Wildcard -Composite

Goal of the week

individual assignment:

-read the safety data sheet (SDS) and technical data sheet (TDS) for the resins that you're using -design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it,with resin infusion and compaction

individual work

I've decided to do a jar for the plants: first of all I've designed with Onshape:

Composition of my object

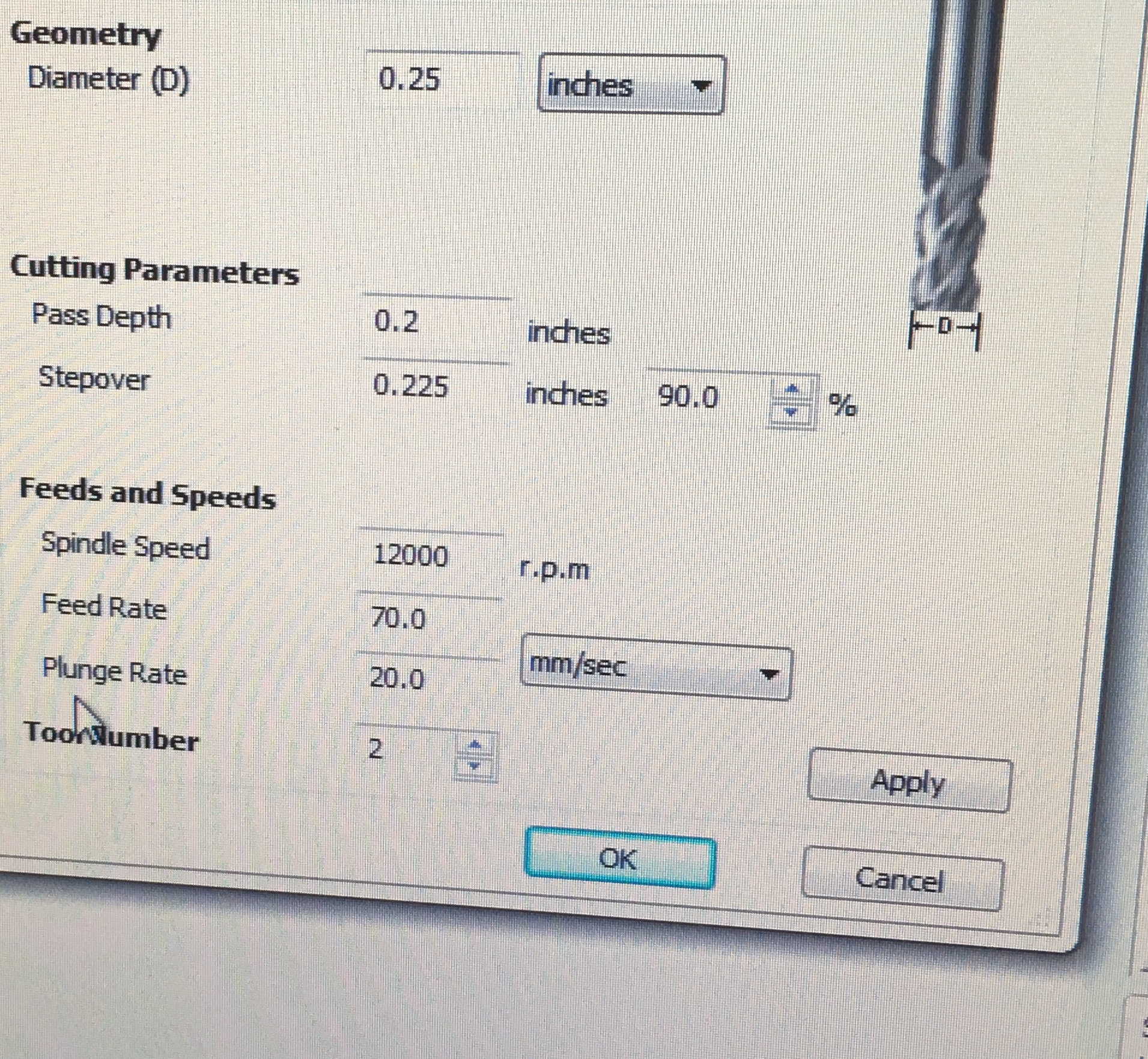

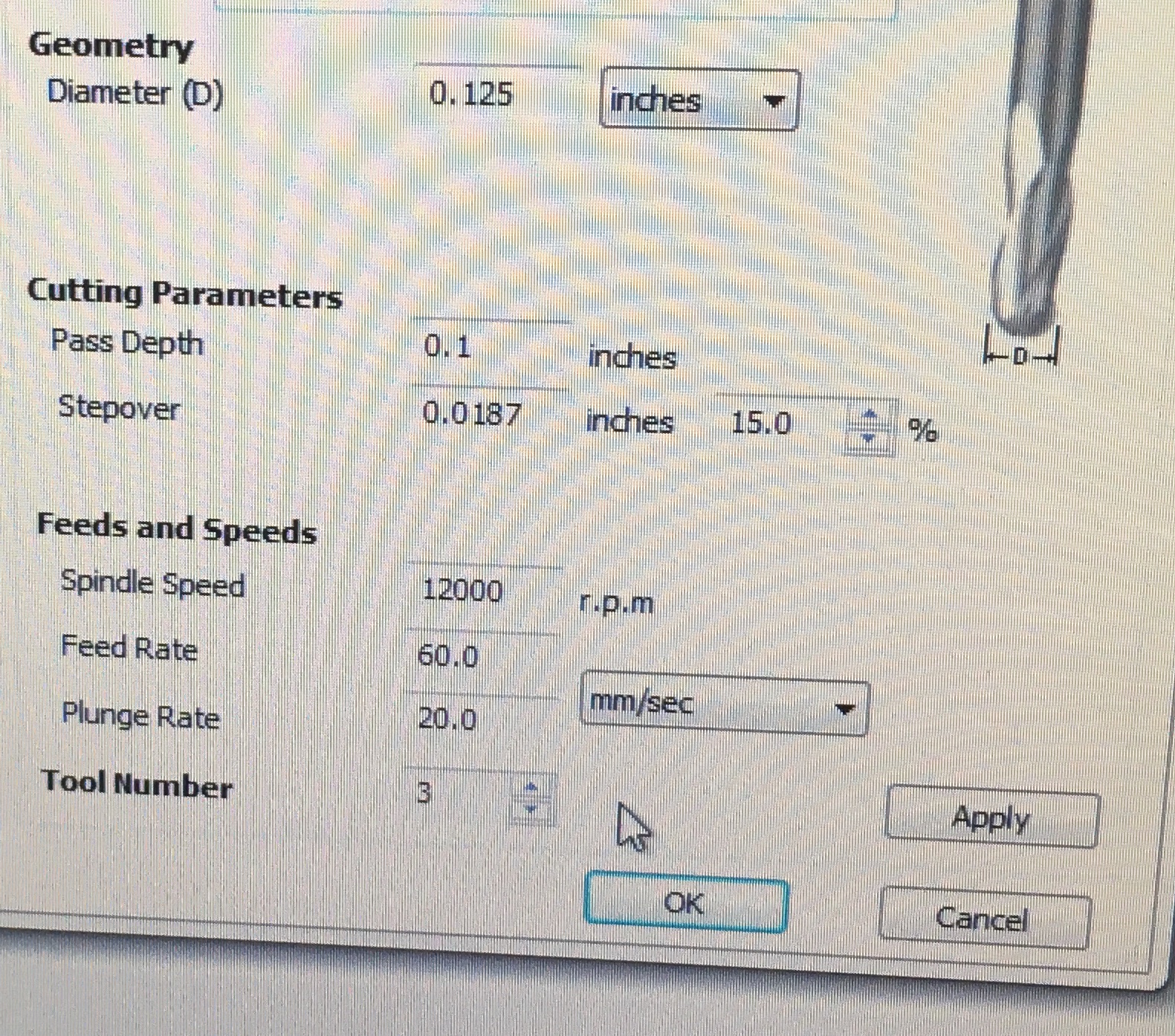

The first step to do is the milling of the polystyrene mold: I have had to done two mold slicing the whole object because it is higher than the thickness material: the toolpath of the milling is very similar than the molding and casting one; a small