5. Electronics production¶

This week I worked on the following 3 things.

Group Assignment¶

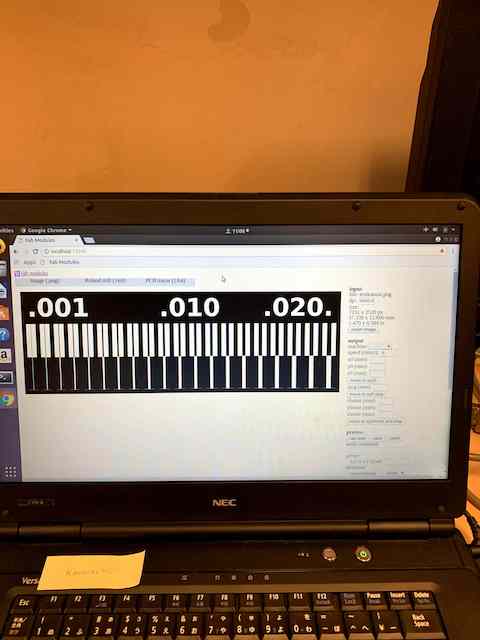

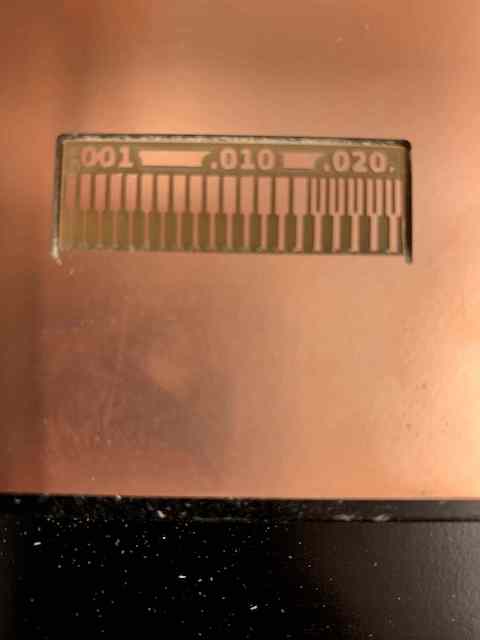

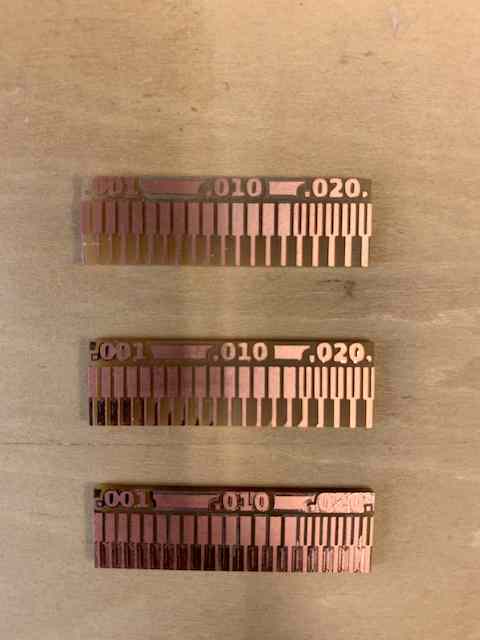

We worked on finding the best settings for milling machine. Here’s our environment

- Machine:Roland MDX-15

- OS:Ubuntu

- Software:Fabmodules

- Cable:StarTech ICUSB232V2

Firstly, we tried to print sample, but there was a problem trace interior

- When we hit a calcurate button, machine freezed for like 5 mins.

- Then we tried again decrease ofset from 4 to -1

- Machine worked well but horizontal level were not even

- We cut correctly inside but we had a problem with outline(only 3 lines milled)

- Convert image then change diameter to 0.3mm

- Problem solved

Milling and Soldering¶

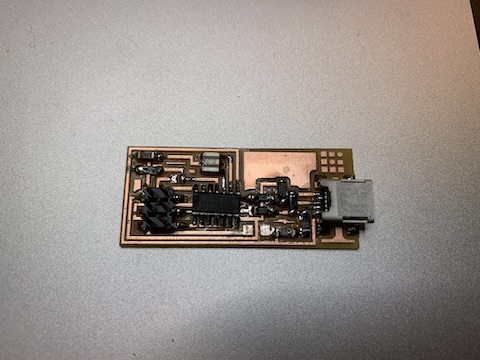

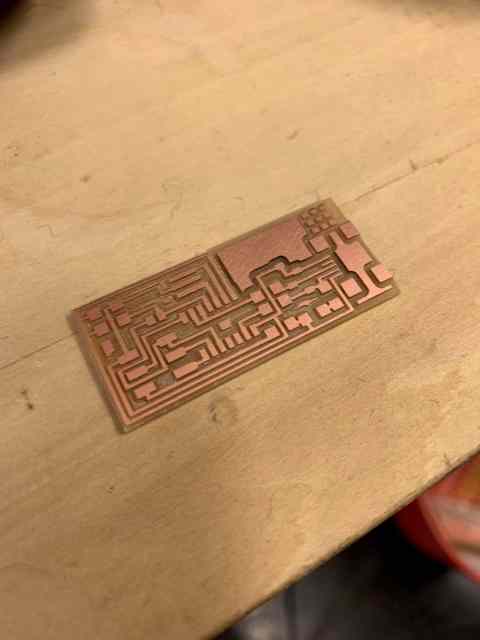

Then, I milled my own board through Fabmodules. I choose ATtiny44 for my ISP. So I downloaded traces and interior images.

