Giada Allocca

This is my website for the Fab Academy

Final result

The concept

Since the delivery of the final project of my BA degree at University of Siena is approaching,

I chose to develop my thesis in human-machine interaction. My supervisor told me about an European project named PRIMA which might be a good opportunity

for me to get into the food and computing area and eco-sustainability, so I started researching on the subject.

These are the three main goals of the PRIMA project:

- Sustainable management of water for arid and semi-arid areas;

- Sustainable farming systems under Mediterranean environmental constraints;

- Mediterranean food value chain for regional and local development.

I found some articles presenting edible insects as a sustainable food of the future. Edible insect farming

could be a way to lower the emissions usually produced by other animal farms, and cut the costs compared to intensive breeding. However,

the adoption of such paradigm implies a deep cultural shift. In Western cultures, edible insects are not considered as a

sustainable alternative.

Schedule

Computer-aided design

Computer-controlled cutting

Electronics production

Electronics design

Input devices

3D printing

Interface and application programming

State of art

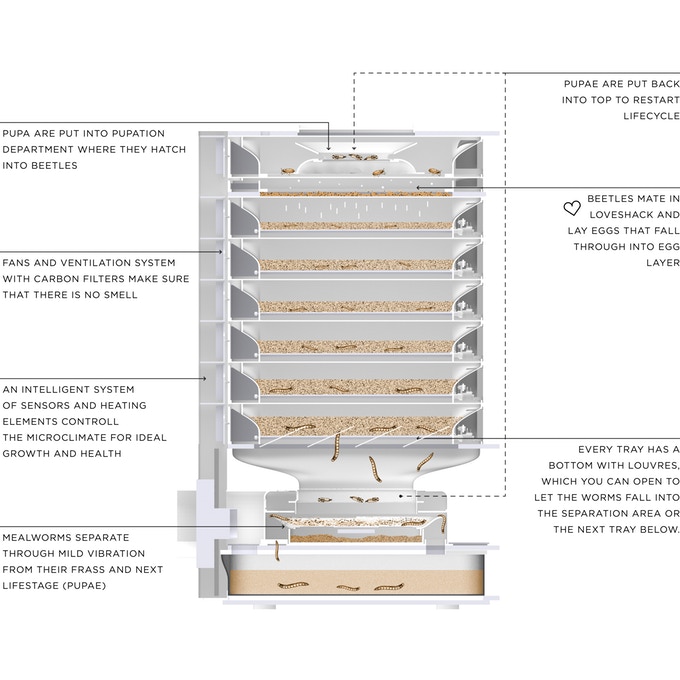

I searched projects about greenhouses for edible insects in the web and I found

The hive a sort of home for worms, a new way of

breeding insects and make them more accessible to the people.

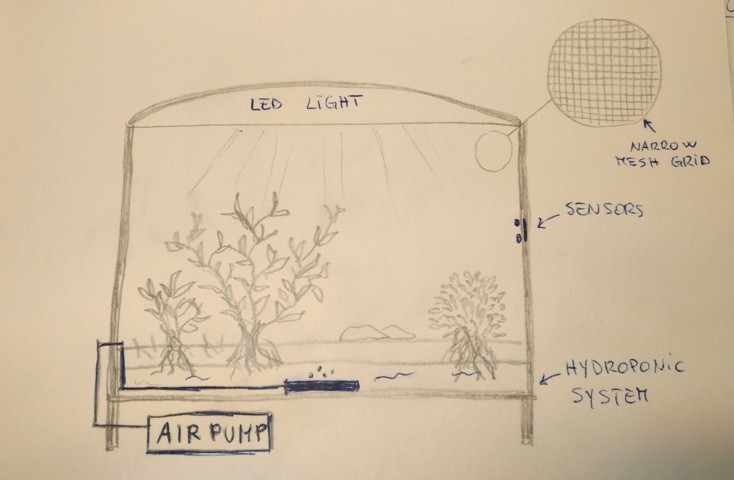

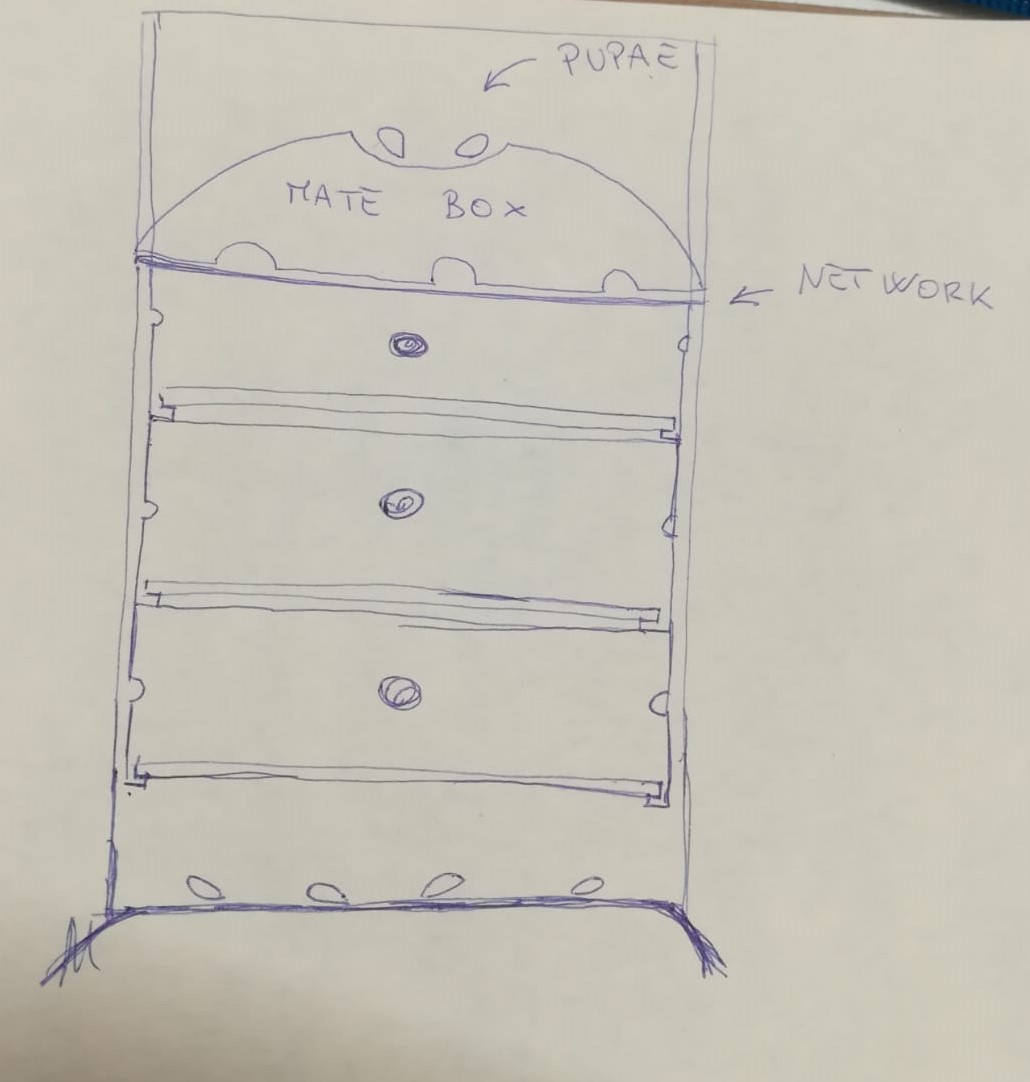

Sketch

My final project consists in the development of a greenhouse for edible insects. I would like to develop an eco-sustainable

way of collecting, breeding and growing edible insects. Once the greenhouse will be developed, I would like to use the

prototype to provoke reflections and discussion on a possible future of food including and edible-insect-based diet.

I'll try to understand under what condition people would accept this perspective. Would and appropriate form, smell

or shape of insect-based food make it acceptable?

