Week 13. Applications and Implications

13. Applications and Implications

Assignment

Propose a final project that integrates the range of units covered. See Final Project Requirements for a complete list of requirements you must fulfil.

assignment

Propose a final project masterpiece that integrates the range of units covered,

answering:

- What will it do?

- Who’s done what beforehand?

- What will you design?

- What materials and components will be used?

- Where will come from?

- How much will they cost?

- What parts and systems will be made?

- What processes will be used?

- What questions need to be answered?

- How will it be evaluated?

Your project should incorporate 2D and 3D design,

additive and subtractive fabrication processes,

electronics design and production,

microcontroller interfacing and programming,

system integration and packaging

Where possible, you should make rather than buy

the parts of your project

Have you answered these questions?

what will it do?

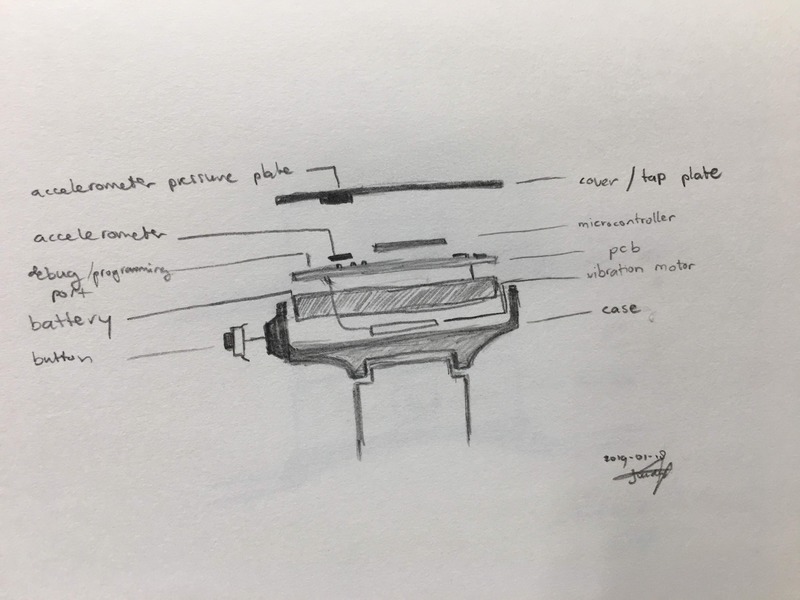

We envision a smart wearable optimised for delivering haptic in- and output for VI. By starting with presenting notifications via vibrations and input via buttons and tap patterns, we believe we can create a small, affordable and flexible wearable that is easy to use by VI.

Requirements

- Recognise tap gestures via accelerometer

- Vibrations as output

- Has at least one button for input

- Bluetooth connected to phone

- Can work standalone as watch (tap pattern for getting time in vibrations)

- LED indicators (for debugging)

- USB-port for power and programming

Optional: - Uses (rechargeable) battery

- Long battery life: last at least a day preferable a week or longer

What parts and systems will be made?

- Micocontroller with vibration motor, Bluetooth module, and accelerometer.

- Casing for the microcontroller

- Smartphone app for Bleutooth communication

What materials and components will be required?

Materials

- Microcontroller -> Henk advices to use the Atmega 328p instead of the ATTiny becasue it has more memory., Waag,

- Accelerometer -> MPU6050 (used in week 12), supply myself

- Vibration motor -> used in week 11, supply myself, estimated cost about 50 cents