difference is in the setting of the roughing and finishing tips : this is the two setting different for the 1/4 and 1/8 tip:

IMG_6162 from Marco Cialone on Vimeo.

after the milling I have two part that I have to fix together:

The second process is to put a polyvinyl release agent in order to manage to remove the final object from the mold:

To use it in the correct way I've read the datasheet

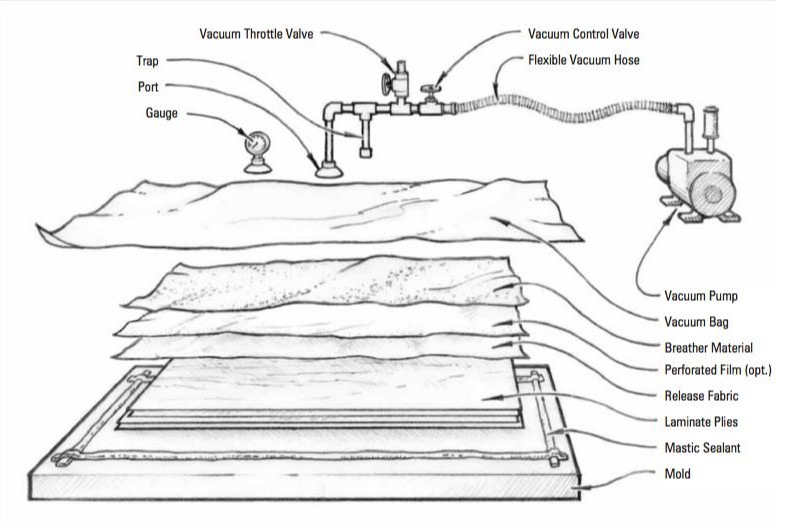

after this process I am going to do this step to have the final object

so then I've cut the yuta and prepared the resin A and B with the proportion 100g(A)-30g(B) like I've seen in the datasheetof the material(this datasheet is completely in italian because the supplier is italian):

