Fabacademy 2020

What are composites?

Composite material is made up of two or more materials combined together to make a superior material. The main constituents of composites are a matrix and a reinforcement. Polymers are the main matrix materials, here we are using epoxy as the matrix material. The reinforcement materials are fibres, here we used burlap and cotton cloth as fibres material. The main advantage of these are light weight and high strength. For my first work, I thought I would make an fruit bowl. I really like the idea of fruits kept on structures made of leaf but sice leafs dont last long, I would like to make a composite bowl which looks like made of leafs. It would be bit tricky since leafs have intricate patterns but it would be an interesting experiance.

Group Assignment

The group assignement for this week is explained in detail in the group page. To access the group page click here.

Mould designing

To start with the mould.I tried to look out how to get a shape a bowl and saw several methods to make a mould. Milling of wood using shopbot, milling using a thermocoal, using wax and laser cutting. I was interested to use laser cutting since the other methods are a waste of material and time in creation of mould. With laser cutting we can create a mould using material like cardboard or balsa and can be done in just few minutes.

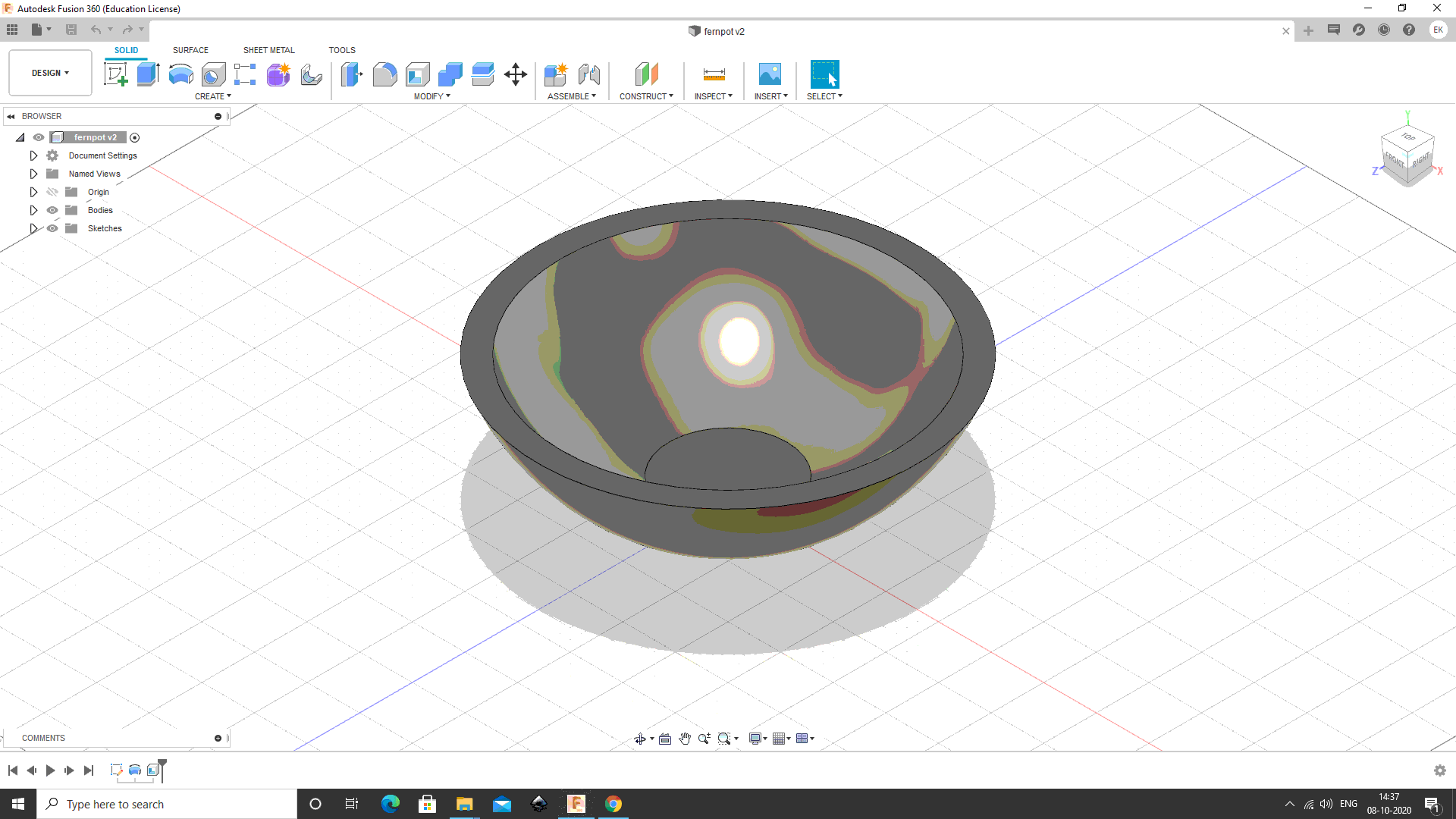

I started to design the mould in fusion 360. And after all this weeks of designing it was a simple process.Iniatially i thought of designing the complete bowl using parametric method, but i was interested in using slicer for that purpose. I saved the stl file of the design to use in slicer.