<

Update 15/04/2018

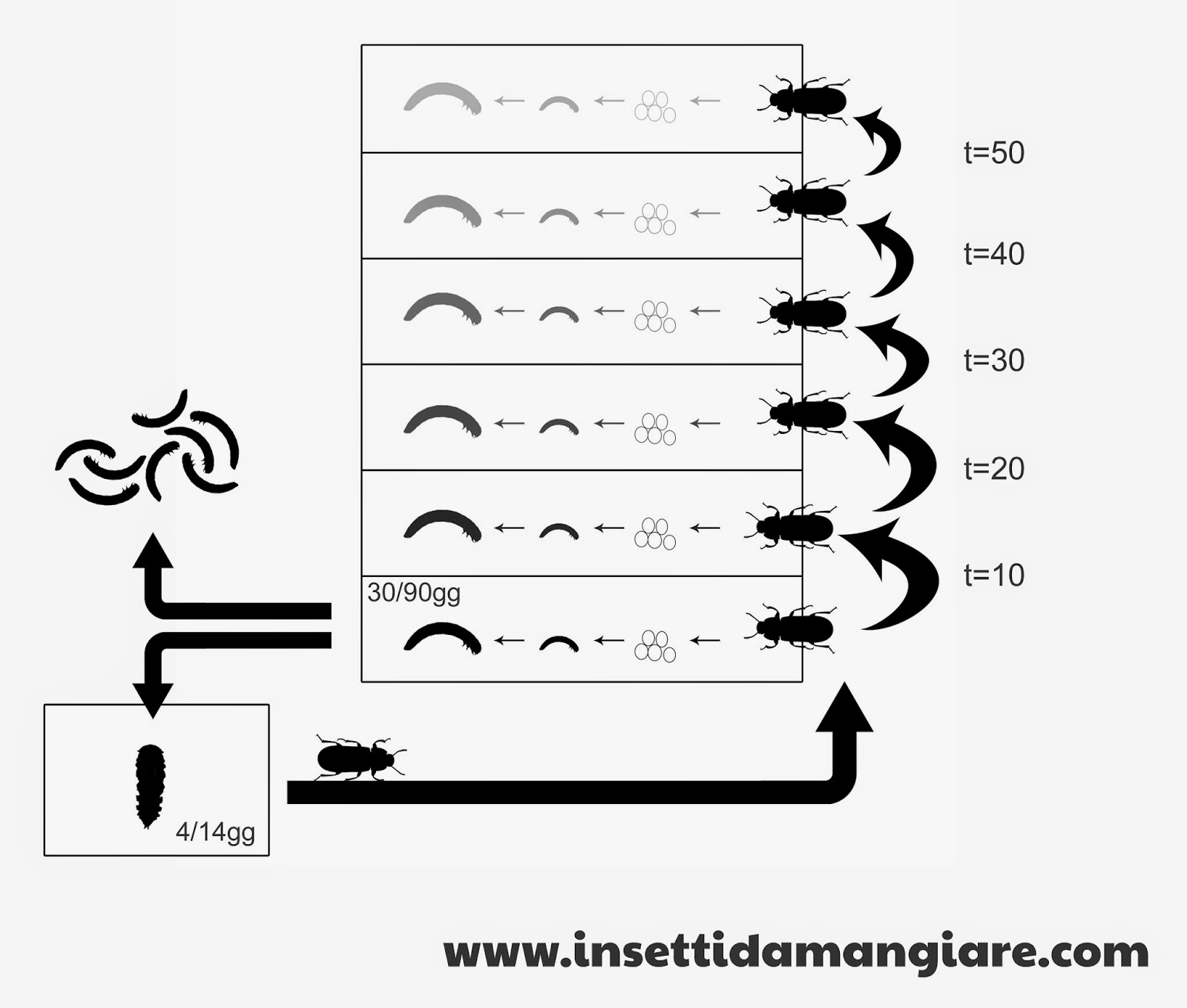

After some research I discovered that there are 17 species of edible insects, among these are the camole, an undemanding species that has three stages of growth:

larva, pupa and beetle. The three types must be separated to avoid canibalism, which is why breeders have come up with a drawers model that works in this way:

This gif helps to understand the process

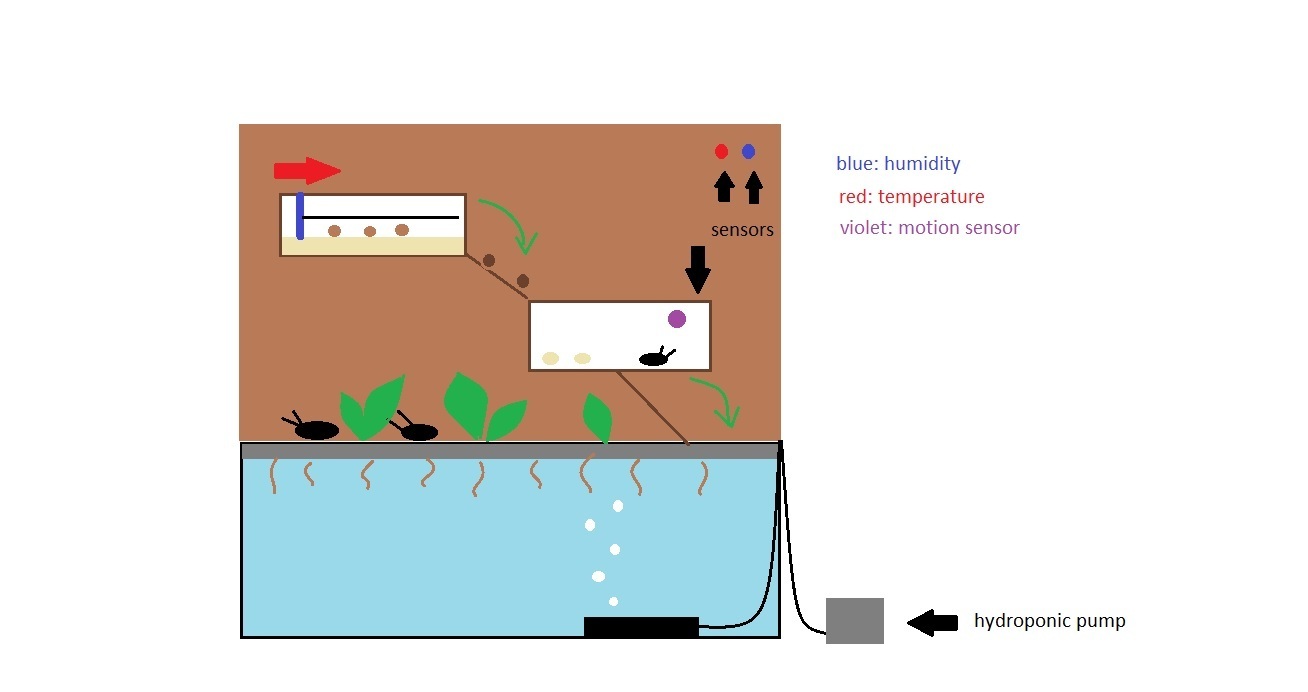

So the new project will be more or less like this:

Update 09/11/2018

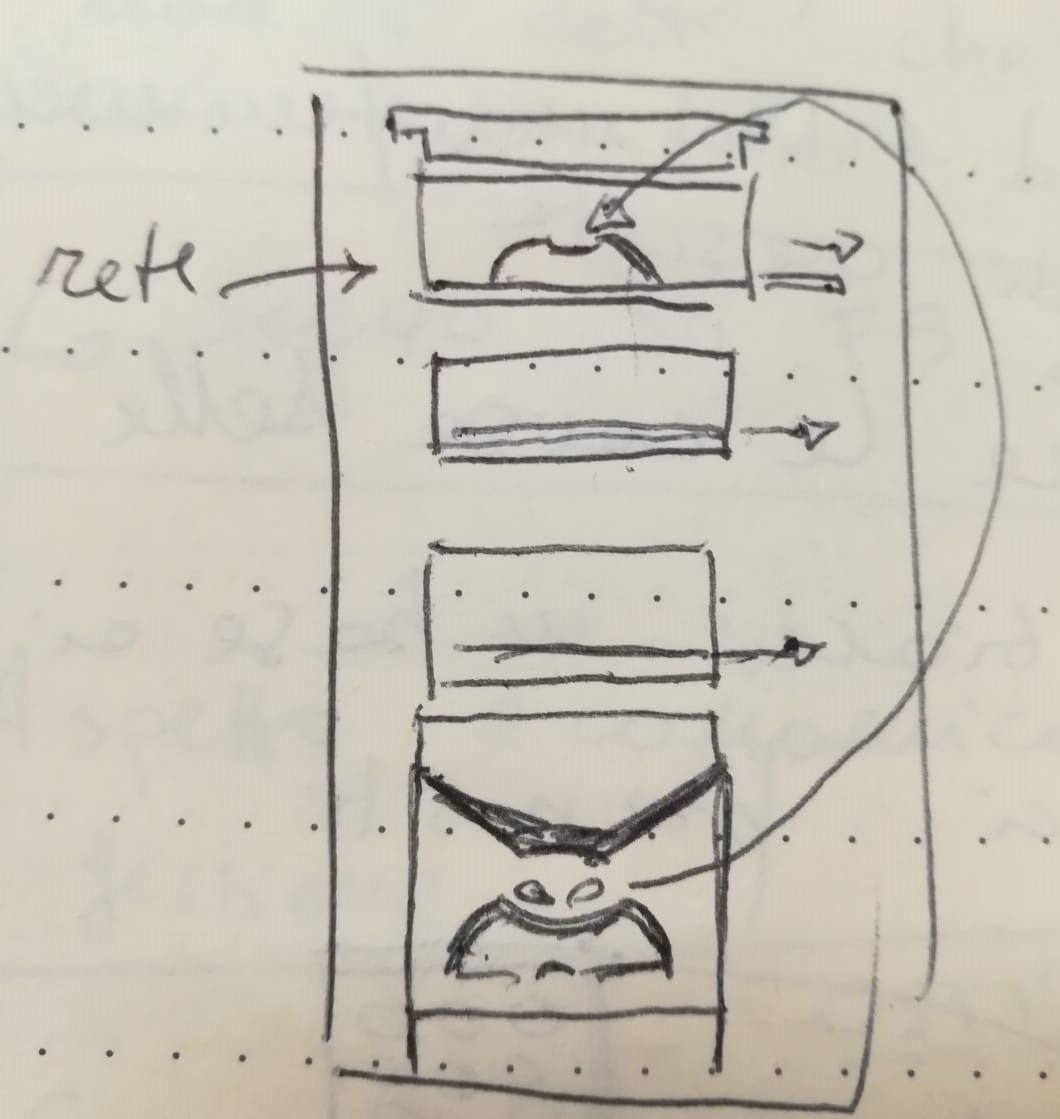

Thinking about a part of my final project I did not find a good solution to separate the pupae from the worms, so I did further research until

