Machine design

Work assignement

-actuate and automate your machine

Individual Work

In this week I have to actuate my mechanical system: in my case I've used a stepper motor because the rack and pinion structure need more power than rotation speed. To controll the stepper motor I've decided to use the cnc sheld with the arduino using grlb

Cnc Sheld Hardware

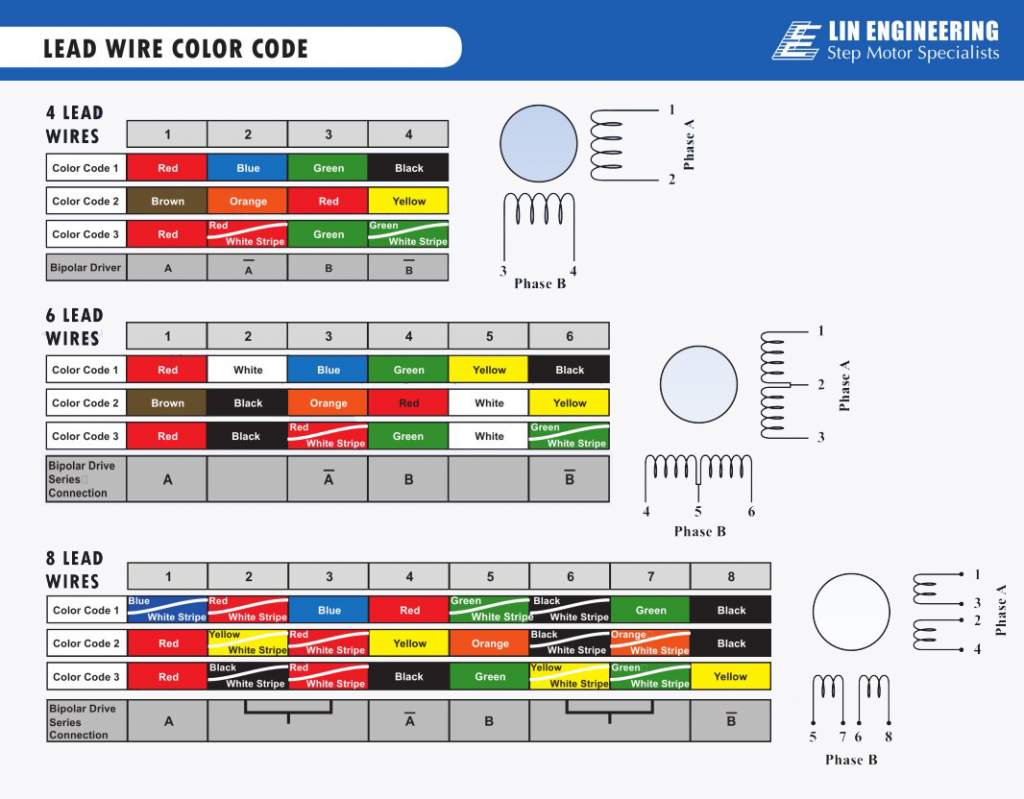

In the hardware point of view I've had to do the wiring of the motor: I've linked the wire in our correct position with this scheme:

and seeing this tutorial and others: I linked the arduino's 5v to my computer and I power the cnc shels with a 12v power supply.

Software Grbl

The software used in this scope is grbl; to launch it I have had to do some step:

- I' ve dowloaded the Grlb source code on github(https://github.com/grbl/grbl) (download zip)