- button -> fabacademy

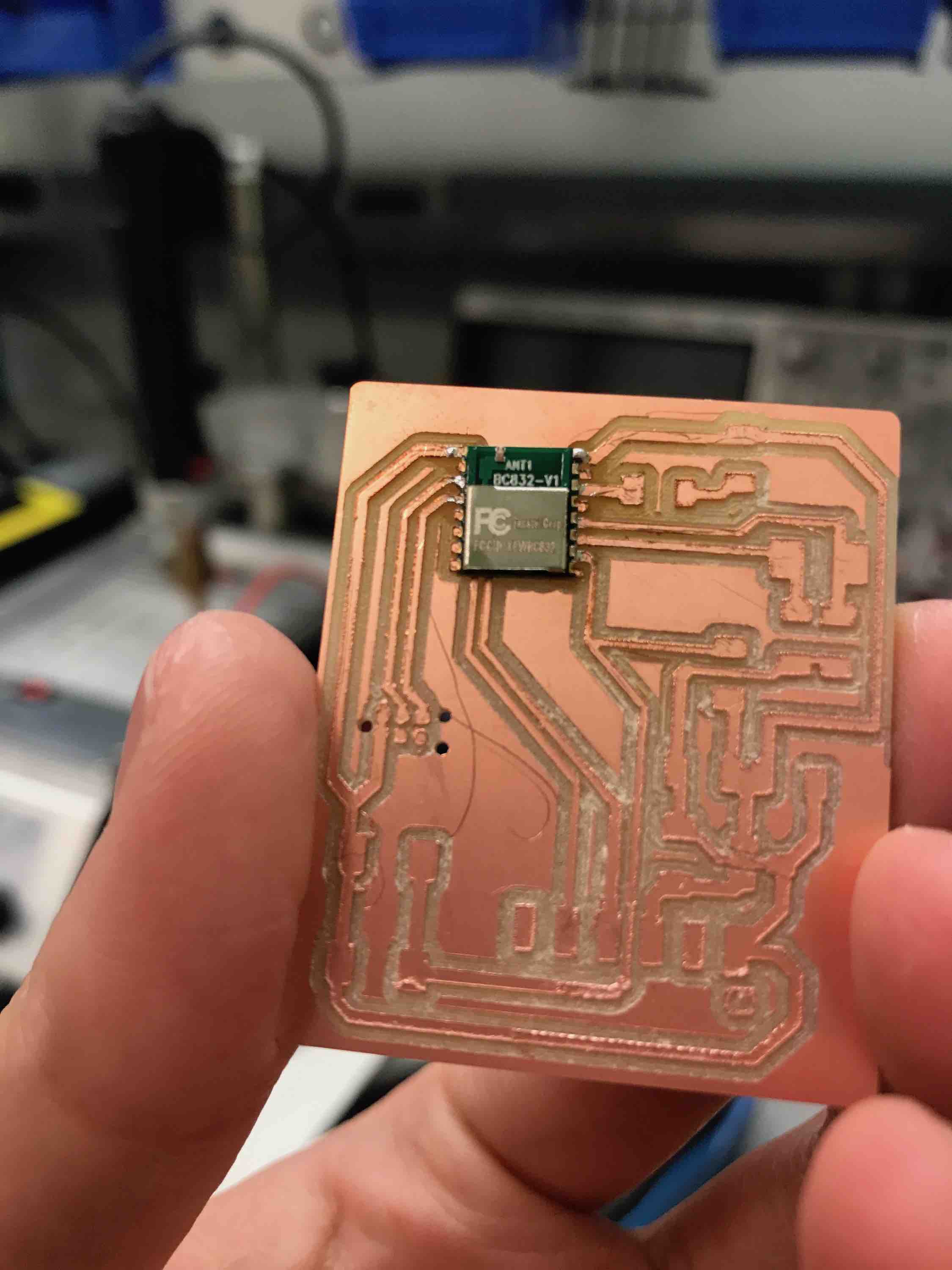

- Bleutooth chip with antenna (BLE 4.0) - NR4871, supply fabacdemy

- Battery -> myself, salvaged from toy, about 1 euro estimated cost

- various components for charging battery, supplied by Henk (fabacademy), cost about 3 euros

- various components for power to module (3V or 5V?) from USB, about 1 euro

- various LEDs, resistors, capacitors, ect. each component is a few cents each, so total will be about 5 euros max

- PCB

- casing (plastic/wood/fabric), one set is about 20 euros, wood will be 5 euros or even only scrap wood, I only need small pieces. fillament for the 3D printer will be a few meters, so max 5 euros

What processes will be used?

- Jan 31: Computer Aided Design with Fusion360: Design of case for prototype board. Normal arm form and to allow for elastic bands.

- Feb 06: computer-controlled cutting: Cut designed prototype case from cardboard/paper

- Feb 20: 3D scanning and printing: Print components or full case for prototype board.

- Feb 27: electronics design: Development of prototype board base with round PCB design.

- Mar 06: computer-controlled machining: Learning how to use the CNC router, will use this knowledge in the molding week.

- Mar 13: embedded programming: Write first code for first prototype board, explore Serial communication and interrupts needed for end board

- Mar 20: molding and casting: Mold the designed 3D armband case and cast it.