I found this very interesting image

Here you can see how they solved the problem, in fact the solution was simpler than I thought: the mechanism drop pupae and worms and let the

latters simply go away, passing to the box where they are collected to be eaten. So this is what my project will do: in the first box there will be the beatles which will mate

and make eggs. Below them I will put a network, so the box mate and the beatles will not fall into the box below, but only the eggs. To make the eggs fall down I will build the box so that the bottom is movable.

Moreover, the first box will have a perforated cover to let the air pass and prevents beetles from flying away. The eggs will pass to the second box where they will grow, then they will be moved to the third box (to allow the eggs of the first box go down to the second one). Under the third box there will be a sort of funnel that will channel worms and pupae into a dell, where the worms will come down and the pupae will remain. Now it is appropriate to move the pupae in the dell of the first box, so the cycle will starts again.

But who would use this product? Food consumption of insects and worms is still low in our part of the world, at the moment only elite chefs have started using them in the kitchen. Hoping to become the next fashion in the kitchen, this product could interest anyone who wants to have a healthier diet, without renounce the protein of meat but at the same time helping the planet not wasting water and not emitting CO2. Buyers can be families but also exotic restaurants.

First of all I created the boxes, this is the one with movable bottom.

After laser-etched the sides of the box I glued some wooden guides to slide the bottom.

Once the glue has dried I have finished the boxes with the vinyl sheet, in this way the worms can not climb to escape

Then I made the "dome of love"(where the beetles will reproduce). There is a dell at the top to accommodate the pupae and holes at the bottom to let the beetles enter. Inside it is empty.

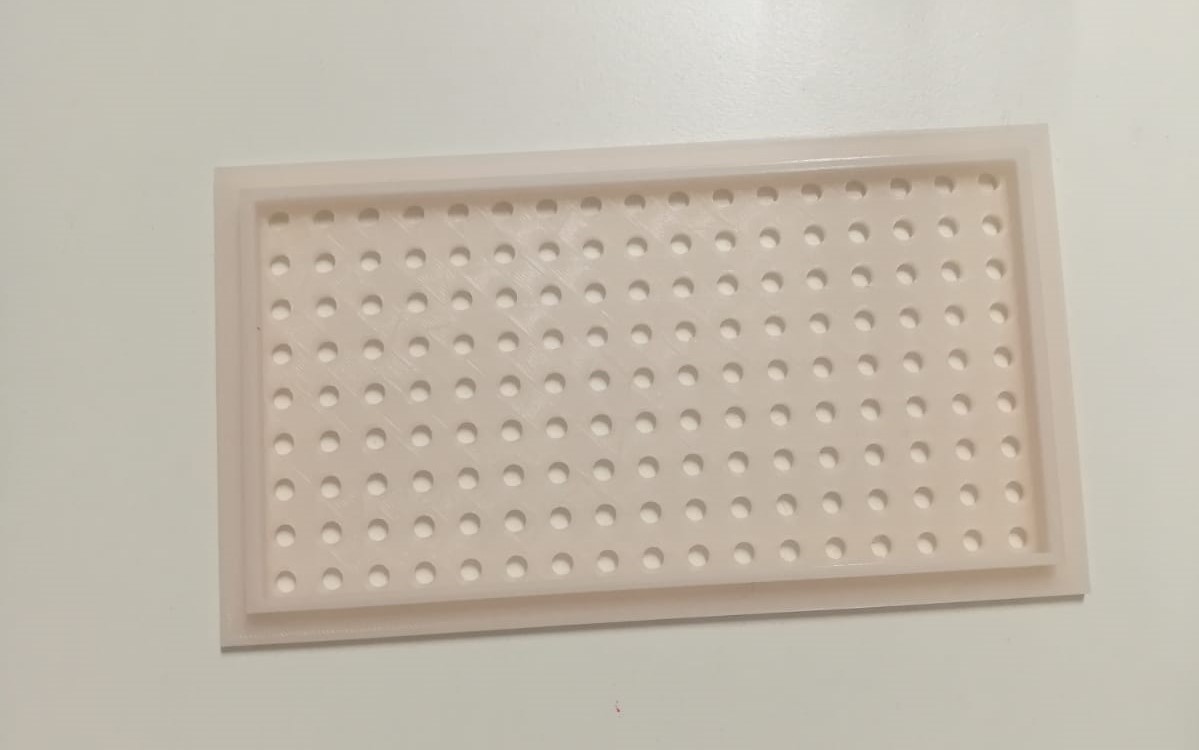

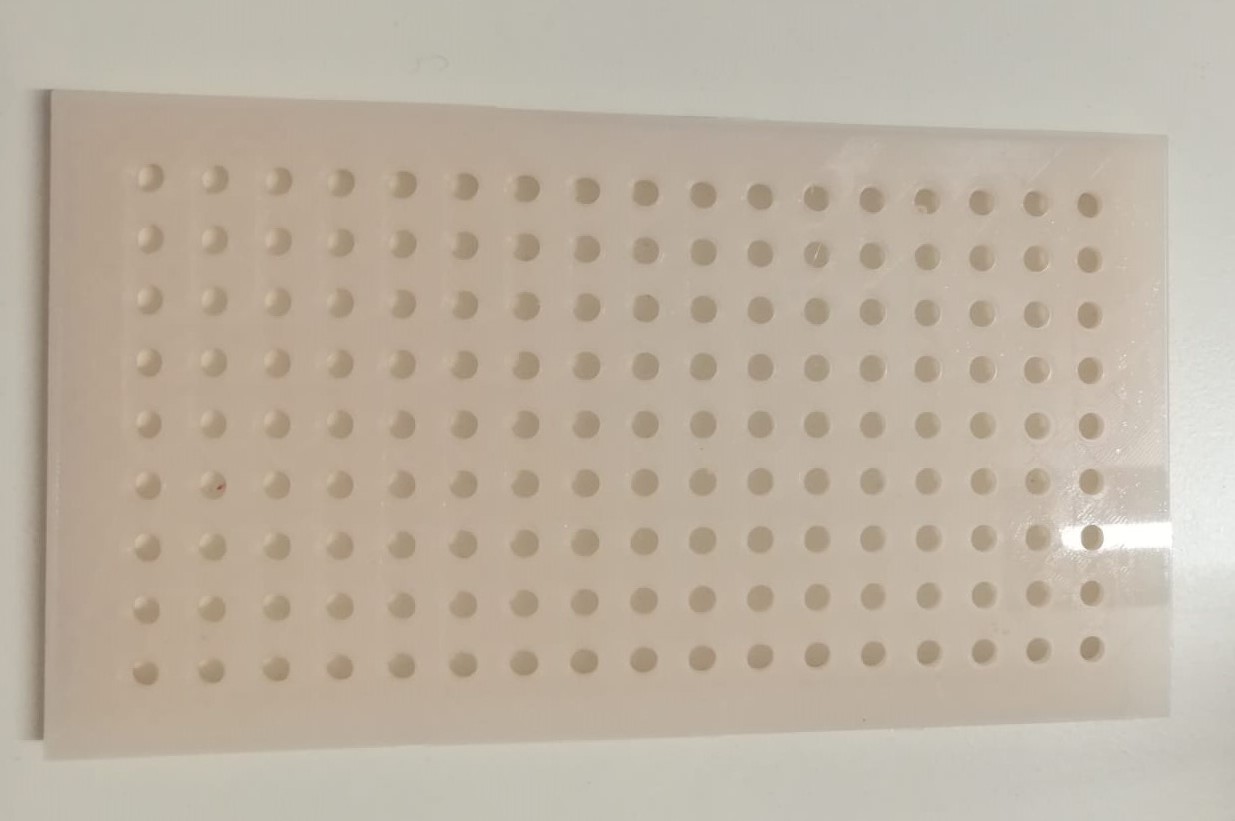

then I made this cover for the first box, I created many holes for ventilation

The first box will have a net to allow the eggs to go down to the next box and avoid the dome fall down with the beetles

