Week Six

Print something with the 3D printer and scan something with a 3D scanner.

3D Printing

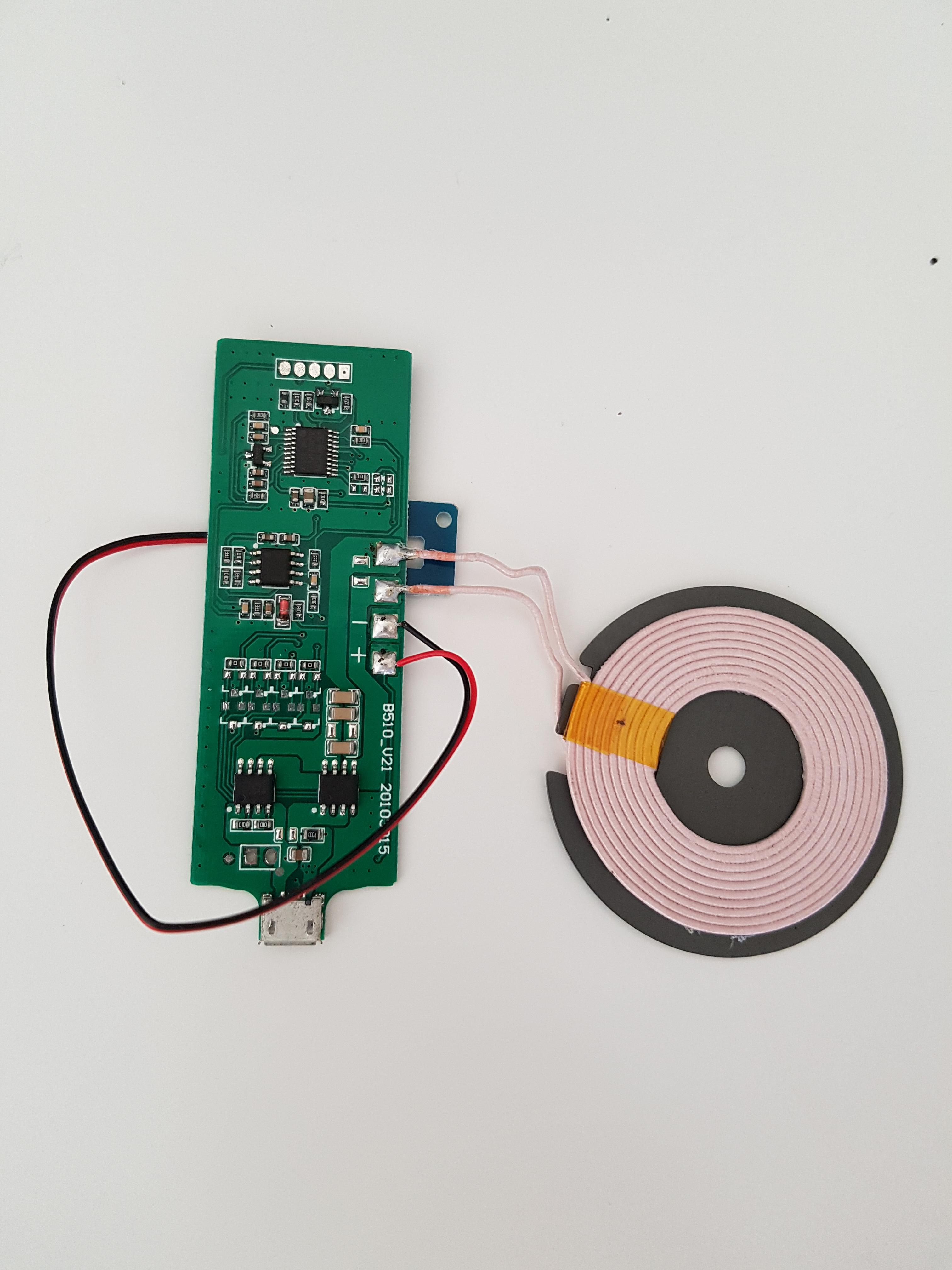

The role of a 3d printer in my eyes is to prototype concepts for future engineering. Whilst new filaments are becoming available for domestic printers with more dynamic properties, only a few enter the practicality of end market use, printing with materials such as glass cement or metal. For this project I chose to make a casing, with similar design criteria to that I will be using in my final project. The casing will house a QI wireless charging board and coil powered by a micro USB. Being a useful proof of concept.