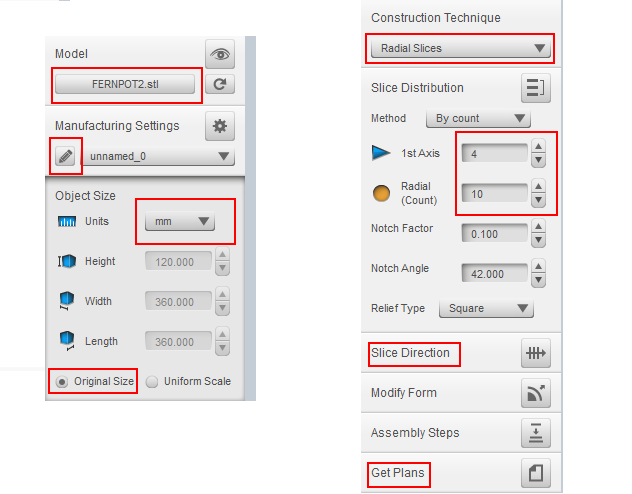

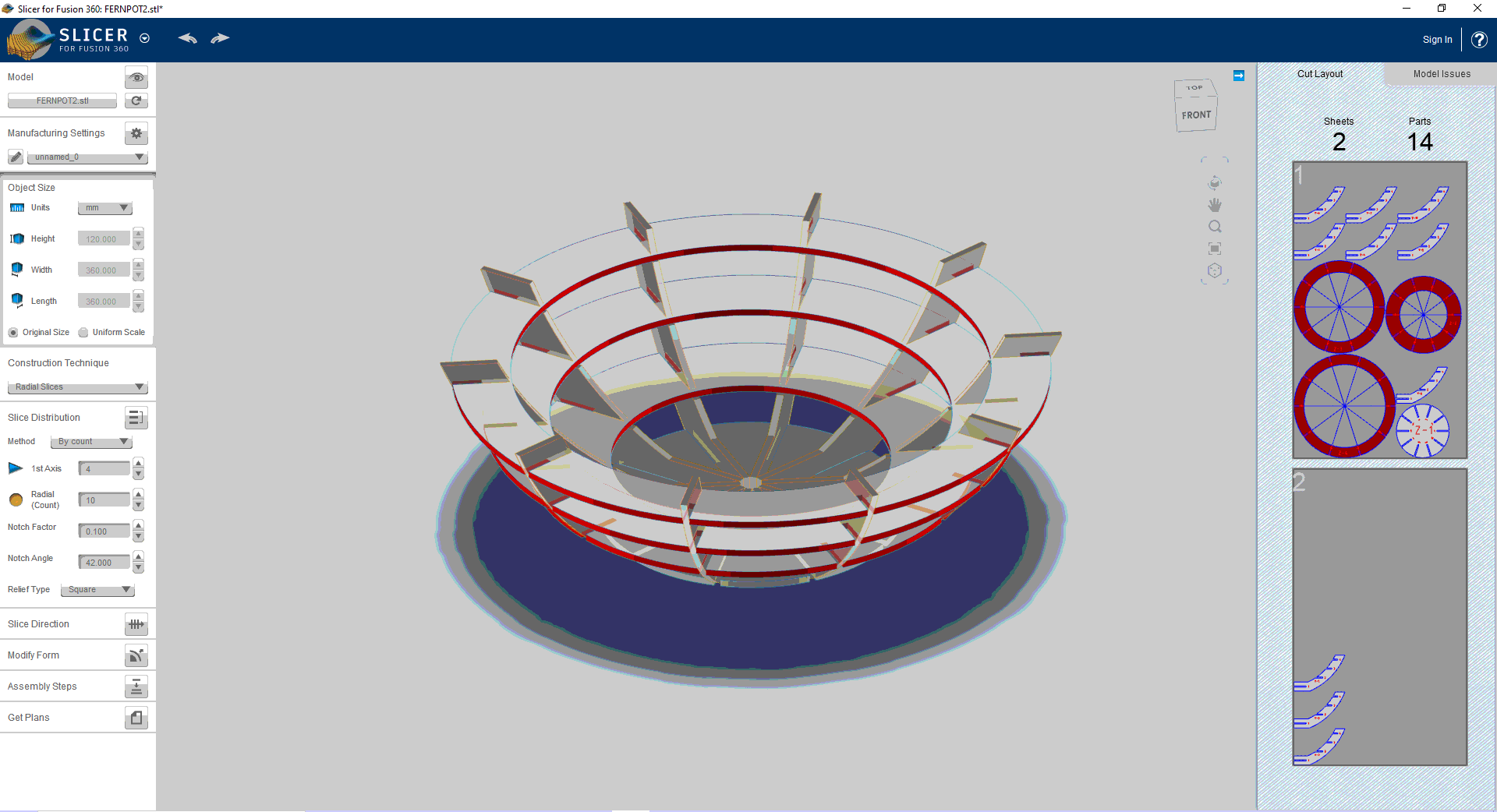

Slicer software is available for windows and mac.The instalation was pretty straight forward. The stl file was imported to the slicer.

At first Import the file. Then change the Manufacturing settings so that the slicer can arrange the files based on the bedsize of the laser cutter. Change Object size accordingly. After doing these steps we need to decide which type of construction technique to use. After that change the SLice distribution to decide the number of slides. Then change the Slice directionfor the right angle to slice.

