|

|

|

|

Week8. Computer Controlled Machining

assignment

group assignment:

test runout, alignment, speeds, feeds, and toolpaths for your machine

individual assignment:

make something big

Equipment

• Hardware: shopbot

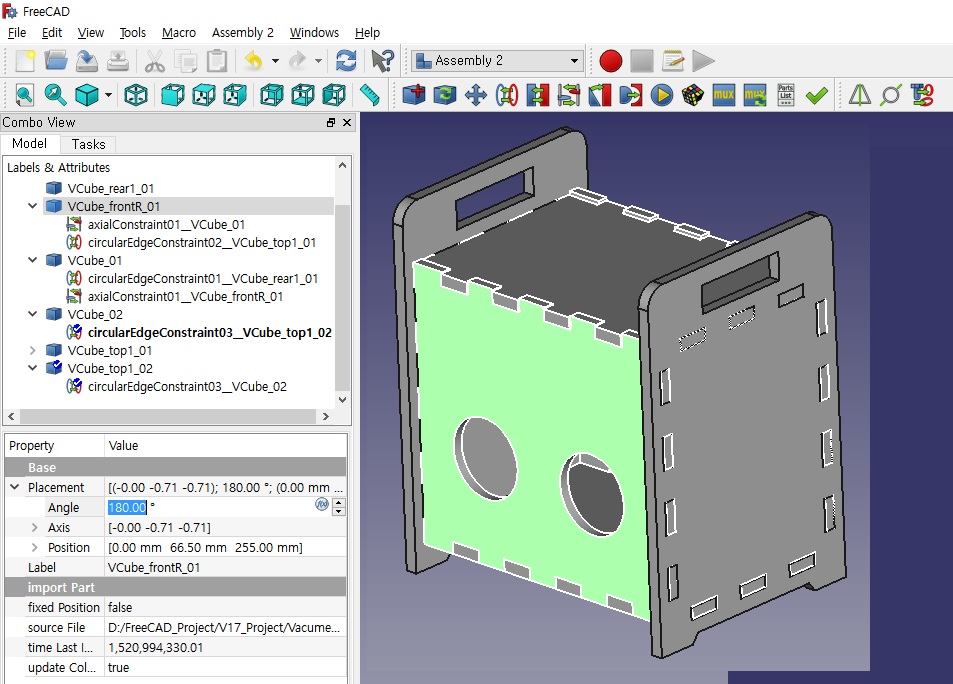

• Software: V-carve pro, FreeCAD

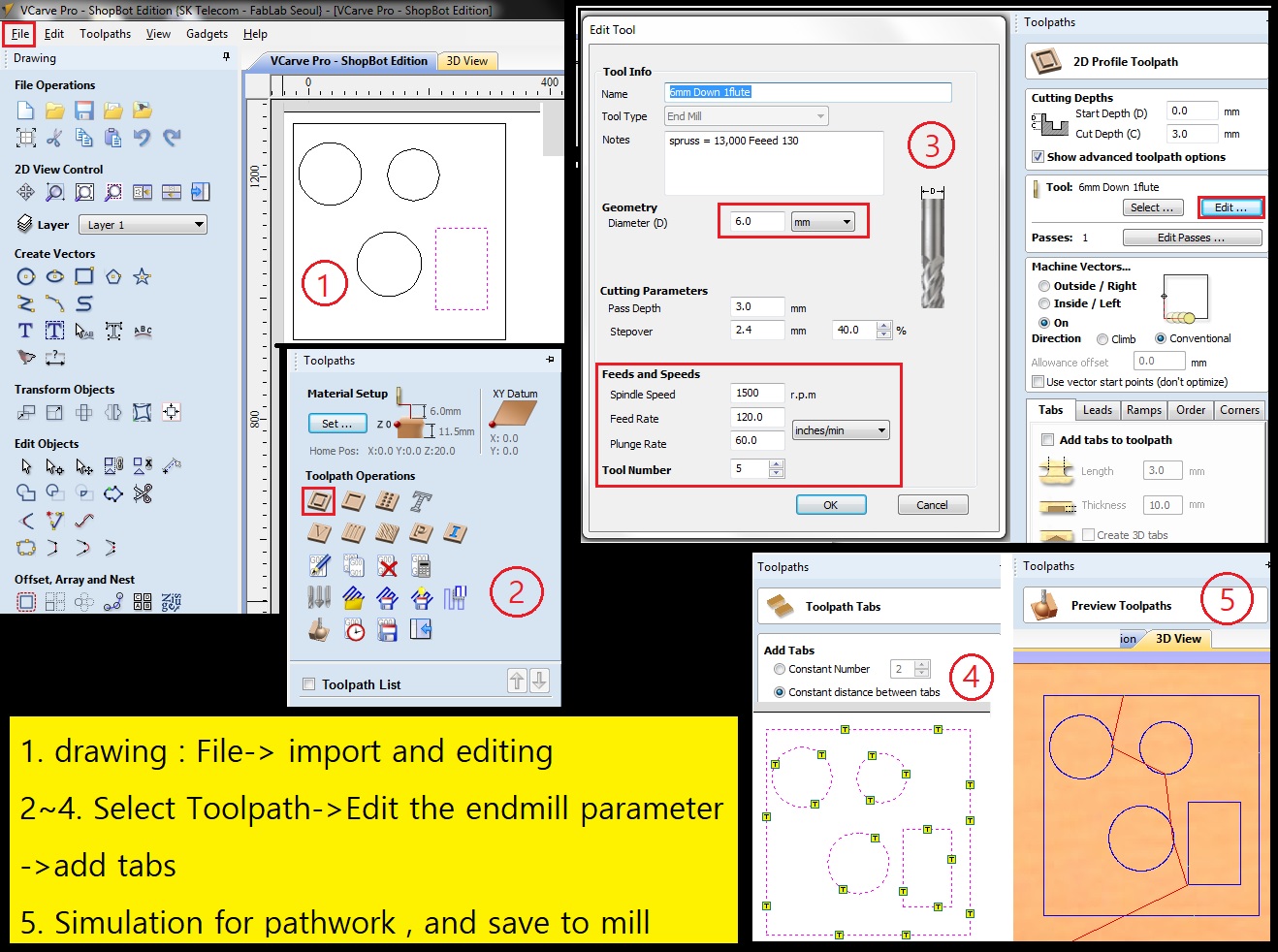

1. V-carve Pro

- This program can make a G-code file and configuration about endmill parameters for toolpaths.

