Design a machine that includes mechanism+actuation+automation Build the mechanical parts and operate it manually Document the group project and your individual contribution

Wireless and communication part assigned to me .Apart from that mobile application part is also assined to me . Initially i faced problem of communication between app and HC-05 Bluetooth.I searched lot for app for our machine project.Finally I Found open source app from palystore and download that App.The problem that I faced is communication between app and HC-05 Bluetooth then I discuss this proble with my local instructor Sir Sohail Ahmed Somro and he helped me to sort out that problem. Another task is Assigned to me is to generate Barcode for the products and Cutted on Cutted on vinyl cut

This week's assignment is that we have to design machine that include mechanism, actuation and automation. Considering to above requirements we looked at number of ideas among which vending machine was at top because of it's need and advantages. A vending machine is an automated machine that provides items such as snacks, beverages, cigarettes and lottery tickets to consumers after money, a credit card, or specially designed card is inserted into the machine. The first modern vending machines were developed in England in the early 1880s and dispensed postcards. Vending machines exist in many countries, and in more recent times, specialized vending machines that provide less common products compared to traditional vending machine items have been created. For designing the vending machine we are using this useful link.

Seaga Small Vending Machine

Easy Management: These machines are so easy to manage as nobody has to be there to sell any goods. All that needs to be done is the machine’s installation, and then you can simply monitor it’s progress from afar. There won’t be any payment problems either, as an instant cash payment is needed to buy items. No Overhead Costs: Operating vending machines carries no overhead costs as you eliminate the need for employees who sell food. You don’t have to worry about monthly wages and pay rolls, and there’s also no need for you to rent any extra work space. Time Saving: No precious time will be wasted preparing a beverage, as a hot drinks vending machine can dispense a drink in around 20 seconds, saving loads of time! Diversity of Products: The wide range of products can be sold using vanding machine for example fruits, the beverages, the drinks, and the snacks among the other products. Working Capability: Vending machines work 24 h day 365 days a year , They need neither stuff nor specialized attention , They does not take a long time , You will need short time to keep them serviced and stocked with the products .

Machine is composed of following parts

Six discharging units.

An LCD

Cashless payment system

E-Payment

In order to make it possible we divided our work individualy as given below.

1.CAD Modeling (Tariq)

2.CNC Milling (Haider)

3.Electronics (Zeeshan)

4.Programming (Azmat)

5.Wireless Communication and Mobile Application (Ali Raza)

