Applications and Implications

Final Project: Autonomous manure grinder for a turkey farm

Problem: When the manure is compacted due to the weight of the birds and to the humidity a suitable environment for the fly larvae is formed. So one way for have some control upon this plague is manualy collect the manure.

In the video, you see the initial stage of breeding, but as the weeks go by, the manure weighs more, and collect it up requires more effort and time.

Another way to control is use a walking tractor, which has the objective of mechanically destroying the larvae environment.

So, i was looking for something similar but autonomous. So far, the biggest restriction for me is the amount of energy a machine needs to do a similar job, assuming that the project will only have electricity and not fuel. So I looked for an alternative that does not require such an aggressive torque, and I found this: (see from minute 9)

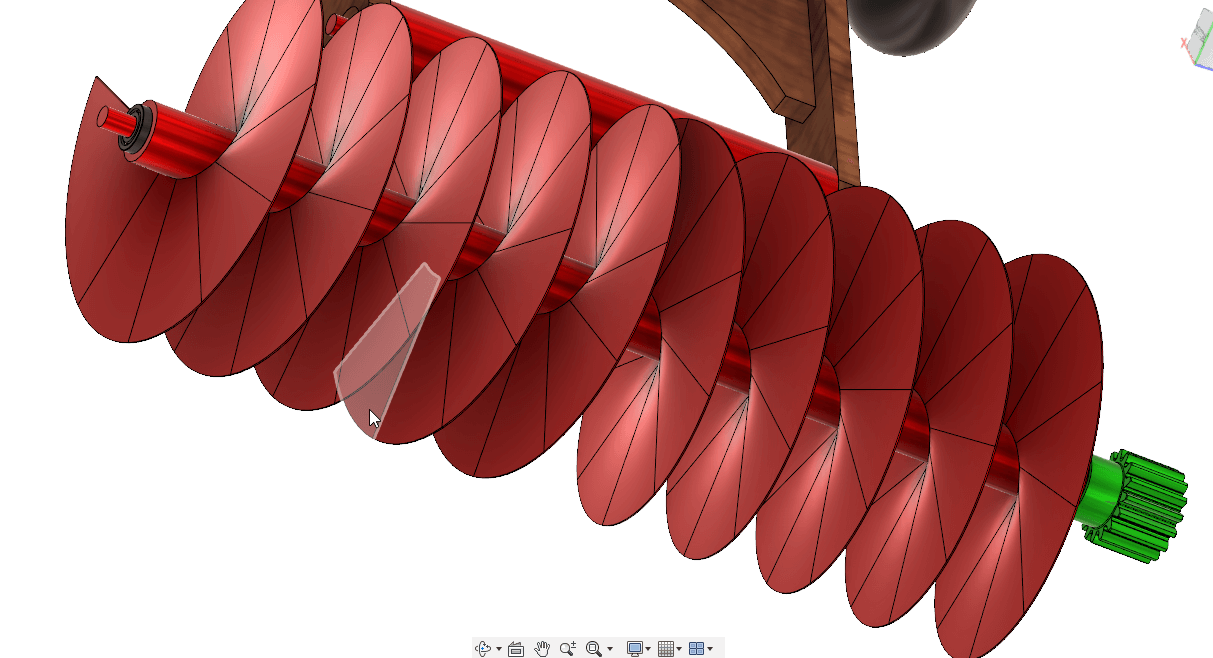

This is a system that uses a double endless screw, takes the material to a conveyor belt and then uses a pair of propellers to return the material. (The design is in progress)

