Answering question regarding the final project.

Designing

Designing

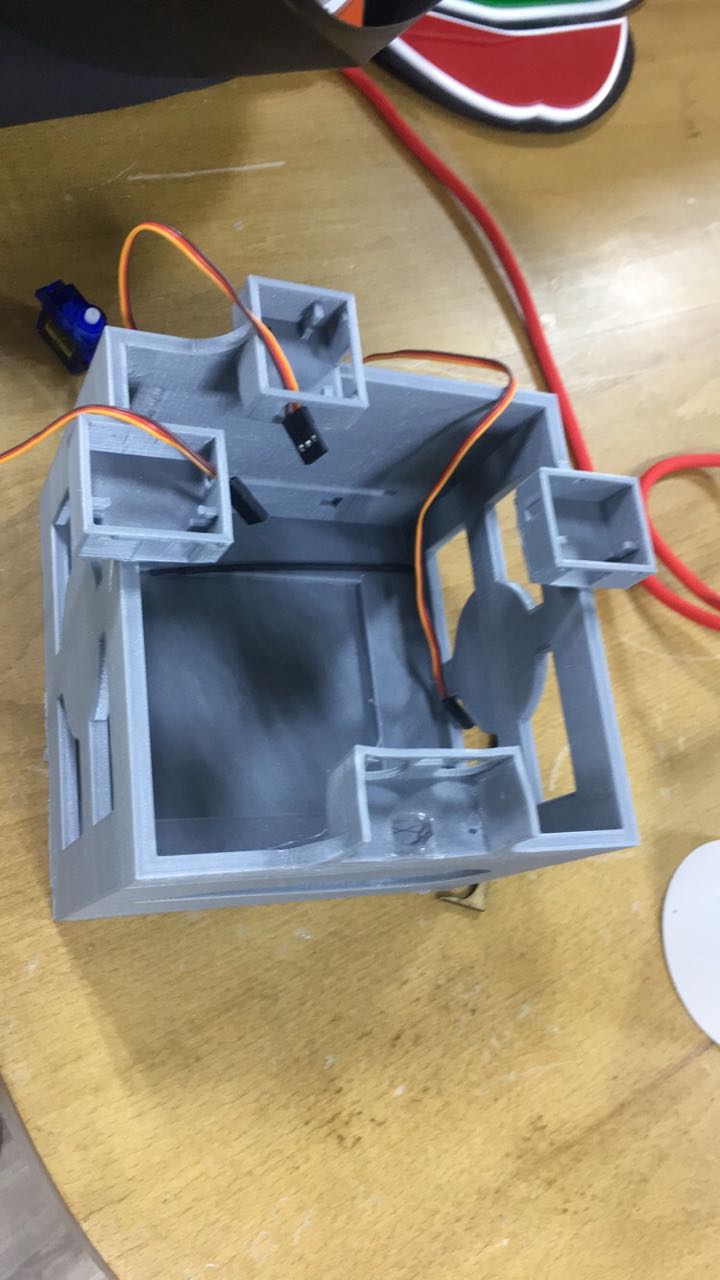

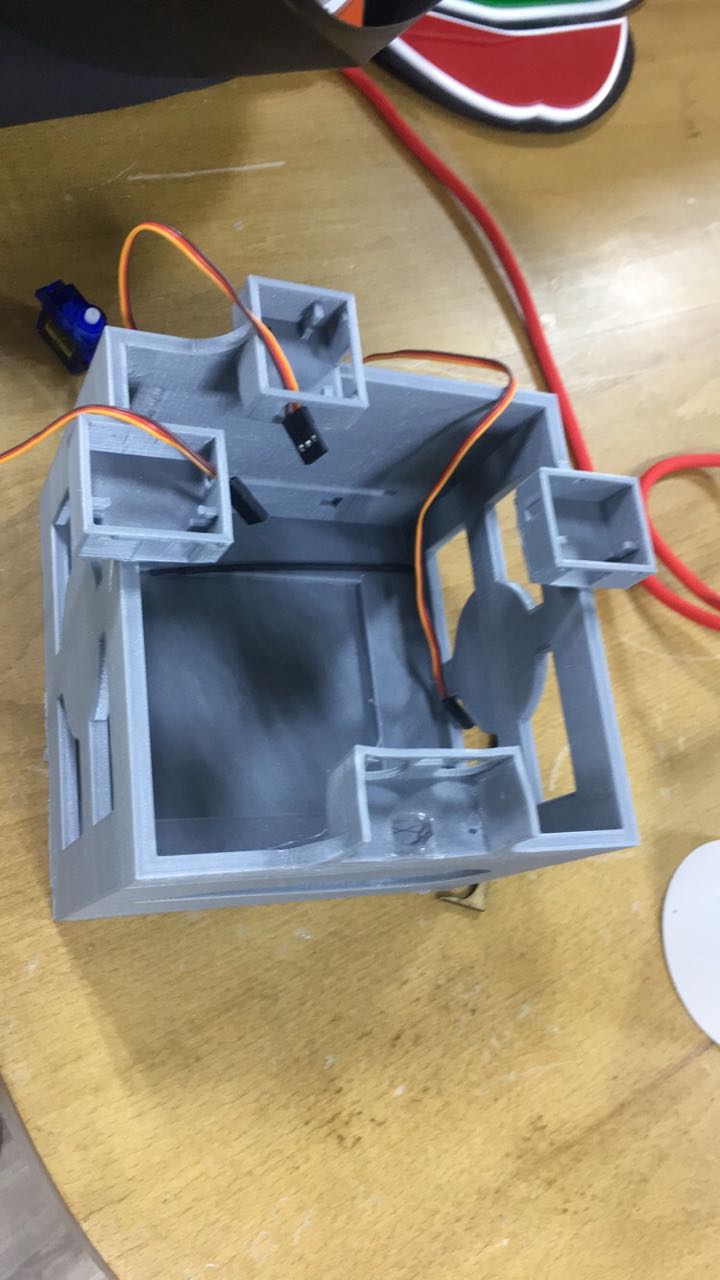

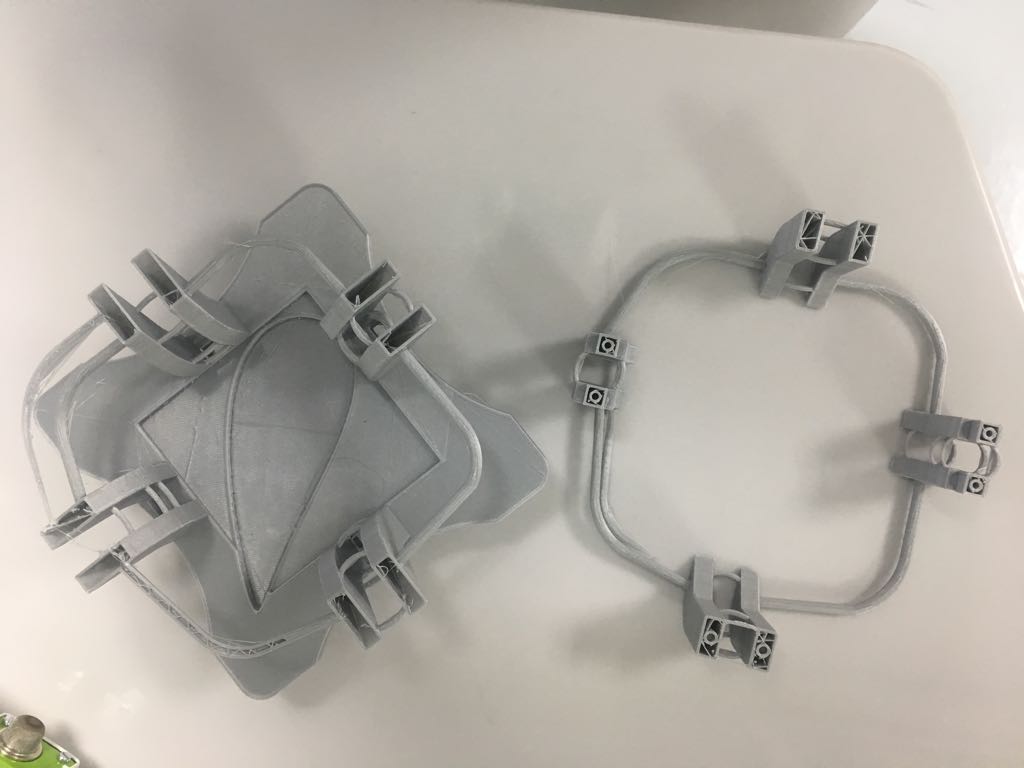

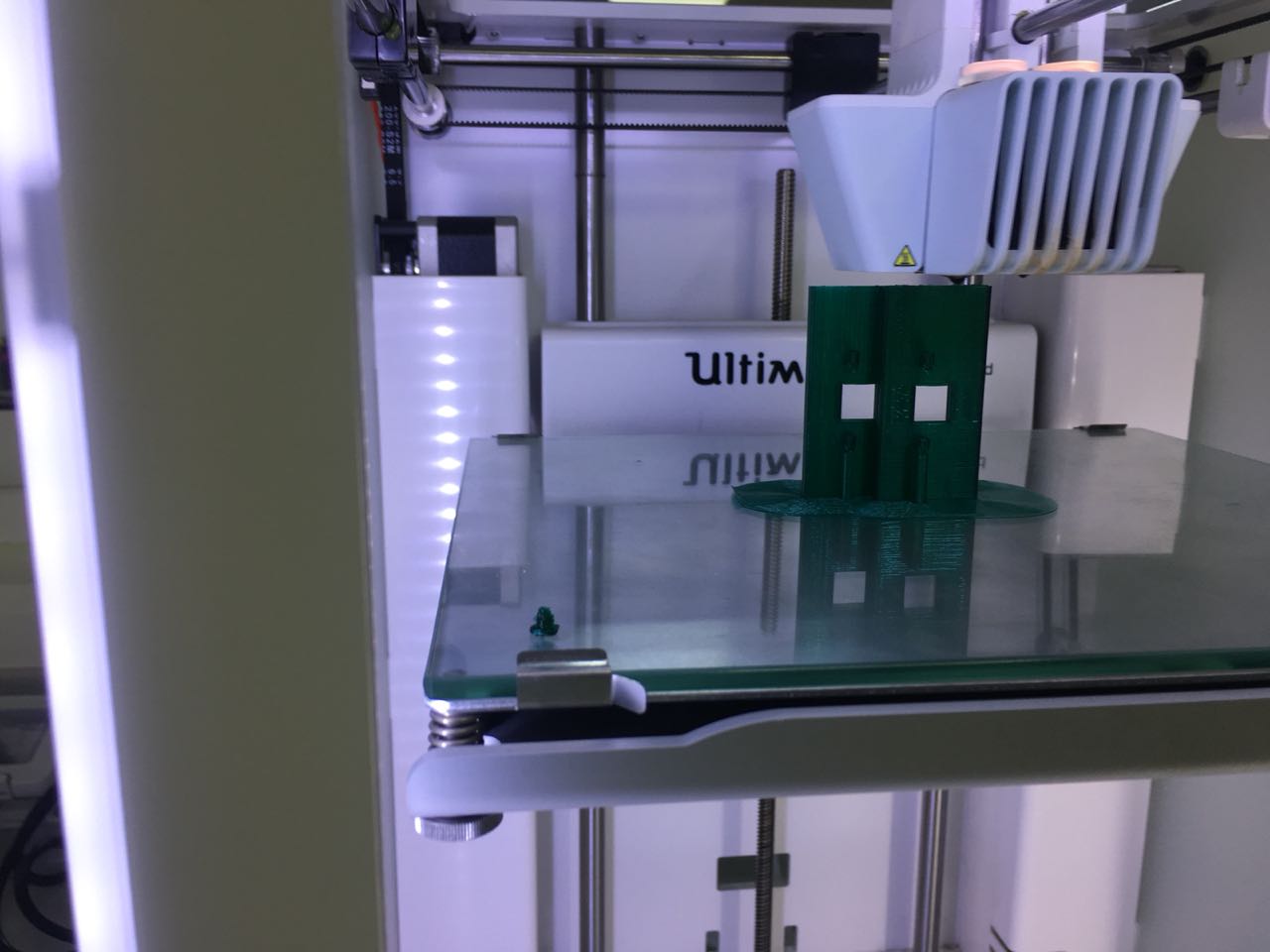

The first design I made of the project was like a box and inside this box. I Designed the three servers and the sensor together with the box After I print it.

I designed and cut the arms of the servos using 3mm cardboard. I made two short arms for the sides and one long to close the cover of the box. When I wanted to fix them in the original arm of the servo I notice that I cant tight the screw because it will touch the holder. This meant that I must change the design of the holder. I decide to continue and change the side-arm to make it more simple and to add a little length to the long arm. Also, I thought of using a wire to fix the arms to the servo for now just to test the code. (Note:After many tries, I succeed to close the box using the servos but I didn't take a video because already I was tired so I forget)