- then we need to launch arduino IDE

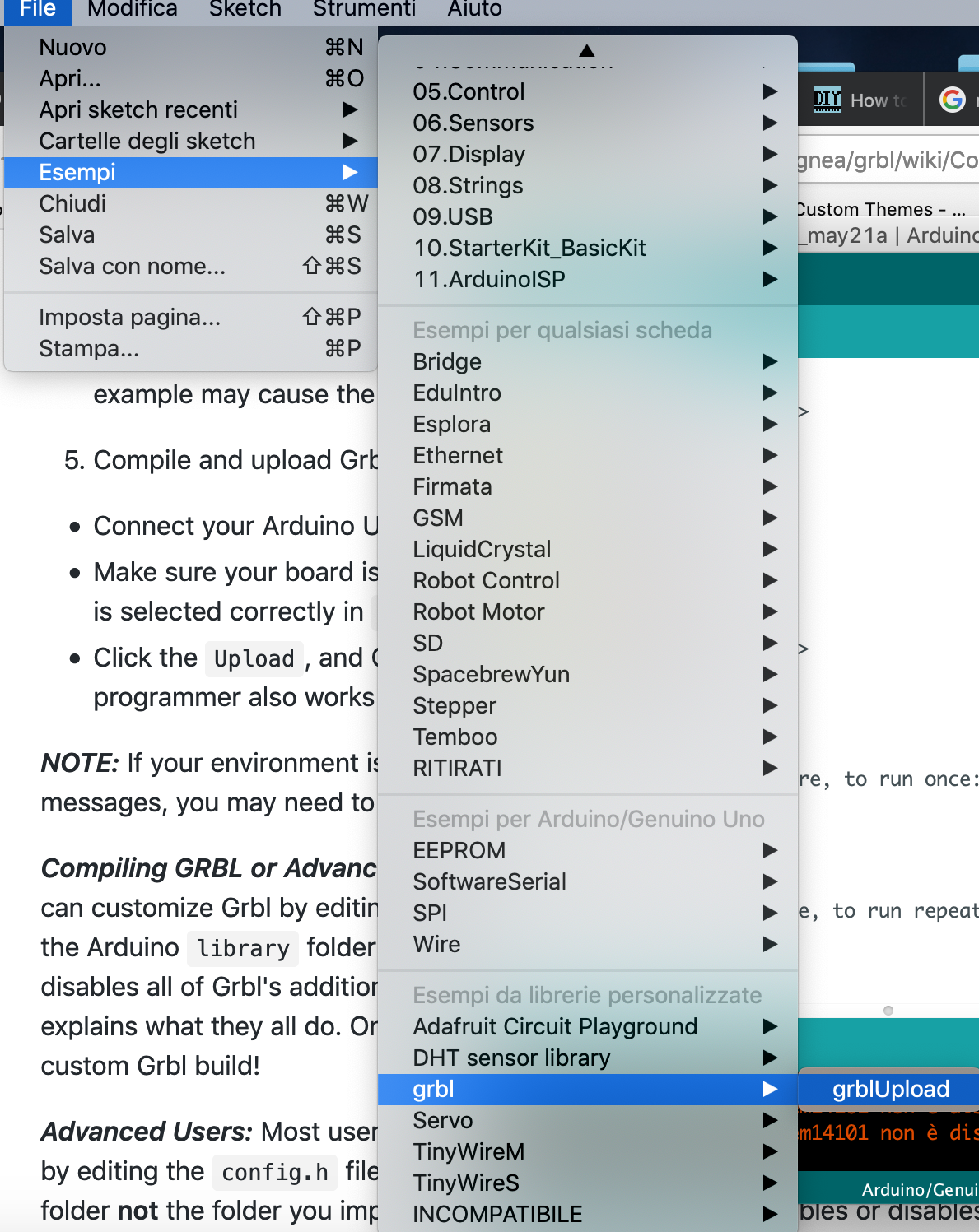

- include librery(grbl) adding the zip file

- so It is now visible in the library list (in provided by third parties)

- now we launch the example code of the library Grbl and launch the gcode in the plot serial

