WEEK 15 - MECHANICAL DESIGN

Assignment

group assignment :

- design a machine that includes mechanism+actuation+automation

- build the mechanical parts and operate it manually

- document the group project and your individual contribution

Here is the link to Group assignment.

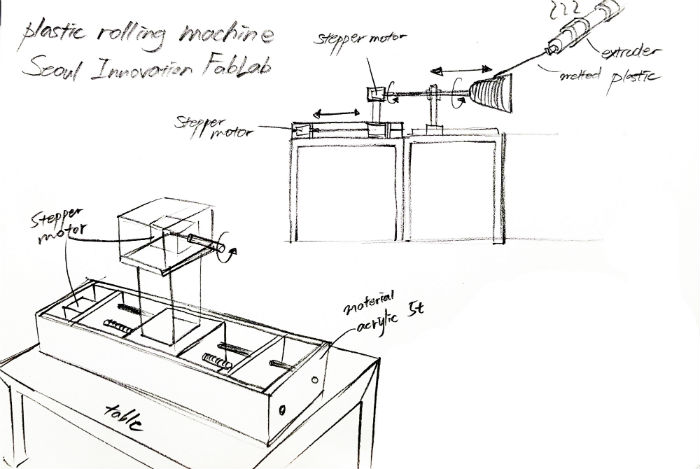

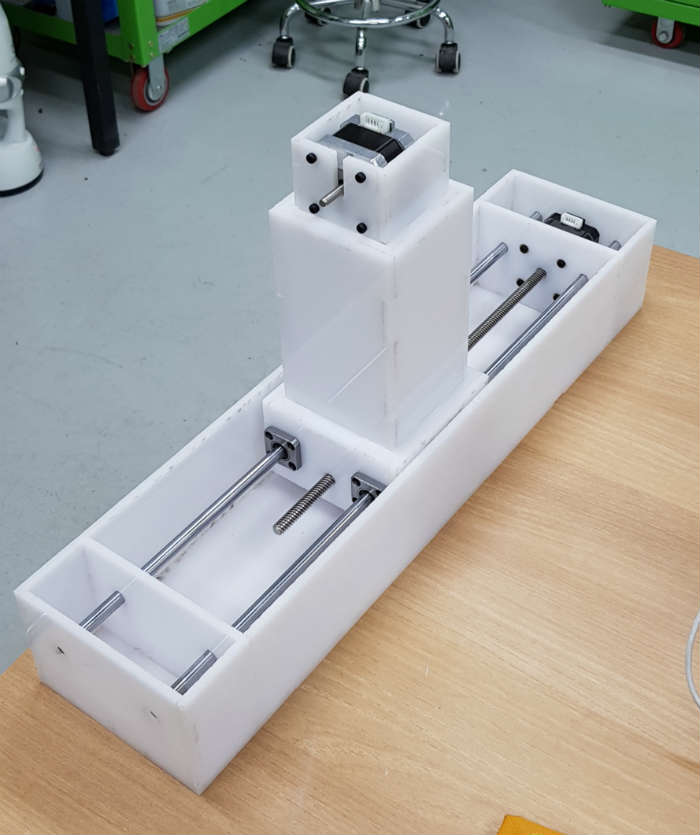

What and Why we build

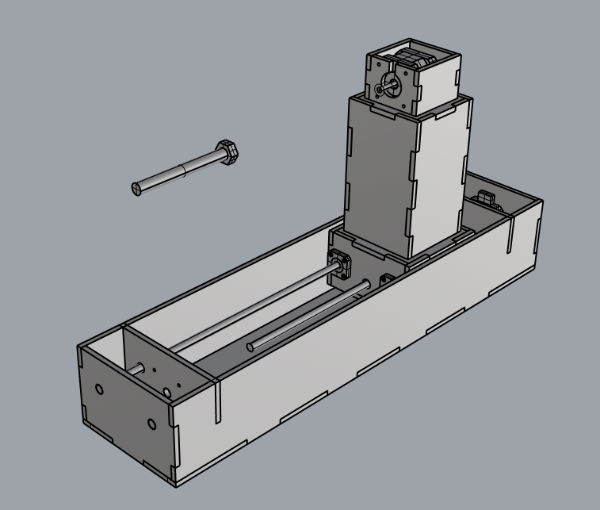

We decided to make a plastic rolling machine. Originally, we used it by hand, but we thought it was inefficient to turn it by hand for a long time. I need a motors that one moves left and right, moving the stacking position and the other is for rotating template. This was our first idea.

How to make it

We will cut acrylic 5t plate with laser cutter and assemble.