- Mar 27: input devices: Design new board with accelerometer and implement tab gestures

- Apr 03: output devices: Design new board with vibration motor and implement vibrations

- Apr 10: applications and implications: Further explore Serial communication and smartphone app

- Apr 24: networking and communications: Bluetooth as network communication further optimise protocol, and smartphone app

- May 08: interface and application programming: Further develop smartphone app and online platform

- May 29: invention, intellectual property, and income: Develop a plan for dissemination of your final project

- Jun 05: project development: compete final project

- Jun 12: project presentations: present final project

Who has done what beforehand?

Jin Hyeok has created a smartband that can detect a cardiac arrest. Jin uses an external accelerometer board. From Jin I learn that it is possible to create a 3D printed casing that is solid enough to use for a smart band. Further although his band is quite large, I find the design elegant. My band will have 3 times the features, and I want it to be at least twice as small.

Jin Hyeok has created a smartband that can detect a cardiac arrest. Jin uses an external accelerometer board. From Jin I learn that it is possible to create a 3D printed casing that is solid enough to use for a smart band. Further although his band is quite large, I find the design elegant. My band will have 3 times the features, and I want it to be at least twice as small.

David has a beautifull designed smart band, unfortunately it only can show lights, does not have any communication or GPS, or accelerometer.

David has a beautifull designed smart band, unfortunately it only can show lights, does not have any communication or GPS, or accelerometer.

David linked from his site to an Open Source Android watch WALLTECH smartwatch. A beatifull complete design, with screen and accelerometer and bluetooth. It uses the Atmel32 and a Nordic chip for Bluetooth. Both chips are very difficult to solder by hand, and will need mee first practicing the reflow oven, if I want to use this design. It does inspire me though that is possible to make a full smart watch by one person.

Mohammed created a smartwatch that uses Bluetooth and has a screen. Very impressive result as well on the design of the package.

Mohammed created a smartwatch that uses Bluetooth and has a screen. Very impressive result as well on the design of the package.

Prakash also made a LED band, very elegant board design and impressive alluminium casing.

Prakash also made a LED band, very elegant board design and impressive alluminium casing.

So I could not find and exact match to my project, where the aim is for a small band with bluetooth connection that could vibrate and register gestures. Still I find the casing desings inspiring, teaching me that with some effort a beautifull device can be made.

For the connection part, I know I want to use the RN4871 Bleutooth chip. Many people used this device in their networking week. Most used the board that is provided, some used it as their own design. But seeing that more than 5 people have succefully created a board by hand soldering the components, inspires me to use this chip and try to solder it myself. Some examples: Darle used the board for his networking week Ivan made his own board Still from Natalie I learn that I really need to be carefull soldering, removing such a chip with a heatgun is very difficult.

What questions need to be answered?

- Can a 3D printed casing be solid enough, while being elegant in size? -> Try out with a prototype

- Can I create a double sided PCB using the Modella -> Answer, yes I can, but it requires some ingenuity in shapes of the PCB for flipping the copper.

On the Fablab op de Amsterdam University of Applied Sciences we have a PCB mill that can mill double sided. Better to learn how to use this device. Loes Bogers of the class of 2015 actually made a manual on how to use this specific mill with EAGLE. - Can I lasercut leather? -> yes you can

Wow will it be evaluated?

- Is there effort made to make everything by myself?

- Is there a substractive technique used?

- Is there an additive technique used?

- Is there electronics design and production technique used?

- Is the microconroller interfaced and programmed?

- Is there a system (combination board and app)?

- Is the system packaged (casing for the microcontroller)?

- Is it documented?

- Are the files available?

-

Are there things to improve?

- Is there a working board?

- Is there effort made to make it small to wear on the wrist?

- Can it vibrate?

- Can it detect user input using the accelerometer?

- Can it transmit data to the Smartphone via Bluetooth?

- Can it receive data from the Smartphone via Bluetooth?

- Can it run without a connected power cable?

- Can the app send data to the microcontroller via Bluetooth?

- Can the app receive data from the microcontroller via Bleutooth?

Reflection

I still have a lot of work to do. While I am eager to make a fully working and nicely packaged smartband,

I feel it might be a little bit to ambitious.

I will probably drop some of my requirements when the deadline comes closer, making sure I have a working devide at the end of the run.

I will prepare my work, family and friends that the month of June is Fabacademy month.