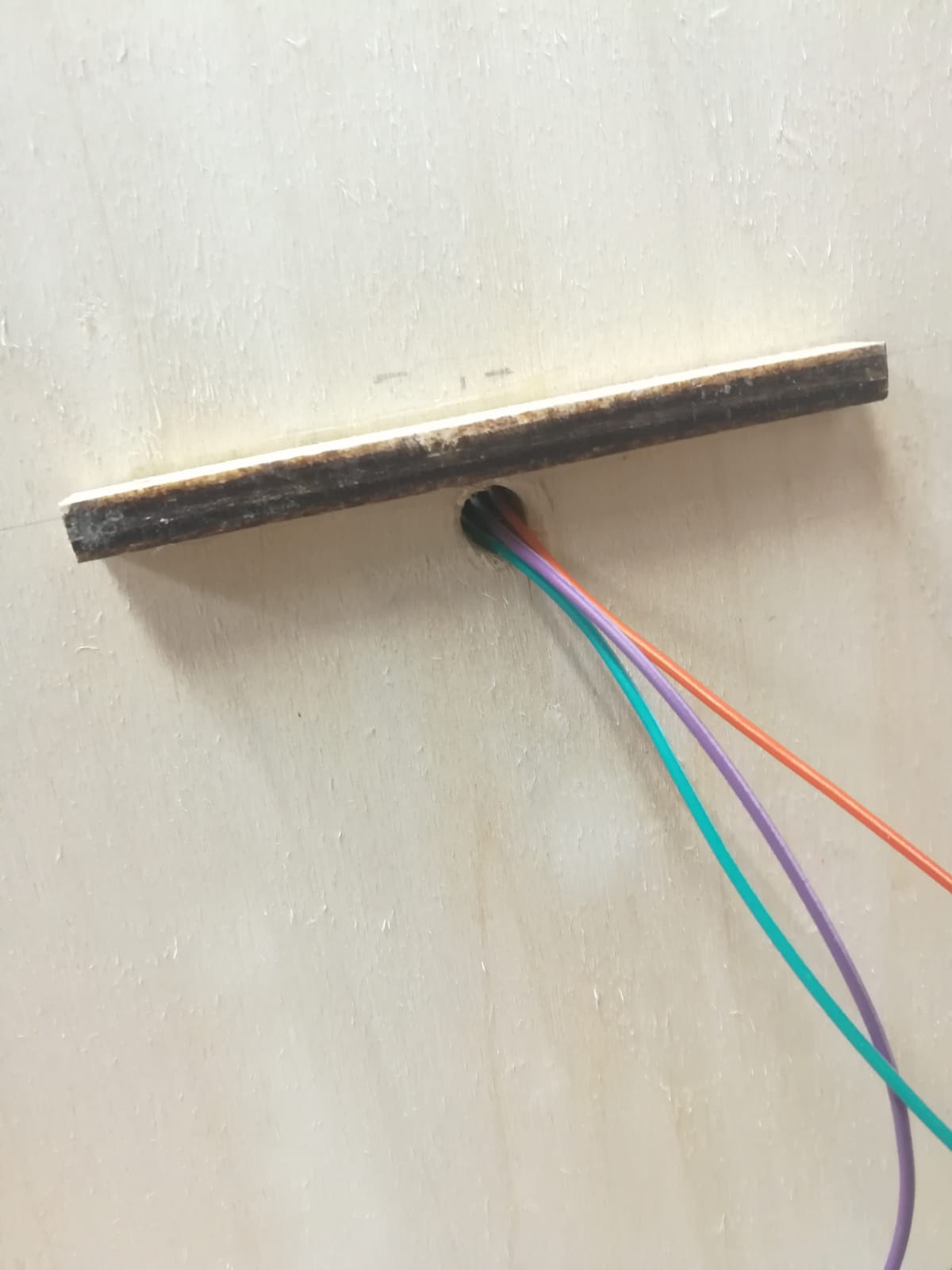

I made a hole with a column drill to allow the sensor wires to pass through and enter the box.

I glued a small piece of wood in order to create a support for the back box that will contain the electronic part

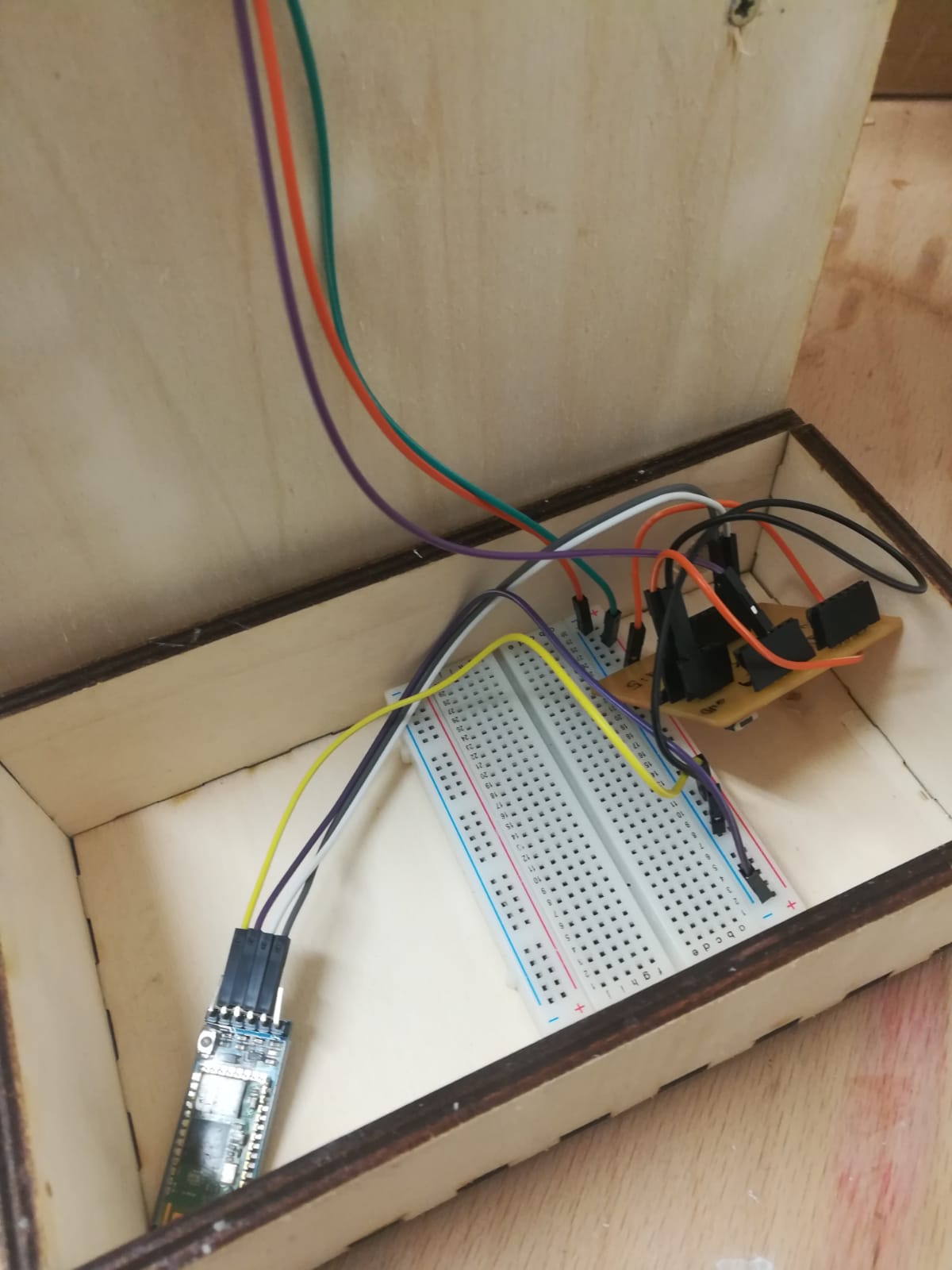

I inserted the wires with the sensor and screwed the box with electronic components (and already programmed) inside.

I made a small logo with inkscape and engraved it with the laser cutter.

Then I attacked all the parts again (I screwed them together to see how the project was coming).