I firstly forgot modfying cut depth, so I done the same process with 0.4mm cut depth. At the same time, I adjusted drill depth(pushed it firmly.) Milling machine worked properly and I got a board.

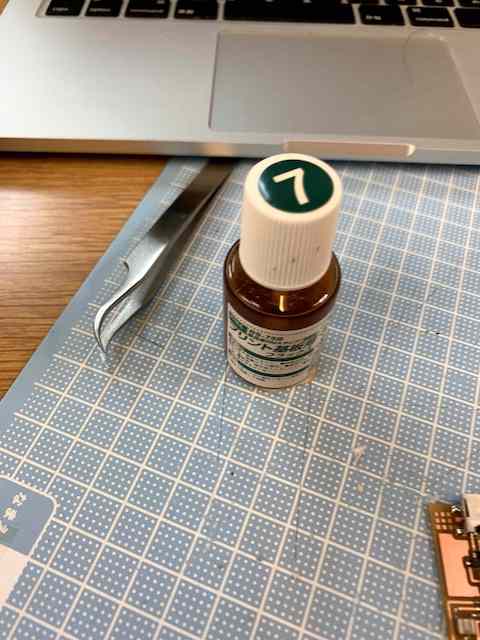

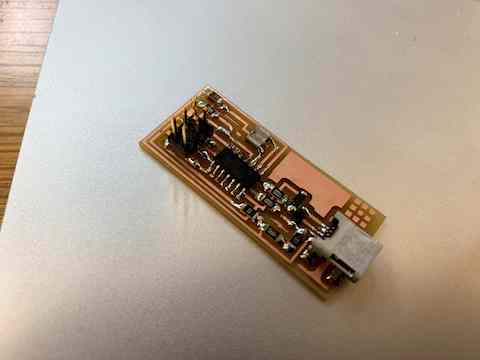

Next, I moved to soldering. For this time, I used 0.8mm solder. Soldered with 320 degrees celcius. To avoid mistake, I put all components on a paper as the same arrengement as the circuit.

I’m not good at soldering, so I used flux to stick the parts.

Making ISP¶

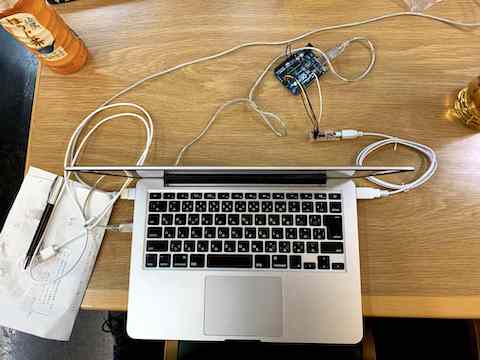

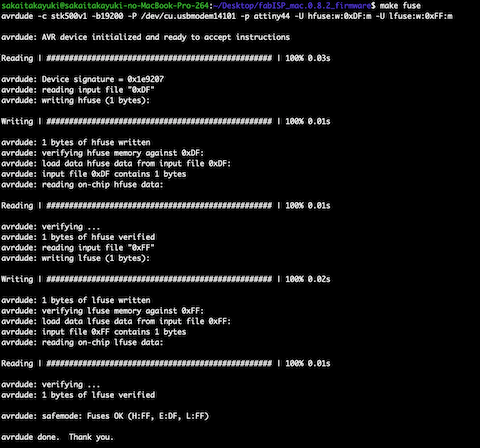

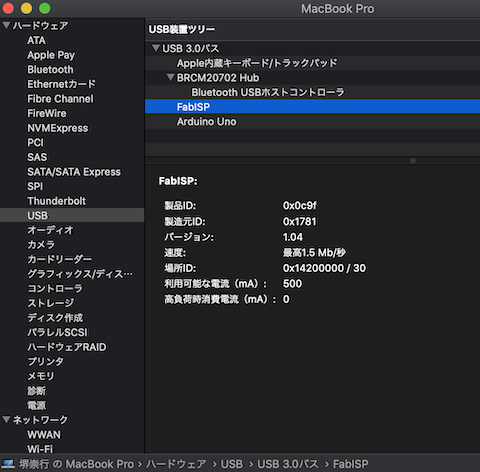

Lastly, I wrote ISP. I firstly tried writing it via Atmel Ice but “make fuse” failed again and again. So I changed device to Arduino and it worked out.

I finished this week’s assignment by removing 0 ohm resister and jumper.