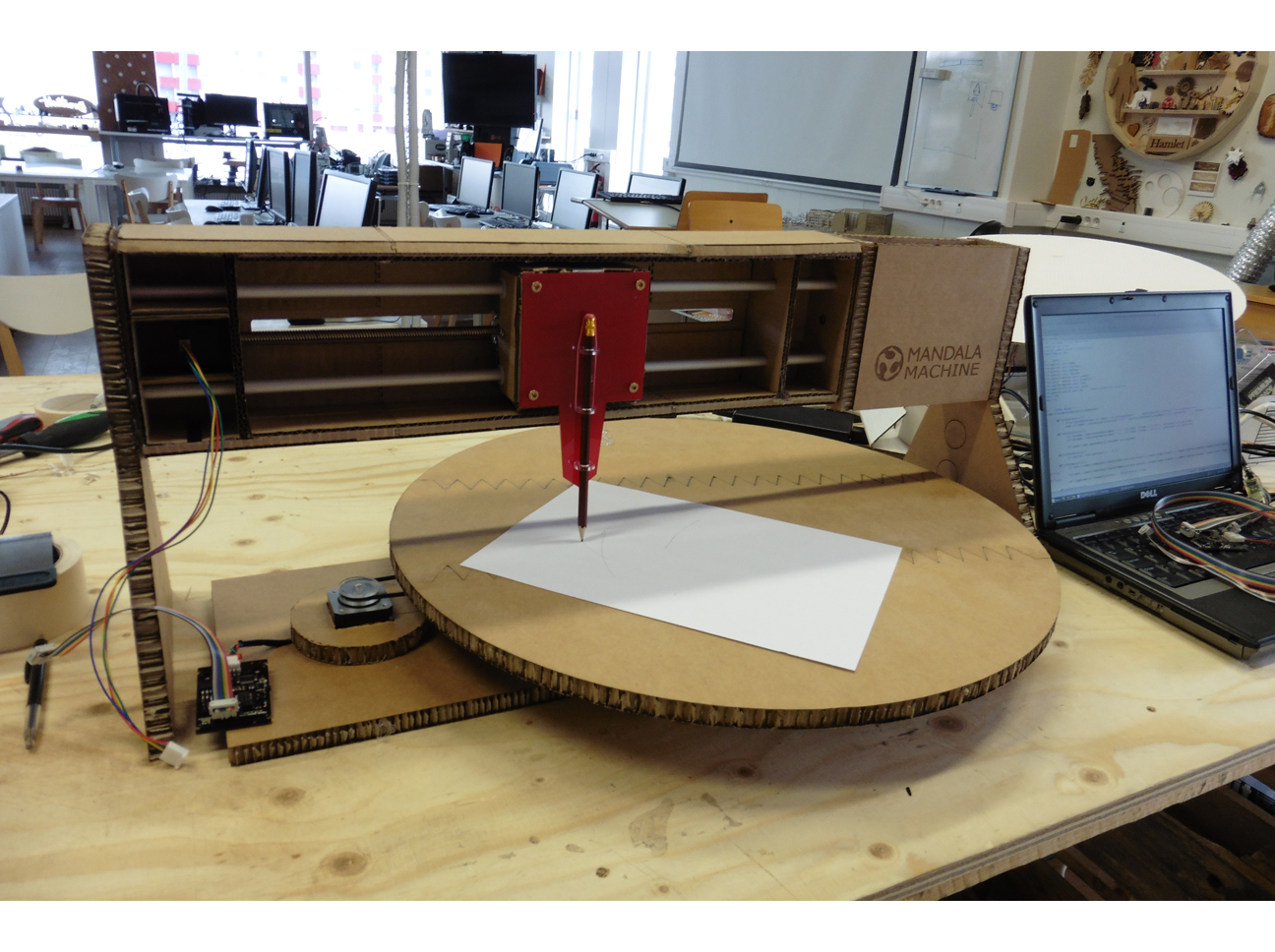

This week together with all other Fab Academy Reykjavik students and one Fab Academy Höfn student we have built a Mandala machine. The machine consists of two parts, one part taking care of the movement of a pen along a horizontal axis, a second part taking care of spinning a disk in a horizontal plane (see picture). Hence our Mandala machine basically is a (r, theta)-plotter. The building process and what we have learned from it is documented in detail on our group's Machine Building website.

7

I also contributed to the group by applying some of my other skills, amongst which ideation. This is one of the ideas I presented to the group: a puffin cooky cutter machine. Unfortunately the other members of the group rejected the proposal, which is really a pity since everything that has the shape of a puffin sells like crazy in Iceland to the millions of tourist flooding into the country each year.