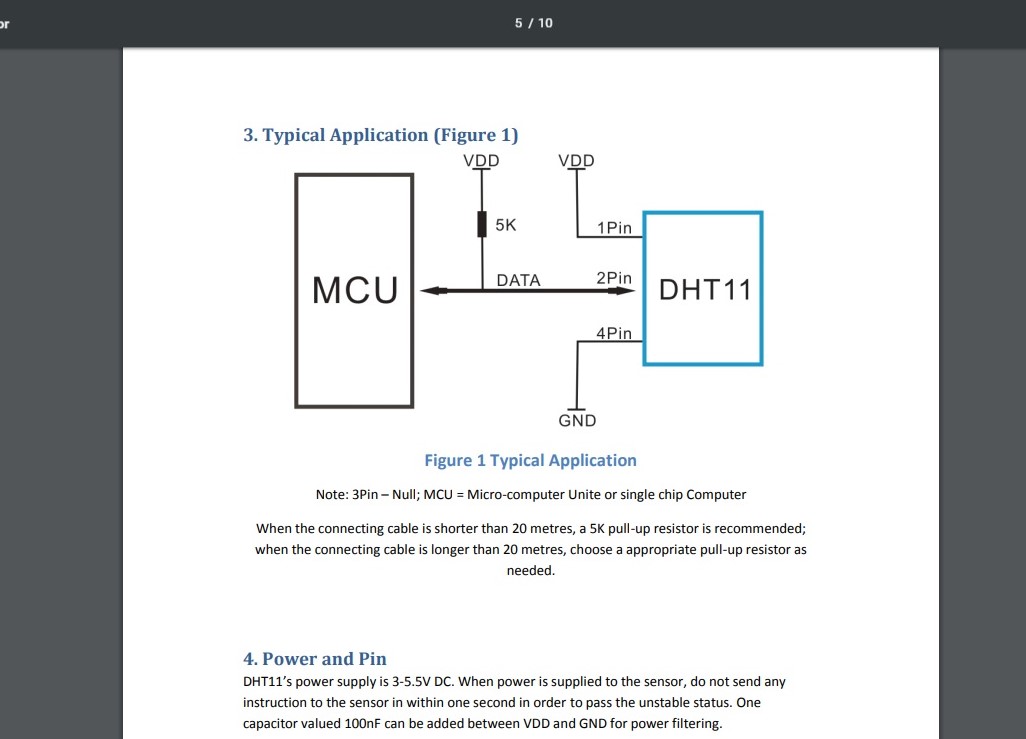

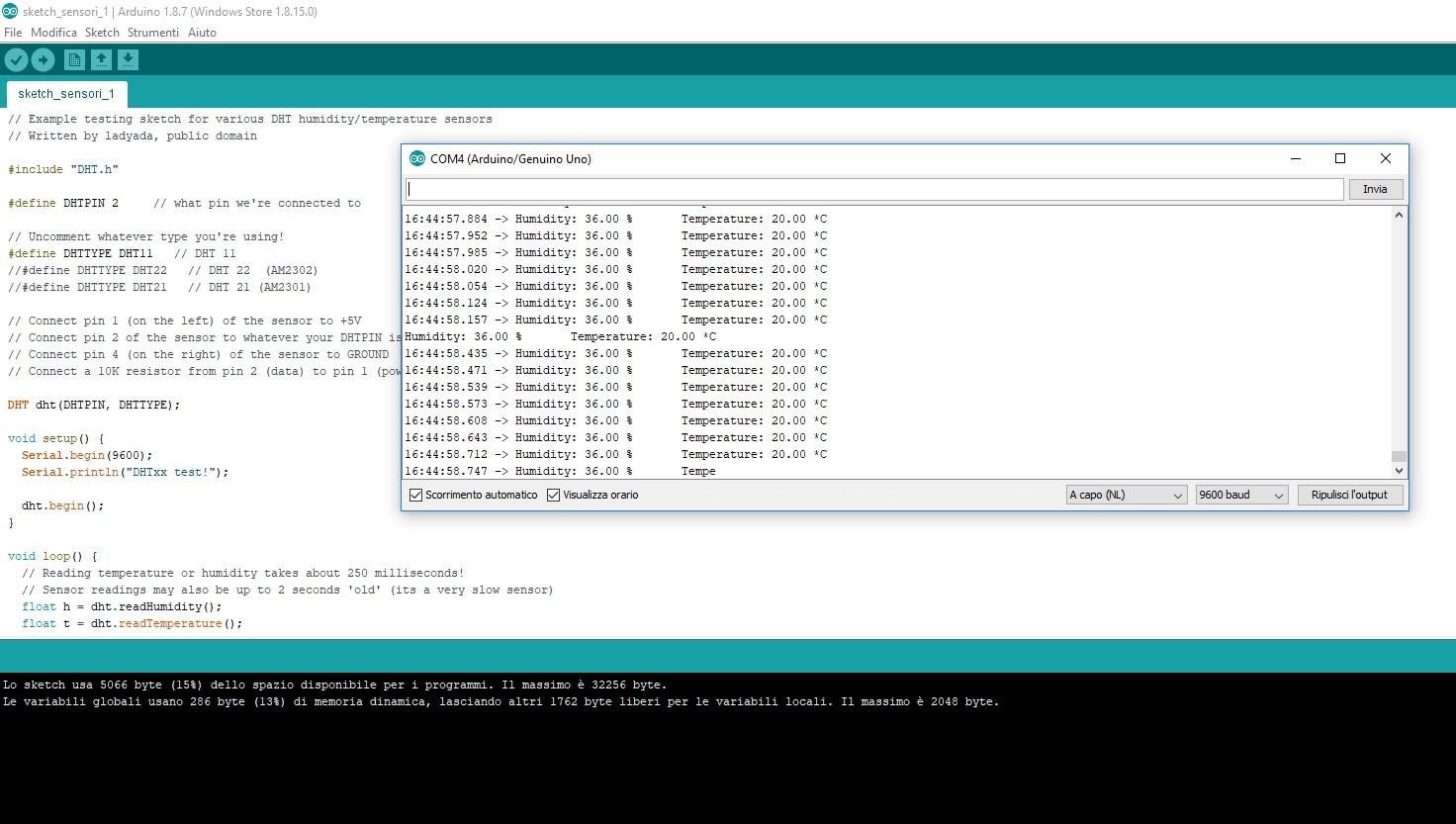

I looked up the info on the dht 11 to understand its characteristics and since I've never used a dht 11 sensor, I've done some tests before to see how it worked

I made a simple sketch to read the serial datas.

After that I modified the sketch to read the data via bluetooth

Now it's time to create the interface on processing

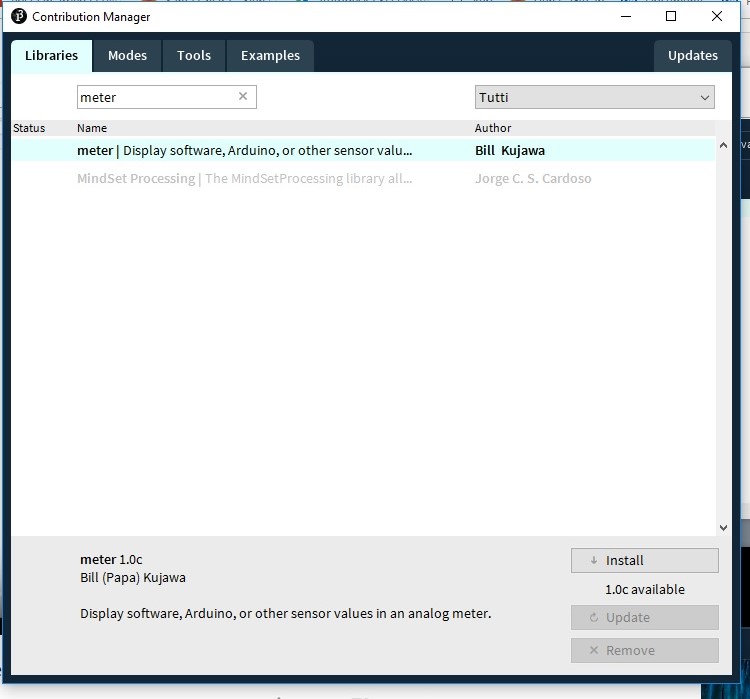

I imported this library to use a meter already configured, my intention is to create another 6, two per box. 3 for temperature and 3 for humidity.

