|

|

|

|

Week16. Mechine Design

group assignment

- actuate and automate your machine

- document the group project and your individual contribution

* my role : Arduino Code design for actuate and automation

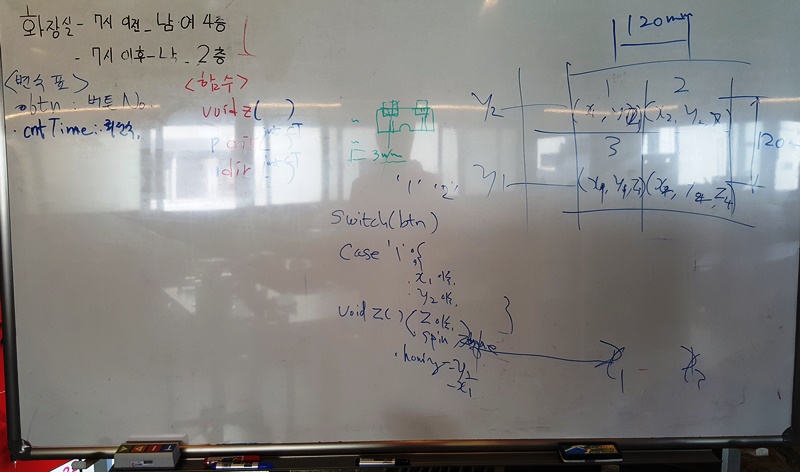

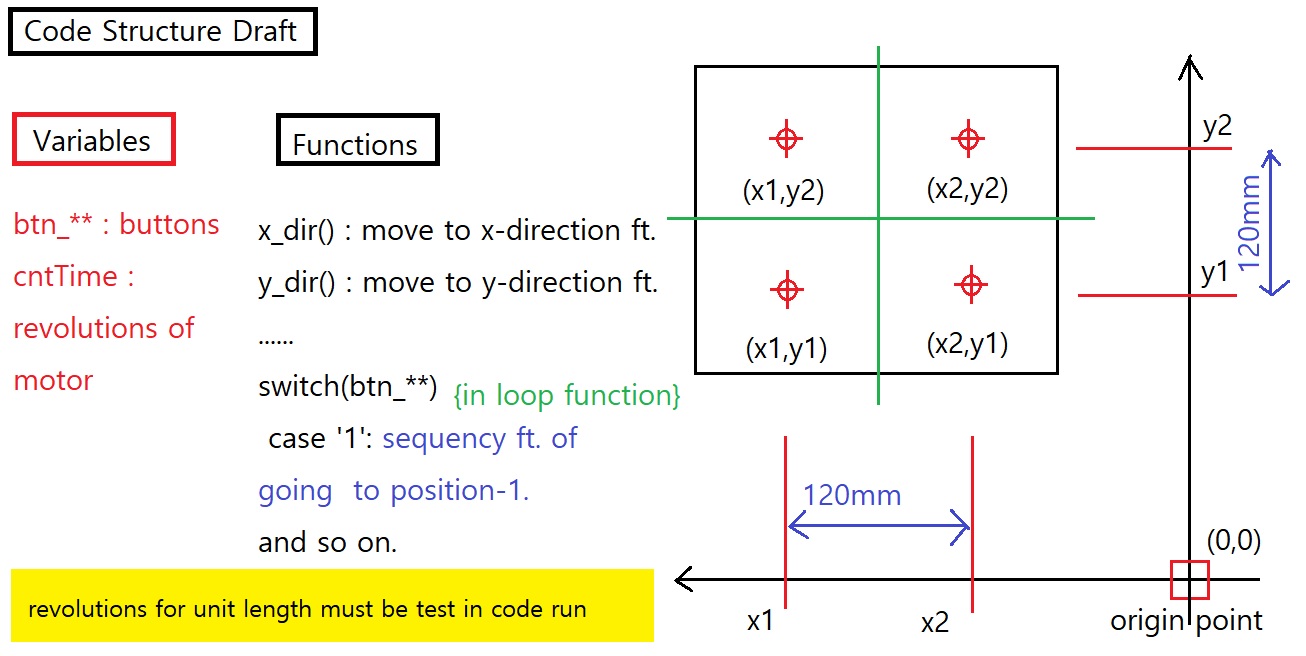

1. Algorithm

-First draft on white board directly make a basic code structure.