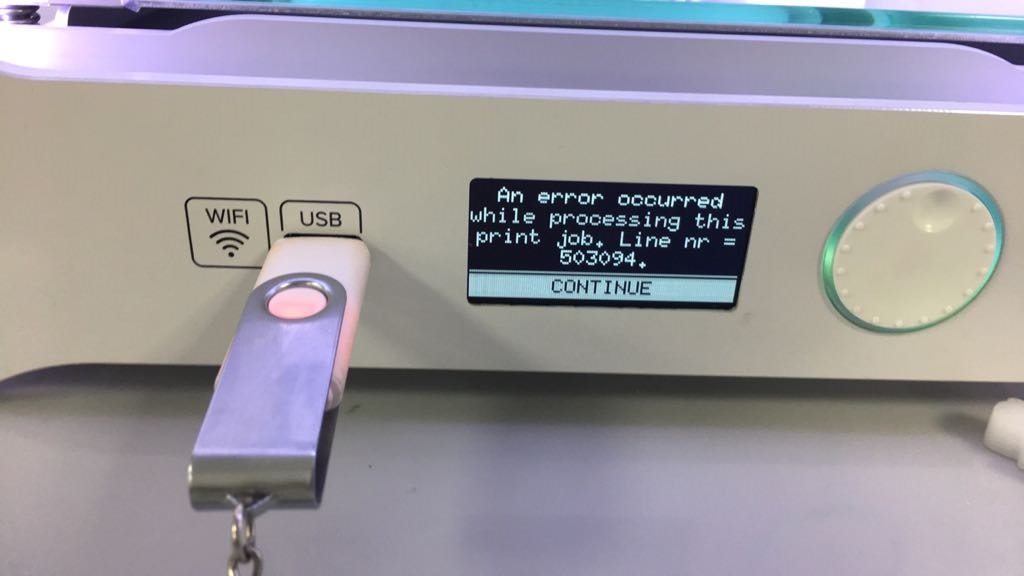

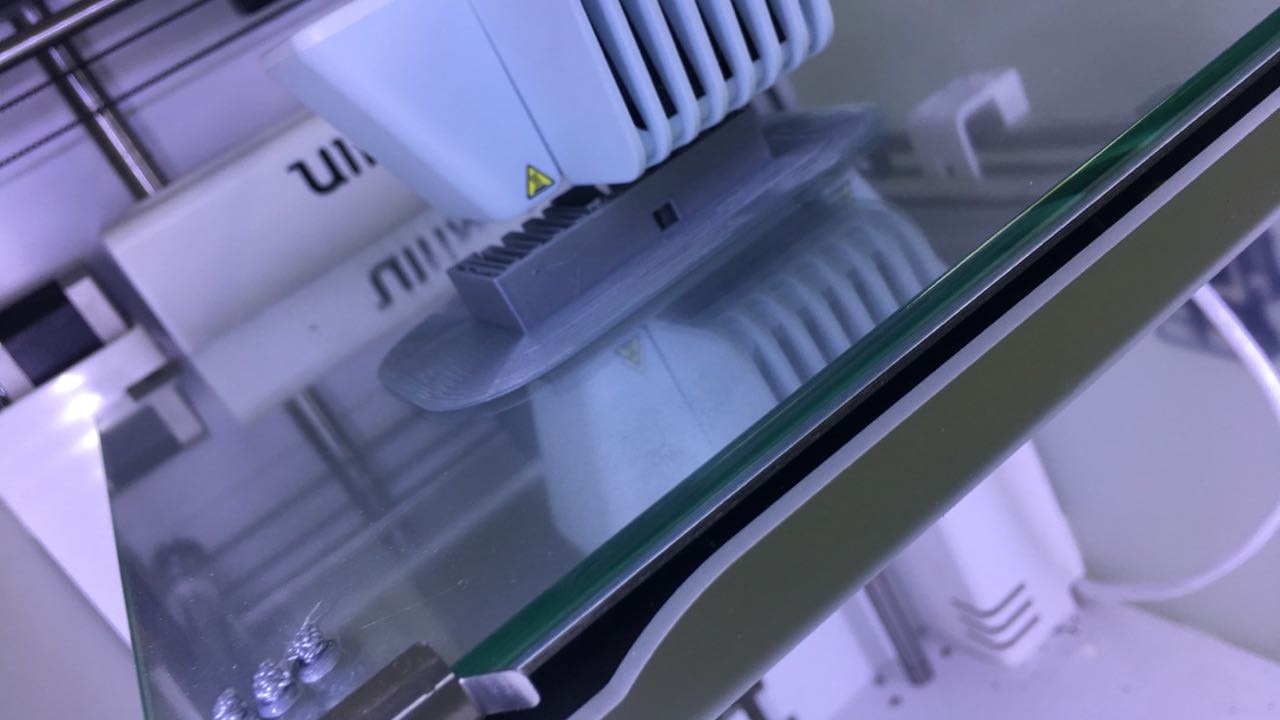

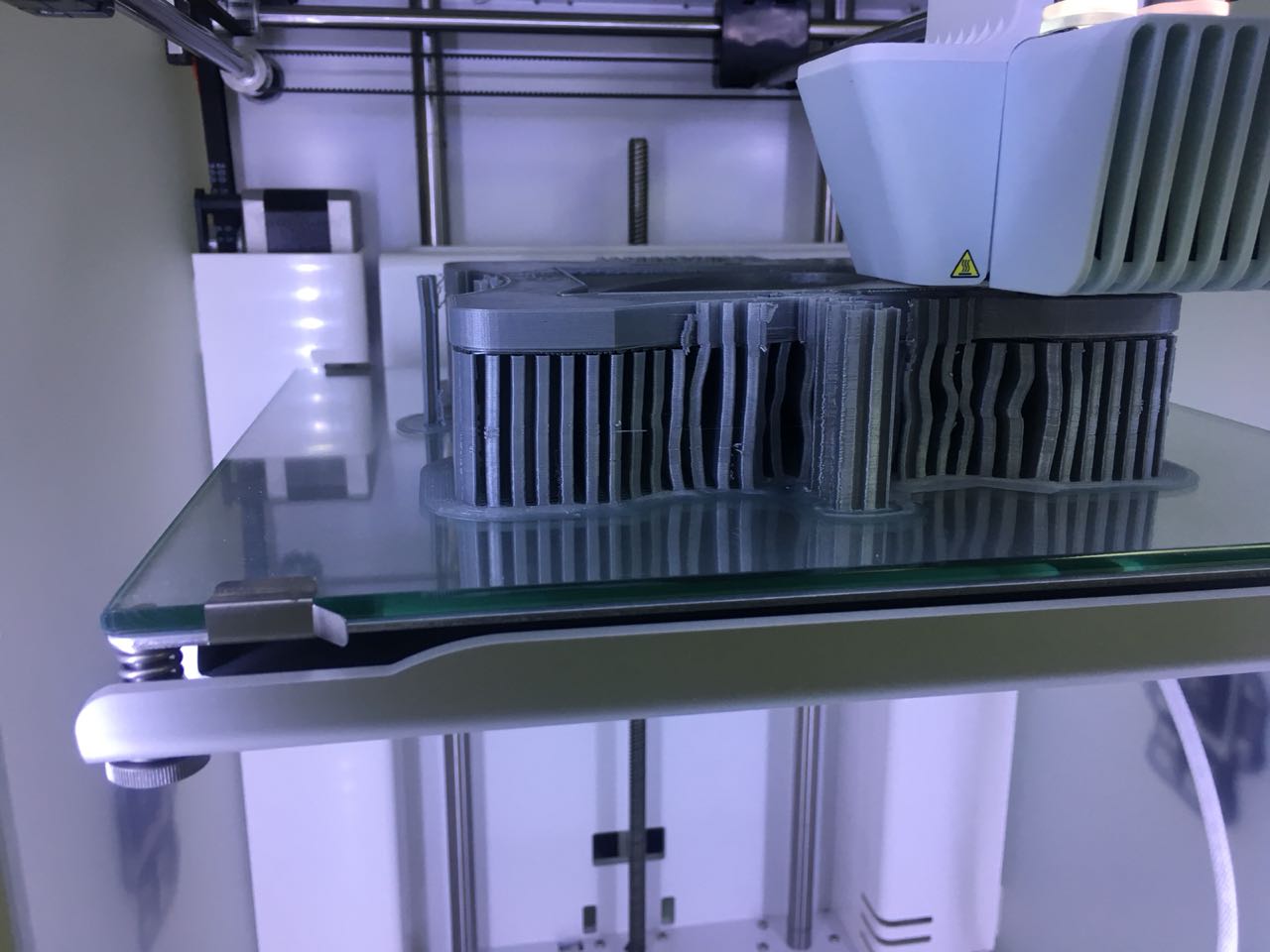

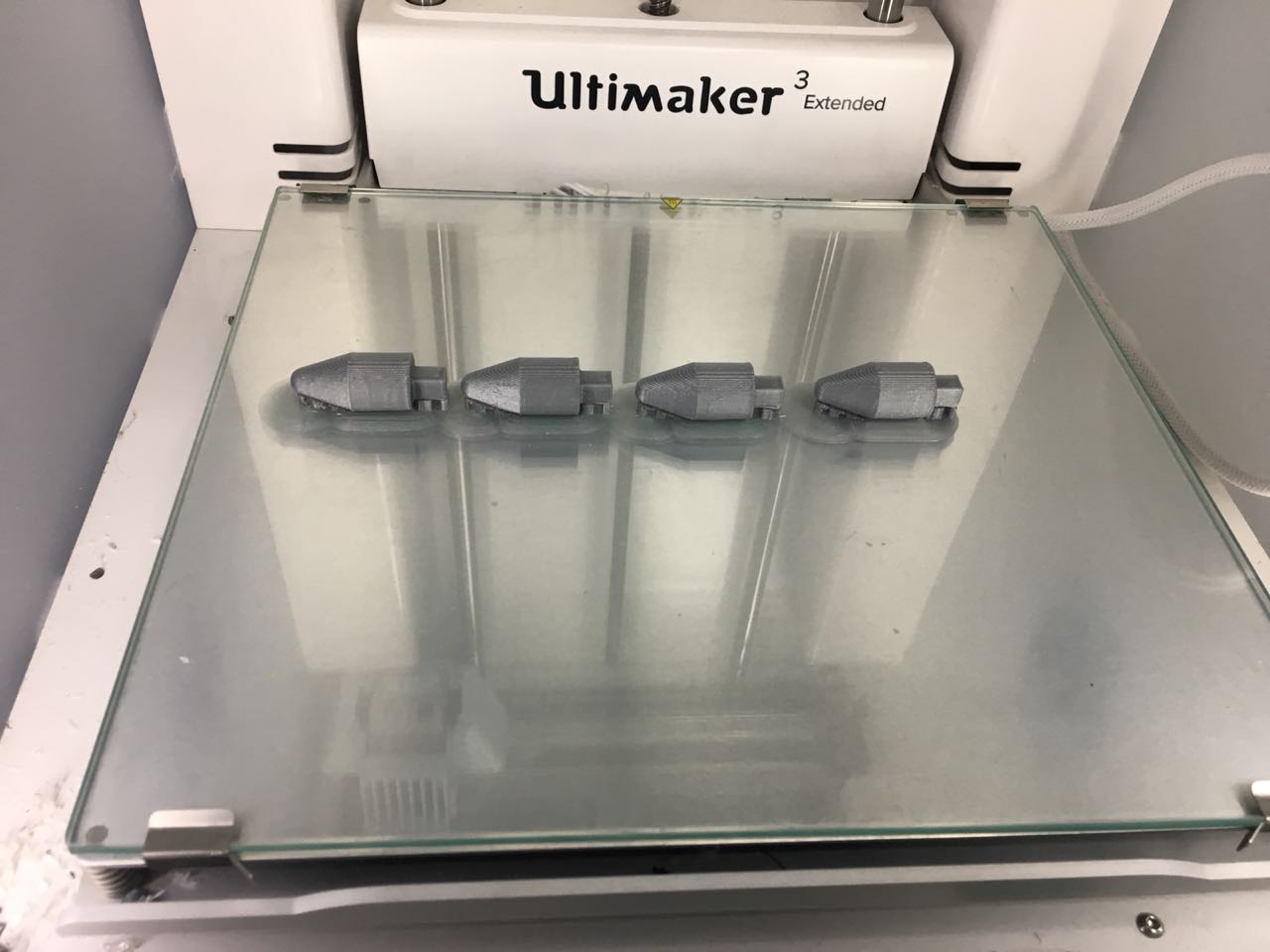

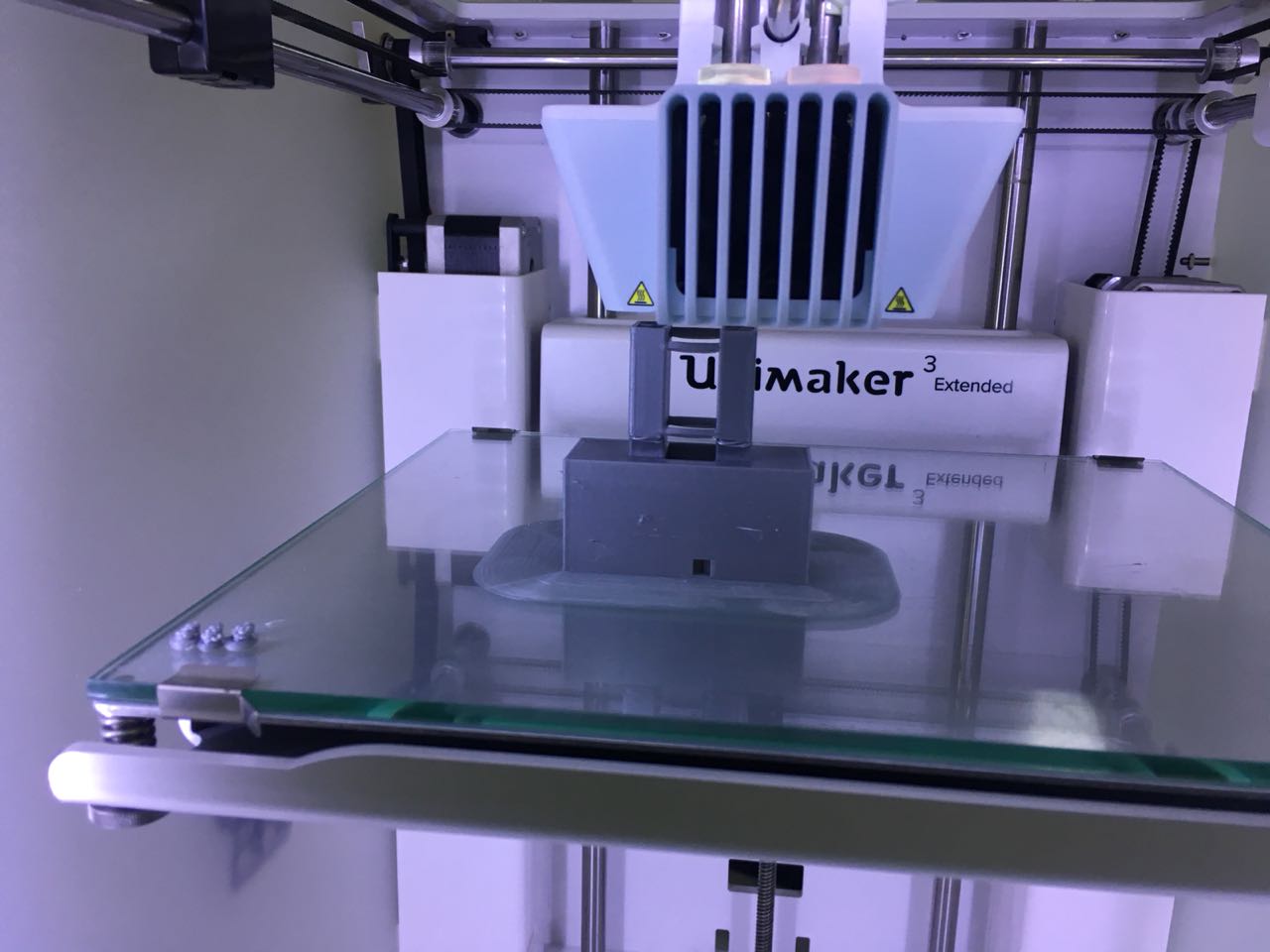

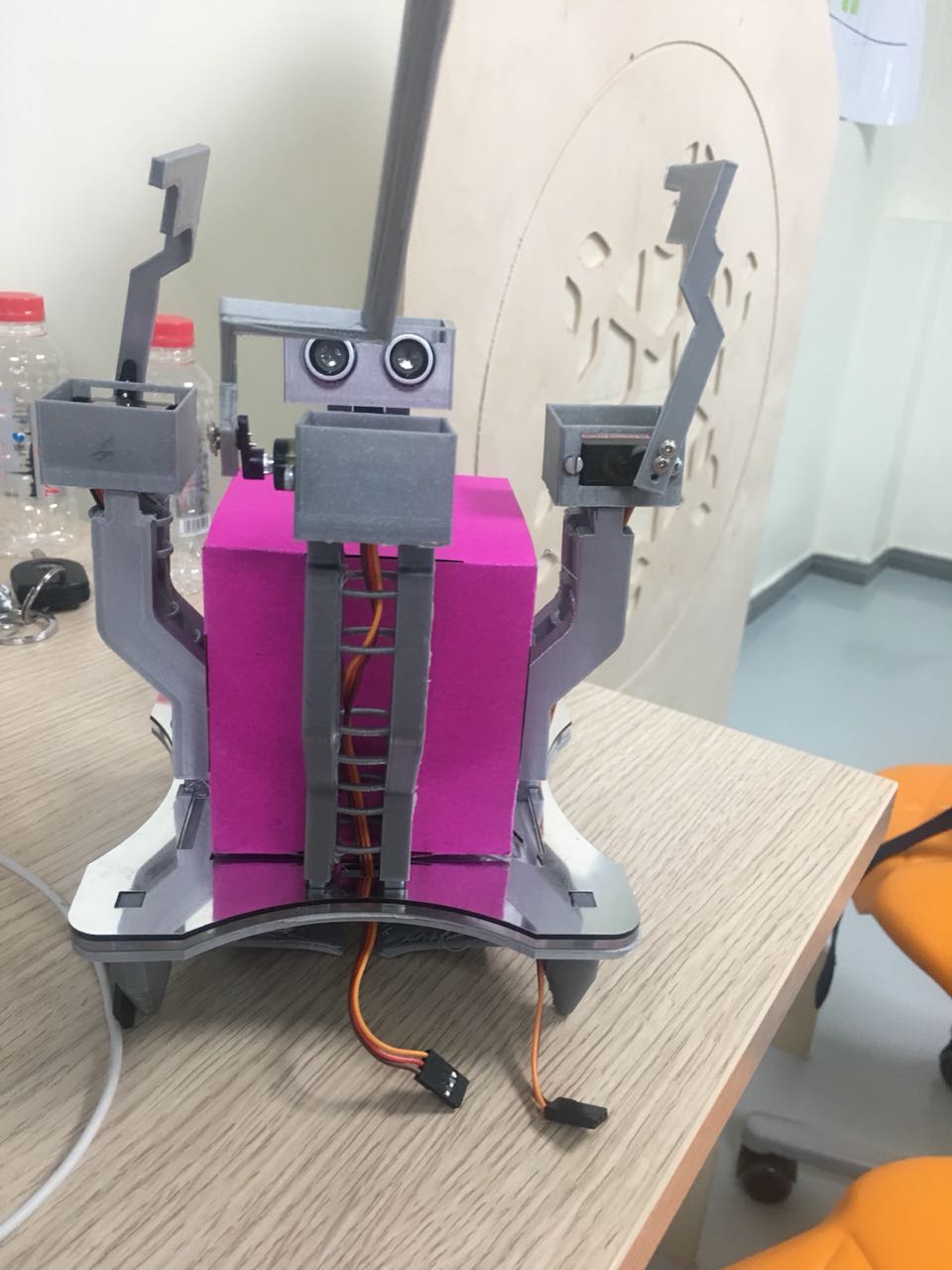

I noticed that The servos and the sensor will not fit in the holders. Then I went to Wendy and Hashim and I discuss the design and to see how we can improve it. Because Wendy suggests changing the design because it’s very simple design and she shows me the presentations of last year student there wes some student that made simple design and Neal commented that. Also, I learned that we use 3-D printers to print shapes that it’s difficult to cut in the laser. Also when I saw my design I noticed that there is no place for the boards. So I discussed with Wendy and Hashim regarding the design and they help me a lot and gave me an idea of the new design. So I started to redesign the project and it was better than the previous design and much complicated but it has all the things I want. I printed the design and it took so much time. The first design it didn’t work my colleague Zubair stoped the Printer. Then I asked him to print it but it failed the second time. the first and second time I used ABS material I thought of changing the material because I get used to using PLA. Then third time I changed the material to PLA and it failed again. In the third time there shape was good but it stoped saying that there is an error some line then Wendy split the design to make it print the upper part. It worked until it rech a point and stoped again. I looked to the error it was writting that there is an error with line 503094.