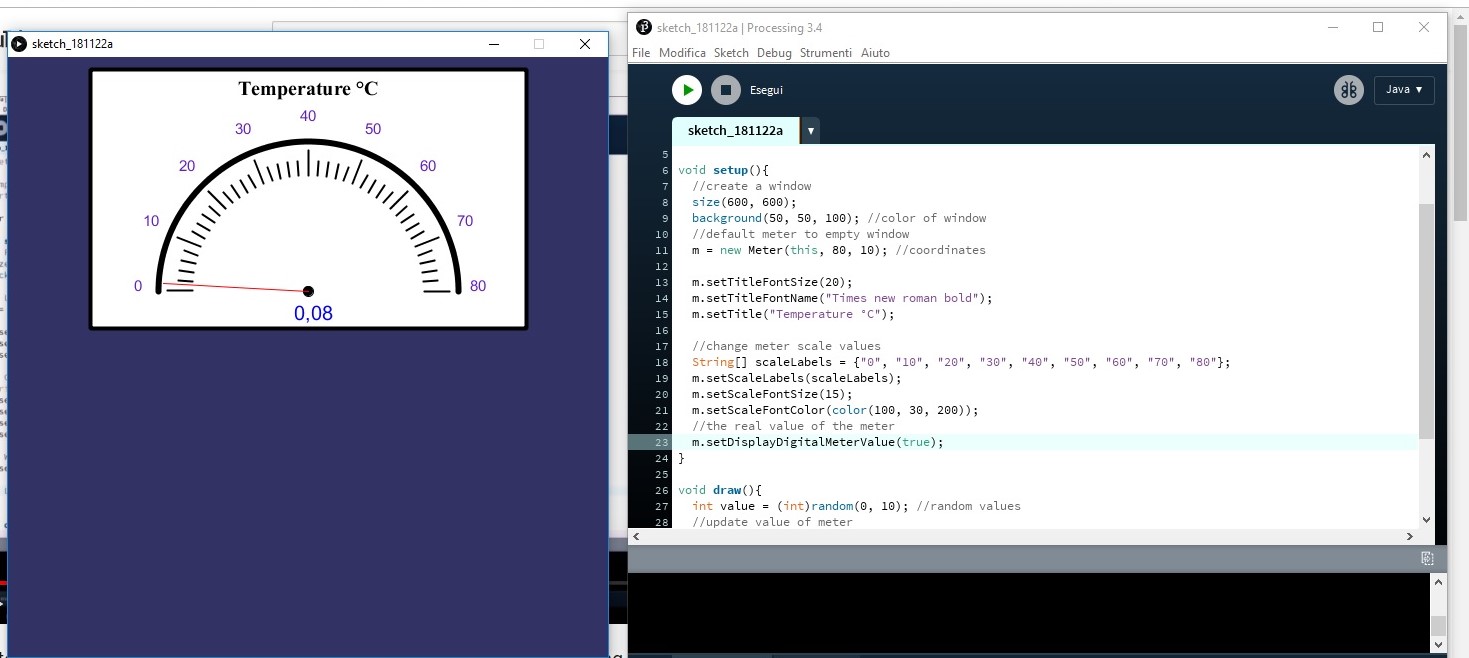

To see how to modify the meter I read this page

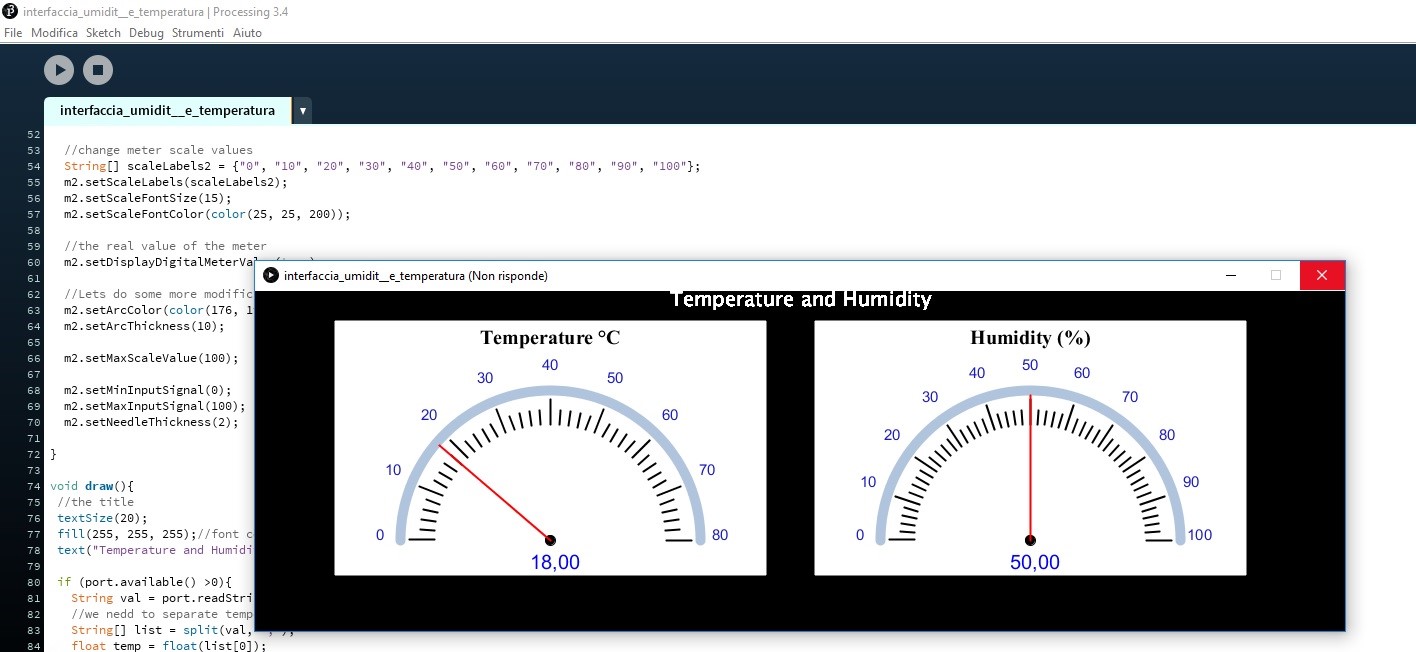

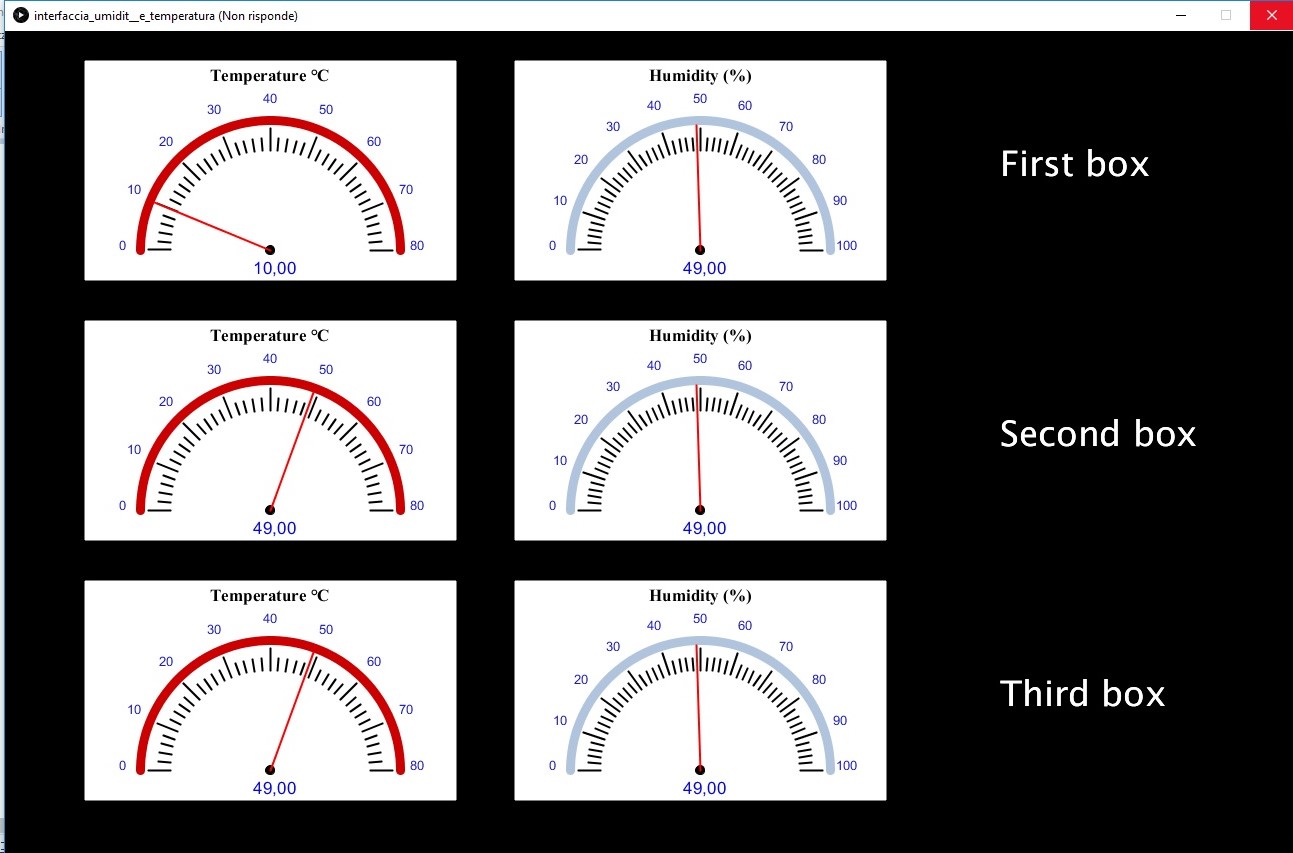

After deciding how to make the meter aesthetically I started to duplicate others and to place them in the window