-Rewrite and thought about sequencies to run of program.

2. Coding

Here is our Arduino code : bendingM2.ino

Explain about a code.

PreProcessors Setup() Loop() Functions 1. external Libraries

- I2c

- LCD

- keypad

2. configuration

- kepad :

a. set array(2x2)

b. assign as alias

- LCD :

a. assign alias

b. set address(0x27)

3. variables

a. cntTime : motor run counts

b. gkey : keypad number

c. run counts preset for

each position(ex. x2_ct=4000)

d. I/O pin define for each Motors

Initialize

- Serial port : 9600 bps

- LCD :

a. back light on

b. welcome sign

- Motor IO pin preset

a. EstepPin :

-> role = spin to spring

-> state = enable

b. XstepPin :

-> role = move to X-axis motor

-> state = enable

c. YstepPin :

-> role = spin to Y-axis motor

-> state = enable

d. ZstepPin :

-> role = spin to Z-axis motor

-> state = enable

1. Key-in Process

a. waiting for user input button

b. get key to store as a control variable(gKey)

2. actuating Process

- If find a correct position as a gKey

run to each position process

in Switch()..case structure

- the Quantity of revolutions of

each motors defined in PreProcessor area

by experimentally after build of machine.

1. Foward run function

- name : pDir(uint32_t ct, int p_dir, int p_step)

- parameters :

a. ct : destination run count

b. p_dir : motor direction pin

-> set to LOW state to foward

c. p_step : motor run control pin

2. backWard run function

- name : mDir(uint32_t ct, int p_dir, int p_step)

- parameters :

a. ct : destination run count

b. p_dir : motor direction pin

-> set to HIGH to backWard

c. p_step : motor run control pin

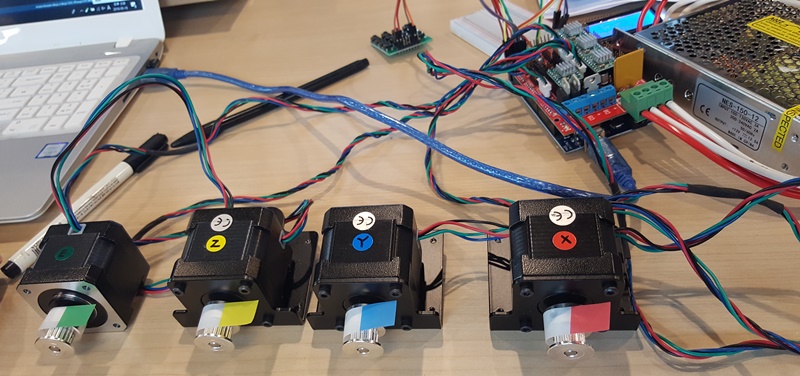

3. Hardware assemble and Software Debugging

1. Software Code test before Hardware assemble

This test for check about working of each motors correctly.

If any motor not working properly, check about electronics wiring next

change that motor to stable motor.

