Success is a journey, not a destination

Group Assignment:

- produce test coupons for your composite fabrication process(es)

Individual Assignment:

- read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using

- design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it, with resin infusion and compaction

What's different about this week's assignment?

This week is named as wildcard week, so I was expecting that may be we will be given some time to complete the previous assignments or we can get any different assignment which includes the fabrication tools that were not used till now. So, my second guess was right. It is really going to be an intersting week of learning and making new things. This week's task is to make something by employing the learnt CAD skills along with the digital fabrication process used and then document it. There were following choices given to us :

Why did I choose to make something using Composites?

I really wanted to try this different way of making things using different kind of resins. I have seen some creative ideas on pinterest incorporating composites.In addition to it, Mr. Francisco Sanchez Arroyo had come to visit Fab LAb Khairpur during week12 , and he taught us about shopbot and gave us some basics on composites too. So, I wanted to do make something practically using that knowledge.

So, What do we mean by composites??

Basically, composites are the combination of some components having different physical and chemical properties, which combine to make a composite , which is stronger than the individual elements.Composites can be natural or synthetic. Wood, a natural composite, is a combination of cellulose or wood fibers and a substance called lignin. To make a composite you need four things:

- mold or internal structure

- fiber based material to combine with resin

- Resin

- force or pressure to compress the composite as it cures

For making a test design we made a simple curvy shape in solidworks.The Curve was saved as .stl file and the tool path was generated in Vcarve. All the steps for making the composite are given below and also illustrated through pics.

Initially, a new Vcare file was opened and the dimensions were set according to the size of the model (370 by 370mm).Then by importing the Component/ 3D model , the model is imported. Here we make some settings as described in the video attachd for individual assignment section.

.jpg )

In the next step we place the model at center so that the model comes inside the dimesnions we set.

.jpg)

From the toolpath tab, we generate the toolpath for roughing and finsihing.

.jpg)

.jpg)

.jpg)

The next step was to cut the model on the 50mm foam, the toolpaths were generated and then used in cutting on shopbot.

.jpg)

We are using Jute as the fiber, we already cut the two pices on Laser cutter. The arrangement of the composite is shown below:

- Layer1:Food wrapping plastic

- Layer2:mold of oam covered with wrapping plastic

- Layer3:2 pieces of jute fiber mixed in resin

- Laye4:wrapping plastic

- Laye5:Breather for vaccum

.jpg)

.jpg)

.jpg)

The model ws put for curing for the whole day and then the next day, we removed the mold and removed all the extra layers.

.jpg)

Individual Task:

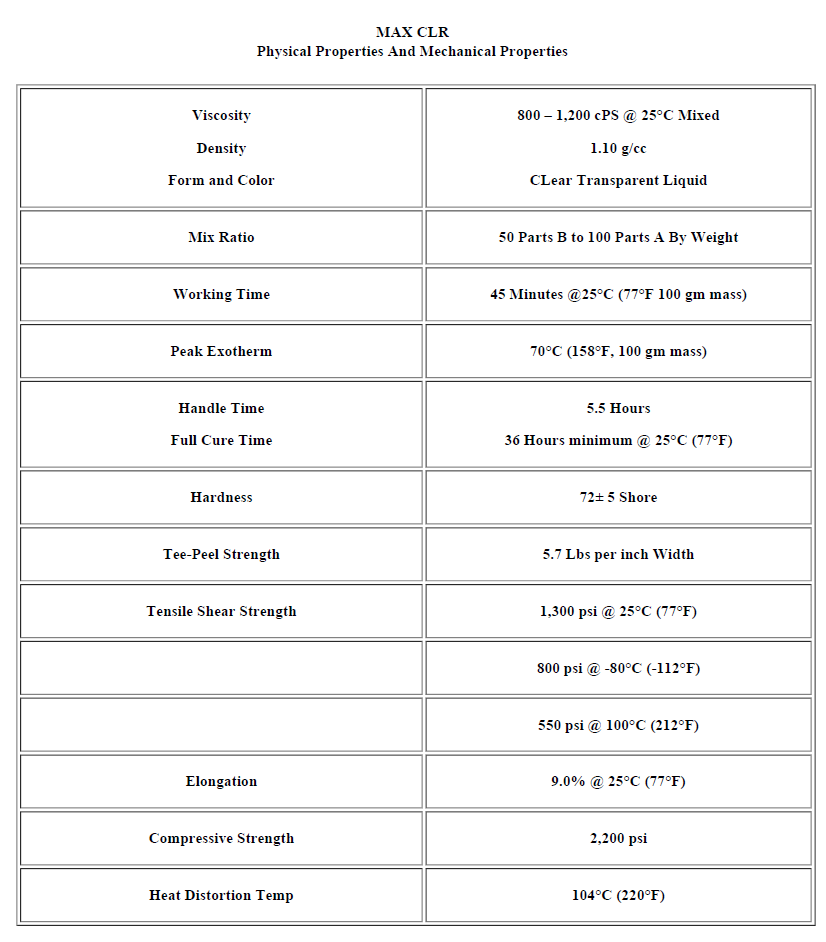

We are required to make a 3D mold and then make a fiber composite part in it using resin and compaction.The first thing that I needed to do was reading the datasheets of the materials , and use the analysis obtained from group assignment.

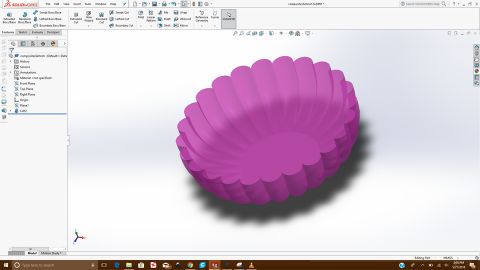

Initially, I made a bowl in solidworks but while toolpath generation i gor error due to the structure of model.

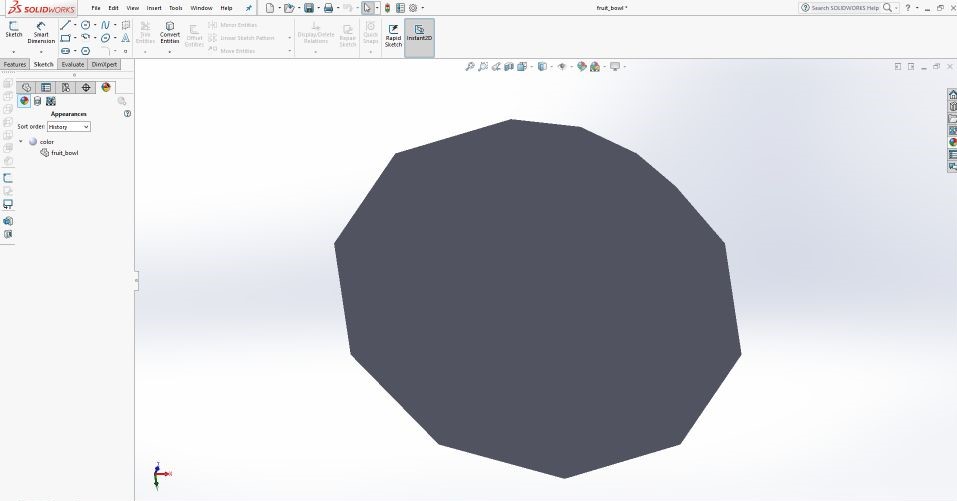

Then I made a simple structure, which can be used as a plate for fruit or like stuff in solidworks as shown below:

Generating the toolpath:

As we know that , we need to make the mold by roughing and finishing through shopbot, so we need to generate the toolpth first. The whole process is shown step by step in the video below:

Milling the mold

The shobot machine was used for milling and the pictures during this process are shown below:

And in order to make the mold , the next step was to do finishing as shown below:

Then I prepared the resin by using the following materials:

The datasheet of the material is given below:

- Layer1:Food wrapping plastic

- Layer2:mold of oam covered with wrapping plastic

- Layer3:2 pieces of jute fiber mixed in resin

- Laye4:wrapping plastic

- Laye5:Breather for vaccum

The mold was then placed inside the vaccum bag after using the arrangement given below

The files for this week are attachedHERE

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.