After all these operations the plans can be seen in the right side of the window. I found radial direction better which takes only minimum material. After these steps click get plans and save the file as dxf.

Laser cutting process

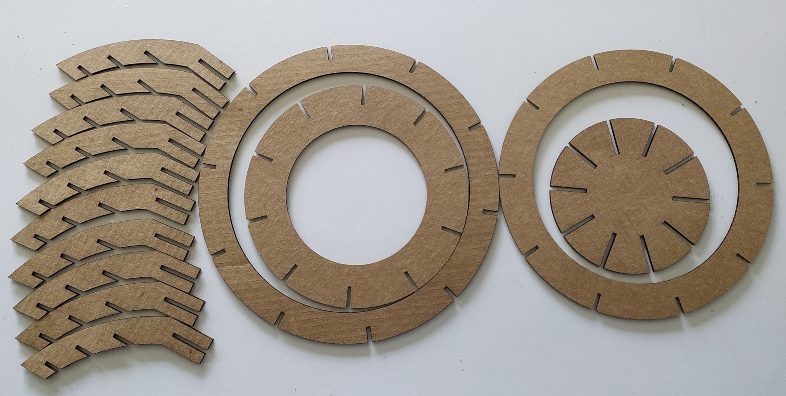

For the process of mouldimg i used cardboard.The cut file is arranged properly and cut pieces after laser cutting can be seen.

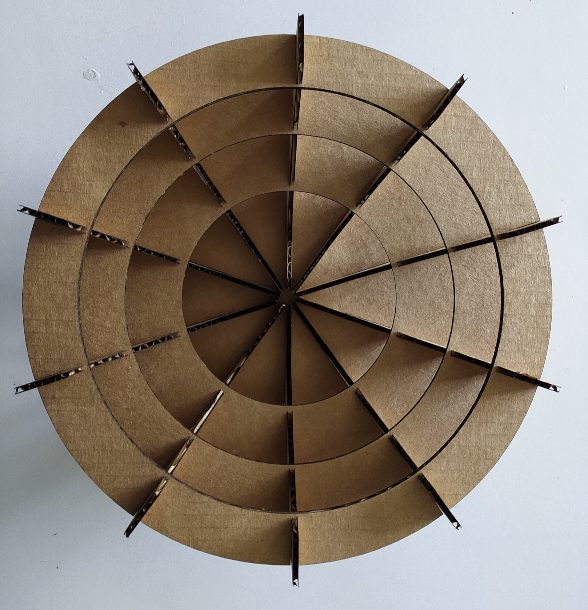

Arranging the cardboard was simple since i am used to it now.The top portion of the mould can be seen