1. Arrange parts to use and measure the size, and model them same size on Rhino.

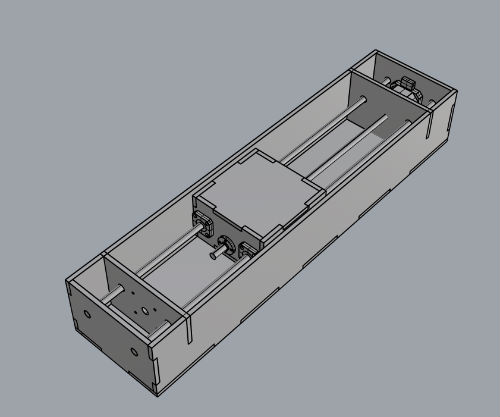

2. Create a structure that moves left and right with reference to mtm.

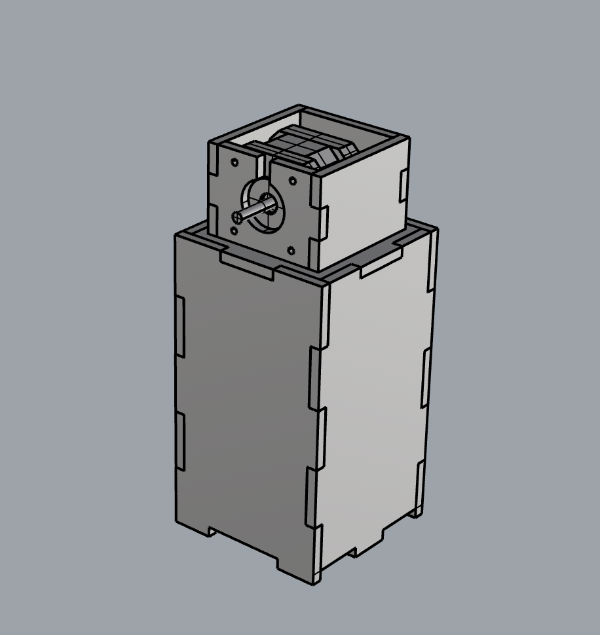

3. Make a structure that can fix the motor to turn the shank.

4. Make a structure to connect motor and shank.

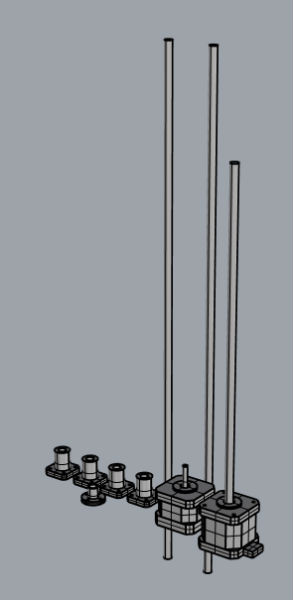

1. Components include four flange bearings, one flange nut, two stepper motors and two abrasive rods. Measure the size and length of these parts and draw them exactly the same on Rhino. And make the structure to fit these parts.

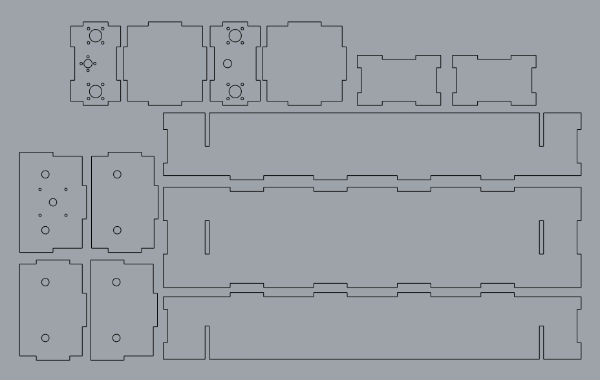

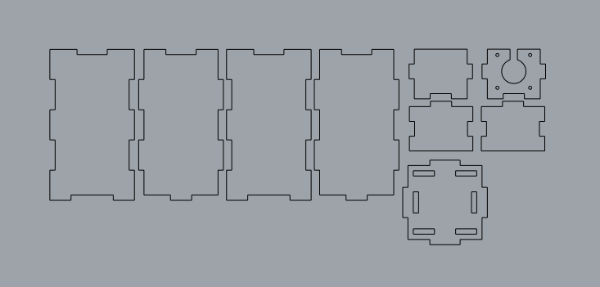

2. Draw curves to Make surfaces by aligning the size of the acrylic plate to fit and fix the parts. Make a hole for securing the part with bolts. I extrude this curve to 5t and make a plate. Make a kerf that plates can fit each other. Once the plates are made, assemble them in Rhino. If it’s fine laser cut acrylic and assemble with components.

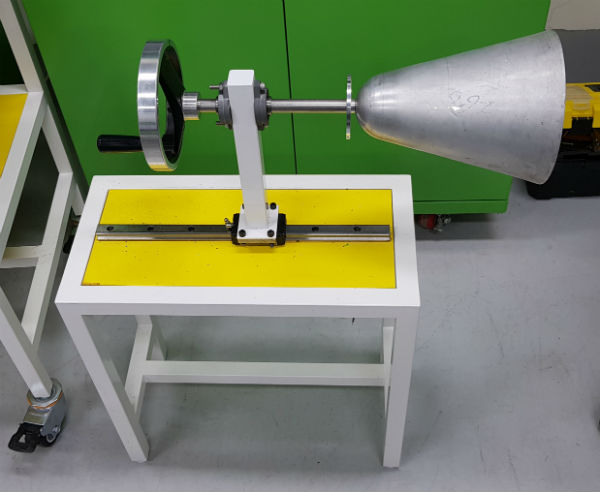

3. Measure the height of the original machine and make the structure by setting the height so that the height of the machine and the height of the motor match. Create a height in the form of a box and build a wall over which the motor can be fixed. Make holes that can be fastened motor with bolt.

4. Since the shank has m10 thread, make a structure that can fix the motor and m10 bolts. Couplings are attached to the motor. Weld rod to the bolt that can be fitted to the coupling and shank.

Here are my works.

Download