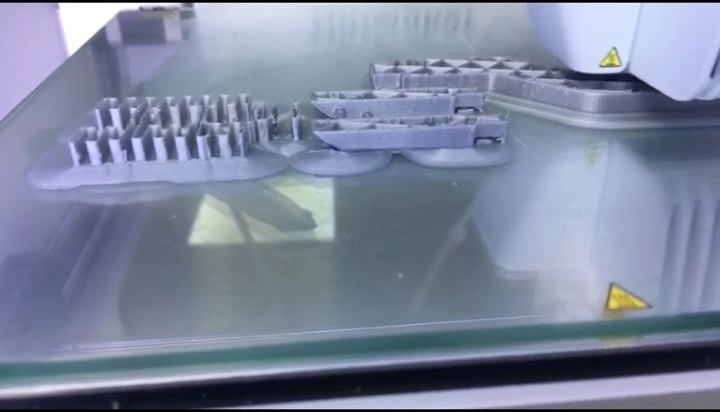

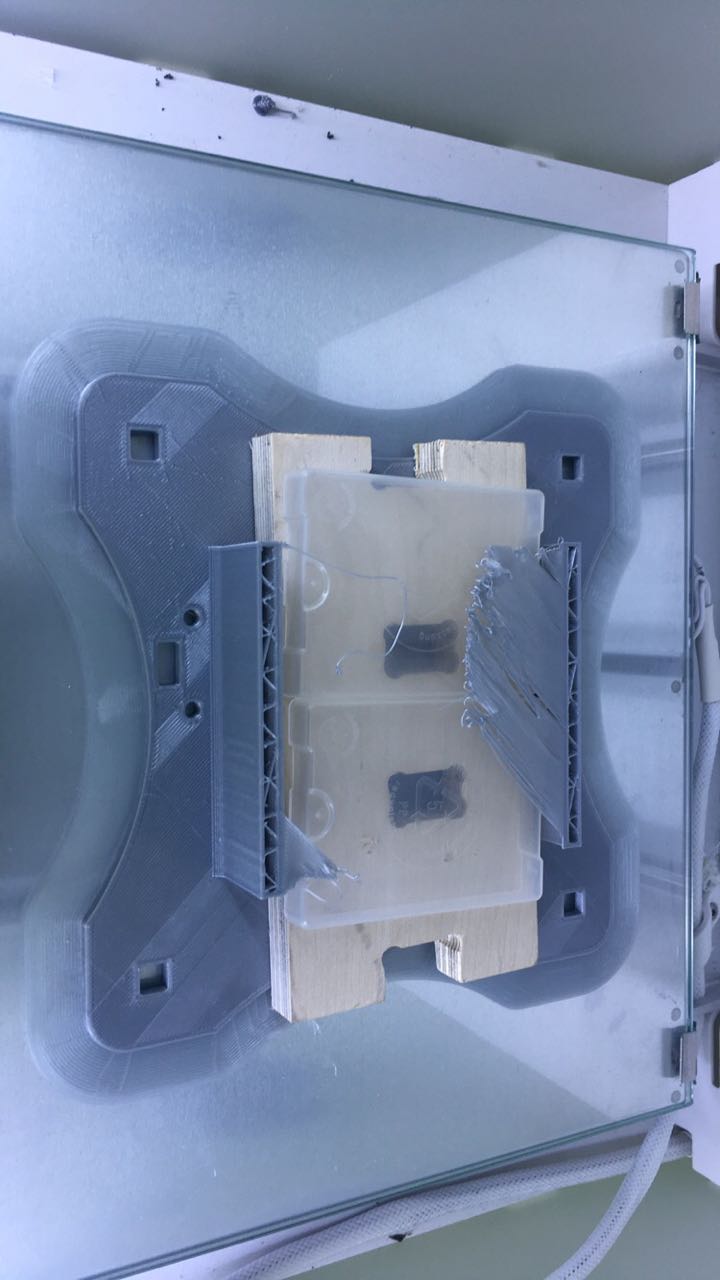

So I decided to separately print the towers, holders, the feet, and I divide the base into three layers which will be from acrylic. I print the component and cut the layers.

I tried to combine the component toghter and it not fit. This means I will change the layers multible times to find the best measrument. So I decided to print only the last layer with the holder of the boards togther and to make holes for the towers to fix them toghter. I faced one problem when I print the last layer which was the printer couldent print the holder because it's in the air an there is no support so I put box to act like a support. I cloud rotate the design to avoid this problem but it will take 12 hour to print it when this design actually took hours.

Regarding the input and output I already document every thing that happened to me in input week and output week. The only thing I didnt meantion there is that I changed the micro servo because it was weak so I change it to MG90S Micro Servo. Also I used 5 voltage adapter as my source to power the machine.

In coding, I faced little problems. I made a simple code in the ultrasonic board to make it send a character 1 and turn the LED when the I put anything less than 4cm from the sensor. In the three servo board, I wanted to turn the LED when it receives character 1 from the master(ultrasonic board). I tried a lot but it didn't receive, I opened the slave board(servo board) and I opened the serial monitor and I wrote 1 and it worked. But whenever I connect them it doesn't work. After many tries I forget really how much I reach for a solution. I wrote for the sender to send 1 when the condition is true and to send 0 when the condition is false. So I deleted the order to send 0 when it false. SO the master will send 1 and turn the LED ON when the distance is less than 4cm and will turn the LED OFF when its more than 4cm. When I did tha that it worked. So I added servo and I notice some noise from the servo then I think the gear pushing the physical limits so maype the servo doesn't realize it's in angle 0. So I make them move to another angle more than 0.

The deadline is 27th of June, I still have a couple of days.

I did finish the logo but maybe I will change it because its big. I still left with almost all work like the two PCB one for the sensor and one for the three servos. Also, I didn't make the final design for my final project I didn't work seriously on it I just make the first design.

After one week I finished the two board (input and output). still now working to make the Networking.

I finish now all the tasks regarding the final project. I still have to document about C language in embedded week.

I will finish the shopbot and the vinyl tomorrow 21-5-2018. Then I will focus this week on making first servos PCB then Ultrasonic sensor PCB. then the week after I will finish Interface and Application Programming because completing the two PCB means completing Input and Output weeks.

Now its 16/6/2018 I finished all of my weeks still one part on embedded week. I already printed the design it will finish in one day.

I will set with Hashim to learn C language and I will document it in the same day, it will take around 1hour.

The ultrasonic sensor worked, I made the PCB and I tested.

Now everything worked the servos close the box perfectly so this means the length of the arms are enough for this size of the box.

The PCB of the three servos because I was using attiny44 as the microcontroller, but now I made another PCB with ATMega328p.

Nothing, everything worked regarding the project.

For now, I will test the atmega328p to move three servo if it works this will leave me with zero questions. If it didn't work my question will be how to move three servos?

Nothing I learned how to control the three servos and I print the perfect size of the arms and holders.

I learned that finding or making a code for attiny44 with three servo is very very hard. I also learned that programing using Atmega328p is like Arduino beacause Arduino use Atmga328p.

I wanted to print the last layer with the PCB holder because this will help in assempling the machine and because it was hedic to have a lot of component seperet. Also I want to cut covers for sensor and servos cases.

I will mention here some stuff I wanted to try through the course and things my global evaluator Stephen point at. I couldn't try them before because there is no time and I want to focus more in college to raise my grades. Like I said there a lot of stuff I will mention few Such as training python, trying full networking with more than three boards, and programming the PCB boards with C.