Tasks of this week:

The weekly assignment started with the simple tasks:1. design a machine that includes mechanism+actuation+automation 2. build the mechanical parts and operate it manually 3. document your individual contribution

mechanical design:

This was a big week for all of us. It was the most awaited and exiting week. All of us were having really hard efferts for this week. it was the two week make a machine assignment. at the beginning we though about.1.XY plotter

2.3D printer

but this time we wanted to make something diffrent. so we decided to do a robotic arm. We worked on a robotic arm which is having laser as a end effector.

This was a group assignment so we were eight members:

1. ROHAN and CHAITANYA: Brain Storming and main Designing of the arm.

2. KAMALESH and KOMAL: Prototyping, Hands on skill.

3. ANAMUL AREFIN and RUTVIJ: Electronics and Interfacing.

4. SANKET(this is me!): Documentation, video.

5. UGYEN: End effector design.

As you work in a team for something interesting you need team leader, so KAMLESH was our team leader. as his was leader we decided to split the tasks between us as per our intrest. so everybody took thier task by thier intrest. in this I took responsibility of the documentation of our arm. as I am photographer I was so happy to document this (All the pictures and videos are taken by me). but I was also intrested in few more things. so I decided to help KOMAL and KAMLESH in prototyping.

'The Zhero'

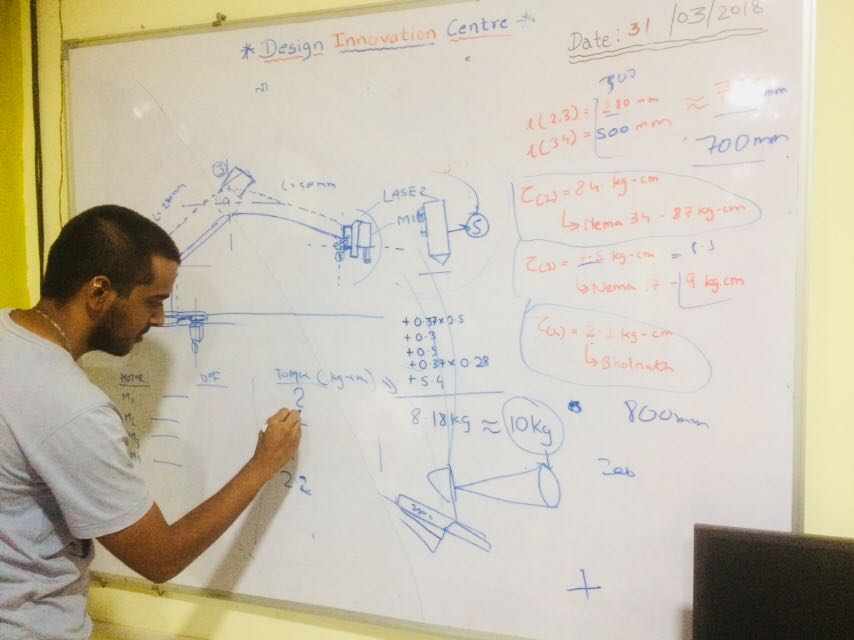

At the beginning We started with the design, how actually we will start, what type of materials we will be used. Most importantly the motor and how much torque will be this motor. Rohan (who is a machanical enginner) calculated the torque, reach of the zhero.

As we were having discussion about the mechanism everyday. we came to our design.