8

Another skill that came in handy is that I have a good sense for numbers and what their practical relevance is. For instance: when the group was considering to make a circulair sandbox (circle I should say) Zen machine, I calculated the sand for a 30 cm radius and 2 cm heigh circle would weight 8.5 kg. The cardboard would bend under that weight, sand would get into the construction, motors would get damaged: bad idea and the group quickly was convinced not to go this route.

11

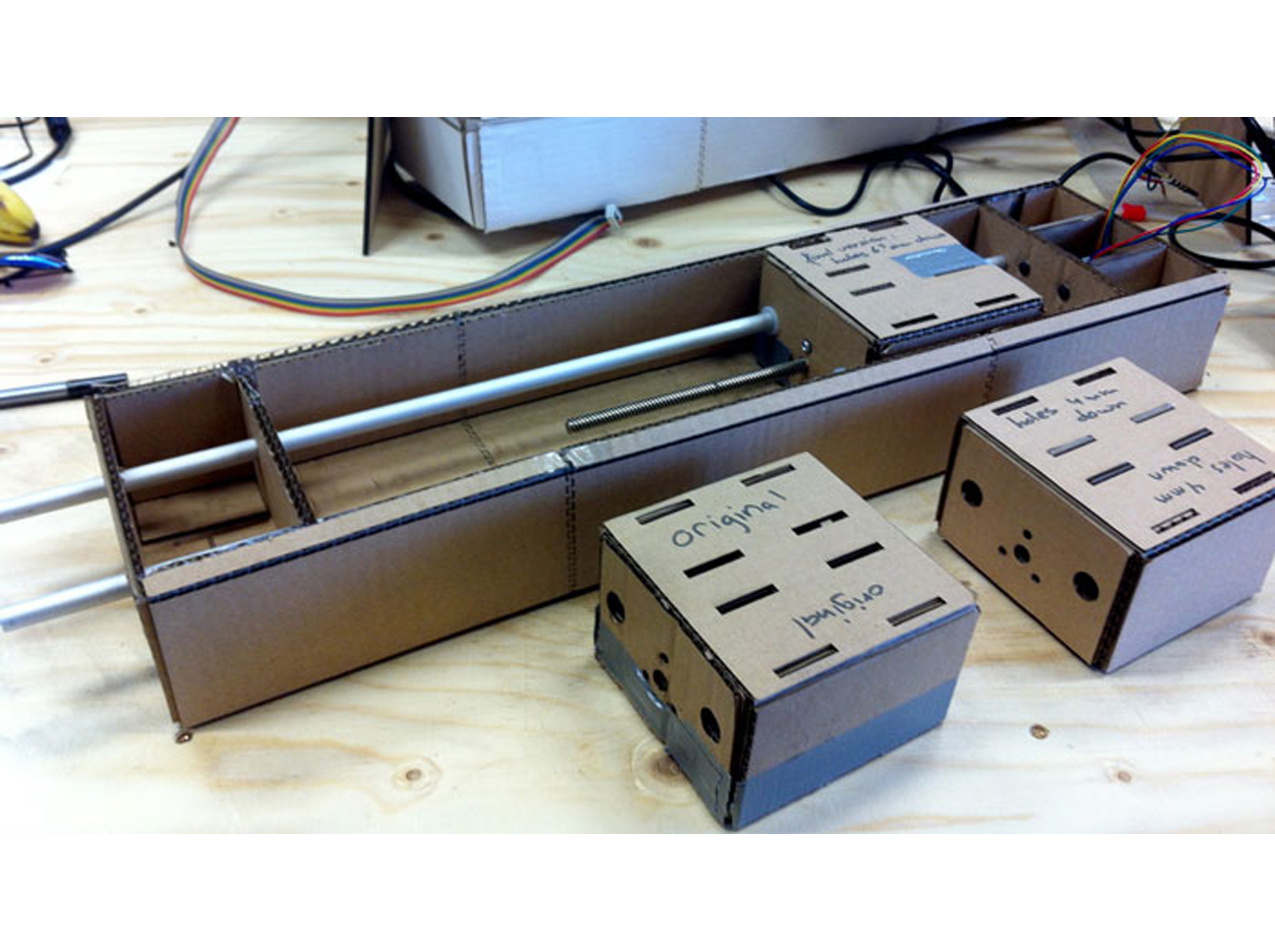

More troubleshooting: in the stage group a problem arose because we only could get cardboard that was thicker than the one the original design was made for. That was not good for accuracy and gave problems later in the process: the holes in the inside box (stage part) that runs on the aluminum slide bars were to low and the motor could not move it freely inside the frame. I helped measuring and recalculating how this could be corrected and according to this information new drawings were made to fix this.