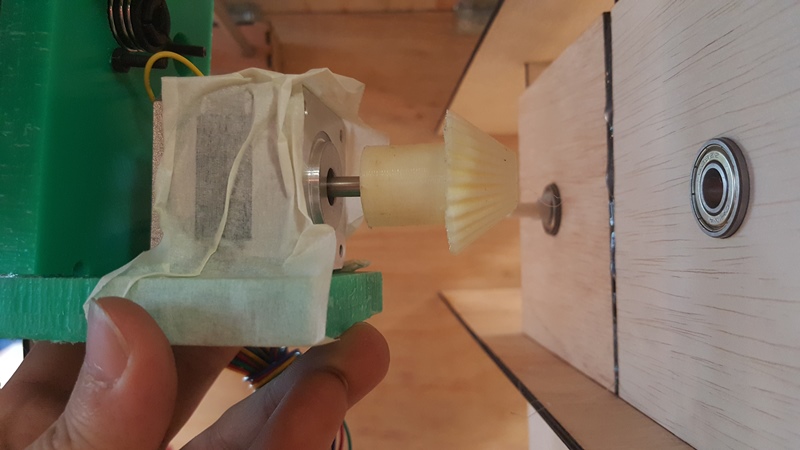

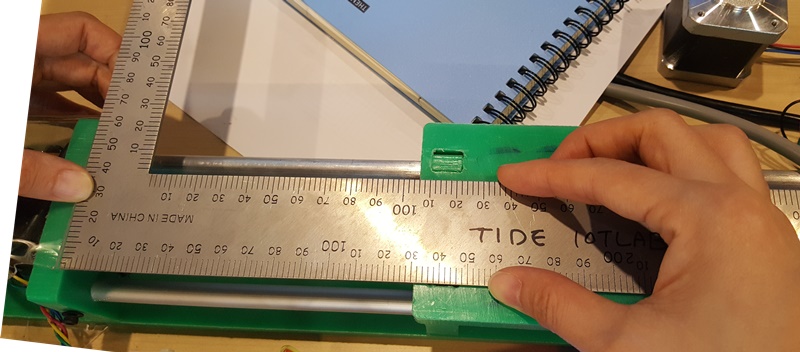

2. Motor revolutions test to convert linear actuating.

This step is a pretest before whole assemble.

At first, 1 axis assemble and manually working state. If it's not smoodly running

check about mechanical joint such as ball screw or frame alignments.

Second, several times tests must be done to take a resoneable test value.

Here is our parameter test results.(There are some offsets where is long distance to go.)