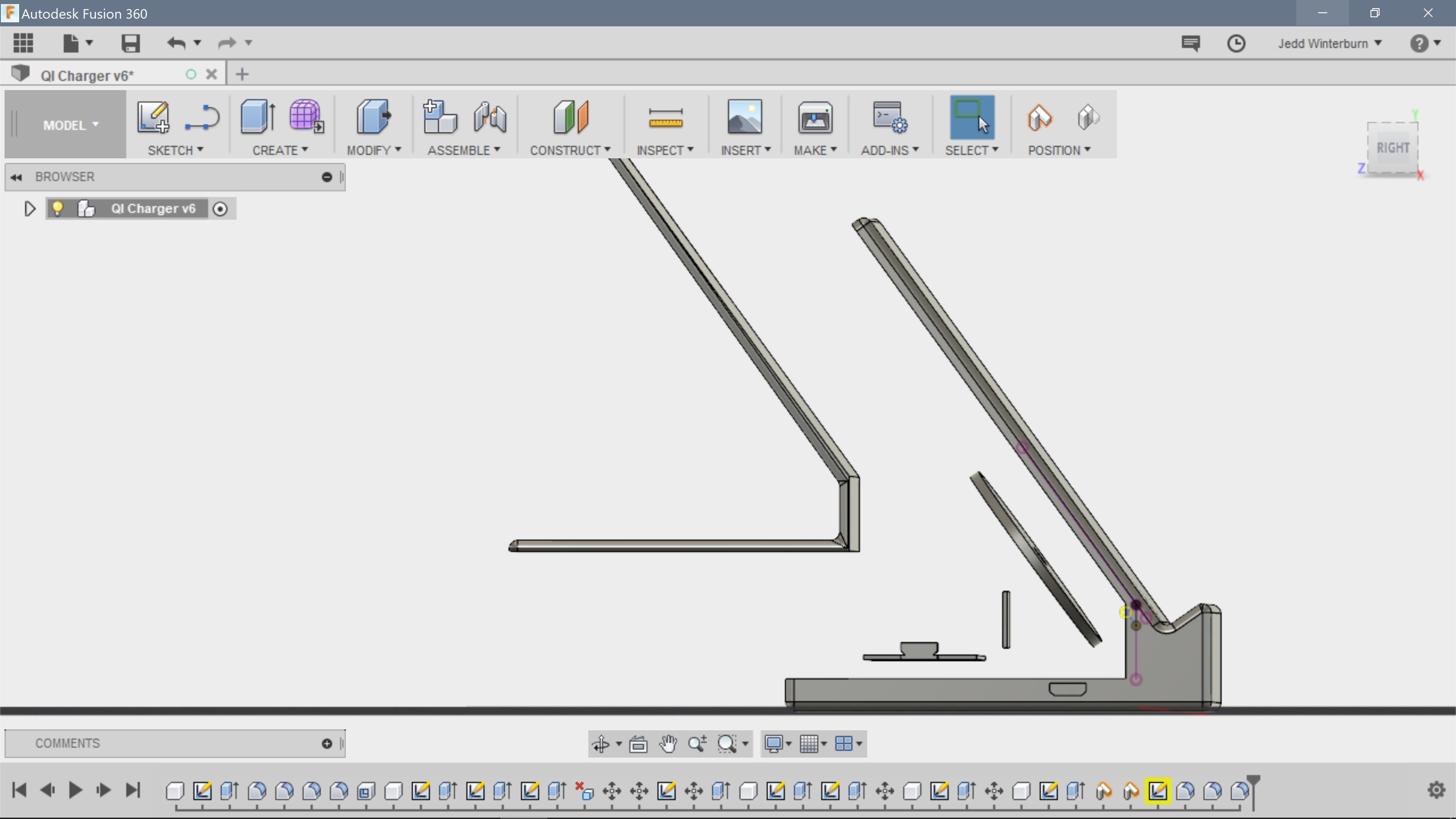

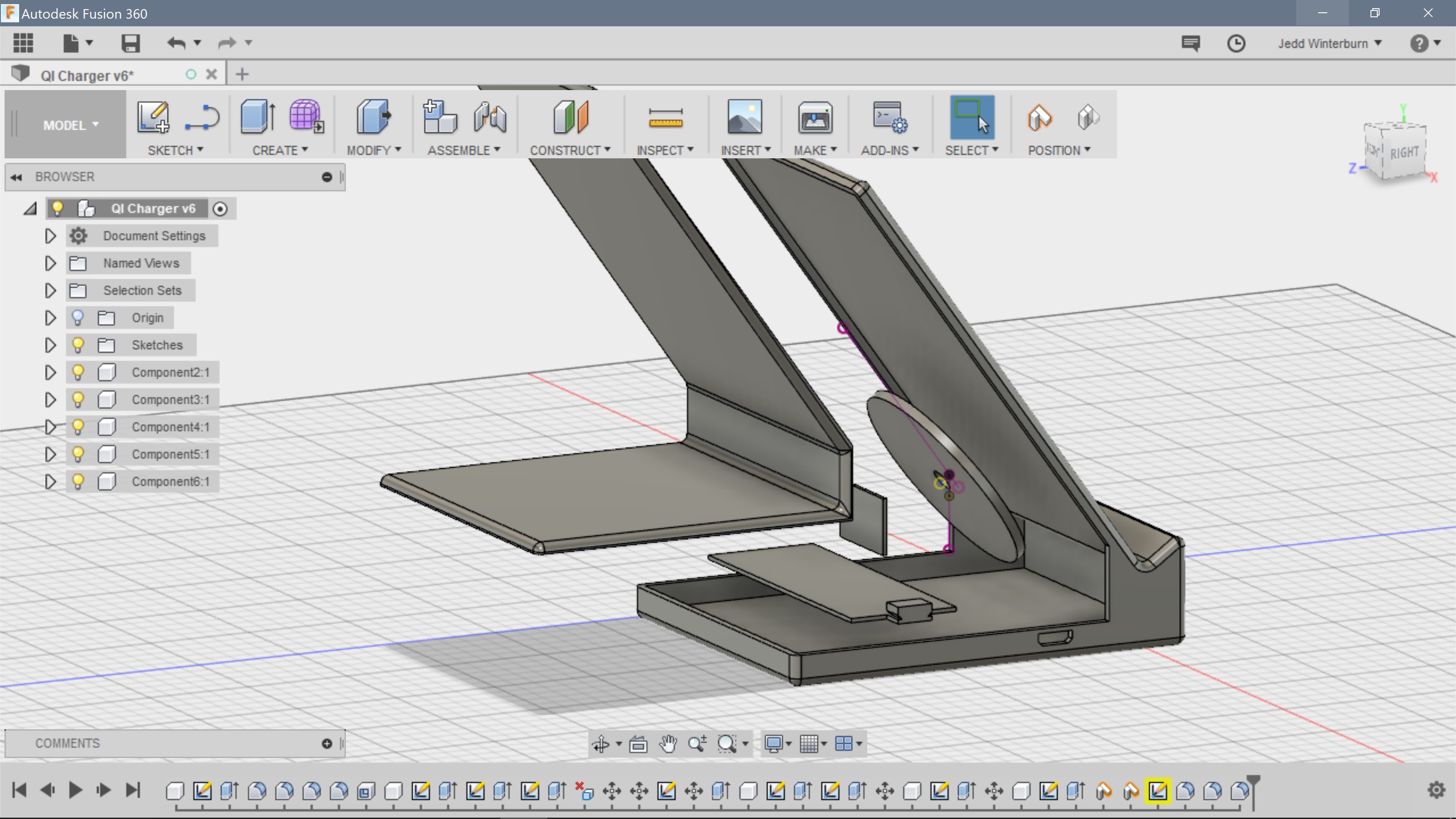

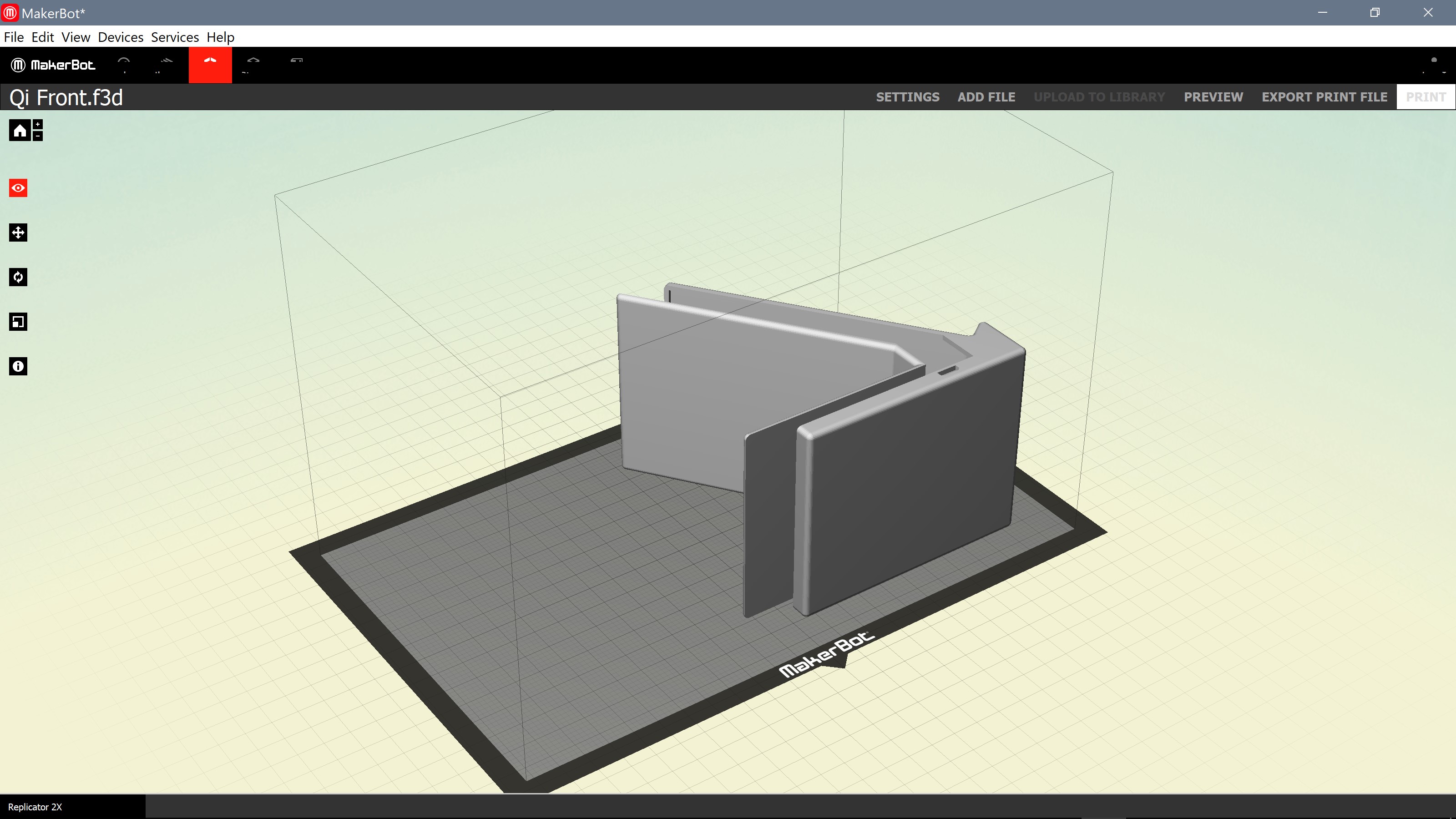

I began by modelling the parts of the coil and board of the Qi charger in Fusion 360. I then shaped a casing around the coil and board working from a basic sketch. I was aiming to create a mating connection so that the case would hold together, but the accuracy of my printer and time constraints made me push forward with the two parts relying on a touch of adhesive.