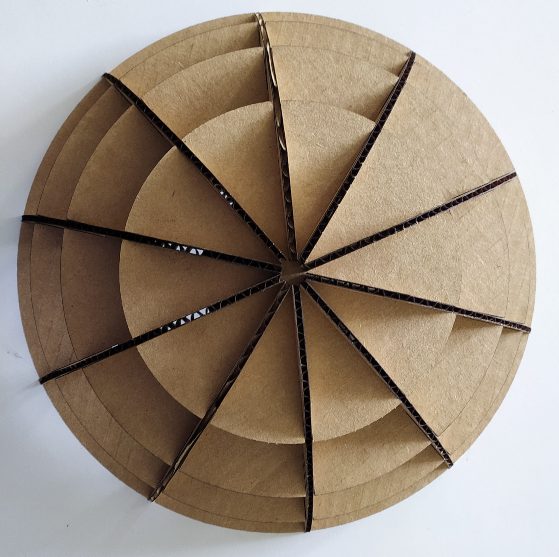

The bottom portion of the mould.

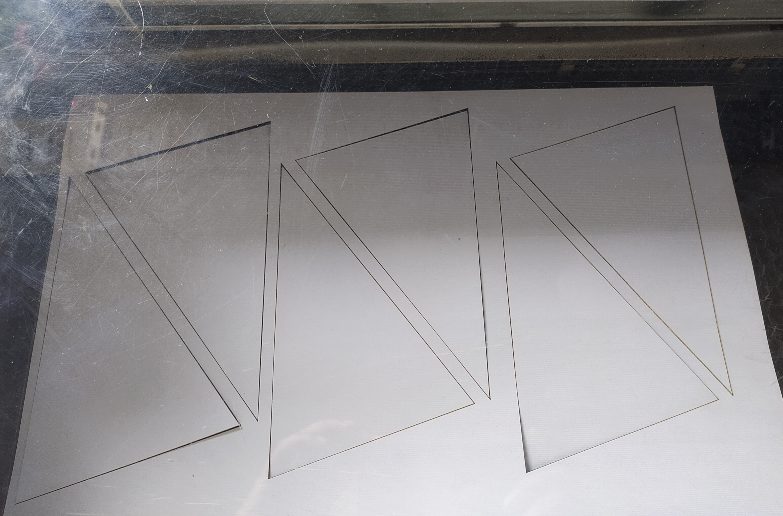

It is essential to have a uniform surface for moulding.So to get a shape of the bowl i decided to use a thin sheet of paper. I used laser cutting to make several triangular pieces of paper.

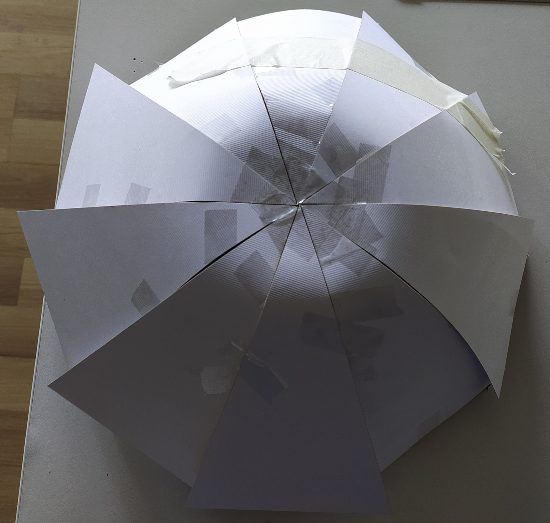

I stuck each sheet of paper on the cardboard to form a even surface.

After that to make a sticky free surface i used cello tape to cover the surface everything was stuck perfectly and the mould was stable with a uniform surafce.

Fabric designing and cutting

Since i decided to make a fruit bowl in shape of leaves. I have to make a design which can be used cut the fabric. Iniatially i was planing to make a fern based fruitbowl but since it would be hard to arrange it precisley. I decide to use oak leaf.