And this is the final interface

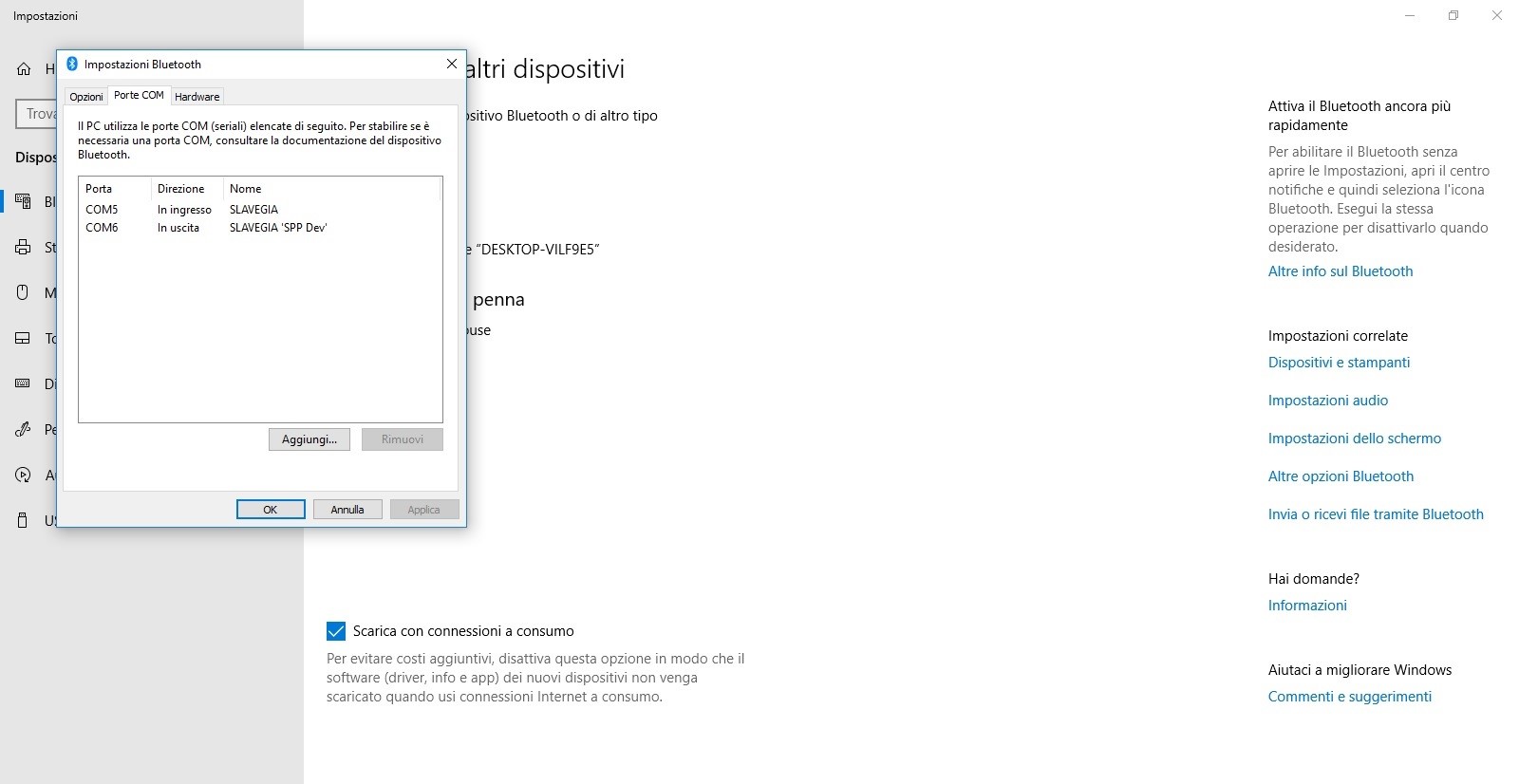

After programming the board I set the bleutooth module to make it visible and connect it to the pc. At the beginning it was a bit difficult to find the right port to insert in the sketch of Processing to read the data, but then going to the ->bluetooth settings I realized that I had to select the COM 5 port (in entrance)

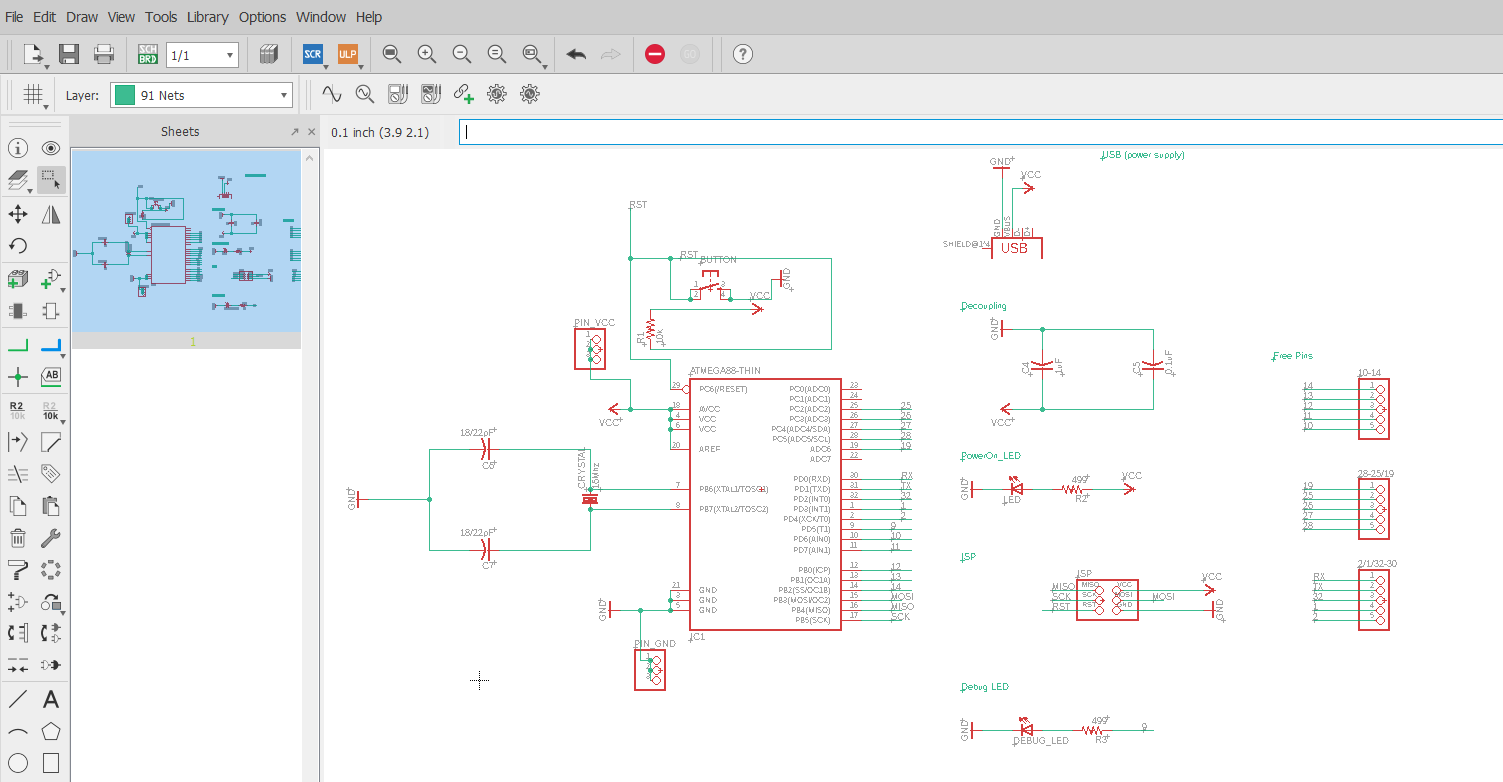

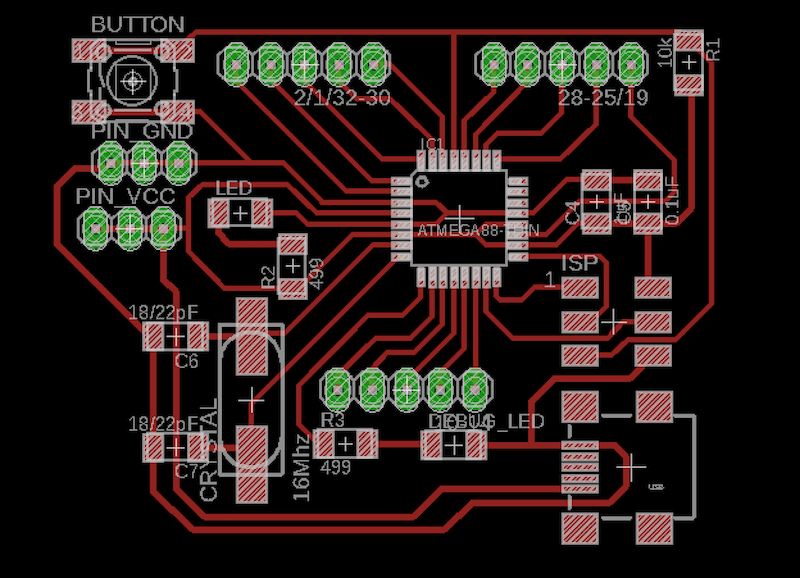

I made a satshakit to be able to communicate the Bluetooth module with the interface on the PC

BOM

Resistor 10k ohm

Resistor 499 ohm

Capacitor 0,1uF

Capacitor 18/22 pF

ATmega328P

Crystal 16 MHz

Led

Headers

After programming the board I put it in the back box of the final project, which I screwed in to make it stable but also easy to remove. I created a hole to pass the thread.