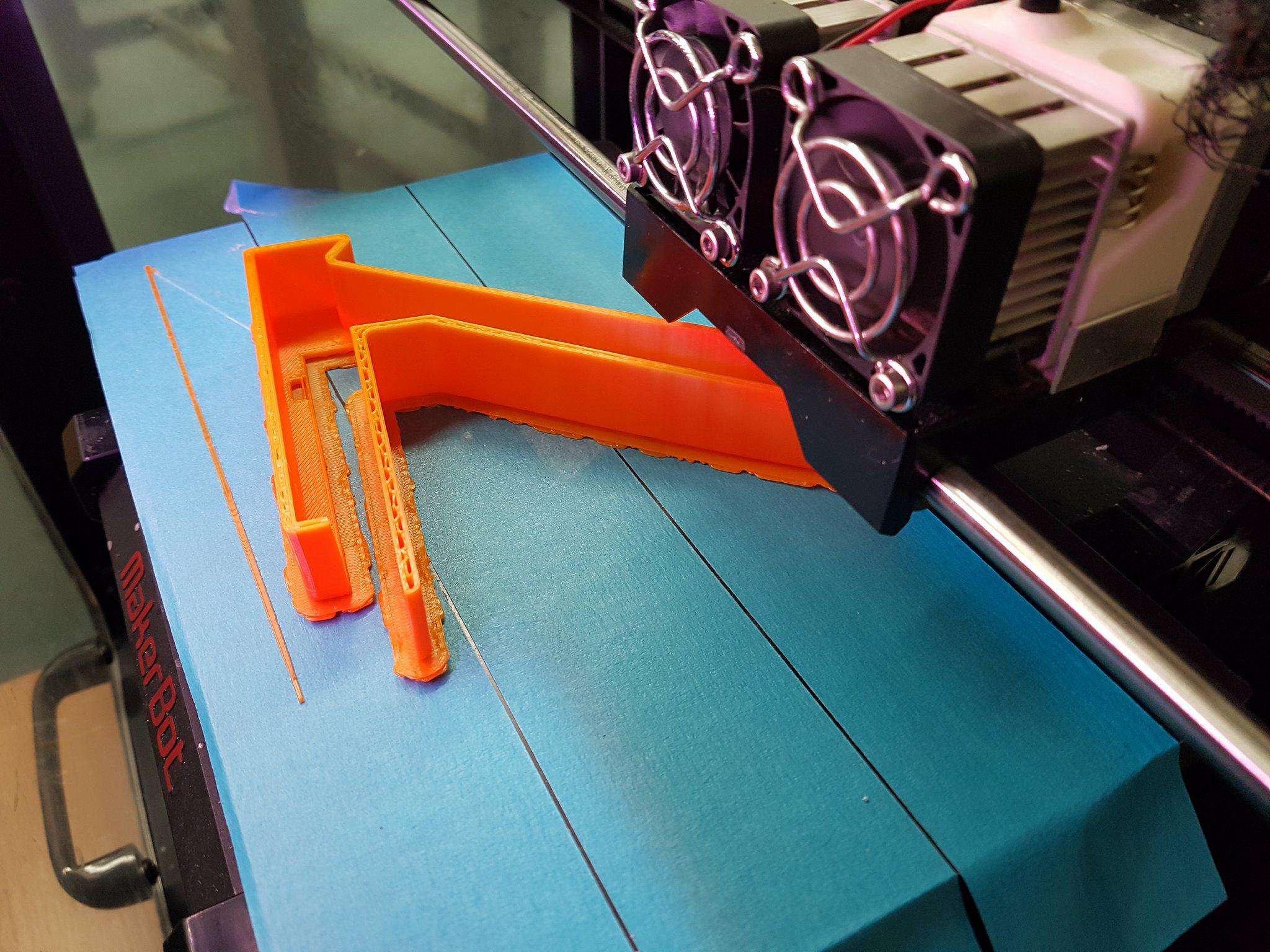

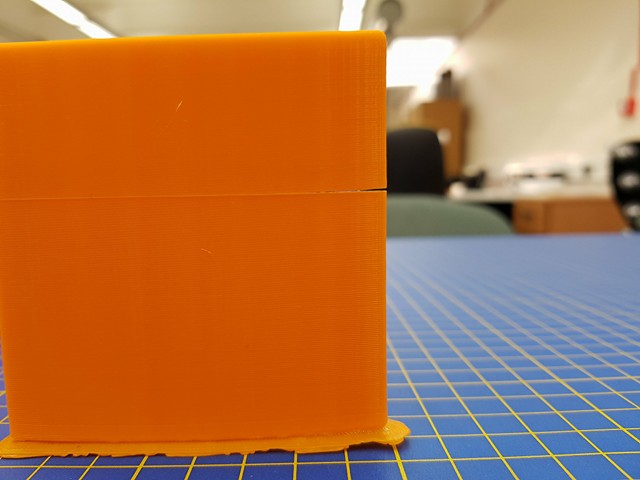

Whilst in a lengthy print, of around 5 hours, I came across two issues, my first attempt instantly was written off by not bonding to the bed properly, becoming a mess of filament rolling around the print housing. After a quick reset and some masking tape this seemed to work fine. Around half way through the print though my reel of filament ran out, but luckily our lab technician noticed and did a pretty skilful swap around on the fly. This did however leave a joining crease which I assume is from the filament cooling down too rapidly.