For that i purpose i downlaoded an image of Oakleaf from net. And processed using inkscape.

Using bitmapping i mapped the oak leaf and converted it to vector format.And made a a design to cut the fabric.

I used linen fabric for the fiber part of the composite.I made linen cut of appropriate size for the laser cutting the design

SInce the laser cutting machiene had some issues identifying the curves, the cutting process was bit slow.

After the laser cutting process.6 pieces where cutout to give enough strength to the material.

composite preperation

For composite preperation the linen material is coated with epoxy.And is kept for setting.

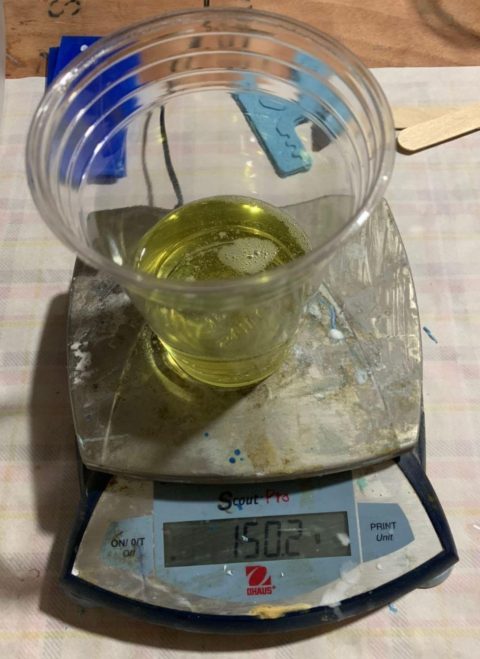

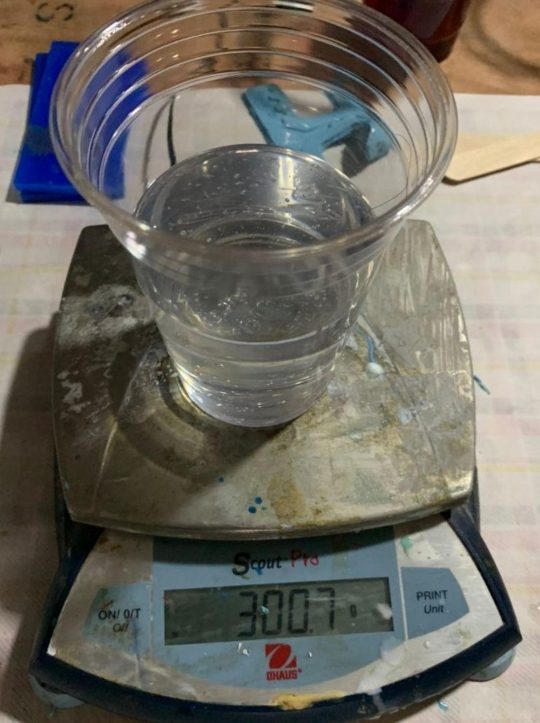

The epoxy used is indian made. The epxoy consits of part A and part B. The part is the epxoxy solution and part b is the hardner. Part A is mixed with part b in ratio 2:1 of weight respectievely. It takes 24 hours to set.

First i arranged the pieces and planned how to arrange the leaf patterns.

First I took epoxy part B - 150 g

I wanted to give a colour to epoxy. So i used a 0.5 percent of red colour dye and mixed it thoroughly.It was mentioned in the data sheet that colour dye should be added to part B.

Ater that i measured 300 g of part A.

After that i mixed the epoxy part B to part A.

The mixture was mixed toroughly untill the complete solution was mixed uniformly.

Each fabric piece was dipped in the epoxy and placed on the mould perfectly.

After placing the individual fabric pieces perfectly. The epxoy was brushed on to the surface of the fabric

Next step is to create a vaccum enviormnment so that the composite sticks to mould perfectly. The mould with composite was covered with a sheet of plastic. And closed at one end as shown above and using a vaccum cleaner a mild vaccum was created. And the setup was kept aside for 1 day to set.

The composite came out better than what i expected.

View of the bowl from the side.

Overall the wildcard week was interesting. I learned process behind composite making and how epoxy can be used for various purposes.