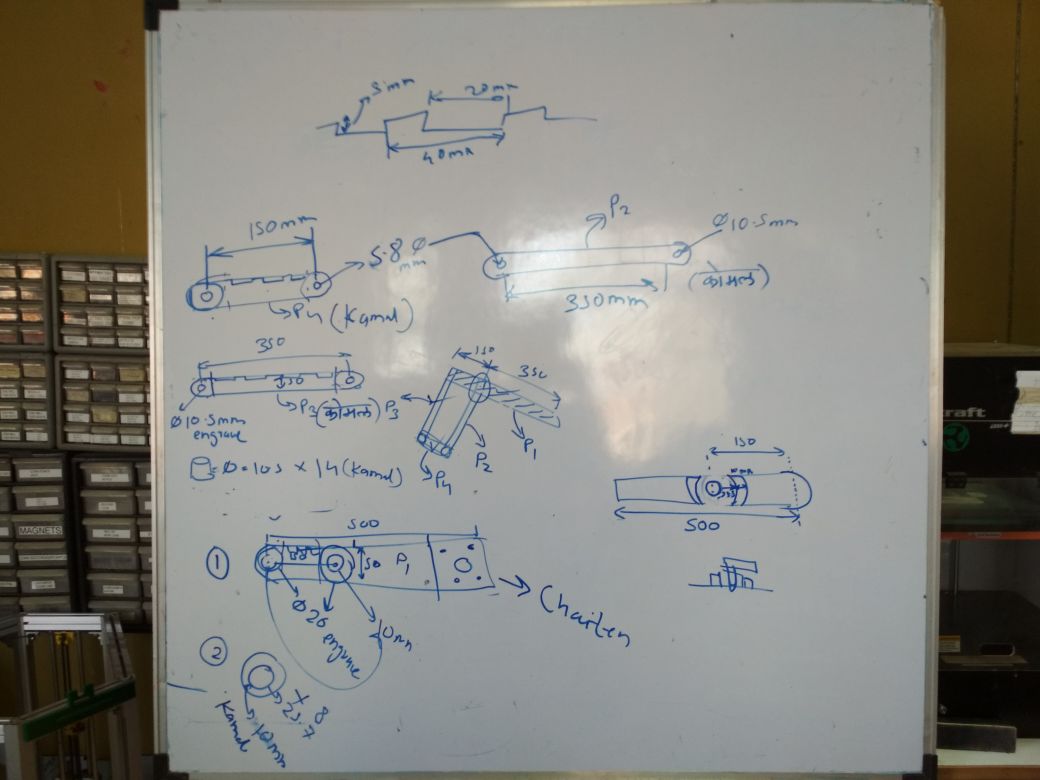

These were the rough parts we designed and decided to cut. so this was our little step towords the final output. we decided to make a small prototype in MDF. The Zero is a robotic arm which has 4 degrees of freedom, with changble end factor.

So at the small step we tried to find out the reach of arm. the image showing bellow is This is the first prototype which is cuted it on the laser cutter. hence the maximum reach and minimum reach of the arm will depend upon the angles between the two links.

We roughly observed the maximum and minimum reach.

after a long discussion we fixed our arm lengths to 350mm and 400mm. Then we draw the linkages with dimension on white board. As we wanted to rotate the base we attached a step up motor and also for the sides. Then we attched the controller for that motors. in the picture you can see, komal, arefin, kamlesh and rohan were trying to fix it. (I was also helping them while standing behind the camera!!)

This is the frist prototyping video.

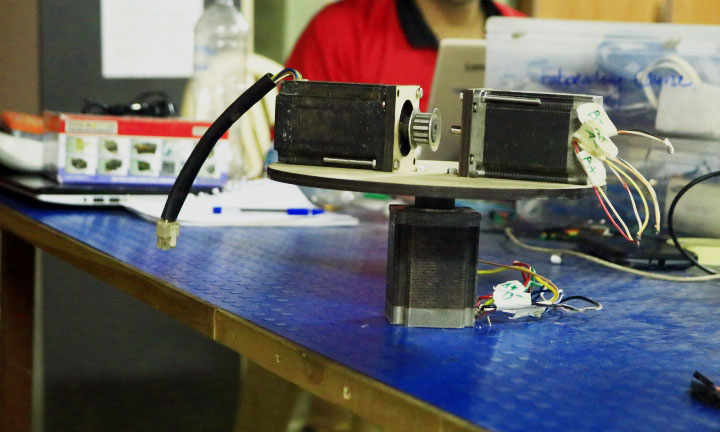

After this prototype we calculated the force and material and we started working on it. here is the base assembly of the mahcine. for technical specification you can go here.

Here my teammates were assembling the base of the arm. all of us had fun while assenbling the parts. especially komal enjoyed a lot.

After the mechanical assembly arefin and rutvij focused on controling part of the machine. Here is the elctronics part of the machine.

and the finally the arm was ready to move.

Learning outcomes:

In this week I learnt about machine designing. how a machine works, the principles behind enginnering.how to Work and communicate as team for a project. also how to find the problem and make a solution.

The project page for this assignment is available here.

All the Model files for the arm are available to download here.