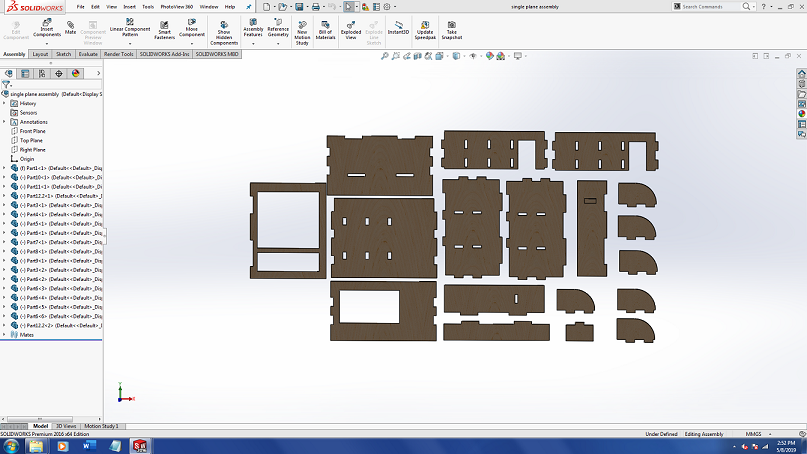

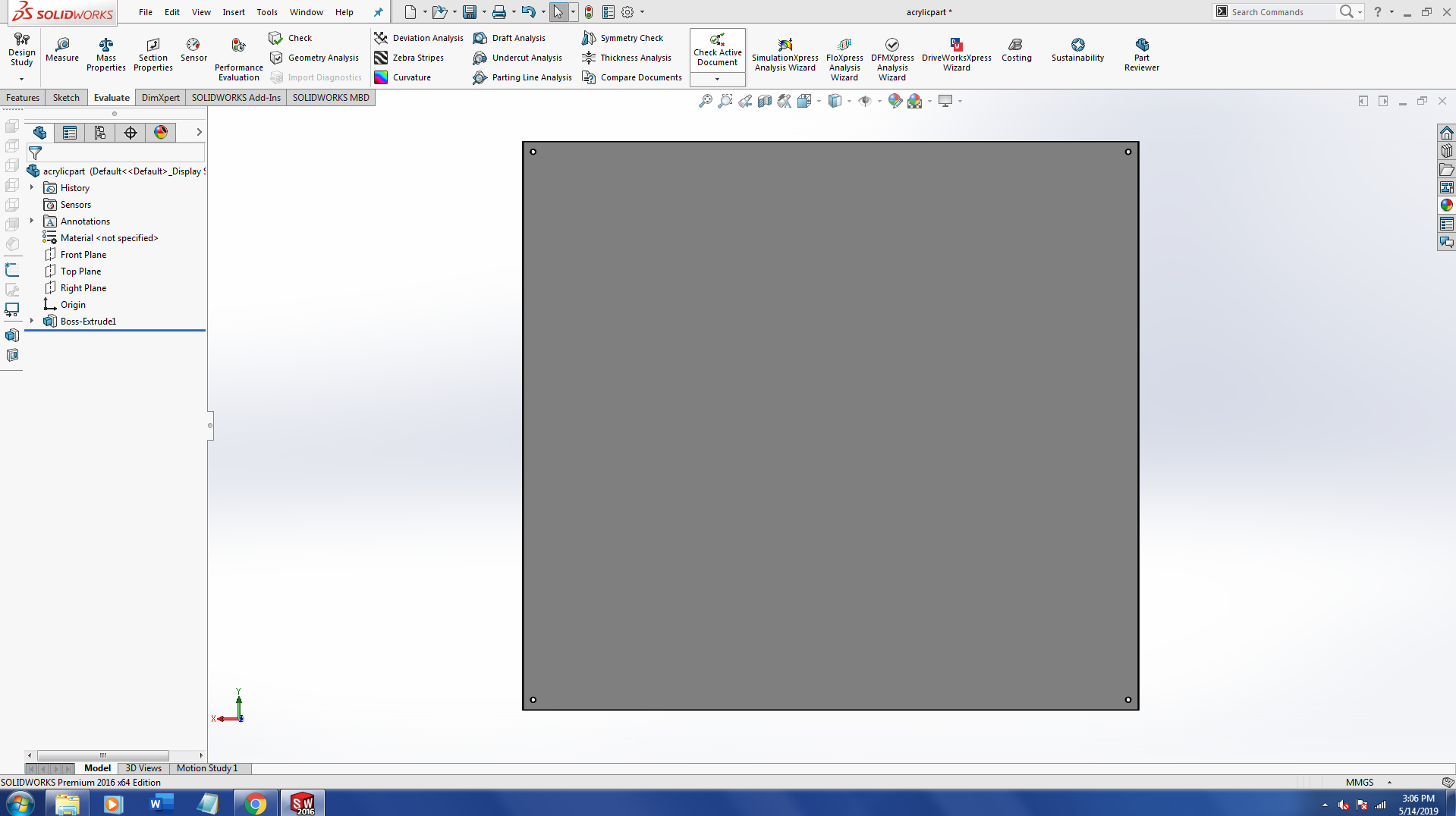

This week's requirement is to design the mechanical design so for that our machine's body is primarly made of mdf cardboard. Cad modeling is part of our group member Mr. Tariq Shaikh where he used solidworks software for designing the mechanical design of vending machine. The cad is comprised of different parts like base part, back part, six discharging units and front panel with cash less payment and coin detection system. All of the parts are shown below in figure (a). Rendered assembly image is also shown figure (b) which looks real :D Figure (c) shows the acrylic based front side of vending machine which shall be laser cut after cnc machining

CAD Parts

(b) Rendered image of CAD Model

(c) Front Panel made of Acrylic sheet in solidworks

In order to avoid mistakes in cnc milling we initially laser cut the designed model by using cardboard with thickness of 4mm. Press-fit laser cut model is shown in figure below. From this laser cut we observed that there is no any such error in design therefore we can now move to cnc milling just to get the actual design.