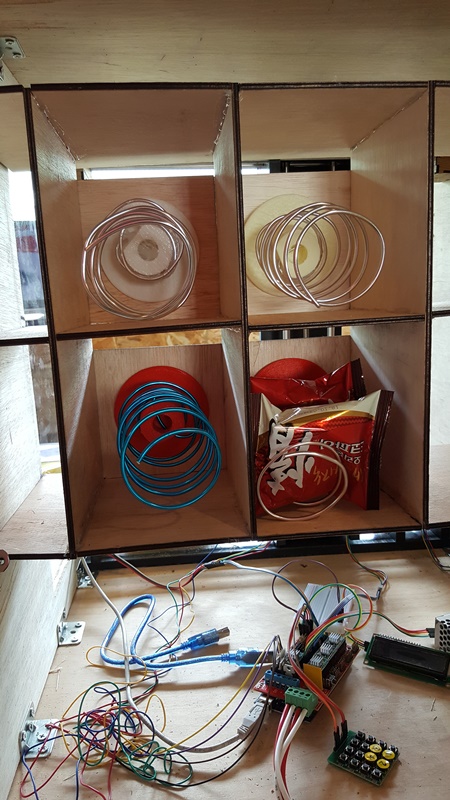

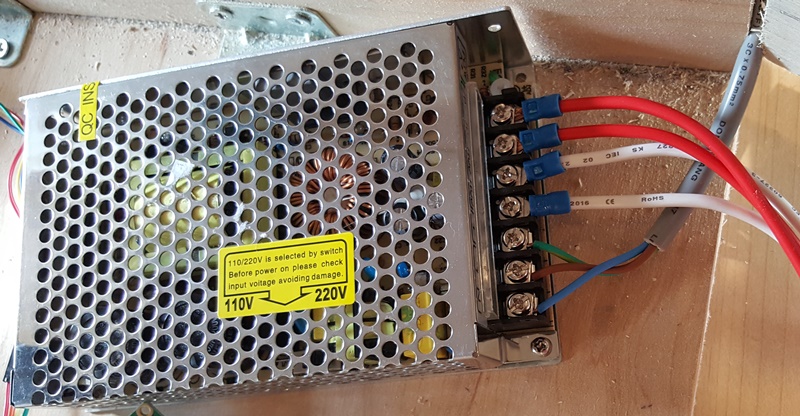

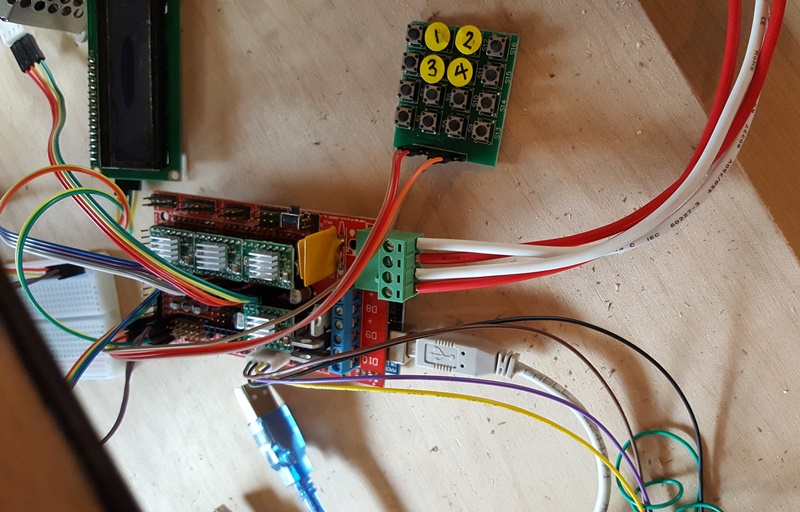

Category Revolutions Length (mm) Note. unit 10,000 (25) x1 51,000 (127.5) x2 4,000 (10) y1 35,000 (87.5) y2 88,000 (220) z 16,000 (40) spin 5,500 (13.75) 3. Electronics assembly

In this step, we consider about cable diameters and lengths while moving motors.

And try to make a good electrical wiring especially to connect high-current lines.

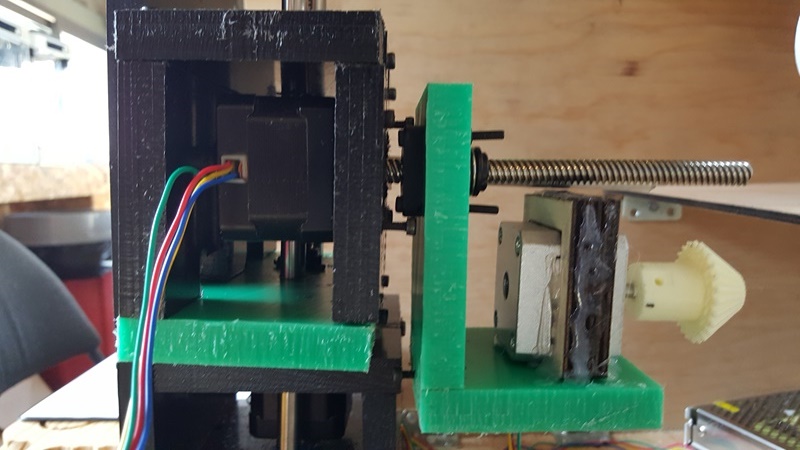

4. Mechatronics assembly

The last move work test for Z-axis left till assemble combine chassis.

Because of it can be find when assembl body frame and spring frame.

5. Machine assembly

Here we have pre install whole chassis to making completely

I was noticed about wiring and un defined mechanical work

(especially consern about Z-axis linear motion and spinning to handle spring shafts.).