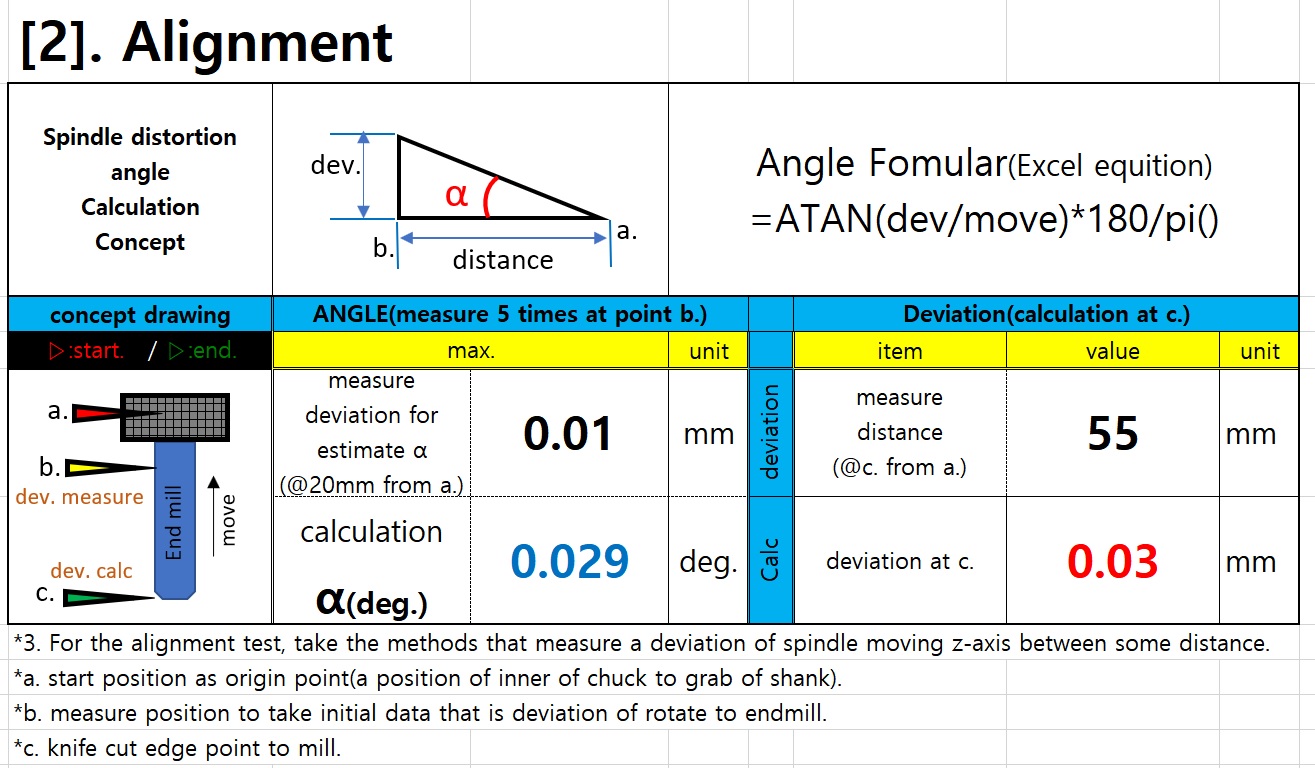

2. test runout, alignment, speeds, feeds, and toolpaths for your machine

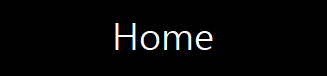

To take this data(runout), I just read datasheets of shopbot CNC machine and

read more documents about to explain cocept for technical terms as mentioned above.

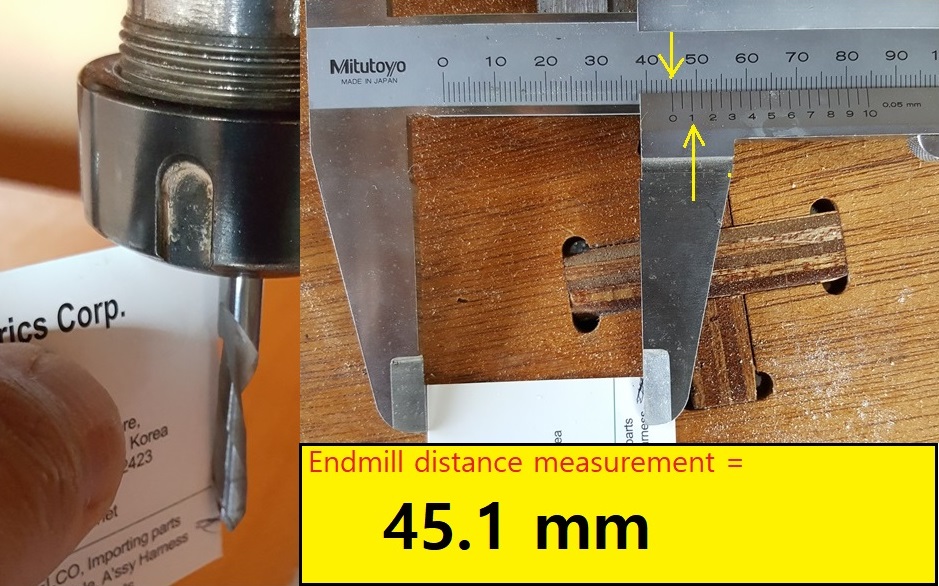

First, I try to measure runout of endmill(10mm diameter) nearest position of shank

with no powered state , setup dial guage meter(0.01 mm units) and reads variation of

scales manually, for the reading accuracy need doing to it several time what reads

match the meaning as below show.

By the way, TIR means that runout of edge of endmill flute assembled in motor axis

so I check about length of from center point of rotation to end of endmill.

And make a calculation to get TIR. Calculation chart and measurements shows below.