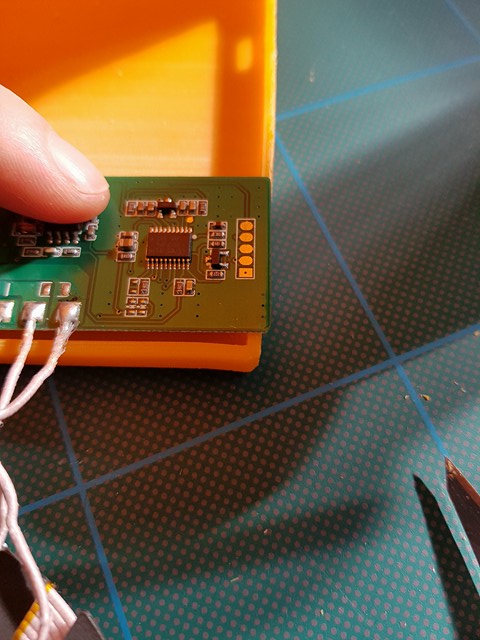

The shape finished with some contortion and what I can only assume was thermal shrinkage, as the circuit board could not fit directly in as it should, after checking my measurement inside Fusion the width of the part was lost somewhere in one of these processes, most likely being the printing. I amended the problem by sniping off the end of the board with some plyers. After fixing all the parts and case, we have a finished wireless QI charging stand.