Laser cut of cad design

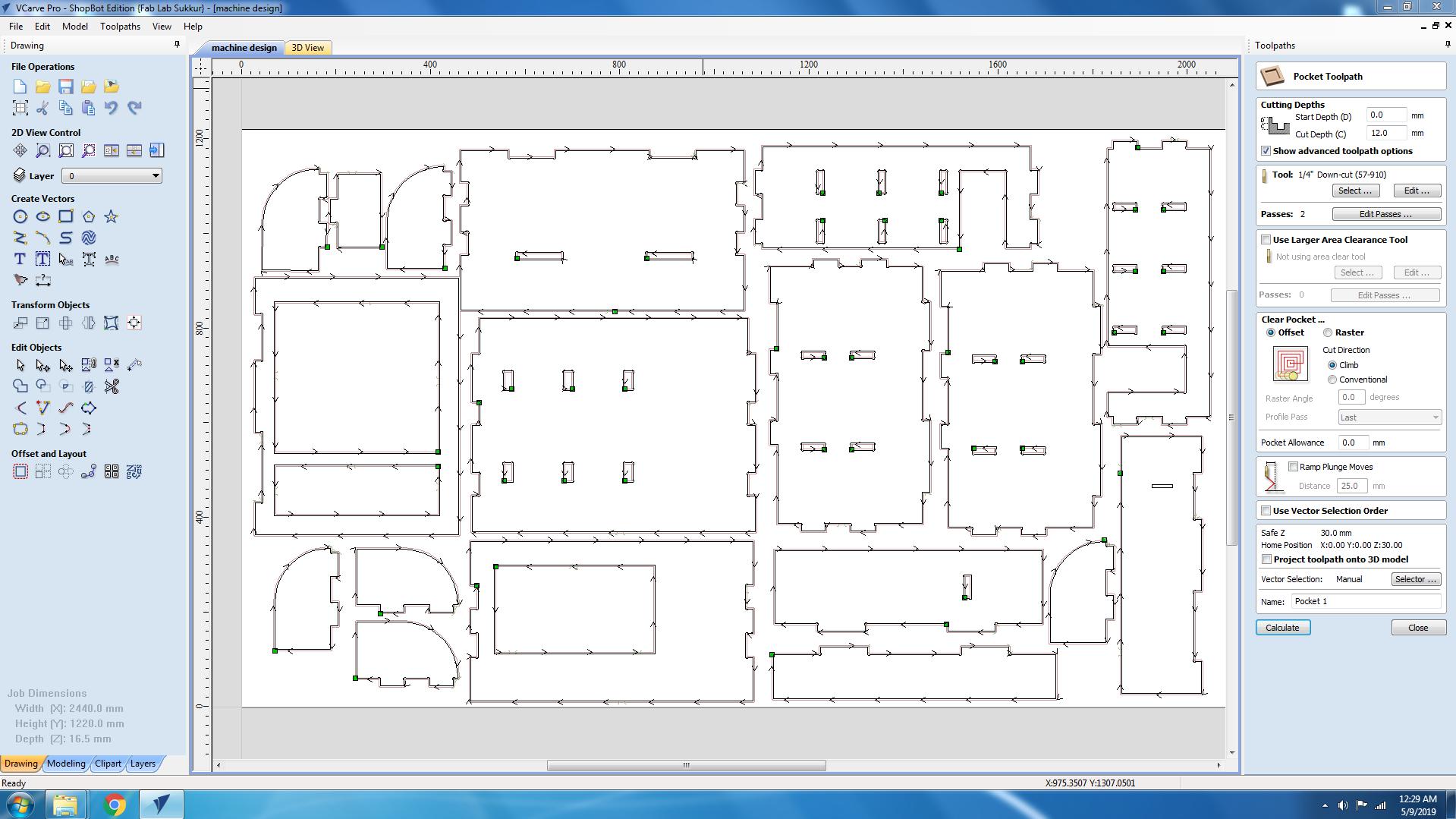

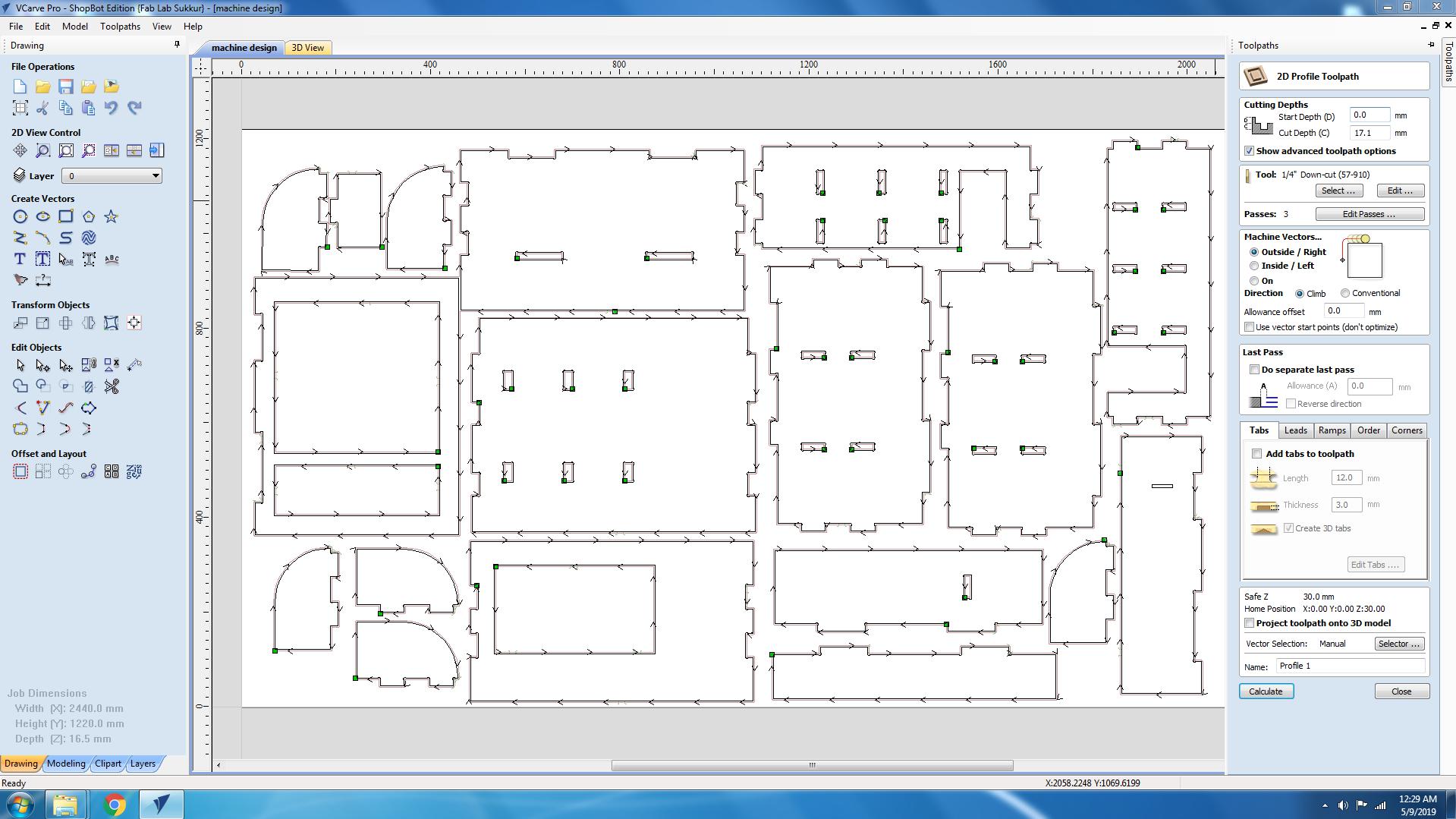

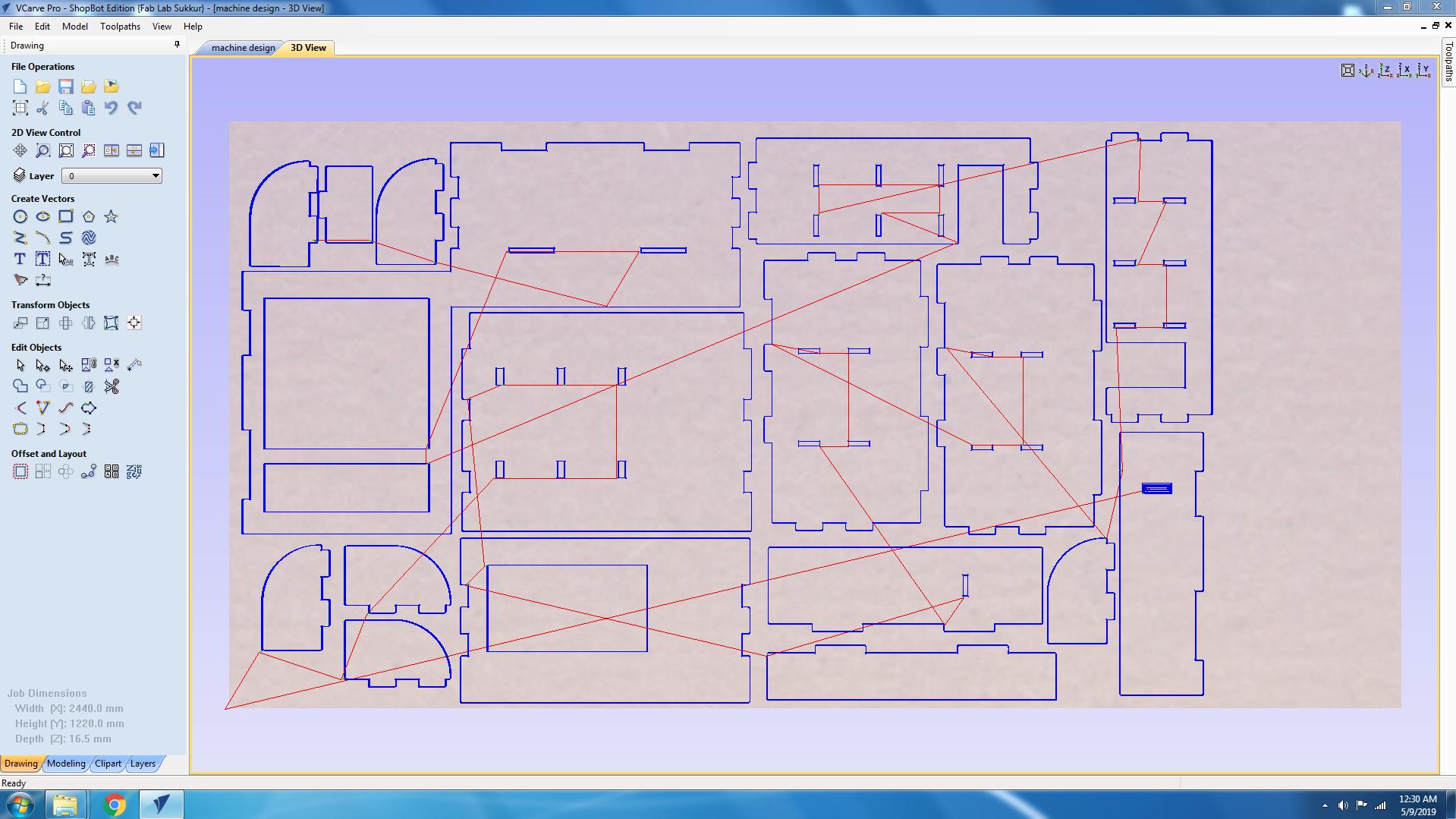

This part was done by our group member Mr. Haider. In cnc milling we normally use vcarve software for generating toolpaths. Before generating any tool path he used dog bones in order to pressfit the design accurately and used tabs at various points just to hook up the parts in mdf card board. Since we are using the Liquid crystal display (LCD) so for that he used pocket toolpath and for cutting he used profile toolpath. The generated pocket tool paths, profile toolpaths and 3d view of toolpaths is shown below in figure(a), (b) and (c) respectively. Furthermore it can also be seen in figure (a) that there is joint between two parts i-e front panel which is minor mistake and was resolved after cnc milling.

(a) V Carve pocket toolpaths

(b) V carve profile toolpaths

(c) 3D View of toolpaths

We tried to cut this in shopbot where we used laminated 16mm thick mdf sheet. After cnc milling we assembled this machine in a team and proceeded further. The cutting process and assembly of design is shown figure (a) and (d) respectively. Furthermore we laser cut the front panel which is also shown figure (b) and (c). It was nice experience to work togethor.

(a) CNC Milling by Shopbot

An acrylic white sheet is used to cut the fron panel of vendig machine. In order to give it a look we just wrote the name fab lab khairpur and vanding machine at upper side of the panel. video shows the cutting process. All of the process was carried by our mate Tarik as he was assigned this part in group.

(c) Laser cutting of front panel

(d) Assembly of Vending Machine