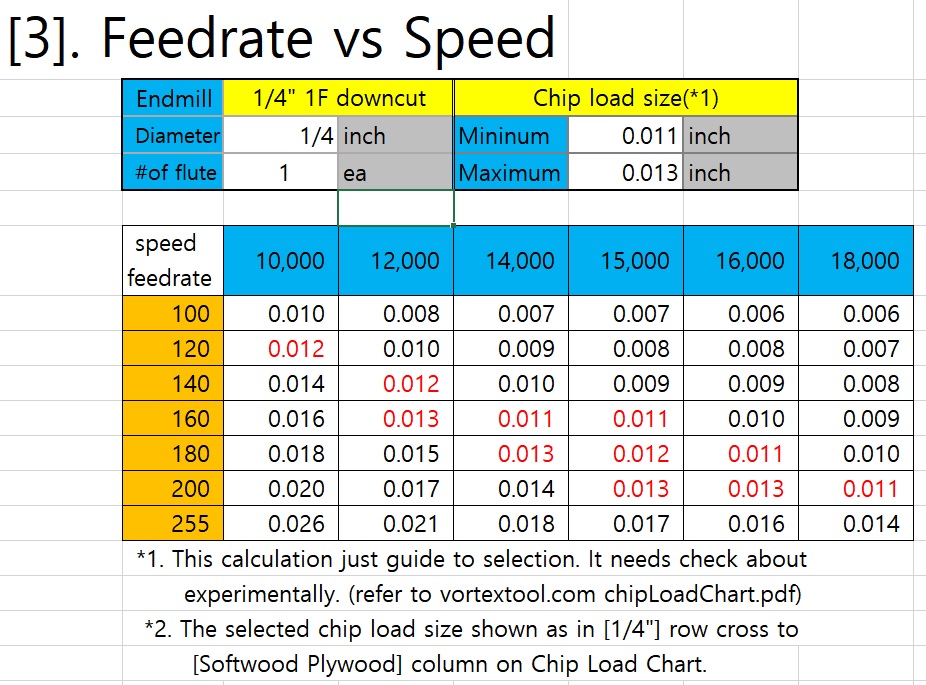

In this section, we have pre calculation for experimentally to find good value of

feedrate and spindle speeds. We have also read about the document treat the chip load chart.

It gives us for about chip load range for our material that is softwood or flywood.

Reference document : ChipLoadChart.pdf

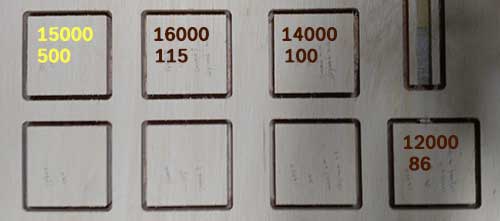

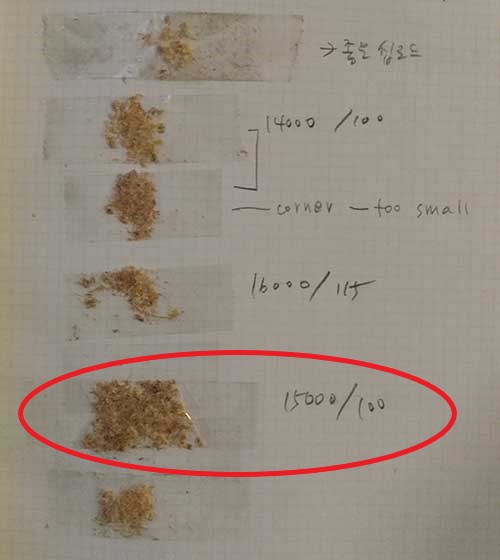

Now, we tested about good condition to find speed and feedrate for various combination of both.

We discussed about the result of chip load size and spindle sounds and finally to get some range.

The best feedrate is :

• At 15000 rpm: 100 IPM

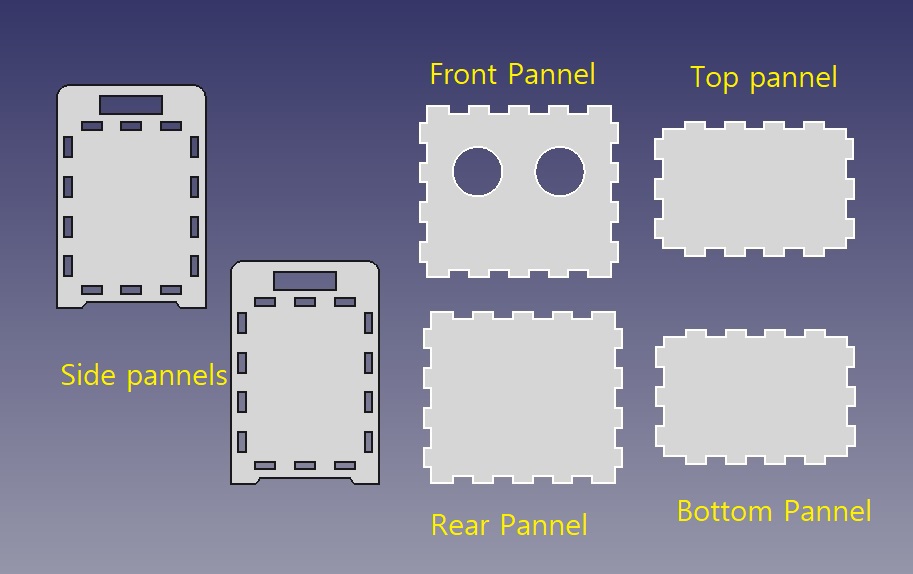

2. design modeling

3. Make toolpaths

To make a toolpath, I use vcarve program. At first, import some path design file and edit the paths

for each shape. In this step, also check endmill paarameters, make sure the variables as followed above

feedrate and speed for the best result. If to think about the situation after mill each parts, optionally

put some toolpath tabs on each shapes. After check about simulation of milling, save the work file for

shopbot CNC.