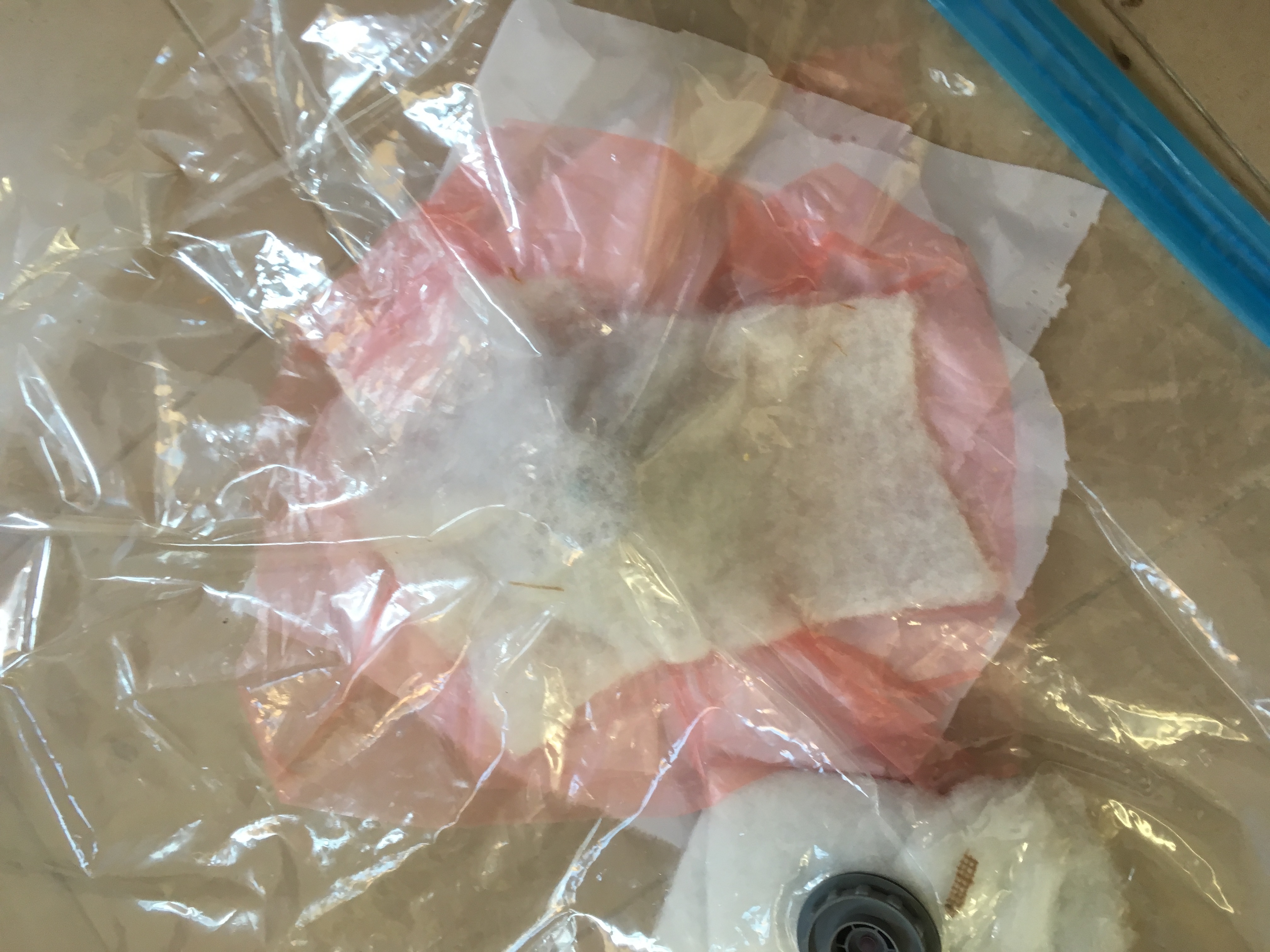

when I've done every strate I've put the object in the vacuum bag:

after a day I've remove every strate from my object and the resul is this:

Marco Cialone

Marco Cialone