Moreover, the first box will have a perforated cover to let the air pass and prevents beetles from flying away. The eggs will pass to the second box where they will grow, then they will be moved to the third box (to allow the eggs of the first box go down to the second one). Under the third box there will be a sort of funnel that will channel worms and pupae into a dell, where the worms will come down and the pupae will remain. Now it is appropriate to move the pupae in the dell of the first box, so the cycle will starts again.

But who would use this product? Food consumption of insects and worms is still low in our part of the world, at the moment only elite chefs have started using them in the kitchen. Hoping to become the next fashion in the kitchen, this product could interest anyone who wants to have a healthier diet, without renounce the protein of meat but at the same time helping the planet not wasting water and not emitting CO2. Buyers can be families but also exotic restaurants.

Hardware

The idea of the project is based on a sort of chest of drawers, the most used method by worm breeders. The structure will be vertically with 4 boxes: the top three will have a movable bottom that will be activated manually while the last one will have the function of collecting and base of device (to create stability). The first box will have a perforated lid. To get an idea of the final result I created an assembly with the various parts. I made the models with SolidworksFirst of all I created the boxes, this is the one with movable bottom.

After laser-etched the sides of the box I glued some wooden guides to slide the bottom.

Once the glue has dried I have finished the boxes with the vinyl sheet, in this way the worms can not climb to escape

Then I made the "dome of love"(where the beetles will reproduce). There is a dell at the top to accommodate the pupae and holes at the bottom to let the beetles enter. Inside it is empty.

then I made this cover for the first box, I created many holes for ventilation

The first box will have a net to allow the eggs to go down to the next box and avoid the dome fall down with the beetles

I made a hole with a column drill to allow the sensor wires to pass through and enter the box.

I glued a small piece of wood in order to create a support for the back box that will contain the electronic part

I inserted the wires with the sensor and screwed the box with electronic components (and already programmed) inside.

I made a small logo with inkscape and engraved it with the laser cutter.

Then I attacked all the parts again (I screwed them together to see how the project was coming).

Software

I looked up the info on the dht 11 to understand its characteristics and since I've never used a dht 11 sensor, I've done some tests before to see how it worked

I made a simple sketch to read the serial datas.

After that I modified the sketch to read the data via bluetooth

#include#include int pinDHT11 = 2; SimpleDHT11 dht11(pinDHT11); SoftwareSerial btserial(10, 11);//bluetooth pin void setup() { btserial.begin(9600); delay(20); } void loop() { float temperature = 0; float humidity = 0; int err = SimpleDHTErrSuccess; if ((err = dht11.read2(&temperature, &humidity, NULL)) != SimpleDHTErrSuccess) { btserial.print("Read DHT11 failed, err="); btserial.println(err);delay(1000); return; } btserial.print((float)temperature); btserial.print(","); btserial.println((float)humidity); // DHT11 sampling rate is 1.0HZ. delay(1000); }

Now it's time to create the interface on processing

I imported this library to use a meter already configured, my intention is to create another 6, two per box. 3 for temperature and 3 for humidity.

To see how to modify the meter I read this page

After deciding how to make the meter aesthetically I started to duplicate others and to place them in the window

And this is the final interface

After programming the board I set the bleutooth module to make it visible and connect it to the pc. At the beginning it was a bit difficult to find the right port to insert in the sketch of Processing to read the data, but then going to the ->bluetooth settings I realized that I had to select the COM 5 port (in entrance)

Electronics

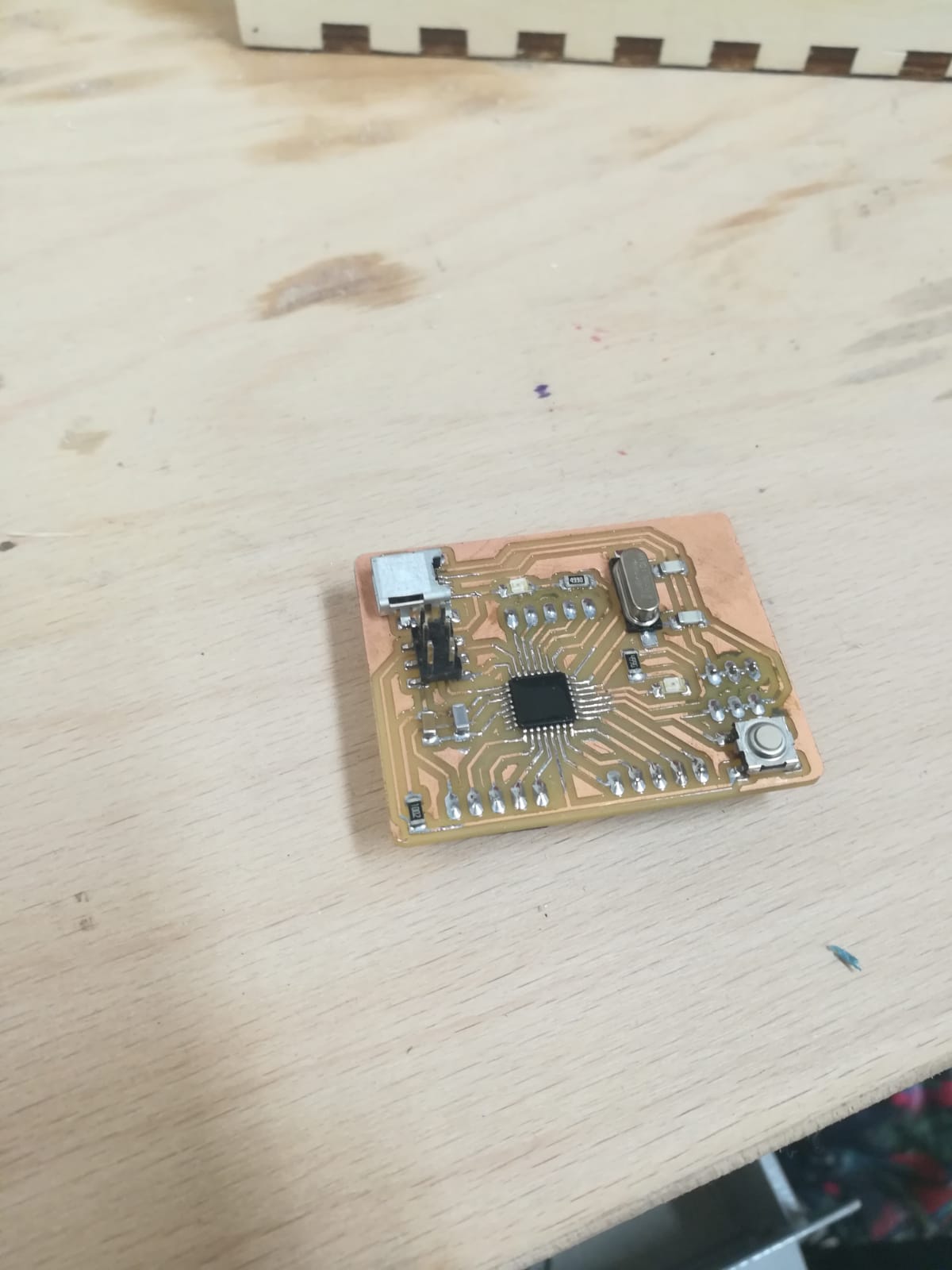

I made a satshakit to be able to communicate the Bluetooth module with the interface on the PC

BOM

Resistor 10k ohm

Resistor 499 ohm

Capacitor 0,1uF

Capacitor 18/22 pF

ATmega328P

Crystal 16 MHz

Led

Headers

After programming the board I put it in the back box of the final project, which I screwed in to make it stable but also easy to remove. I created a hole to pass the thread.