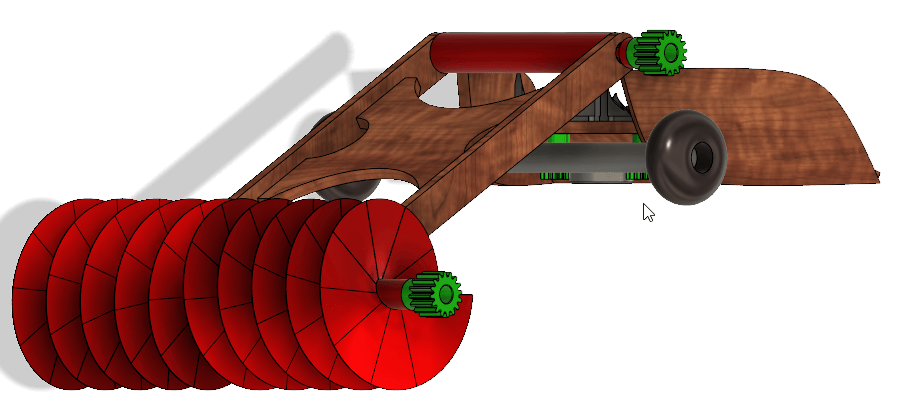

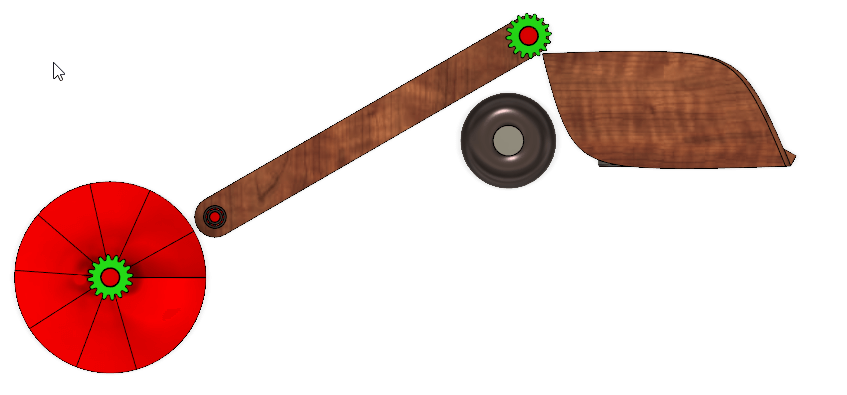

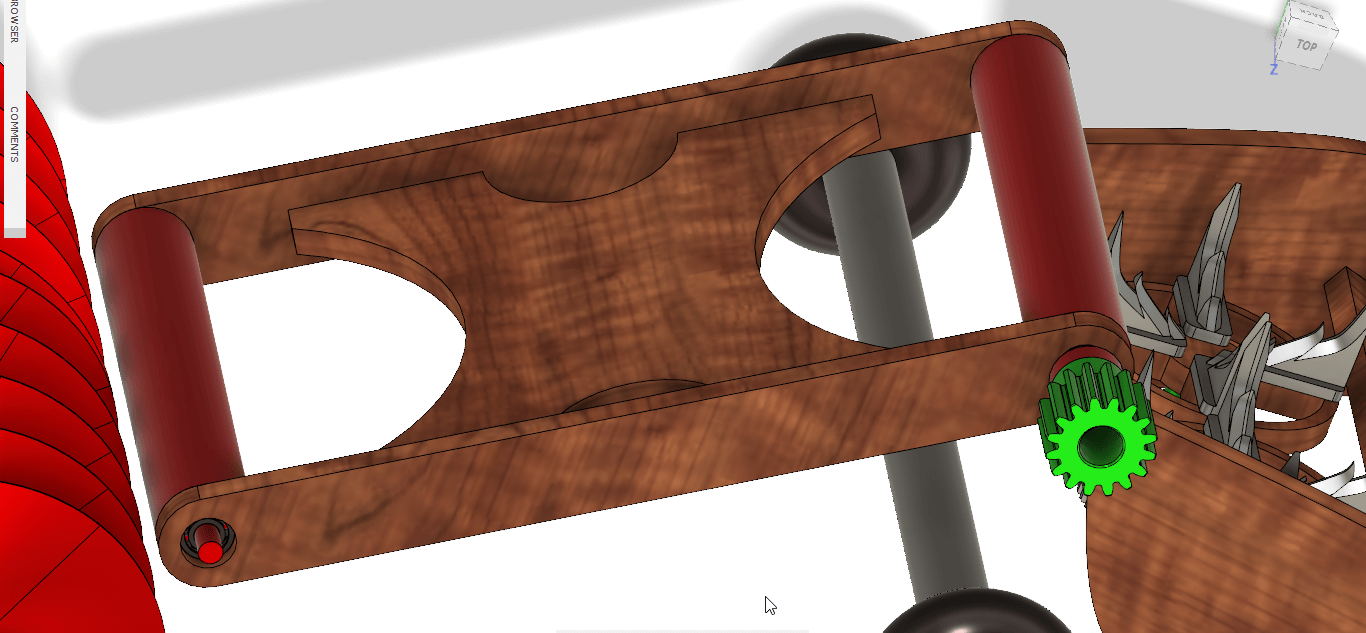

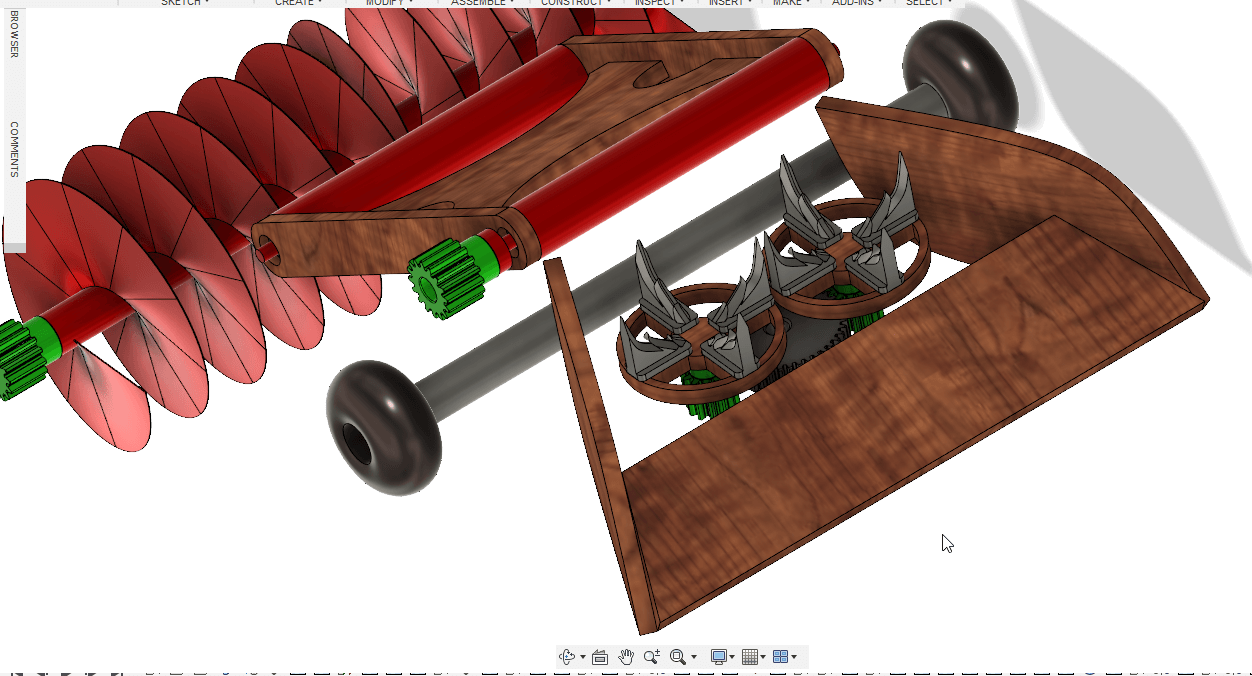

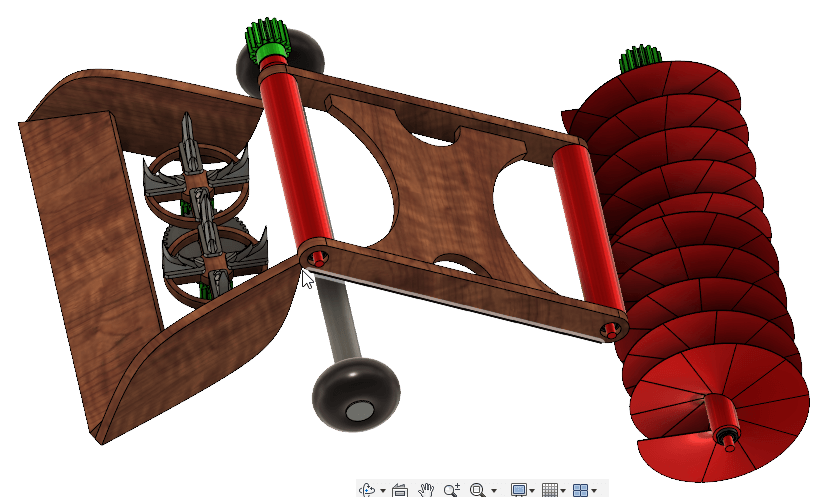

In the case of my design, the part of the system to remove the manure will not be controlled, I will only use dc motors and a switch to turn on the system. This system consists of three parts: the endless screw, the conveyor belt and the propellers to break the material and return it to the ground. Each system is independent and will be driven by an engine of each.

The endless screw takes de material from the ground, it has an offset of 20 cm below the floor, because the "bed" of manure has this width.

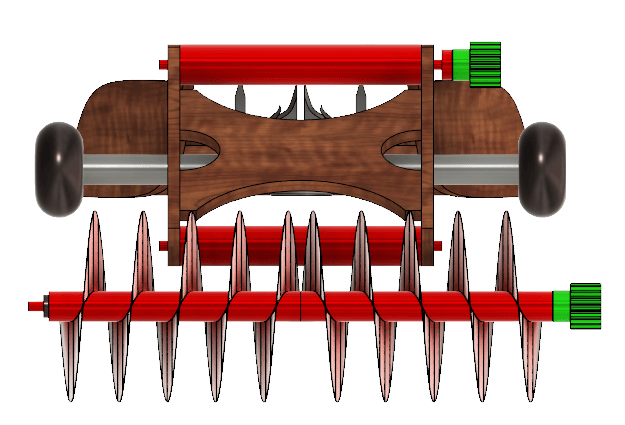

The conveyor belt picks up the material and climbs it to then throw it towards the propellers.

The propellers rotate and split the material at the same time they eject it due to the centrifugal force that is generated when turning.

The part that will be controlled is that of the car system, which will use an ultrasound sensor to avoid obstacles, and a DC motor on each wheel to be able to maneuver.

I still do not know how I'm going to manufacture some things like the endless screw or conveyor belt system. The body or skeleton of the car will be made with playwood 15 mm thick, some parts will be made in 3d printing.

I got some engines in a used goods store, the cost of the DC motors was $ 3.00 each (and there are two) and the step motors also cost $ 3.00 each (and there were 3), plus drivers for the step motors. They cost $ 4 each (and they were 3) so far I have spent $ 27.00.

These are some interesting experiences of robots on farms

How will you evaluate your machine?

- Operation of the electromechanical system

- The implement must be of sufficient size and strength to move the manure (bed)

- The speed of advance must allow efficient work of the equipment