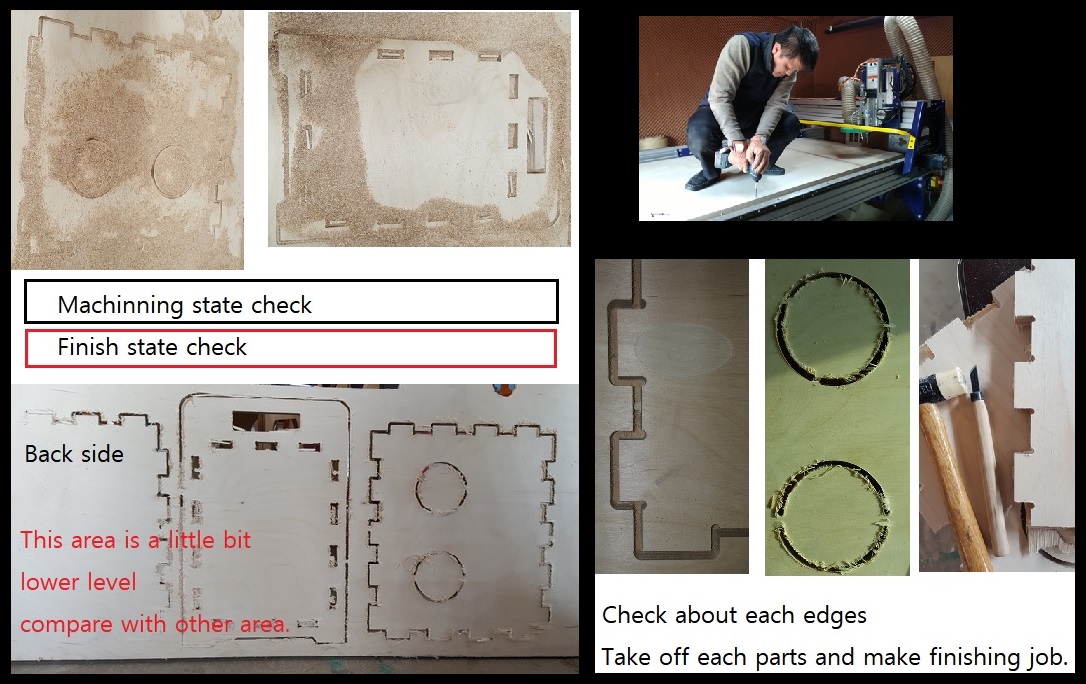

3. machine work

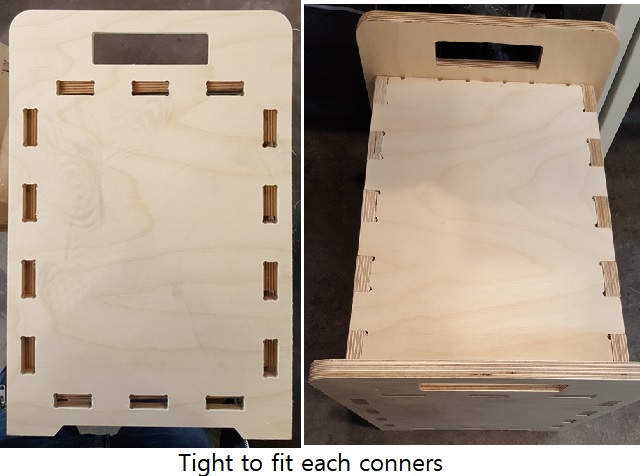

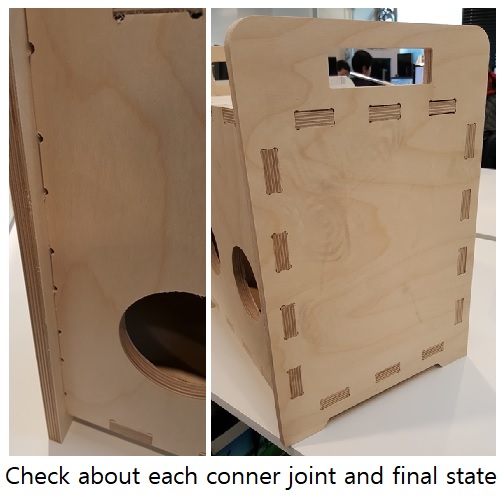

4. assembly

5. Add more bigger model work