12

And then there was my big roll of gaffer tape! As already can be seen in the previous picture, always having gaffer tape at hand is a must in Iceland to solve material problems that otherwise would have to wait till the next boat with stuff arrives. "Tape together what needs to stay together and is not glued or screwed together" could have been the motto of our group.

18

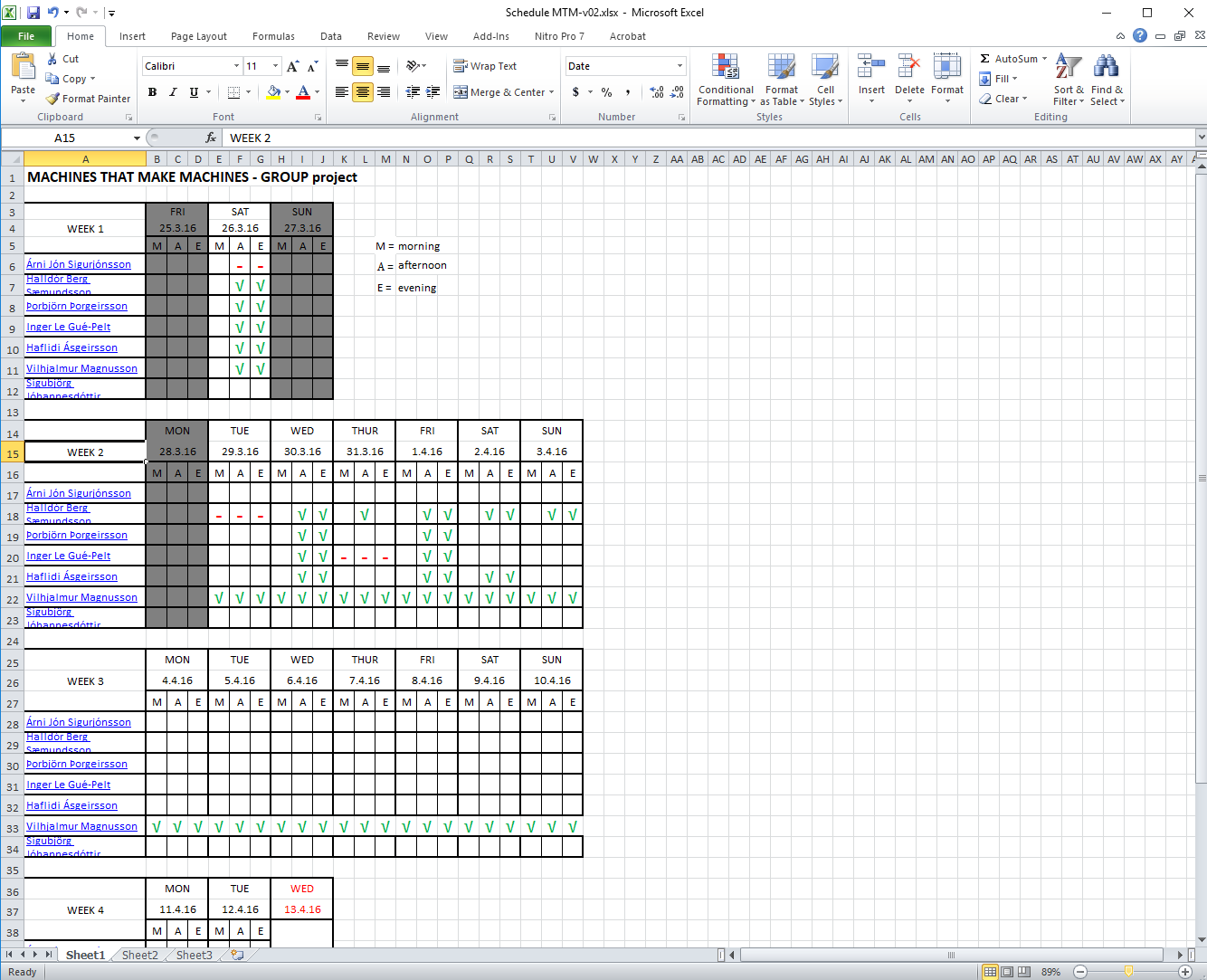

... but reality in Iceland is: nothing goes according to a fixed plan, people come and go in an organic rather than scheduled way, but at the end all is well. This was even true for this picture where all group members are standing proudly behind our working Mandela machine: it took my Photoshop skills to make it happen!