The G-Code

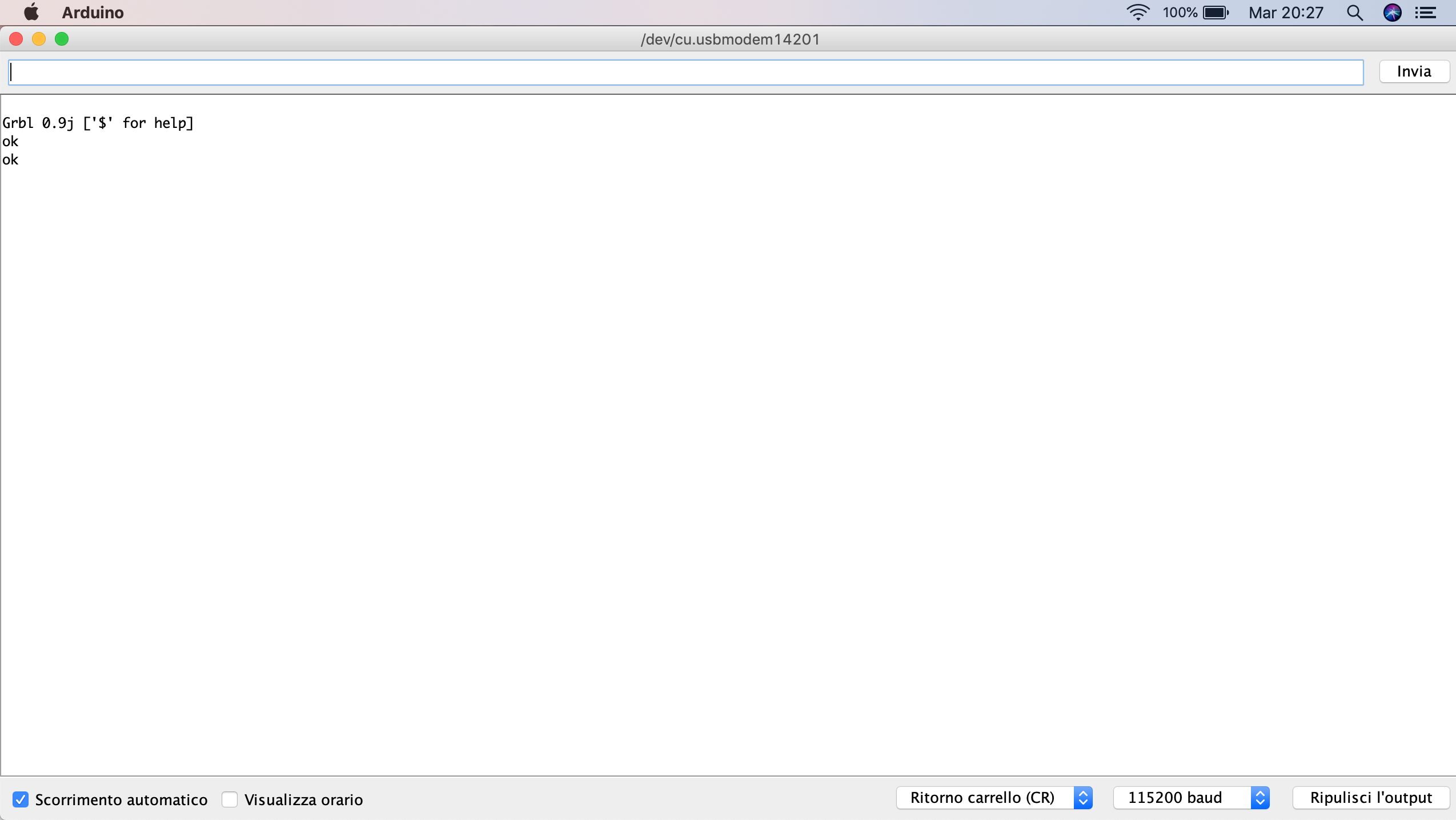

When I've load the sketch I am going to see this screen in the serial port.

I see some tutorials to give information about the code instruction:

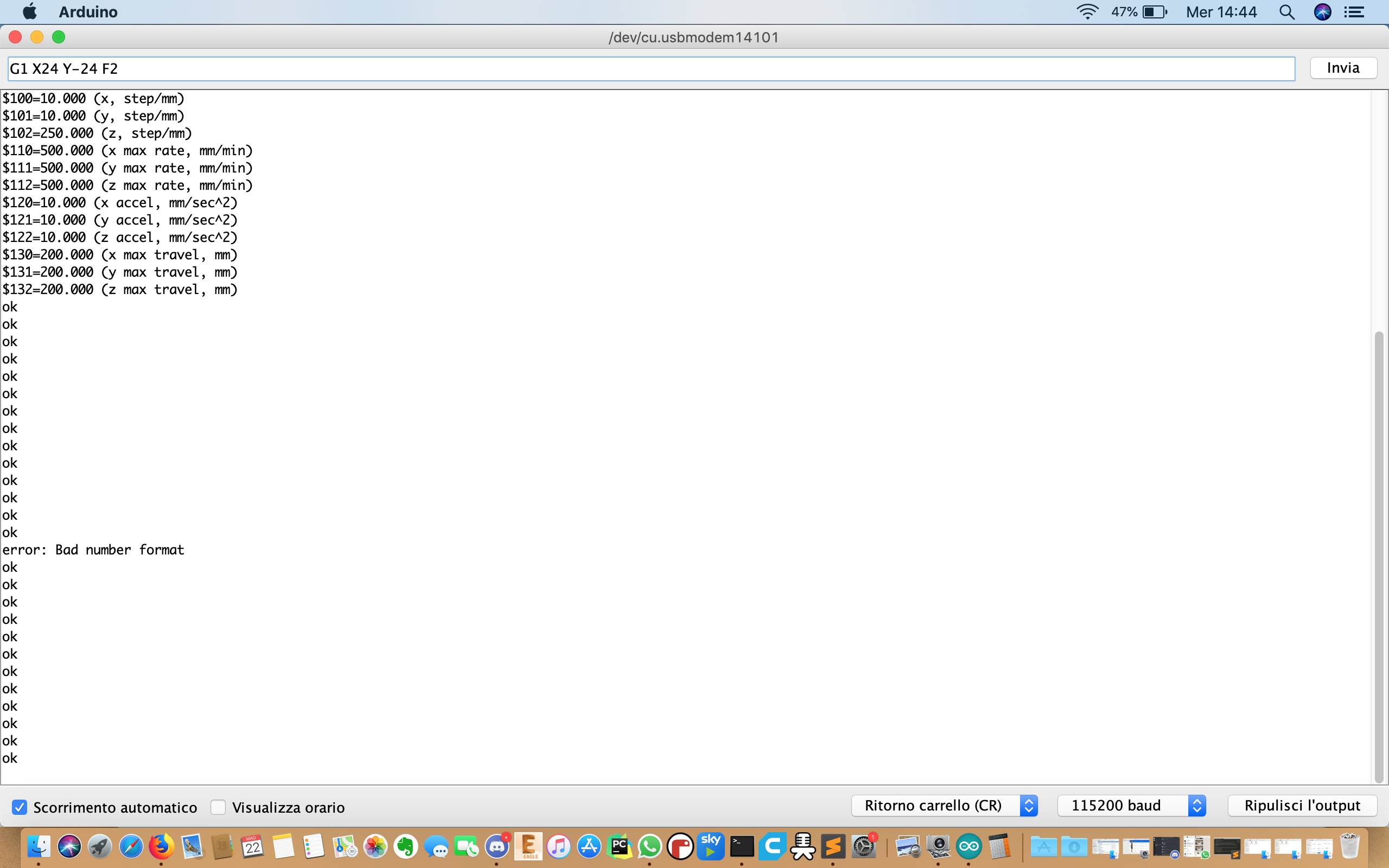

- an important instruction is the changing of the setting of the step/mm: in my case I use a small value of this because I don't need more "resolution" in the movement of my pinon: I select:

$$100=10 ( (x,step/mm) )

I have done this for the other motor too (y axis) ,

$$101=10

- I also set with the command:

G91

the relative position value of the movement: in this way I select each time how much is my movement lenght.

I've used two motor to have more power because the rack and pinion system needed to grip: this motor are put in specular position so the positive direction for one is the negative one for the other(they aren't moving different axis). In this tutorial I see the command to move them togheter :

G1 X-24 Y24 F10

- The

F10command is about the feed rate: I don't need a great feedrate because in this way the rack and pinion system don't work weel (the motor could be lose this phases)

The working of the compressor test

- the rack and pinion system work well:

video from Marco Cialone on Vimeo.

To see my machine working go to this link

while to see the week of mechanic and machine togheter go to the link of the machine

Design link On Shape

this is the command line code that I've used to actuate the machine:

Marco Cialone

Marco Cialone